- Configuring LinuxCNC

- HAL

- HAL Examples

- Powerchuck Hal component, operates hydrualic chucks, collet closers etc.

Powerchuck Hal component, operates hydrualic chucks, collet closers etc.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 718

- Thank you received: 138

15 Jan 2023 21:08 #262064

by smc.collins

Powerchuck Hal component, operates hydrualic chucks, collet closers etc. was created by smc.collins

simple little hal component to control hydraulic or even a pneumatic chuck mechanism.Fairly straight forward little program, works as follows.Chuck in and chuck out should be connected to a double throw switch , this will control the locked behavior of the jaws or mechanism.CycleChuck should be hooked to a momentary footpedal switch etc this will operate the jaws or collet closer etc.Spindle brake and spindle enable need to be connected to hal signals, preferably to a feedback sensor would be best but we don't want the chuck actuating once the spindle starts up. If spindle brake is false, the chuck WILL NOT OPERATE AT ALL

here is the component, the hal and the source file Installs and builds like a regular hal component. Beats messing around with ladder logic.

here is the component, the hal and the source file Installs and builds like a regular hal component. Beats messing around with ladder logic.

The following user(s) said Thank You: tommylight, abdulasis12, Soccer Kid

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 718

- Thank you received: 138

16 Jan 2023 06:14 #262102

by smc.collins

Replied by smc.collins on topic Powerchuck Hal component, operates hydrualic chucks, collet closers etc.

updated this with the final version off of my machine. Added a few new features, some error checking, have fun, as stated no warranty implied given etc. code is AS IS. ADDED error checking and a way to use 1 switch to control direction with 1 input. it's all in the hal file

The following user(s) said Thank You: ChironFZ16, abdulasis12

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 8

08 Jan 2024 08:56 - 08 Jan 2024 09:05 #290191

by abdulasis12

Replied by abdulasis12 on topic Powerchuck Hal component, operates hydrualic chucks, collet closers etc.

Hi MR. smc.collins

I'm read and think your share file .comp maybe can use with my Lathe cnc too.

I want same safty for when run spindle , chuck must Interlock ,not respond any signal and foot switch too.

Now I Download your Comp and complie to my Linuxcnc done.

