- Configuring LinuxCNC

- Basic Configuration

- Question about using Deadband in calibration when switching from Position to Spe

Question about using Deadband in calibration when switching from Position to Spe

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 8

24 Jan 2026 15:38 #341869

by abdulasis12

Question about using Deadband in calibration when switching from Position to Spe was created by abdulasis12

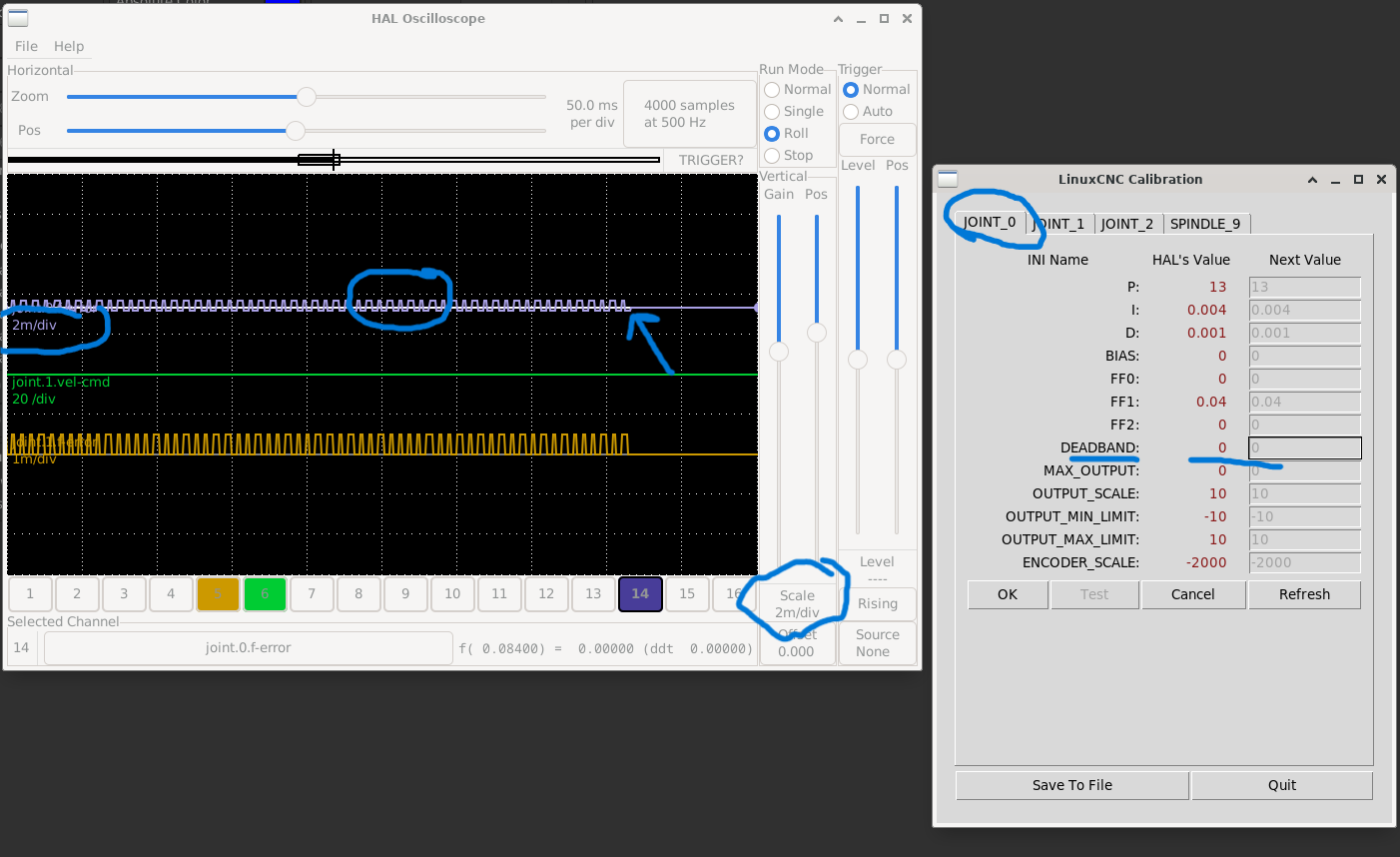

Hello everyone,I have a question regarding the use of deadband in the calibration function.I am using a Delta servo motor. Previously, I ran the servo drive in position control mode (pulse train input), using a Mesa 7i77 for feedback control. In that setup, setting the deadband to 0.003 worked well and the motor was able to stay still without hunting.Recently, I changed the servo drive mode to speed control using ±10 V analog input, because I expected smoother motion compared to pulse train control (this was suggested to me earlier). After that, I modified my HAL and INI files to use analog ±10 V output instead of pulses.The problem is that I can no longer get the motor to stay still using deadband.When I apply any value to the deadband, the value of joint0.f-error immediately jumps to the deadband value, and the motor still shows oscillation near zero error. It feels like the deadband is not helping at all—in fact, it seems to make the behavior worse. The motor still dithers or ripples at the error endpoint.My question is:

- Is deadband supposed to be used differently when operating in speed control (analog velocity mode)?

- Is this behavior expected, and if so, what is the correct way to achieve a stable standstill in this mode?

