"pwm/dir" (Out1) switches for spindle CCW

- juergen-home

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 15

11 Aug 2025 12:05 - 11 Aug 2025 12:18 #333214

by juergen-home

"pwm/dir" (Out1) switches for spindle CCW was created by juergen-home

Hi there

A question about my configuration:

1. I have a HF milling spindle which needs only to turns clockwise. The PWM canal (Out0) works fine. My config for "pwm/dir" (Out1) is set to a relay output (P17/"GPIO7"). The relay should be on when CW is commanded but here it is on when CCW is commanded. How config it so that the relay switch on when CW is commanded?

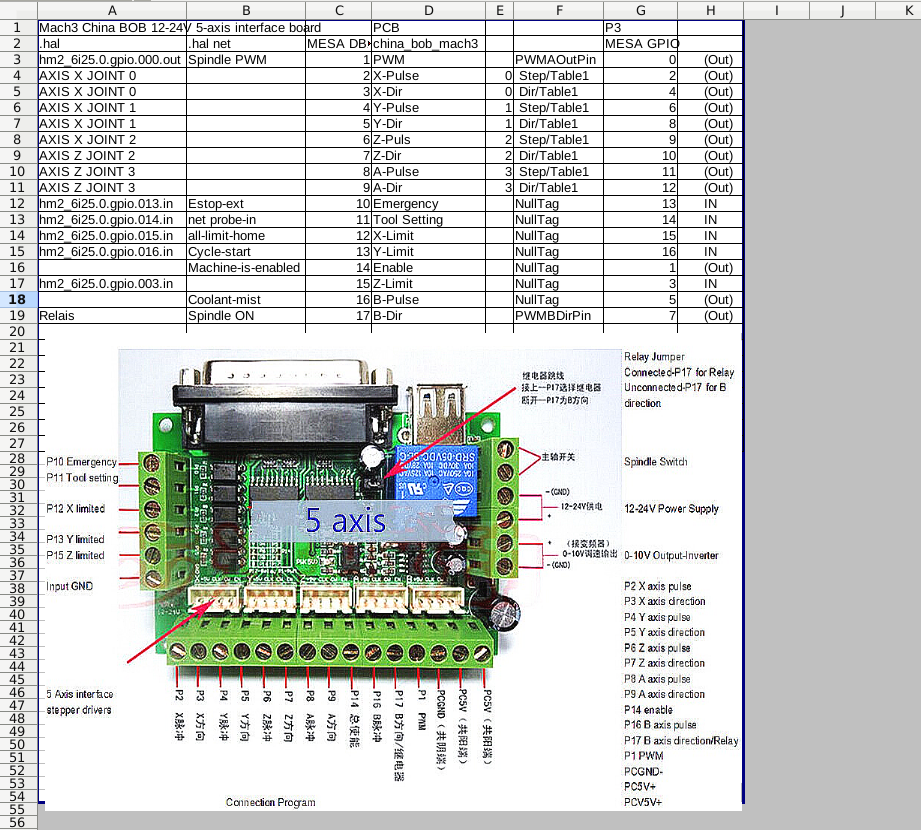

Mesa 6i25 with homemade pin file

China BOB Mach3

Linuxcnc 2.8.4-1gb7824717b

A question about my configuration:

1. I have a HF milling spindle which needs only to turns clockwise. The PWM canal (Out0) works fine. My config for "pwm/dir" (Out1) is set to a relay output (P17/"GPIO7"). The relay should be on when CW is commanded but here it is on when CCW is commanded. How config it so that the relay switch on when CW is commanded?

Mesa 6i25 with homemade pin file

China BOB Mach3

Linuxcnc 2.8.4-1gb7824717b

# Erstellt von PNCconf am Mon May 1 19:24:03 2023

# Verwendete LinuxCNC version: Master (2.9)

# Änderungen an dieser Datei werden beim nächsten

# wird überschrieben sobald Sie PNCconf erneut ausführen

#2.8.4

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_pci config="num_encoders=5 num_pwmgens=1 num_stepgens=4 sserial_port_0=0xxxxxxx"

#loadrt hm2_pci config="num_encoders=5 num_pwmgens=1 num_stepgens=3 sserial_port_0=0xxxxxxx"

# firmware=hm2/Discovered:6i25/~/mesa0_discovered.xml.BIT

setp hm2_6i25.0.pwmgen.pwm_frequency 1000

setp hm2_6i25.0.pwmgen.pdm_frequency 6000000

setp hm2_6i25.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z,pid.a,pid.s

# lut5: look up table für all-limit-home (because of problem with linit stop detection by other axes when homing)

loadrt lut5 names=lut_homing

addf lut_homing servo-thread

setp lut_homing.function 0x10000

net all-limit-home => lut_homing.in-4

net all-limit <= lut_homing.out

net homing-x <= joint.0.homing => lut_homing.in-0

net homing-y <= joint.1.homing => lut_homing.in-1

net homing-z <= joint.2.homing => lut_homing.in-2

##setp lut_homing.in-3 0

##net homing-a <= joint.2.homing => lut_homing.in-3

addf hm2_6i25.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.a.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf hm2_6i25.0.write servo-thread