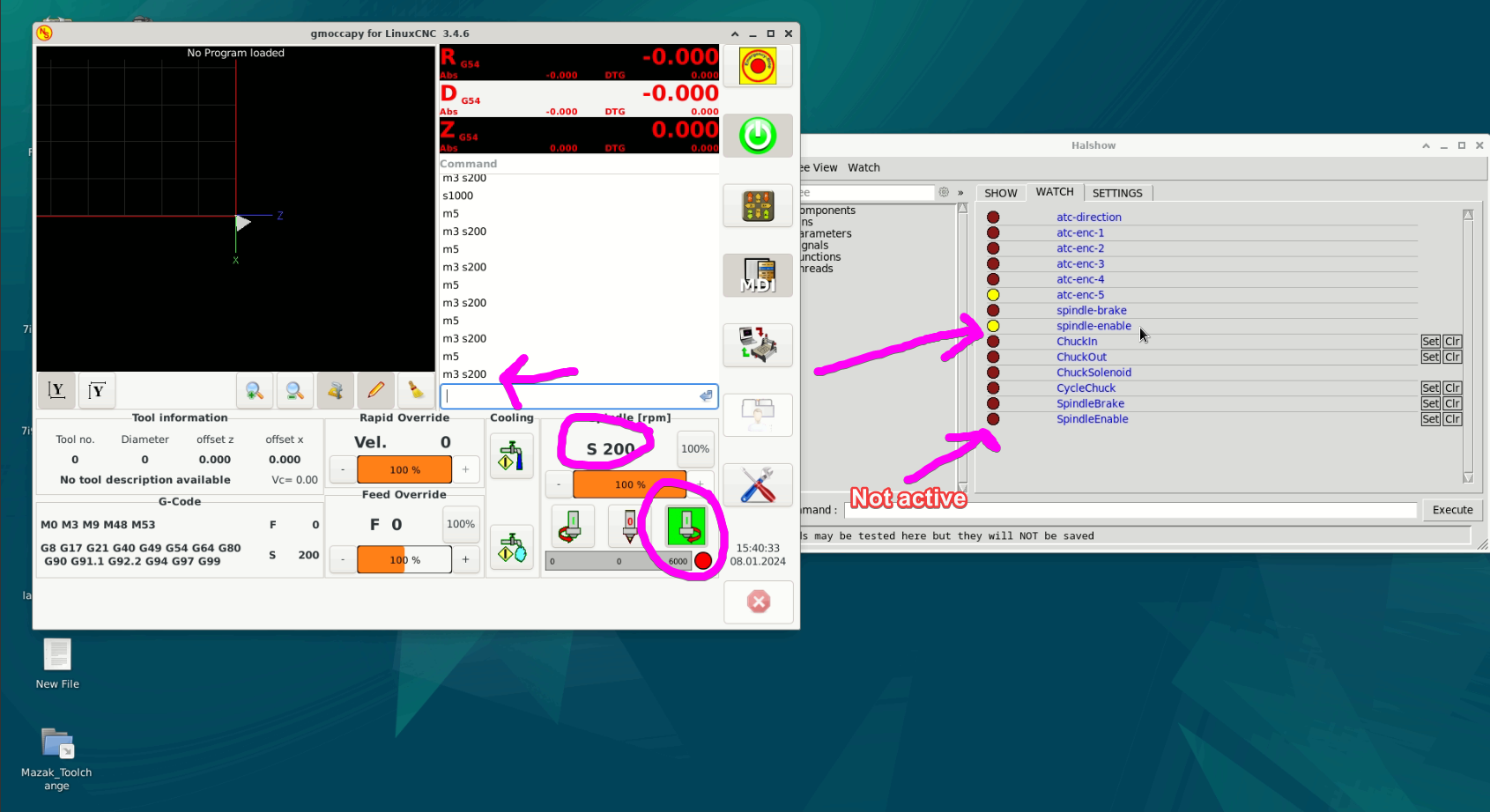

I try open hall show and show

signal spindle-brake

signal spindle-enable

and list your signal Powerchuck signal

ChuckIn

ChuckOut

.

.

.

SpindleBrake

SpindleEnable

I try MDI

M3 S200

spindle-enable change to 1 but SpindleEnable from your component not change from 0 to 1 .

I must go to link something to your signal first ?

Please example some code for connect signal I'm newbie for linuxcnc .

Below I show some picture

Thank you.

Asis,

I'm read and think your share file .comp maybe can use with my Lathe cnc too.

I want same safty for when run spindle , chuck must Interlock ,not respond any signal and foot switch too.

Now I Download your Comp and complie to my Linuxcnc done.

I try open hall show and show

signal spindle-brake

signal spindle-enable

and list your signal Powerchuck signal

ChuckIn

ChuckOut

.

.

.

SpindleBrake

SpindleEnable

I try MDI

M3 S200

spindle-enable change to 1 but SpindleEnable from your component not change from 0 to 1 .

I must go to link something to your signal first ?

Please example some code for connect signal I'm newbie for linuxcnc .

Below I show some picture

Thank you.

