G0 XY move fail

- looping

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 10

07 Sep 2015 03:48 #62173

by looping

G0 XY move fail was created by looping

Hello

I currently setting up my CNC powered by a Gecko G540 and V2.6.9. So far, first tests were perfect : everything in stepconf testing axis is OK

The default linuxCNC GCode program executed nicely

But with the attached program, the line 49 doesn't product the correct move : the Y move that should be 50mm, but only a small Y move occurs.10mm at most.

I have the same failure each time I run the program, on the same line

I tried to

1) to change the line

from: X61.1344 Y83.995

to: G1 X61.1344 Y83.995

=> the program run to the end with no other malfunction

2) to change the XY move into a X move, then an Y move: I change the line 49

from: X61.1344 Y83.995

to: X61.1344

Y83.995

=> the program run to the end with no other malfunction

3) Reduce the max_acceleration down to 60mm/s2 with no success.

4) I changed the origin but the same failure still occurs always on line 49

Is it possible that someone try my program on his hardware, I let me know ?

regards

I currently setting up my CNC powered by a Gecko G540 and V2.6.9. So far, first tests were perfect : everything in stepconf testing axis is OK

The default linuxCNC GCode program executed nicely

But with the attached program, the line 49 doesn't product the correct move : the Y move that should be 50mm, but only a small Y move occurs.10mm at most.

I have the same failure each time I run the program, on the same line

I tried to

1) to change the line

from: X61.1344 Y83.995

to: G1 X61.1344 Y83.995

=> the program run to the end with no other malfunction

2) to change the XY move into a X move, then an Y move: I change the line 49

from: X61.1344 Y83.995

to: X61.1344

Y83.995

=> the program run to the end with no other malfunction

3) Reduce the max_acceleration down to 60mm/s2 with no success.

4) I changed the origin but the same failure still occurs always on line 49

Is it possible that someone try my program on his hardware, I let me know ?

regards

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 19096

- Thank you received: 5270

07 Sep 2015 05:54 #62174

by PCW

Replied by PCW on topic G0 XY move fail

Is the DRO readout correct after the X/Y move?

( that is, is this a hardware issue or a interpreter/trajectory planner issue )

( that is, is this a hardware issue or a interpreter/trajectory planner issue )

Please Log in or Create an account to join the conversation.

- Rick G

-

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 155

07 Sep 2015 12:33 #62181

by Rick G

Replied by Rick G on topic G0 XY move fail

Have you tried changing

To

It appears that the line you refer to is the first X move in the positive direction.

Rick G

O1 (LG_PCB)

(COMPENSATION-WEAR)

(REV-0.70)

(AUG-22-2015-11:01:41AM)

G90

G17

G54

M06 T1 ()

(interrupteur)

S1000 To

O1 (LG_PCB)

(COMPENSATION-WEAR)

(REV-0.70)

(AUG-22-2015-11:01:41AM)

G40 ( turn cutter compensation off.)

G90

G17

G54

M06 T1 ()

(interrupteur)

S1000 It appears that the line you refer to is the first X move in the positive direction.

Rick G

Please Log in or Create an account to join the conversation.

- looping

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 10

07 Sep 2015 13:28 #62182

by looping

Replied by looping on topic G0 XY move fail

Thanks for you help

@PCW

After line 49, the readout shows values Y => 83.995

The the next and last G0 command on XY (line 82) is execute correctly.

@Rick G

I'll try the G40.

But if it was about compensation, it should also happen after the program modification n°2 when I change to :

...

G00 Z25.

X61.1344

Y83.995

Z2.

...

But like this, it's ok

@PCW

After line 49, the readout shows values Y => 83.995

The the next and last G0 command on XY (line 82) is execute correctly.

@Rick G

I'll try the G40.

But if it was about compensation, it should also happen after the program modification n°2 when I change to :

...

G00 Z25.

X61.1344

Y83.995

Z2.

...