setp hm2_6i25.0.dpll.01.timer-us -50

setp hm2_6i25.0.stepgen.timer-number 1

# extern signal input

# --- MACHINE-IS-ENABLED ---

#gpio.001 MESA DB25 PIN PIN 14

setp hm2_6i25.0.gpio.001.is_output true

net machine-is-enabled => hm2_6i25.0.gpio.001.out

# --- COOLANT-MIST ---

#gpio.005 MESA DB25 PIN PIN 16

setp hm2_6i25.0.gpio.005.is_output true

#net coolant-mist => hm2_6i25.0.gpio.005.out

# externe signal output

# --- ESTOP-EXT ---

#gpio.013 MESA DB25 PIN PIN 10

# .in_not for NC / .in for NO Limit Switch

net estop-ext <= hm2_6i25.0.gpio.013.in_not

#net estop-ext <= hm2_6i25.0.gpio.013.in

# --- PROBE-IN ---

# -wird in Probe_postgui.hal verwendet / definiert -

#gpio.014 MESA DB25 PIN PIN 11

#net probe-in <= hm2_6i25.0.gpio.014.in

# --- ALL-LIMIT-HOME ---

# gpio.015 MESA DB25 PIN PIN 12

# .in_not for NO / .in for NC Limit Switch

net all-limit-home <= hm2_6i25.0.gpio.015.in_not

#net all-limit-home <= hm2_6i25.0.gpio.015.in

# --- CYCLE-START ---

#gpio.016 MESA DB25 PIN PIN 13

#net cycle-start <= hm2_6i25.0.gpio.016.in

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.012700

#net x-index-enable => pid.x.index-enable

#net x-enable => pid.x.enable

#net x-pos-cmd => pid.x.command

#net x-pos-fb => pid.x.feedback

#net x-output <= pid.x.output

# Step-Gen Signal/Setup

setp hm2_6i25.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_6i25.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_6i25.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_6i25.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_6i25.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_6i25.0.stepgen.00.step_type 0

#setp hm2_6i25.0.stepgen.00.control-type 1

setp hm2_6i25.0.stepgen.00.control-type 0

setp hm2_6i25.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp hm2_6i25.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

#-closed loop umgehen (von sim-maschine)

net x-pos-fb joint.0.motor-pos-fb <= hm2_6i25.0.stepgen.00.position-fb

net x-pos-cmd joint.0.motor-pos-cmd => hm2_6i25.0.stepgen.00.position-cmd

net x-enable joint.0.amp-enable-out => hm2_6i25.0.stepgen.00.enable

# ---Closed-Loop Schrittmotor-Signale---

#net x-pos-cmd <= joint.0.motor-pos-cmd

#net x-vel-cmd <= joint.0.vel-cmd

#net x-output => hm2_6i25.0.stepgen.00.velocity-cmd

#net x-pos-fb <= hm2_6i25.0.stepgen.00.position-fb

#net x-pos-fb => joint.0.motor-pos-fb

#net x-enable <= joint.0.amp-enable-out

#net x-enable => hm2_6i25.0.stepgen.00.enable

# ---Einrichtung Referenzfahrt / Signale der Endschalter---

net all-limit-home => joint.0.home-sw-in

net all-limit => joint.0.neg-lim-sw-in

net all-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Y JOINT 1

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.y.maxerror 0.012700

#net y-index-enable => pid.y.index-enable

#net y-enable => pid.y.enable

#net y-pos-cmd => pid.y.command

#net y-pos-fb => pid.y.feedback

#net y-output <= pid.y.output

# Schritt-Gen Signale/Setup

#setp hm2_6i25.0.gpio.003.invert_output true

setp hm2_6i25.0.stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp hm2_6i25.0.stepgen.01.dirhold [JOINT_1]DIRHOLD

setp hm2_6i25.0.stepgen.01.steplen [JOINT_1]STEPLEN

setp hm2_6i25.0.stepgen.01.stepspace [JOINT_1]STEPSPACE

setp hm2_6i25.0.stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp hm2_6i25.0.stepgen.01.step_type 0

#setp hm2_6i25.0.stepgen.01.control-type 1

setp hm2_6i25.0.stepgen.01.control-type 0

setp hm2_6i25.0.stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp hm2_6i25.0.stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

#-closed loop umgehen (von sim-maschine)

net y-pos-fb joint.1.motor-pos-fb <= hm2_6i25.0.stepgen.01.position-fb

net y-pos-cmd joint.1.motor-pos-cmd => hm2_6i25.0.stepgen.01.position-cmd

net y-enable joint.1.amp-enable-out => hm2_6i25.0.stepgen.01.enable

# ---Closed-Loop Schrittmotor-Signale---

#net y-pos-cmd <= joint.1.motor-pos-cmd

#net y-vel-cmd <= joint.1.vel-cmd

#net y-output => hm2_6i25.0.stepgen.01.velocity-cmd

#net y-pos-fb <= hm2_6i25.0.stepgen.01.position-fb

#net y-pos-fb => joint.1.motor-pos-fb

#net y-enable <= joint.1.amp-enable-out

#net y-enable => hm2_6i25.0.stepgen.01.enable

# ---Einrichtung Referenzfahrt / Signale der Endschalter---

net all-limit-home => joint.1.home-sw-in

net all-limit => joint.1.neg-lim-sw-in

net all-limit => joint.1.pos-lim-sw-in

#*******************

# AXIS Z JOINT 2

#*******************

setp pid.z.Pgain [JOINT_2]P

setp pid.z.Igain [JOINT_2]I

setp pid.z.Dgain [JOINT_2]D

setp pid.z.bias [JOINT_2]BIAS

setp pid.z.FF0 [JOINT_2]FF0

setp pid.z.FF1 [JOINT_2]FF1

setp pid.z.FF2 [JOINT_2]FF2

setp pid.z.deadband [JOINT_2]DEADBAND

setp pid.z.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.z.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.z.maxerror 0.012700

#net z-index-enable => pid.z.index-enable

#net z-enable => pid.z.enable

#net z-pos-cmd => pid.z.command

#net z-pos-fb => pid.z.feedback

#net z-output <= pid.z.output

# Schritt-Gen Signale/Setup

setp hm2_6i25.0.gpio.003.invert_output true

setp hm2_6i25.0.stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp hm2_6i25.0.stepgen.02.dirhold [JOINT_2]DIRHOLD

setp hm2_6i25.0.stepgen.02.steplen [JOINT_2]STEPLEN

setp hm2_6i25.0.stepgen.02.stepspace [JOINT_2]STEPSPACE

setp hm2_6i25.0.stepgen.02.position-scale [JOINT_2]STEP_SCALE

setp hm2_6i25.0.stepgen.02.step_type 0

#setp hm2_6i25.0.stepgen.02.control-type 1

setp hm2_6i25.0.stepgen.02.control-type 0

setp hm2_6i25.0.stepgen.02.maxaccel [JOINT_2]STEPGEN_MAXACCEL

setp hm2_6i25.0.stepgen.02.maxvel [JOINT_2]STEPGEN_MAXVEL

#-closed loop umgehen (von sim-maschine)