Asis,

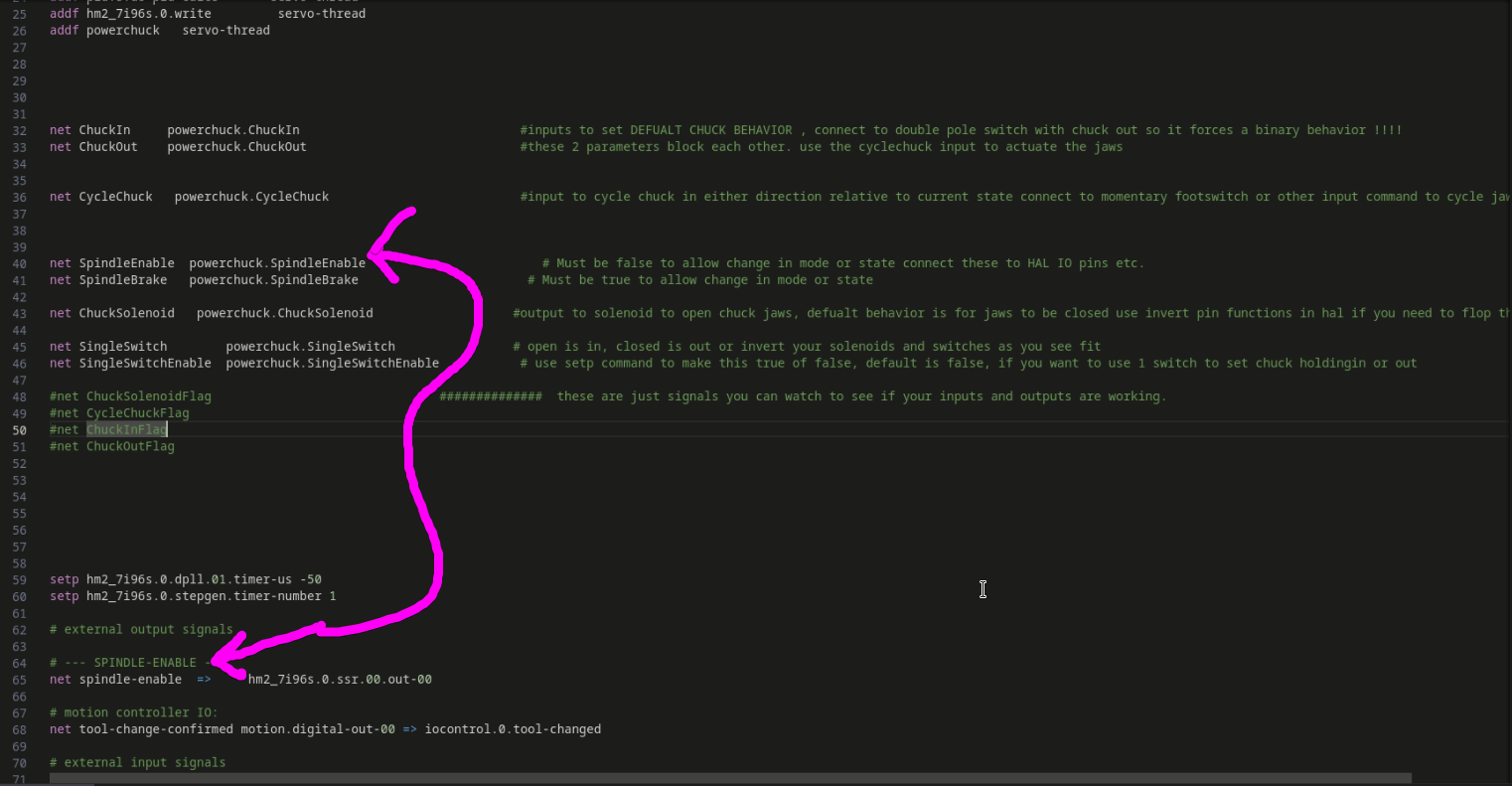

[size=85]# Generated by PNCconf at Thu Jan 4 13:13:52 2024

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt hm2_eth board_ip="10.10.10.10" config="num_encoders=1 num_pwmgens=1 num_stepgens=5 sserial_port_0=0xxxxxxx"

setp hm2_7i96s.0.pwmgen.pwm_frequency 20000

setp hm2_7i96s.0.pwmgen.pdm_frequency 6000000

setp hm2_7i96s.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.z,pid.s

loadrt powerchuck

addf hm2_7i96s.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf hm2_7i96s.0.write servo-thread

addf powerchuck servo-thread

net ChuckIn powerchuck.ChuckIn #inputs to set DEFUALT CHUCK BEHAVIOR , connect to double pole switch with chuck out so it forces a binary behavior !!!!

net ChuckOut powerchuck.ChuckOut #these 2 parameters block each other. use the cyclechuck input to actuate the jaws

net CycleChuck powerchuck.CycleChuck #input to cycle chuck in either direction relative to current state connect to momentary footswitch or other input command to cycle jaws

net SpindleEnable powerchuck.SpindleEnable # Must be false to allow change in mode or state connect these to HAL IO pins etc.