But like this, it's ok

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

Less

More

- Posts: 25

- Thank you received: 758

07 Sep 2015 15:25 #62185

by ArcEye

Replied by ArcEye on topic G0 XY move fail

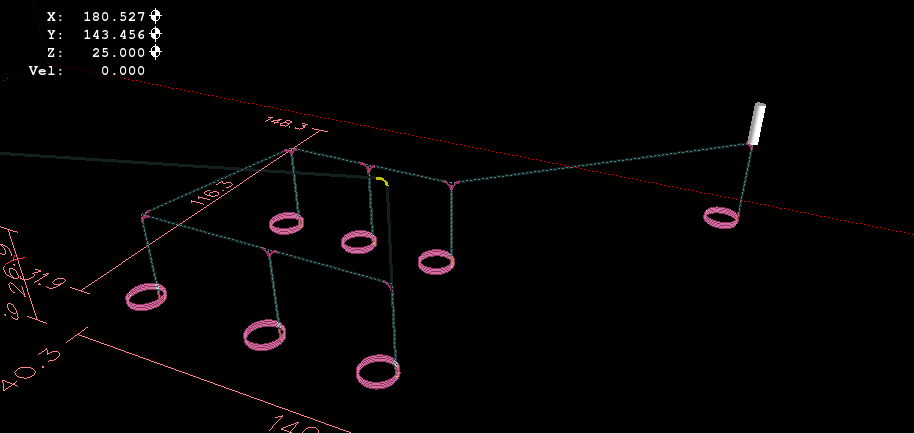

I assume this is what your plot should look like?

I removed the % top and bottom, changed the header so that G40 was applied before the tool change and G43 applied where it should be, immediately after

the M6T? (not after a linear move that will go to the wrong place) and it seems to run as intended.

regards

I removed the % top and bottom, changed the header so that G40 was applied before the tool change and G43 applied where it should be, immediately after

the M6T? (not after a linear move that will go to the wrong place) and it seems to run as intended.

G90

G17

G54

G40

M06 T1

G43

S1000

M03

G00 X120.1703 Y36.7129

Z25.

Z2.

G01 G40 Z-0.5 F100.

G02 X120.1703 Y36.7129 I-4.8 J0. F200.

G01 Z-1. F100.

G02 X120.1703 Y36.7129 I-4.8 J0. F200.

G01 Z-1.5 F100.

G02 X120.1703 Y36.7129 I-4.8 J0. F200.

G01 Z-1.9 F100.

G02 X120.1703 Y36.7129 I-4.8 J0. F200.

G00 Z25.

X88.0584

Z2.

G01 Z-0.5 F100.

G02 X88.0584 Y36.7129 I-4.8 J0. F200.

G01 Z-1. F100.

G02 X88.0584 Y36.7129 I-4.8 J0. F200.

G01 Z-1.5 F100.

G02 X88.0584 Y36.7129 I-4.8 J0. F200.

G01 Z-1.9 F100.

G02 X88.0584 Y36.7129 I-4.8 J0. F200.

G00 Z25.

X49.9203

Z2.

G01 Z-0.5 F100.

G02 X49.9203 Y36.7129 I-4.8 J0. F200.

G01 Z-1. F100.

G02 X49.9203 Y36.7129 I-4.8 J0. F200.

G01 Z-1.5 F100.

G02 X49.9203 Y36.7129 I-4.8 J0. F200.

G01 Z-1.9 F100.

G02 X49.9203 Y36.7129 I-4.8 J0. F200.

G00 Z25.

X61.1344 Y83.995

Z2.

G01 Z-0.5 F100.

G02 X61.1344 Y83.995 I-4.8 J0. F200.

G01 Z-1. F100.

G02 X61.1344 Y83.995 I-4.8 J0. F200.

G01 Z-1.5 F100.

G02 X61.1344 Y83.995 I-4.8 J0. F200.

G01 Z-1.9 F100.

G02 X61.1344 Y83.995 I-4.8 J0. F200.