- Should I avoid using deadband entirely in this configuration and rely on other parameters (PID, FF terms, output scaling, etc.) instead?

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7265

25 Jan 2026 03:01 #341883

by tommylight

Replied by tommylight on topic Question about using Deadband in calibration when switching from Position to Spe

It does seem something is not set correctly as setting deadband should not trigger joint error, at least i do not recall it ever happening to me, but i do use lower values:

DEADBAND = 0.0001

DEADBAND = 0.001

as a starting point, and go up or down a bit till i get soft noiseless motor standstill.

For a Delta drive, i would try with 0 I and 0 D values, find FF1 where machine would run at full speed properly, then set a very low value for deadband if you end up needing it.

First and foremost, find the P value where the motor does not lag to much at full speed and does not vibrate at standstill.

DEADBAND = 0.0001

DEADBAND = 0.001

as a starting point, and go up or down a bit till i get soft noiseless motor standstill.

For a Delta drive, i would try with 0 I and 0 D values, find FF1 where machine would run at full speed properly, then set a very low value for deadband if you end up needing it.

First and foremost, find the P value where the motor does not lag to much at full speed and does not vibrate at standstill.

The following user(s) said Thank You: abdulasis12

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 8

26 Jan 2026 05:29 #341919

by abdulasis12

Replied by abdulasis12 on topic Question about using Deadband in calibration when switching from Position to Spe