net z-pos-fb joint.2.motor-pos-fb <= hm2_6i25.0.stepgen.02.position-fb

net z-pos-cmd joint.2.motor-pos-cmd => hm2_6i25.0.stepgen.02.position-cmd

net z-enable joint.2.amp-enable-out => hm2_6i25.0.stepgen.02.enable

# ---Closed-Loop Schrittmotor-Signale---

#net z-pos-cmd <= joint.2.motor-pos-cmd

#net z-vel-cmd <= joint.2.vel-cmd

#net z-output => hm2_6i25.0.stepgen.02.velocity-cmd

#net z-pos-fb <= hm2_6i25.0.stepgen.02.position-fb

#net z-pos-fb => joint.2.motor-pos-fb

#net z-enable <= joint.2.amp-enable-out

#net z-enable => hm2_6i25.0.stepgen.02.enable

# ---Einrichtung Referenzfahrt / Signale der Endschalter---

net all-limit-home => joint.2.home-sw-in

net all-limit => joint.2.neg-lim-sw-in

net all-limit => joint.2.pos-lim-sw-in

#*******************

# AXIS A JOINT 3

#*******************

#*******************

# SPINDEL

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]MAX_OUTPUT

setp pid.s.error-previous-target true

#net spindle-index-enable => pid.s.index-enable

#net spindle-enable => pid.s.enable

#net spindle-vel-cmd-rpm-abs => pid.s.command

#net spindle-vel-fb-rpm-abs => pid.s.feedback

#net spindle-output <= pid.s.output

# ---PWM Generator Signale/Setup---

setp hm2_6i25.0.pwmgen.00.output-type 1

setp hm2_6i25.0.pwmgen.00.scale [SPINDLE_0]OUTPUT_SCALE

# Invert the DIR signal

#setp hm2_6i25.0.gpio.007.invert_output true

# invert the PWM signal

setp hm2_6i25.0.gpio.000.invert_output true

#--- SPINDLE-ENABLE ---

net spindle-vel-cmd-rpm => hm2_6i25.0.pwmgen.00.value

net spindle-enable => hm2_6i25.0.pwmgen.00.enable

net spindle-enable => hm2_6i25.0.gpio.005.out

# ---Setup Spindel Steuerungs-Signale---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Einrichtung der Signale zur Spindel-Geschwindigkeits-Steuerung---

sets spindle-at-speed true

#******************************

# Verbinden verschiedener Signale

#******************************

# ---HALUI Signale---

# xhc: net axis-select-x halui.axis.x.select

# net jog-x-pos halui.axis.x.plus

# net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

# xhc: net x-is-homed halui.joint.0.is-homed

# xhc: net axis-select-y halui.axis.y.select

# net jog-y-pos halui.axis.y.plus

# net jog-y-neg halui.axis.y.minus

net jog-y-analog halui.axis.y.analog

#net y-is-homed halui.joint.1.is-homed

# xhc: net axis-select-z halui.axis.z.select

# net jog-z-pos halui.axis.z.plus

# net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

#net z-is-homed halui.joint.2.is-homed

net axis-select-a halui.axis.a.select

net jog-a-pos halui.axis.a.plus

net jog-a-neg halui.axis.a.minus

net jog-a-analog halui.axis.a.analog

#net a-is-homed halui.joint.3.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

# xhc: net machine-is-on halui.machine.is-on

# net jog-speed halui.axis.jog-speed

# xhc: net MDI-mode halui.mode.is-mdi

# xhc: net cycle-start halui.program.run

# net abort halui.abort

# ---Kühlmittel-Signale---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---Sonde/Taster Signal (probe signal)---

# easyprobe net probe-in => motion.probe-input

# ---Signale zur Bewegungs-Steuerung---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---Digitale ein-/ausgehende-Signale---

# ---E-Stop--

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# ---signal manual toolchange---

net tool-change-request <= iocontrol.0.tool-change

net tool-change-confirmed => iocontrol.0.tool-changed

net tool-number <= iocontrol.0.tool-prep-number

# ---use extern dialog for toolchange---

loadusr -W hal_manualtoolchange

net tool-change-request => hal_manualtoolchange.change

net tool-change-confirmed <= hal_manualtoolchange.changed

net tool-number => hal_manualtoolchange.number

# ---ignoriere Anfragen zu Werkzeug-Vorbereitungen---

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared# Erstellt von PNCconf am Mon May 1 19:24:03 2023

# Verwendete LinuxCNC version: Master (2.9)

#2.8.4

# reduced to bare minimum 2025-08-10 #aa

[EMC]

MACHINE = ttm_a

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = axis

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 3.000000

MAX_SPINDLE_OVERRIDE = 1.500000

MIN_SPINDLE_OVERRIDE = 0.500000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/cnc/linuxcnc/nc_files/ngc

OPEN_FILE=""

INCREMENTS = .1mm .05mm .01mm .005mm

#POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 8.3333

MAX_LINEAR_VELOCITY = 90

MIN_LINEAR_VELOCITY = 0.100000

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

EDITOR = geany

#GEOMETRY = xyza

GEOMETRY = xyz

PYVCP = custompanel.xml

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

RS274NGC_STARTUP_CODE = G21 G40 G90 G94 G97 G64 P0.025

#SUBROUTINE_PATH = /home/cnc/linuxcnc/nc_files/ngc/sub

SUBROUTINE_PATH = ./sub

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

SERVO_PERIOD = 1000000

[HMOT]

# **** Nur zur Information ****

CARD0=hm2_6i25.0

[HAL]

HALUI = halui

HALFILE = ttm_a.hal

HALFILE = custom.hal

POSTGUI_HALFILE = custom_postgui.hal

SHUTDOWN = shutdown.hal

[HALUI]