net SpindleBrake powerchuck.SpindleBrake # Must be true to allow change in mode or state

net ChuckSolenoid powerchuck.ChuckSolenoid #output to solenoid to open chuck jaws, defualt behavior is for jaws to be closed use invert pin functions in hal if you need to flop this around

net SingleSwitch powerchuck.SingleSwitch # open is in, closed is out or invert your solenoids and switches as you see fit

net SingleSwitchEnable powerchuck.SingleSwitchEnable # use setp command to make this true of false, default is false, if you want to use 1 switch to set chuck holdingin or out

#net ChuckSolenoidFlag ############## these are just signals you can watch to see if your inputs and outputs are working.

#net CycleChuckFlag

#net ChuckInFlag

#net ChuckOutFlag

setp hm2_7i96s.0.dpll.01.timer-us -50

setp hm2_7i96s.0.stepgen.timer-number 1

# external output signals

# --- SPINDLE-ENABLE ---

net spindle-enable => hm2_7i96s.0.ssr.00.out-00

setp hm2_7i96s.0.pwmgen.pwm_frequency 20000

setp hm2_7i96s.0.pwmgen.pdm_frequency 6000000

setp hm2_7i96s.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.z,pid.s

loadrt powerchuck

addf hm2_7i96s.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf hm2_7i96s.0.write servo-thread

addf powerchuck servo-thread

net ChuckIn powerchuck.ChuckIn #inputs to set DEFUALT CHUCK BEHAVIOR , connect to double pole switch with chuck out so it forces a binary behavior !!!!

net ChuckOut powerchuck.ChuckOut #these 2 parameters block each other. use the cyclechuck input to actuate the jaws

net CycleChuck powerchuck.CycleChuck #input to cycle chuck in either direction relative to current state connect to momentary footswitch or other input command to cycle jaws

net SpindleEnable powerchuck.SpindleEnable # Must be false to allow change in mode or state connect these to HAL IO pins etc.

net SpindleBrake powerchuck.SpindleBrake # Must be true to allow change in mode or state

net ChuckSolenoid powerchuck.ChuckSolenoid #output to solenoid to open chuck jaws, defualt behavior is for jaws to be closed use invert pin functions in hal if you need to flop this around

net SingleSwitch powerchuck.SingleSwitch # open is in, closed is out or invert your solenoids and switches as you see fit

net SingleSwitchEnable powerchuck.SingleSwitchEnable # use setp command to make this true of false, default is false, if you want to use 1 switch to set chuck holdingin or out

#net ChuckSolenoidFlag ############## these are just signals you can watch to see if your inputs and outputs are working.

#net CycleChuckFlag

#net ChuckInFlag

#net ChuckOutFlag

setp hm2_7i96s.0.dpll.01.timer-us -50

setp hm2_7i96s.0.stepgen.timer-number 1

# external output signals

# --- SPINDLE-ENABLE ---

net spindle-enable => hm2_7i96s.0.ssr.00.out-00

# motion controller IO:

net tool-change-confirmed motion.digital-out-00 => iocontrol.0.tool-changed

[/size]Attachments:

Last edit: 08 Jan 2024 09:05 by abdulasis12.

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 718

- Thank you received: 138

10 Jan 2024 03:17 #290323

by smc.collins

Replied by smc.collins on topic Powerchuck Hal component, operates hydrualic chucks, collet closers etc.

The source code is heavily commented to explicitly explain how it works, I'm not sure i understand your question. Can you take a short video and walk me through your probem ???

