Physical Control Panel Feedback Wanted

- yeltrow

- Offline

- Senior Member

-

- Posts: 65

- Thank you received: 3

Please Log in or Create an account to join the conversation.

- bkt

-

- Offline

- Platinum Member

-

- Posts: 1111

- Thank you received: 114

rtai response for your security?? apart from this you can connect it to Arduino ...Is there a good reason for a hard-wired cycle start?

modbus is not rtai .... but .... in my modbus rs485 (using a USBconverter on pc it Have Lcnc installed) I have a read/write every 10ms for 12 register .... in 12 register you can connect all remotable signal of Lcnc (the major gui command, 2 register for 1 float, and all major Lcnc response) so a good amount of info ... 100Hz ... but these because the line is connected to 4 machine ... for one to one machine I think is possible make all these in 5-6ms .... so 180-200Hz. (the response time in libmodbus server - client on the same pc for 12 register 6read 6write is about 0,013 ms .... from one pc to another tcp connection is about 0,7/1,3 ms ... test for 7 days, h24 on intel I3 board ... but you can test your arduino connection to pc response time with wiresharck for example ...).

If you have systems that ensure you the personal protection regardless of LinuxCNC control (such as barriers to plc or security control units etc etc) you can very well connect all about Modbus.

i hope these help.

Giorgio

Please Log in or Create an account to join the conversation.

- yeltrow

- Offline

- Senior Member

-

- Posts: 65

- Thank you received: 3

When I read your reply, I was a little confused by what you meant with:

rtai response for your security?? apart from this you can connect it to Arduino ...

I agree that using software for one's security is not good practice, and I try whenever possible to make sure that software is not responsible for my safety. On the topic of a hardware start button, it would still go into an input to LinuxCNC, just like the GUI goes into LinuxCNC, so I am struggling to see how they are different. In both cases, LinuxCNC is responsible to manage when the machine starts, which I think is where the danger can come from. It has me thinking now about how I can keep the table from moving when I need to get my head/body in closer to the workpiece for setup while jogging the table. Maybe a big block of wood between the table and the frame? Your update rates are impressive. I think the 19200 baud drive must be holding up the show for my other transactions, or maybe my PC is too whimpy. Core 2 Duo, 3Ghz.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

- Posts: 21310

- Thank you received: 7279

JT just posted a link to exactly what you need, minus the jog, plenty of jog related stuff in this forum.

forum.linuxcnc.org/24-hal-components/323...gle2nist-description

At the end is the link.

Please Log in or Create an account to join the conversation.

- yeltrow

- Offline

- Senior Member

-

- Posts: 65

- Thank you received: 3

It is true talent to be able to camouflage a 3 ton machine!

Thank you for your link. That will be very helpful. It was suggested to me that a hardware button to "Single step" through a line of code would be useful, so I think I will add it. Any other input on the physical control panel layout (like JT's one finger on pause/resume and run/step) or any other buttons you think are highly desirable that I have omitted?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

- Posts: 21310

- Thank you received: 7279

I always use Axis as a front end for Linuxcnc, keyboard and mouse, nothing more or less. I got used to it so i do not need panels. When retrofiting, i tend to make only useful stuff to work, usualy as they were with feedback to Linuxcnc so it can know if something on the panel is pressed. That is about it.

I can see the start/stop/pause as very useful for sure, also a spindle on and spindle speed is nice to have, and a feed overide pot . Anything beyond that, i can not think of.

On big machines that move a lot of mass, i tend to put 2 limit switches at each end, 1 as a usual limit to Linuxcnc and the outer most as extreeme limits that cut power to drives and spindle or torch. For that i put a momentary switch to override extreeme limits after inspection. On older machines that is a must, i had a case lately where the encoder connector was faulty and the X motor just took off till it hit that extreeme limit. That is a nice feature to have especialy when using closed loop servo drives where the loop is closed in the drive. In the case of loop being closed in Linuxcnc, it will just fault with the mesage joint.N following error and stop the drives.

Nevermind, got a bit carried away.

Regards,

Tom

Please Log in or Create an account to join the conversation.