# midi 0-->26 (27)

#custom_postgui.hal

# midi 0-->26

MDI_COMMAND = m3 s2000

MDI_COMMAND = m3 s3000

MDI_COMMAND = m3 s4000

MDI_COMMAND = m3 s5000

MDI_COMMAND = m3 s6000

MDI_COMMAND = m3 s7000

MDI_COMMAND = m3 s8000

MDI_COMMAND = m3 s9000

MDI_COMMAND = m3 s10000

MDI_COMMAND = m3 s11000

MDI_COMMAND = m3 s12000

MDI_COMMAND = m3 s13000

MDI_COMMAND = m3 s14000

MDI_COMMAND = m3 s16000

MDI_COMMAND = m3 s18000

MDI_COMMAND = m3 s20000

MDI_COMMAND = m3 s22000

MDI_COMMAND = m3 s24000

# midi 18-28

MDI_COMMAND = g0 x0 y0

MDI_COMMAND = O<midi_com1> CALL

MDI_COMMAND = O<midi_com2> CALL

MDI_COMMAND = O<midi_com3> CALL

MDI_COMMAND = O<midi_com4> CALL

MDI_COMMAND = O<midi_com5> CALL

MDI_COMMAND = O<midi_go_tool_probe> CALL

MDI_COMMAND = O<midi_go_tool_change_pos> CALL

MDI_COMMAND = O<midi_set_tool_length> CALL

MDI_COMMAND = O<midi_load_tool> CALL

MDI_COMMAND = M5 M9

#29

#/custom_postgui.hal

[KINS]

#JOINTS = 4

JOINTS = 3

#KINEMATICS = trivkins coordinates=XYZA

KINEMATICS = trivkins coordinates=XYZ

[TRAJ]

#COORDINATES = XYZA

COORDINATES = XYZ

MAX_ANGULAR_VELOCITY = 360.00

DEFAULT_ANGULAR_VELOCITY = 36.00

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 2.50

MAX_LINEAR_VELOCITY = 90

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#******************************************

[AXIS_X]

MAX_VELOCITY = 50

MAX_ACCELERATION = 1500

#MIN_LIMIT =-255

MIN_LIMIT =-190

MAX_LIMIT =0

[JOINT_0]

TYPE = LINEAR

HOME = -1

FERROR = 0.01

MIN_FERROR = 10

MAX_VELOCITY =50

MAX_ACCELERATION = 1500

# Die folgenden Werte sollten 25% größer sein als MAX_VELOCITY und MAX_ACCELERATION

# Bei Verwendung der UMKEHRSPIEL-Kompensation sollte STEPGEN_MAXACCEL um 100% größer sein.

#STEPGEN_MAXVEL = 62.5

#STEPGEN_MAXACCEL = 187.5

STEPGEN_MAXVEL = 200

STEPGEN_MAXACCEL = 1875

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# diese sind in Nanosekunden

DIRSETUP = 3000

DIRHOLD = 3000

STEPLEN = 2000

STEPSPACE = 1000

#STEP_SCALE = 160

STEP_SCALE = 250

MIN_LIMIT = -190

MAX_LIMIT = 0

#HOME_OFFSET = 3

#HOME_SEARCH_VEL =30

#HOME_LATCH_VEL = 5

HOME_FINAL_VEL = 0

#HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

HOME_IS_SHARED = 1

#HOME_SEQUENCE = 2

#4.5.6.14 Immediate Homing

HOME_SEARCH_VEL = 0

HOME_LATCH_VEL = 0

HOME_USE_INDEX = NO

HOME_OFFSET = 0

HOME_SEQUENCE = 0

#******************************************

[AXIS_Y]

MAX_VELOCITY = 50

MAX_ACCELERATION = 1500

MIN_LIMIT =0

MAX_LIMIT =120

[JOINT_1]

TYPE = LINEAR

HOME = 1

FERROR = 0.01

MIN_FERROR = 10

MAX_VELOCITY =50

MAX_ACCELERATION = 1500

# Die folgenden Werte sollten 25% größer sein als MAX_VELOCITY und MAX_ACCELERATION

# Bei Verwendung der UMKEHRSPIEL-Kompensation sollte STEPGEN_MAXACCEL um 100% größer sein.

STEPGEN_MAXVEL = 200

STEPGEN_MAXACCEL = 1875

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# diese sind in Nanosekunden

DIRSETUP = 3000

DIRHOLD = 3000

STEPLEN = 2000

STEPSPACE = 1000

# original: STEP_SCALE = -160

STEP_SCALE = -160

MIN_LIMIT = 0

MAX_LIMIT = 120

# HOME_OFFSET = -3

#HOME_OFFSET = -1

# HOME_SEARCH_VEL = -5

#HOME_SEARCH_VEL = -20

#HOME_LATCH_VEL = -5

HOME_FINAL_VEL = 0

#HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

HOME_IS_SHARED = 1

#HOME_SEQUENCE = 3

#4.5.6.14 Immediate Homing

HOME_SEARCH_VEL = 0

HOME_LATCH_VEL = 0

HOME_USE_INDEX = NO

HOME_OFFSET = 0

HOME_SEQUENCE = 0

#******************************************

[AXIS_Z]

MAX_VELOCITY = 50

MAX_ACCELERATION = 1500

MIN_LIMIT =-210

MAX_LIMIT =0

[JOINT_2]

TYPE = LINEAR

HOME = -2

FERROR = 0.01

MIN_FERROR = 10

MAX_VELOCITY =50

MAX_ACCELERATION = 1500

# Die folgenden Werte sollten 25% größer sein als MAX_VELOCITY und MAX_ACCELERATION

# Bei Verwendung der UMKEHRSPIEL-Kompensation sollte STEPGEN_MAXACCEL um 100% größer sein.

STEPGEN_MAXVEL = 100

STEPGEN_MAXACCEL = 1875

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# diese sind in Nanosekunden