The following user(s) said Thank You: abdulasis12

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 8

10 Jan 2024 17:50 - 10 Jan 2024 18:11 #290387

by abdulasis12

Thank you for respond my question. ^^"

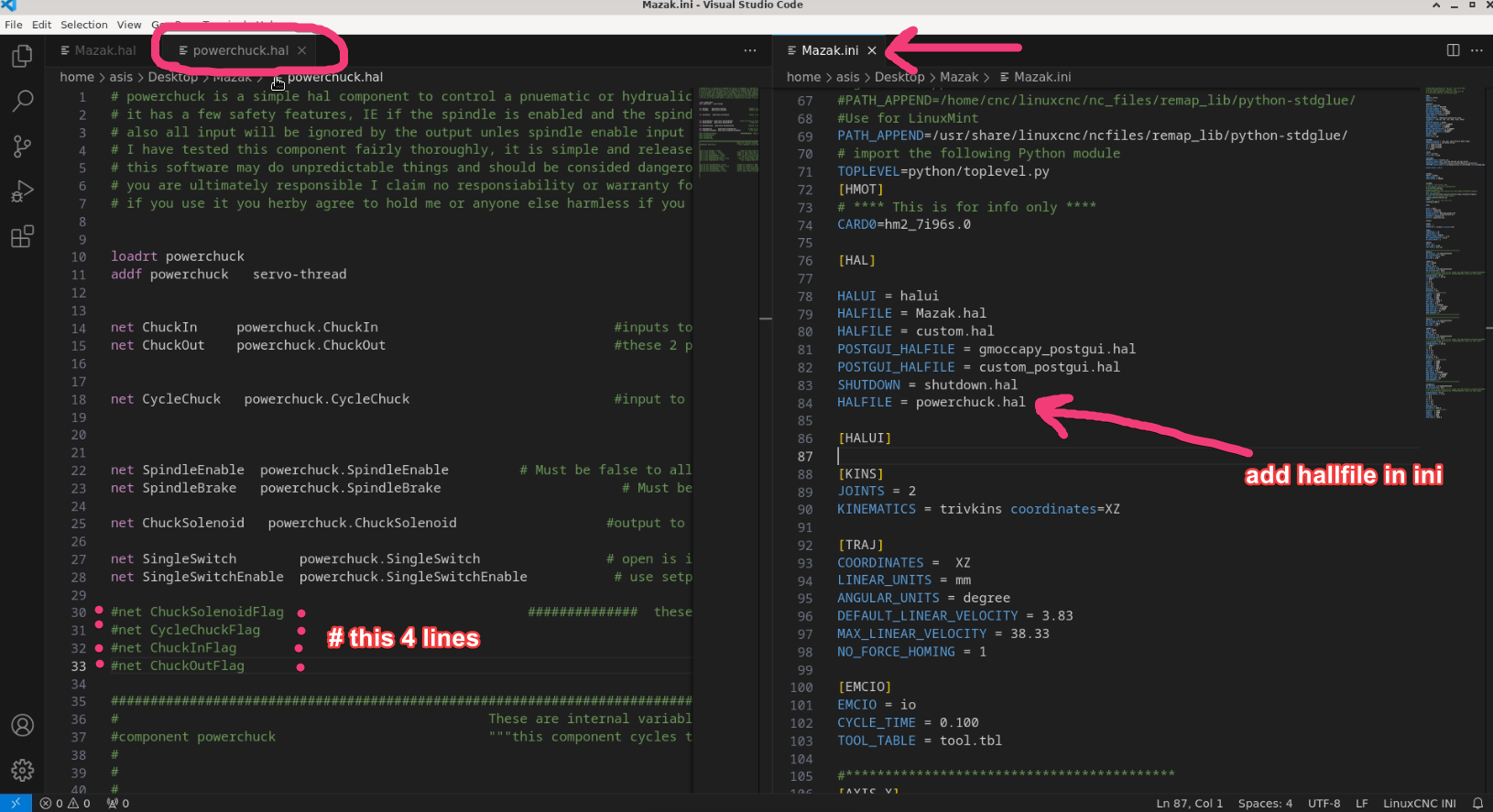

Okay , now I renew about hall

I use your powerchuck.hal , I put it's into folder .

I add HALFILE = powerchuck.hal in .ini file.

I # 4 lines below in powerchuck.hal file.

#net ChuckSolenoidFlag

#net CycleChuckFlag

#net ChuckInFlag

#net ChuckOutFlag

then details in my clip

CLIP Youtube

My question is:

What more for config to use your powerchuck.hal ?