- yeltrow

- Offline

- Senior Member

-

- Posts: 65

- Thank you received: 3

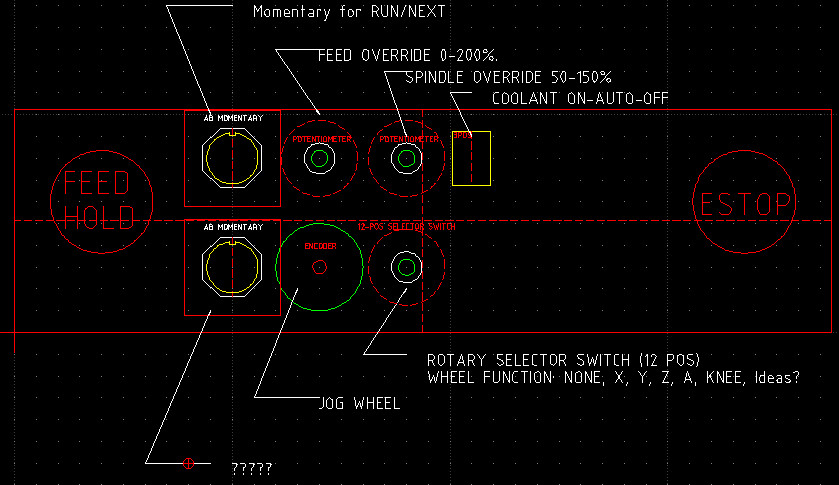

Based on the feedback I have received thus far I have modified my control panel layout as shown in the attached jpg.

My interface is primarily to save humans, the machine, parts, and then consumables. The Axis interface and the others are very complete.

My rank order has been:

E-Stop, because STUFF happens (especially when developing a machine).

Pause - because I will make programming mistakes and realize it just 1/2 second before it goes wrong

[ I was going to make the pause button a latching e-stop painted yellow or blue -- Should it be momentary? ]

Feed Override - Because I made an estimate in programming that didn't pan out

Spindle Override - Same reason

Coolant - I figured that if I forgot coolant or was getting a bath, I would want that to change fast

Jogwheel (Could save that for the MPG, but I can imagine it will save a lot of setup time if I can reach it and see at the same time) Maybe I should save this for the pendant.

Speed Selector - Same

Nice to have:

Run/Next sounds really useful. It seems like it should be directly next to the big pause button. It also seems reasonable to save for the pendant or keyboard.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

- Posts: 21310

- Thank you received: 7279

Please Log in or Create an account to join the conversation.

- bkt

-

- Offline

- Platinum Member

-

- Posts: 1111

- Thank you received: 114

Hi k-1, Thank you for taking time to help me with my machine. What did you think about the attached picture of the proposed user interface panel? Any obviously needed hardware buttons missing?

When I read your reply, I was a little confused by what you meant with:

rtai response for your security?? apart from this you can connect it to Arduino ...

I'm sorry, maybe I misunderstood: you want to connect your Arduino to interface and then communicate in Modbus is true or false?

If false: sorry a lot ... my English is bad .... I write about in English forum to practice because I have no time for courses ...

If true:

some time ago someone inform me about the problem using touch screen or interfaces not directly connected (wire to harware mesa card or other i/o card) ....at that time me too was a little bit confusing but: axis is a gui interfaces as some other .... is write in pyton as some other ... it tranfer data to a realtime thread but it isn't realtime too ... so the touch can unfortunately stop (I see these on my machine) than you can't drive your machine ..... modbus is not a realtime process so it have the same problem .... you must insert estop if modbus error occour for more security .... but is not the same as connect the signal directly to realtime thread ....

Your update rates are impressive. I think the 19200 baud drive must be holding up the show for my other transactions, or maybe my PC is too whimpy. Core 2 Duo, 3Ghz.

My baudrate is 115200 but I can improve it to 230400 (not sure if my user comp can utilize these hight baud rate) .... and I use single bit of one register so every register 16 signal....

tommilight write right

on ideas you can connect a special mdi command for ex. press one button and select specialone run halui.mdi0, select specialone and press buttontwo run halui.mdi1, select specialtwo or FOOD if you want ... (where I am, among technicians, when you see a new beautiful built machine / robot often saidl: ok but can make spaghetti?On thebrotary switch you have "none,x,y,z, etc etc ideas"

My rank order has been:

E-Stop, because STUFF happens (especially when developing a machine).

Pause - because I will make programming mistakes and realize it just 1/2 second before it goes wrong

[ I was going to make the pause button a latching e-stop painted yellow or blue -- Should it be momentary? ]

Feed Override - Because I made an estimate in programming that didn't pan out

Spindle Override - Same reason

Coolant - I figured that if I forgot coolant or was getting a bath, I would want that to change fast

Jogwheel (Could save that for the MPG, but I can imagine it will save a lot of setup time if I can reach it and see at the same time) Maybe I should save this for the pendant.

Speed Selector - Same

Nice to have:

Run/Next sounds really useful. It seems like it should be directly next to the big pause button. It also seems reasonable to save for the pendant or keyboard.[\quote]

it seems all good things..

regards

Giorgio

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11720

- Thank you received: 3968

This page on my plasma build shows how I implemented the run/stop, pause/resume features together with some warning lights. There is a video demonstrating how it all works.

forum.linuxcnc.org/show-your-stuff/32029...build?start=20#85378

Please Log in or Create an account to join the conversation.