DIRSETUP = 3000

DIRHOLD = 3000

STEPLEN = 2000

STEPSPACE = 1000

STEP_SCALE = 160

MIN_LIMIT = -210

#HOME_OFFSET = 2

#HOME_SEARCH_VEL =40

#HOME_LATCH_VEL = 5

HOME_FINAL_VEL = 0

#HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

HOME_IS_SHARED = 1

#HOME_SEQUENCE = 1

#4.5.6.14 Immediate Homing

HOME_SEARCH_VEL = 0

HOME_LATCH_VEL = 0

HOME_USE_INDEX = NO

HOME_OFFSET = 0

HOME_SEQUENCE = 0

#******************************************

[SPINDLE_0]

P = 0.0

I = 0.0

D = 0.0

FF0 = 1.0

FF1 = 0.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 24000

OUTPUT_SCALE = 24000

OUTPUT_MIN_LIMIT = 0

OUTPUT_MAX_LIMIT = 24000

MAX_VELOCITY = 24000

MIN_VELOCITY = 0

INCREMENT = 1000

DEFAULT_SPINDLE_0_SPEED = 1000

#MAX_REVERSE_VELOCITY = 2400

#MIN_REVERSE_VELOCITY = 100

#******************************************Configuration Name: HOSTMOT2

General configuration information:

BoardName : MESA6I25

FPGA Size: 9 KGates

FPGA Pins: 144

Number of IO Ports: 2

Width of one I/O port: 17

Clock Low frequency: 66.6667 MHz

Clock High frequency: 200.0000 MHz

IDROM Type: 3

Instance Stride 0: 4

Instance Stride 1: 64

Register Stride 0: 256

Register Stride 1: 256

Modules in configuration:

Module: DPLL

There are 1 of DPLL in configuration

Version: 0

Registers: 7

BaseAddress: 7000

ClockFrequency: 66.667 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: WatchDog

There are 1 of WatchDog in configuration

Version: 0

Registers: 3

BaseAddress: 0C00

ClockFrequency: 66.667 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: IOPort

There are 2 of IOPort in configuration

Version: 0

Registers: 5

BaseAddress: 1000

ClockFrequency: 66.667 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: PWM

There are 1 of PWM in configuration

Version: 0

Registers: 5

BaseAddress: 4100

ClockFrequency: 200.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: QCount

There are 5 of QCount in configuration

Version: 2

Registers: 5

BaseAddress: 3000

ClockFrequency: 66.667 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: SSerial

There are 1 of SSerial in configuration

Version: 0

Registers: 6

BaseAddress: 5B00

ClockFrequency: 66.667 MHz

Register Stride: 256 bytes

Instance Stride: 64 bytes

Module: StepGen

There are 4 of StepGen in configuration

Version: 2

Registers: 10

BaseAddress: 2000

ClockFrequency: 66.667 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: LED

There are 1 of LED in configuration

Version: 0

Registers: 1

BaseAddress: 0200

ClockFrequency: 66.667 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Configuration pin-out:

IO Connections for P3

Pin# I/O Pri. func Sec. func Chan Pin func Pin Dir

1 0 IOPort PWM 0 PWM (Out)

14 1 IOPort None

2 2 IOPort StepGen 0 Step/Table1 (Out)

15 3 IOPort None

3 4 IOPort StepGen 0 Dir/Table2 (Out)

16 5 IOPort None

4 6 IOPort StepGen 1 Step/Table1 (Out)

17 7 IOPort PWM 0 Dir (Out)

5 8 IOPort StepGen 1 Dir/Table2 (Out)

6 9 IOPort StepGen 2 Step/Table1 (Out)

7 10 IOPort StepGen 2 Dir/Table2 (Out)

8 11 IOPort StepGen 3 Step/Table1 (Out)

9 12 IOPort StepGen 3 Dir/Table2 (Out)

10 13 IOPort None

11 14 IOPort None

12 15 IOPort None

13 16 IOPort None

IO Connections for P2

Pin# I/O Pri. func Sec. func Chan Pin func Pin Dir

1 17 IOPort QCount 0 Quad-A (In)

14 18 IOPort QCount 4 Quad-B (In)

2 19 IOPort QCount 0 Quad-B (In)

15 20 IOPort QCount 4 Quad-IDX (In)

3 21 IOPort QCount 0 Quad-IDX (In)

16 22 IOPort SSerial 0 TXData0 (Out)

4 23 IOPort QCount 1 Quad-A (In)

17 24 IOPort SSerial 0 RXData0 (In)

5 25 IOPort QCount 1 Quad-B (In)

6 26 IOPort QCount 1 Quad-IDX (In)

7 27 IOPort QCount 2 Quad-A (In)

8 28 IOPort QCount 2 Quad-B (In)

9 29 IOPort QCount 2 Quad-IDX (In)

10 30 IOPort QCount 3 Quad-A (In)

11 31 IOPort QCount 3 Quad-B (In)

12 32 IOPort QCount 3 Quad-IDX (In)

13 33 IOPort QCount 4 Quad-A (In)Attachments:

Last edit: 11 Aug 2025 12:18 by juergen-home.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

11 Aug 2025 12:15 #333217

by rodw

Replied by rodw on topic "pwm/dir" (Out1) switches for spindle CCW

I've never used a parallel port. Do they have -not pins that are inverted for each pin? If not, there is a not component that inverts a pin.

linuxcnc.org/docs/stable/html/man/man9/not.9.html

linuxcnc.org/docs/stable/html/man/man9/not.9.html

Please Log in or Create an account to join the conversation.

- juergen-home

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 15

11 Aug 2025 12:30 #333219

by juergen-home

Replied by juergen-home on topic "pwm/dir" (Out1) switches for spindle CCW

... it is driven by a 6i25.

I have tried to invert, but that does not the trick for me. It inverts only the Relay signal for CCW but I need the action on CW.