How to link Signal input from switch to your variable signal ?

Can show some example code ? maybe I can Easier to understand ^^" .

Thank you

Asis,

Replied by abdulasis12 on topic Powerchuck Hal component, operates hydrualic chucks, collet closers etc.

Hi,The source code is heavily commented to explicitly explain how it works, I'm not sure i understand your question. Can you take a short video and walk me through your probem ???

Thank you for respond my question. ^^"

Okay , now I renew about hall

I use your powerchuck.hal , I put it's into folder .

I add HALFILE = powerchuck.hal in .ini file.

I # 4 lines below in powerchuck.hal file.

#net ChuckSolenoidFlag

#net CycleChuckFlag

#net ChuckInFlag

#net ChuckOutFlag

then details in my clip

CLIP Youtube

My question is:

What more for config to use your powerchuck.hal ?

How to link Signal input from switch to your variable signal ?

Can show some example code ? maybe I can Easier to understand ^^" .

Thank you

Asis,

Attachments:

Last edit: 10 Jan 2024 18:11 by abdulasis12.

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 8

15 Jan 2024 10:24 #290748

by abdulasis12

Replied by abdulasis12 on topic Powerchuck Hal component, operates hydrualic chucks, collet closers etc.

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 718

- Thank you received: 138

16 Jan 2024 03:14 - 16 Jan 2024 03:19 #290827

by smc.collins

Replied by smc.collins on topic Powerchuck Hal component, operates hydrualic chucks, collet closers etc.

it's been -4 F here for 3 days, I haven't been able to power up the lathe. Put powerchuck in the main hal file mazak.hal, and put those 4 lines in that mazak.hal file as well, load the component in the mazak.hal file as well. I didn't design this to get the signal outside of the main hal file. you'll also have to connect the spindle enable to the spindle.ena , spindlebrake to spindle brake signal etc. You will obviously connect your footswitch to the 7i77 input pins and it you have you want to reverse the grip of the chuck , you'll need to add wiring for the ID OD grip settings IIRC and I haven't looked at the source recently, the pin routes through the powerchuck hal component.

these all go in you mylinuxmachine.hal file if you catch my drift.

these all go in you mylinuxmachine.hal file if you catch my drift.

Last edit: 16 Jan 2024 03:19 by smc.collins.