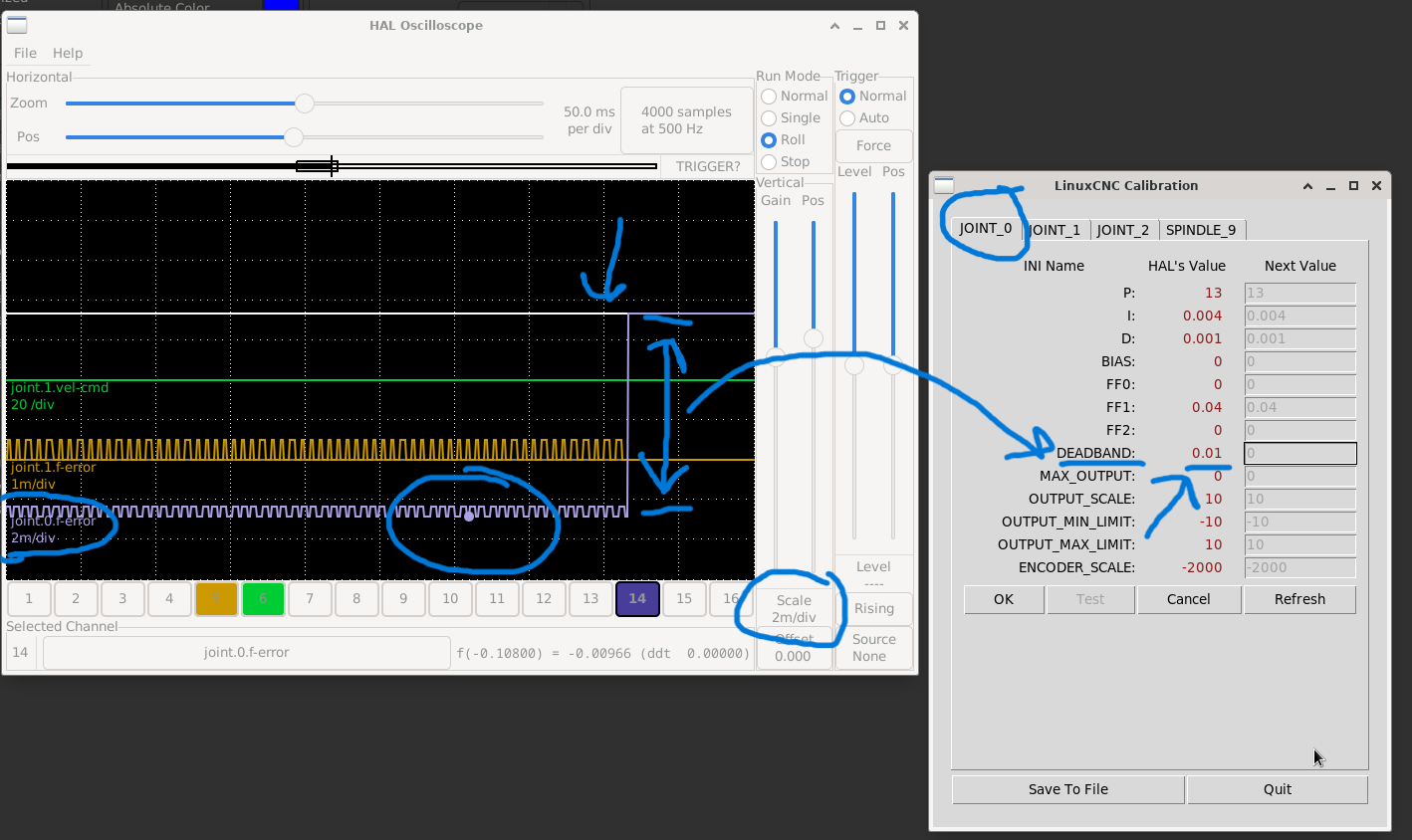

Thnk you , for fast respond

Today I try again with your advice I and D change to 0 and clear all paremeter in calibration box

again its not help

now

X axis

P 17 , I = 0 , D = 0

deadband same result can't touch

I try re config FF0 FF1 FF2 but not any change

now FF0 = 0 FF1 = 0.04 FF2 = 0

but there is still a slight vibration/noise at standstill that I cannot get rid of yet.

FYI : DELTA ASDA-A3 750w

Thank you again for your help.

Asis,

Today I try again with your advice I and D change to 0 and clear all paremeter in calibration box

again its not help

now

X axis

P 17 , I = 0 , D = 0

deadband same result can't touch

I try re config FF0 FF1 FF2 but not any change

now FF0 = 0 FF1 = 0.04 FF2 = 0

but there is still a slight vibration/noise at standstill that I cannot get rid of yet.

FYI : DELTA ASDA-A3 750w

Thank you again for your help.

Asis,

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7265

26 Jan 2026 13:38 #341941

by tommylight

Replied by tommylight on topic Question about using Deadband in calibration when switching from Position to Spe

Again, something is not OK if you can change values of FFx and get no change in response, so are the drives set in "velocity" or "torque" mode?

Please Log in or Create an account to join the conversation.

