- GCode and Part Programs

- O Codes (subroutines) and NGCGUI

- Unsure of next step - Read file data in NGCGUI?

Unsure of next step - Read file data in NGCGUI?

- cts1085

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 1

22 Mar 2014 01:19 - 22 Mar 2014 01:26 #45047

by cts1085

Unsure of next step - Read file data in NGCGUI? was created by cts1085

I am working on recreating some of Dewey Garrett's excellent work.

I have built a XZC lathe and have it working with LinuxCNC - I can make threads, helix designs, OD/ID tapers, etc.

I can probe a shape along the z-axis to get the various points (offsets) on the x-axis. (from a manually turned object)

This results in a file with X,Z pairs. (logfile.txt)

How can i read this data to manipulate or create a rotational g-code output that leverages the profile measured by the probe routine?

Say to overlay a repeating or geometric design on the measured surface?

Thank you for any guidance!

I have built a XZC lathe and have it working with LinuxCNC - I can make threads, helix designs, OD/ID tapers, etc.

I can probe a shape along the z-axis to get the various points (offsets) on the x-axis. (from a manually turned object)

This results in a file with X,Z pairs. (logfile.txt)

How can i read this data to manipulate or create a rotational g-code output that leverages the profile measured by the probe routine?

Say to overlay a repeating or geometric design on the measured surface?

Thank you for any guidance!

Last edit: 22 Mar 2014 01:26 by cts1085.

Please Log in or Create an account to join the conversation.

- newbynobi

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1927

- Thank you received: 392

22 Mar 2014 05:06 #45071

by newbynobi

Replied by newbynobi on topic Unsure of next step - Read file data in NGCGUI?

This will not be possible. As your routine will need to now if the points shoud be a line or an arc.

So take a CAD, enter the points and tell the CAD what geometrie should cover thd points, but be aware, that you probing results will contain geometric errors.

Than take a CAM to generate the gcode.

Norbert

So take a CAD, enter the points and tell the CAD what geometrie should cover thd points, but be aware, that you probing results will contain geometric errors.

Than take a CAM to generate the gcode.

Norbert

Please Log in or Create an account to join the conversation.

- cts1085

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 1

22 Mar 2014 20:39 #45098

by cts1085

Replied by cts1085 on topic Unsure of next step - Read file data in NGCGUI?

Thank you for your reply.

In my case since this is on a lathe so I will know that the points are in a line with variances caused by the curvature of the turned object. The probed points will be along the side of the piece with the C-Axis at zero and the minZ to maxZ being the top and bottom of the probed area. The X values would be the radius of the piece at each Z probed point.

Does this make sense?

What I am trying to accomplish is something similar to what Dewey Garrett accomplished during this video:

-- Full credit to Dewey Garrett for this idea! --

In my case since this is on a lathe so I will know that the points are in a line with variances caused by the curvature of the turned object. The probed points will be along the side of the piece with the C-Axis at zero and the minZ to maxZ being the top and bottom of the probed area. The X values would be the radius of the piece at each Z probed point.

Does this make sense?

What I am trying to accomplish is something similar to what Dewey Garrett accomplished during this video:

-- Full credit to Dewey Garrett for this idea! --

Please Log in or Create an account to join the conversation.

- cts1085

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 1

30 Mar 2014 19:43 #45415

by cts1085

Replied by cts1085 on topic Unsure of next step - Read file data in NGCGUI?

Just in case people are following this...

I have found a solution.

Utilizing the python widgets that can run from Axis I leveraged some of the routines from this site that do the following;

1) Read in the probe data into a list (Now I have a sorted list of Z, X data points)

2) Write a general purpose script to do some design - i.e. a sine wave around the piece

3) As the script is generating the G-Code lookup the X value (Radius) from the probe data based on the current Z value - averaging between points if needed.

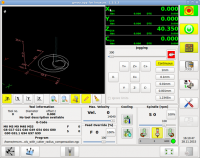

4) It works! I can even visualize the generated G-Code in Axis to determine if i have issues with my widget -

Many thanks to those who contribute on this site - this is an awesome environment!

-Tom

I have found a solution.

Utilizing the python widgets that can run from Axis I leveraged some of the routines from this site that do the following;

1) Read in the probe data into a list (Now I have a sorted list of Z, X data points)

2) Write a general purpose script to do some design - i.e. a sine wave around the piece

3) As the script is generating the G-Code lookup the X value (Radius) from the probe data based on the current Z value - averaging between points if needed.

4) It works! I can even visualize the generated G-Code in Axis to determine if i have issues with my widget -

Many thanks to those who contribute on this site - this is an awesome environment!

-Tom

Please Log in or Create an account to join the conversation.

- GCode and Part Programs

- O Codes (subroutines) and NGCGUI

- Unsure of next step - Read file data in NGCGUI?

Time to create page: 0.252 seconds