The following user(s) said Thank You: abdulasis12

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 8

23 Jan 2024 16:14 #291434

by abdulasis12

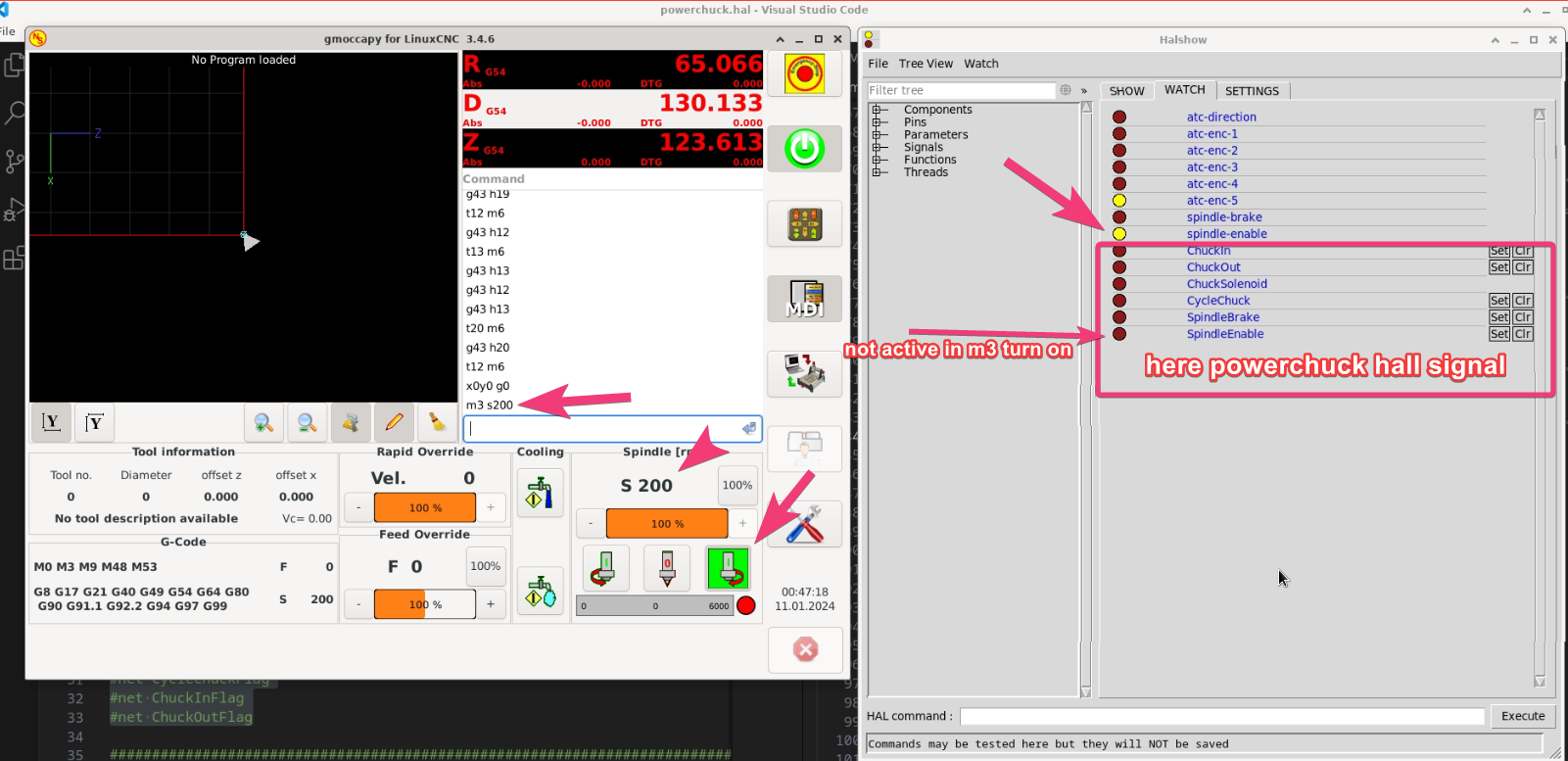

I try change

net SpindleEnable

to

net spindle-enable

now it's can link signal and change other net too.

youe powerchuck.comp good for my CNCLathe I edit some and cut some function now working with my cnc

Thank you. ^^"

Replied by abdulasis12 on topic Powerchuck Hal component, operates hydrualic chucks, collet closers etc.

thank you MR.smc.collinsit's been -4 F here for 3 days, I haven't been able to power up the lathe. Put powerchuck in the main hal file mazak.hal, and put those 4 lines in that mazak.hal file as well, load the component in the mazak.hal file as well. I didn't design this to get the signal outside of the main hal file. you'll also have to connect the spindle enable to the spindle.ena , spindlebrake to spindle brake signal etc. You will obviously connect your footswitch to the 7i77 input pins and it you have you want to reverse the grip of the chuck , you'll need to add wiring for the ID OD grip settings IIRC and I haven't looked at the source recently, the pin routes through the powerchuck hal component.

these all go in you mylinuxmachine.hal file if you catch my drift.

I try change

net SpindleEnable

to

net spindle-enable

now it's can link signal and change other net too.

youe powerchuck.comp good for my CNCLathe I edit some and cut some function now working with my cnc

Thank you. ^^"

The following user(s) said Thank You: smc.collins

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 718

- Thank you received: 138

23 Jan 2024 19:30 #291452

by smc.collins

Replied by smc.collins on topic Powerchuck Hal component, operates hydrualic chucks, collet closers etc.

I'm glad it was useful, there's a v2 design but it's actually integrated into spindle , and it does a lot more.

The following user(s) said Thank You: abdulasis12

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- HAL

- HAL Examples

- Powerchuck Hal component, operates hydrualic chucks, collet closers etc.

Time to create page: 0.172 seconds