G00 Z25.

X86.6995

Z2.

G01 Z-0.5 F100.

G02 X86.6995 Y83.995 I-4.8 J0. F200.

G01 Z-1. F100.

G02 X86.6995 Y83.995 I-4.8 J0. F200.

G01 Z-1.5 F100.

G02 X86.6995 Y83.995 I-4.8 J0. F200.

G01 Z-1.9 F100.

G02 X86.6995 Y83.995 I-4.8 J0. F200.

G00 Z25.

X111.909

Z2.

G01 Z-0.5 F100.

G02 X111.909 Y83.995 I-4.8 J0. F200.

G01 Z-1. F100.

G02 X111.909 Y83.995 I-4.8 J0. F200.

G01 Z-1.5 F100.

G02 X111.909 Y83.995 I-4.8 J0. F200.

G01 Z-1.9 F100.

G02 X111.909 Y83.995 I-4.8 J0. F200.

G00 Z25.

X180.5271 Y143.4564

Z2.

G01 Z-0.5 F100.

G02 X180.5271 Y143.4564 I-4.8 J0. F200.

G01 Z-1. F100.

G02 X180.5271 Y143.4564 I-4.8 J0. F200.

G01 Z-1.5 F100.

G02 X180.5271 Y143.4564 I-4.8 J0. F200.

G01 Z-1.9 F100.

G02 X180.5271 Y143.4564 I-4.8 J0. F200.

G00 Z25.

M2 regards

Please Log in or Create an account to join the conversation.

- looping

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 10

07 Sep 2015 19:24 #62195

by looping

Replied by looping on topic G0 XY move fail

Thanks ArcEye

Yes this is exactly my plot.

I didn't dig into tool compensation yet

I don't event know the content of my tool.tbl

I 'll try your code soon and learn tool compensation .

I'll keep you posted

Regards

Yes this is exactly my plot.

I didn't dig into tool compensation yet

I don't event know the content of my tool.tbl

I 'll try your code soon and learn tool compensation .

I'll keep you posted

Regards

Please Log in or Create an account to join the conversation.

- looping

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 10

08 Sep 2015 16:47 #62235

by looping

Replied by looping on topic G0 XY move fail

Hello

I could only do a few test la night:

1) With ArcEye's modifications, I still have the same wrong move.

2) I removed lines tools related (M06, M40 and M43) and the move is performed correctly

So it seems to be linked with compensation.

I'm using a 3mm endmill

Here's my current tool.tbl

I guess it should be :I'll make this update and retry tonight ArcEye's modifications

Regards

I could only do a few test la night:

1) With ArcEye's modifications, I still have the same wrong move.

2) I removed lines tools related (M06, M40 and M43) and the move is performed correctly

So it seems to be linked with compensation.

I'm using a 3mm endmill

Here's my current tool.tbl

T1 P1 D0.125000 Z+0.511000 ;1/8 end mill

T2 P2 D0.062500 Z+0.100000 ;1/16 end mill

T3 P3 D0.201000 Z+1.273000 ;#7 tap drill

T99999 P99999 Z+0.100000 ;big tool numberI guess it should be :

T1 P1 D3.000000 Z+0.000000 ; 3mm end millRegards

Please Log in or Create an account to join the conversation.

- looping

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 10

09 Sep 2015 13:16 - 10 Sep 2015 21:38 #62303

by looping

Replied by looping on topic G0 XY move fail

Hello

I updated tool.tbl with

and now everything works fine, even the initial GCode post at the beginning of the thread.

Thanks a lot for your help

Regards

I updated tool.tbl with

T1 P1 D3.000000 Z+0.000000 ; 3mm end milland now everything works fine, even the initial GCode post at the beginning of the thread.

Thanks a lot for your help

Regards

Last edit: 10 Sep 2015 21:38 by looping.

Please Log in or Create an account to join the conversation.

Time to create page: 0.112 seconds