- meister

- Offline

- Platinum Member

-

Less

More

- Posts: 699

- Thank you received: 428

26 Jan 2026 14:40 #341946

by meister

Replied by meister on topic Question about using Deadband in calibration when switching from Position to Spe

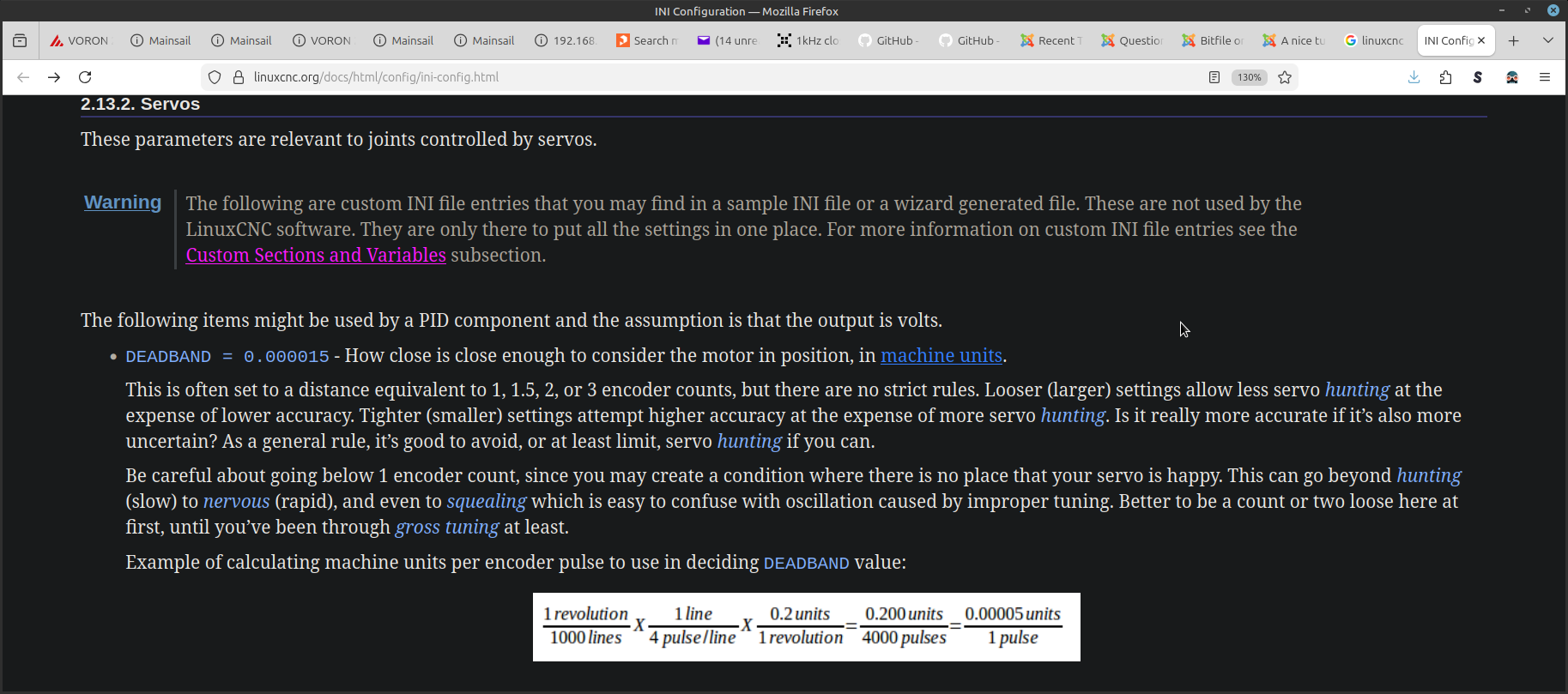

my calculation of the DEADBAND value:

pid_setup["DEADBAND"] = round(1 / abs(joint_config["SCALE_OUT"]) * 2, 4)

works for me

pid_setup["DEADBAND"] = round(1 / abs(joint_config["SCALE_OUT"]) * 2, 4)

works for me

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7265

26 Jan 2026 15:41 #341951

by tommylight

Replied by tommylight on topic Question about using Deadband in calibration when switching from Position to Spe

Attachments:

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Basic Configuration

- Question about using Deadband in calibration when switching from Position to Spe

Time to create page: 0.136 seconds