I have tried to invert, but that does not the trick for me. It inverts only the Relay signal for CCW but I need the action on CW.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17708

- Thank you received: 5181

11 Aug 2025 16:26 #333234

by PCW

Replied by PCW on topic "pwm/dir" (Out1) switches for spindle CCW

Something like this? (no sure if you need inversion or not)

# Invert the DIR signal

setp hm2_6i25.0.gpio.007.is_output true

setp hm2_6i25.0.gpio.007.invert_output true

net spindle-ccw hm2_6i25.0.gpio.007.out

# Invert the DIR signal

setp hm2_6i25.0.gpio.007.is_output true

setp hm2_6i25.0.gpio.007.invert_output true

net spindle-ccw hm2_6i25.0.gpio.007.out

Please Log in or Create an account to join the conversation.

- juergen-home

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 15

12 Aug 2025 07:52 #333267

by juergen-home

Replied by juergen-home on topic "pwm/dir" (Out1) switches for spindle CCW

Thanks Peter for coming by. I put your 3 lines in my .hal file but there is an error message:

...

Debug file information:

Note: Using POSIX realtime

./ttm_a.hal:298: parameter or pin 'hm2_6i25.0.gpio.007.is_output' not found

2077

Stopping realtime threads

...

Perhaps this is because gpio.007 is "hm2/hm2_6i25.0: IO Pin 007 (P3-17): PWMGen #0, pin Out1 (Dir or Down) (Output)"

Seems this gpio.007 is bound to "pwm/dir" (Out1) for signaling CCW, what I want to do is to use it as a signal to enable my VFD while CW rotation.

Because I'm low on outputs I want to use this gpio.007 with the relay.

Juergen

...

Debug file information:

Note: Using POSIX realtime

./ttm_a.hal:298: parameter or pin 'hm2_6i25.0.gpio.007.is_output' not found

2077

Stopping realtime threads

...

Perhaps this is because gpio.007 is "hm2/hm2_6i25.0: IO Pin 007 (P3-17): PWMGen #0, pin Out1 (Dir or Down) (Output)"

Seems this gpio.007 is bound to "pwm/dir" (Out1) for signaling CCW, what I want to do is to use it as a signal to enable my VFD while CW rotation.

Because I'm low on outputs I want to use this gpio.007 with the relay.

Juergen

Error report created by /usr/lib/tcltk/linuxcnc/show_errors.tcl:

Print file information:

RUN_IN_PLACE=no

LINUXCNC_DIR=

LINUXCNC_BIN_DIR=/usr/bin

LINUXCNC_TCL_DIR=/usr/lib/tcltk/linuxcnc

LINUXCNC_SCRIPT_DIR=

LINUXCNC_RTLIB_DIR=/usr/lib/linuxcnc/modules

LINUXCNC_CONFIG_DIR=

LINUXCNC_LANG_DIR=/usr/lib/tcltk/linuxcnc/msgs

INIVAR=inivar

HALCMD=halcmd

LINUXCNC_EMCSH=/usr/bin/wish8.6

LINUXCNC - 2.8.4-1-gb7824717b

Machine configuration directory is '/home/cnc/linuxcnc/configs/ttm_a'

Machine configuration file is 'ttm_a.ini'

INIFILE=/home/cnc/linuxcnc/configs/ttm_a/ttm_a.ini

VERSION=1.1

PARAMETER_FILE=linuxcnc.var

TASK=milltask

HALUI=halui

DISPLAY=axis

COORDINATES=XYZ

KINEMATICS=trivkins coordinates=XYZ

Starting LinuxCNC...

Starting LinuxCNC server program: linuxcncsvr

Loading Real Time OS, RTAPI, and HAL_LIB modules

Starting LinuxCNC IO program: io

Starting HAL User Interface program: halui

Found file(REL): ./ttm_a.hal

Shutting down and cleaning up LinuxCNC...

Running HAL shutdown script

hm2: loading Mesa HostMot2 driver version 0.15

hm2_pci: loading Mesa AnyIO HostMot2 driver version 0.7

hm2_pci: discovered 6i25 at 0000:06:00.0

hm2/hm2_6i25.0: Low Level init 0.15

hm2/hm2_6i25.0: Smart Serial Firmware Version 43

hm2/hm2_6i25.0: 34 I/O Pins used:

hm2/hm2_6i25.0: IO Pin 000 (P3-01): PWMGen #0, pin Out0 (PWM or Up) (Output)

hm2/hm2_6i25.0: IO Pin 001 (P3-14): IOPort

hm2/hm2_6i25.0: IO Pin 002 (P3-02): StepGen #0, pin Step (Output)

hm2/hm2_6i25.0: IO Pin 003 (P3-15): IOPort

hm2/hm2_6i25.0: IO Pin 004 (P3-03): StepGen #0, pin Direction (Output)

hm2/hm2_6i25.0: IO Pin 005 (P3-16): IOPort

hm2/hm2_6i25.0: IO Pin 006 (P3-04): StepGen #1, pin Step (Output)

hm2/hm2_6i25.0: IO Pin 007 (P3-17): PWMGen #0, pin Out1 (Dir or Down) (Output)

hm2/hm2_6i25.0: IO Pin 008 (P3-05): StepGen #1, pin Direction (Output)

hm2/hm2_6i25.0: IO Pin 009 (P3-06): StepGen #2, pin Step (Output)

hm2/hm2_6i25.0: IO Pin 010 (P3-07): StepGen #2, pin Direction (Output)

hm2/hm2_6i25.0: IO Pin 011 (P3-08): StepGen #3, pin Step (Output)

hm2/hm2_6i25.0: IO Pin 012 (P3-09): StepGen #3, pin Direction (Output)

hm2/hm2_6i25.0: IO Pin 013 (P3-10): IOPort

hm2/hm2_6i25.0: IO Pin 014 (P3-11): IOPort

hm2/hm2_6i25.0: IO Pin 015 (P3-12): IOPort

hm2/hm2_6i25.0: IO Pin 016 (P3-13): IOPort

hm2/hm2_6i25.0: IO Pin 017 (P2-01): Encoder #0, pin A (Input)

hm2/hm2_6i25.0: IO Pin 018 (P2-14): Encoder #4, pin B (Input)

hm2/hm2_6i25.0: IO Pin 019 (P2-02): Encoder #0, pin B (Input)

hm2/hm2_6i25.0: IO Pin 020 (P2-15): Encoder #4, pin Index (Input)

hm2/hm2_6i25.0: IO Pin 021 (P2-03): Encoder #0, pin Index (Input)

hm2/hm2_6i25.0: IO Pin 022 (P2-16): IOPort

hm2/hm2_6i25.0: IO Pin 023 (P2-04): Encoder #1, pin A (Input)

hm2/hm2_6i25.0: IO Pin 024 (P2-17): IOPort

hm2/hm2_6i25.0: IO Pin 025 (P2-05): Encoder #1, pin B (Input)

hm2/hm2_6i25.0: IO Pin 026 (P2-06): Encoder #1, pin Index (Input)

hm2/hm2_6i25.0: IO Pin 027 (P2-07): Encoder #2, pin A (Input)

hm2/hm2_6i25.0: IO Pin 028 (P2-08): Encoder #2, pin B (Input)

hm2/hm2_6i25.0: IO Pin 029 (P2-09): Encoder #2, pin Index (Input)

hm2/hm2_6i25.0: IO Pin 030 (P2-10): Encoder #3, pin A (Input)

hm2/hm2_6i25.0: IO Pin 031 (P2-11): Encoder #3, pin B (Input)

hm2/hm2_6i25.0: IO Pin 032 (P2-12): Encoder #3, pin Index (Input)

hm2/hm2_6i25.0: IO Pin 033 (P2-13): Encoder #4, pin A (Input)

hm2/hm2_6i25.0: registered

hm2_6i25.0: initialized AnyIO board at 0000:06:00.0

hm2_6i25.0: dropping AnyIO board at 0000:06:00.0

hm2/hm2_6i25.0: unregistered

hm2_pci: driver unloaded

hm2: unloading

Removing HAL_LIB, RTAPI, and Real Time OS modules

Removing NML shared memory segments

Debug file information:

Note: Using POSIX realtime

./ttm_a.hal:298: parameter or pin 'hm2_6i25.0.gpio.007.is_output' not found

2077

Stopping realtime threads

Unloading hal components

RTAPI_PCI: Unmapped 65536 bytes at 0x7f0222141000

Note: Using POSIX realtime

-----------------------------------------------------------------------

Info report created by linuxcnc_info:

The file: /tmp/linuxcnc_info.txt

can be posted to a forum or a web site like:

http://pastebin.com

in order to provide information about the linuxcnc

system and configuration.

Date: Di 12. Aug 09:22:22 CEST 2025

UTC Date: Di 12. Aug 07:22:22 UTC 2025

this program: /usr/bin/linuxcnc_info

uptime: 09:22:22 up 10 min, 1 user, load average: 1,09, 0,87, 0,52

lsb_release -sa: Debian Debian GNU/Linux 10 (buster) 10 buster

which linuxcnc: /usr/bin/linuxcnc

pwd: /home/cnc/linuxcnc/configs/ttm_a

USER: cnc

LOGNAME: cnc

HOME: /home/cnc

EDITOR:

VISUAL:

LANGUAGE:

TERM: dumb

COLORTERM:

DISPLAY: :0.0

DESKTOP: lightdm-xsession

display size: 1920x1080 pixels (508x285 millimeters)

PATH: /usr/bin:/home/cnc/linuxcnc/configs/ttm_a/bin:/usr/bin:/usr/local/bin:/usr/bin:/bin:/usr/local/games:/usr/games

uname items:

nodename -n: debian

kernel-name -s: Linux

kernel-vers -v: #1 SMP PREEMPT RT Debian 4.19.316-1 (2024-06-25)

machine -m: x86_64

processor -p: unknown

platform -i: unknown

oper system -o: GNU/Linux

/proc items:

cmdline: BOOT_IMAGE=/boot/vmlinuz-4.19.0-27-rt-amd64 root=UUID=9c449597-d44a-4504-9fed-3d2541ad317f ro initrd=/install/initrd.gz quiet

model name: Intel(R) Core(TM) i5-4440 CPU @ 3.10GHz

cores: 4

cpu MHz: 1935.655

parport: 0000-0000 : parport0

serial: 0000-0000 : serial

Versions:

gcc: gcc (Debian 8.3.0-6) 8.3.0

python: Python 2.7.16

git: not_in_PATH

git commit: NA

tcl: 8.6

tk: 8.6

glade: not_in_PATH

glade-gtk2: not_in_PATH

linuxcnc_var all:

LINUXCNCVERSION: 2.8.4-1-gb7824717b

LINUXCNC_AUX_GLADEVCP: /usr/share/linuxcnc/aux_gladevcp

LINUXCNC_AUX_EXAMPLES: /usr/share/linuxcnc/aux_examples

REALTIME: /etc/init.d/realtime

RTS: uspace

HALLIB_DIR: /usr/share/linuxcnc/hallib

dpkg -l '*linuxcnc*':

Gewünscht=Unbekannt/Installieren/R=Entfernen/P=Vollständig Löschen/Halten

| Status=Nicht/Installiert/Config/U=Entpackt/halb konFiguriert/

Halb installiert/Trigger erWartet/Trigger anhängig

|/ Fehler?=(kein)/R=Neuinstallation notwendig (Status, Fehler: GROSS=schlecht)

||/ Name Version Architektur Beschreibung

+++-===================-====================-============-=====================================================================

un linuxcnc <keine> <keine> (keine Beschreibung vorhanden)

un linuxcnc-dev <keine> <keine> (keine Beschreibung vorhanden)

un linuxcnc-doc <keine> <keine> (keine Beschreibung vorhanden)

ii linuxcnc-doc-en 1:2.8.4.1.gb7824717b all motion controller for CNC machines and robots (English documentation)

ii linuxcnc-doc-es 1:2.8.4.1.gb7824717b all controlador de movimiento para máquinas CNC y robots (Español).

ii linuxcnc-doc-fr 1:2.8.4.1.gb7824717b all motion controller for CNC machines and robots (French documentation)

un linuxcnc-sim <keine> <keine> (keine Beschreibung vorhanden)

un linuxcnc-sim-dev <keine> <keine> (keine Beschreibung vorhanden)

ii linuxcnc-uspace 1:2.8.4.1.gb7824717b amd64 motion controller for CNC machines and robots

ii linuxcnc-uspace-dev 1:2.8.4.1.gb7824717b amd64 PC based motion controller for real-time LinuxPlease Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17708

- Thank you received: 5181

12 Aug 2025 15:49 - 12 Aug 2025 15:51 #333283

by PCW

Replied by PCW on topic "pwm/dir" (Out1) switches for spindle CCW

What fIrmware are you using?

5i25_5ABOBx2.bit should have the correct pinout and GPIO 7 is just GPIO on that firmware

5i25_5ABOBx2.bit should have the correct pinout and GPIO 7 is just GPIO on that firmware

Last edit: 12 Aug 2025 15:51 by PCW.

Please Log in or Create an account to join the conversation.

- juergen-home

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 15

12 Aug 2025 15:56 - 12 Aug 2025 16:54 #333284

by juergen-home

Replied by juergen-home on topic "pwm/dir" (Out1) switches for spindle CCW

What do you mean with firmware? The bit-file?

If you mean my IO Connections for the 6i25 they are shown in my first post in the last source code section.

I made my own bit file matching the in and outputs of the mach3 bob.

The 5i25_5ABOBx2.bit is matching my china bob?

Can I remove the "17 7 IOPort PWM 0 Dir (Out)" in the bit file and make a nomal I/O Port out of it or must these PWMs come in pairs of PWM and PWM/DIR?.

If not, can I change a component so that the relay clicks with CW and not with CCW?

If you mean my IO Connections for the 6i25 they are shown in my first post in the last source code section.

I made my own bit file matching the in and outputs of the mach3 bob.

The 5i25_5ABOBx2.bit is matching my china bob?

Can I remove the "17 7 IOPort PWM 0 Dir (Out)" in the bit file and make a nomal I/O Port out of it or must these PWMs come in pairs of PWM and PWM/DIR?.

If not, can I change a component so that the relay clicks with CW and not with CCW?

Last edit: 12 Aug 2025 16:54 by juergen-home.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17708

- Thank you received: 5181

12 Aug 2025 23:27 - 12 Aug 2025 23:30 #333302

by PCW

Replied by PCW on topic "pwm/dir" (Out1) switches for spindle CCW

The 5i25_5ABOBx2.bit is matching my china bob?

Yes, it has a slightly different pinout but is designed for that BOB.

It supports all 5 Axis (on each BOB) so has a stepgen pin on IO7=DB25 pin 17

but was designed to easily reclaim the pins as GPIO since it uses stepgen

8,9 for the per BOB 5th axis so by setting num_stepgens to 8, you can get 4 stepgens

per connector and still have the relay GPIO free.

You could also just recompile your bit file and change the PWM dir pin to just a GPIO pin

The problem with using the PWM DIR pin is that it depends on the PWM sign, this

may work if you connect the PWM value to the signed spindle speed command

rather than the absolute spindle speed command (you may still need to invert the DIR pin).

The advantage is that this may work with your existing bitfile.

Yes, it has a slightly different pinout but is designed for that BOB.

It supports all 5 Axis (on each BOB) so has a stepgen pin on IO7=DB25 pin 17

but was designed to easily reclaim the pins as GPIO since it uses stepgen

8,9 for the per BOB 5th axis so by setting num_stepgens to 8, you can get 4 stepgens

per connector and still have the relay GPIO free.

You could also just recompile your bit file and change the PWM dir pin to just a GPIO pin

The problem with using the PWM DIR pin is that it depends on the PWM sign, this

may work if you connect the PWM value to the signed spindle speed command

rather than the absolute spindle speed command (you may still need to invert the DIR pin).

The advantage is that this may work with your existing bitfile.

Last edit: 12 Aug 2025 23:30 by PCW.

Please Log in or Create an account to join the conversation.

- juergen-home

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 15

13 Aug 2025 09:37 - 13 Aug 2025 09:40 #333320

by juergen-home

Replied by juergen-home on topic "pwm/dir" (Out1) switches for spindle CCW

At the end it was easier for me to compile a new bit file without the pwm/dir (I/O 07 PIN 17) and use it as a GPIO. It is working now.

Many thanks to you Peter!

Another question is about my "26 HDR" internal port of the 6i25 , I wanted to do my own encoder pcb but now I found a used 7I52S.

How to modify my vhd-file to do so and how should the cable from 26 HDR 6i25 to the 50 HDR 7I52S look like?

I don't now if I can use all functionality of the 7I52S but at least the 6 encoders and the rest filled with (stepper)outputs?

Should I open a new thread for this?

Many thanks to you Peter!

Another question is about my "26 HDR" internal port of the 6i25 , I wanted to do my own encoder pcb but now I found a used 7I52S.

How to modify my vhd-file to do so and how should the cable from 26 HDR 6i25 to the 50 HDR 7I52S look like?

I don't now if I can use all functionality of the 7I52S but at least the 6 encoders and the rest filled with (stepper)outputs?

Should I open a new thread for this?

Last edit: 13 Aug 2025 09:40 by juergen-home.

Please Log in or Create an account to join the conversation.

- juergen-home

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 15

14 Aug 2025 12:42 - 14 Aug 2025 12:54 #333409

by juergen-home

Replied by juergen-home on topic "pwm/dir" (Out1) switches for spindle CCW

Question about Connect Mesa 6i25 HDR26 with 7I52S HDR50

moved to

forum.linuxcnc.org/49-basic-configuratio...h-7i52s-hdr50#333411

forum.linuxcnc.org/49-basic-configuratio...h-7i52s-hdr50#333411

Last edit: 14 Aug 2025 12:54 by juergen-home.

Please Log in or Create an account to join the conversation.

Time to create page: 0.204 seconds