[SOLVED] MesaCT problems with 7i96 pwm spindle

- oddwick

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 19

21 May 2025 03:00 #328841

by oddwick

Replied by oddwick on topic MesaCT problems with 7i96 pwm spindle

ok so i for the most part got it working now, thanks jt pete and tom for the help! basically if i run the pwm module at 14v i get close enough to 5-10v to give me 12-24k rpm.

the last thing i just need to figure out is how to get the spindle to actually start. been trying to decipher a chinglish manual all afternoon to program this vfd. to be fair tho, it is actually better translated than the other ones ive dealt with. i can set the working frequency from linuxcnc but cant actually get it to start remotely. if anybody has any experience with a huanyang fc01, any help would be greatly appreciated!

the last thing i just need to figure out is how to get the spindle to actually start. been trying to decipher a chinglish manual all afternoon to program this vfd. to be fair tho, it is actually better translated than the other ones ive dealt with. i can set the working frequency from linuxcnc but cant actually get it to start remotely. if anybody has any experience with a huanyang fc01, any help would be greatly appreciated!

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21205

- Thank you received: 7242

21 May 2025 07:27 #328847

by tommylight

Replied by tommylight on topic MesaCT problems with 7i96 pwm spindle

Pictures of your VFD connectors?

Not from the net, last week i dealt with two of the same make and model VFD that are not the same in any way, nor are the electronics the same.

Not from the net, last week i dealt with two of the same make and model VFD that are not the same in any way, nor are the electronics the same.

The following user(s) said Thank You: oddwick

Please Log in or Create an account to join the conversation.

- oddwick

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 19

21 May 2025 14:33 #328859

by oddwick

Replied by oddwick on topic MesaCT problems with 7i96 pwm spindle

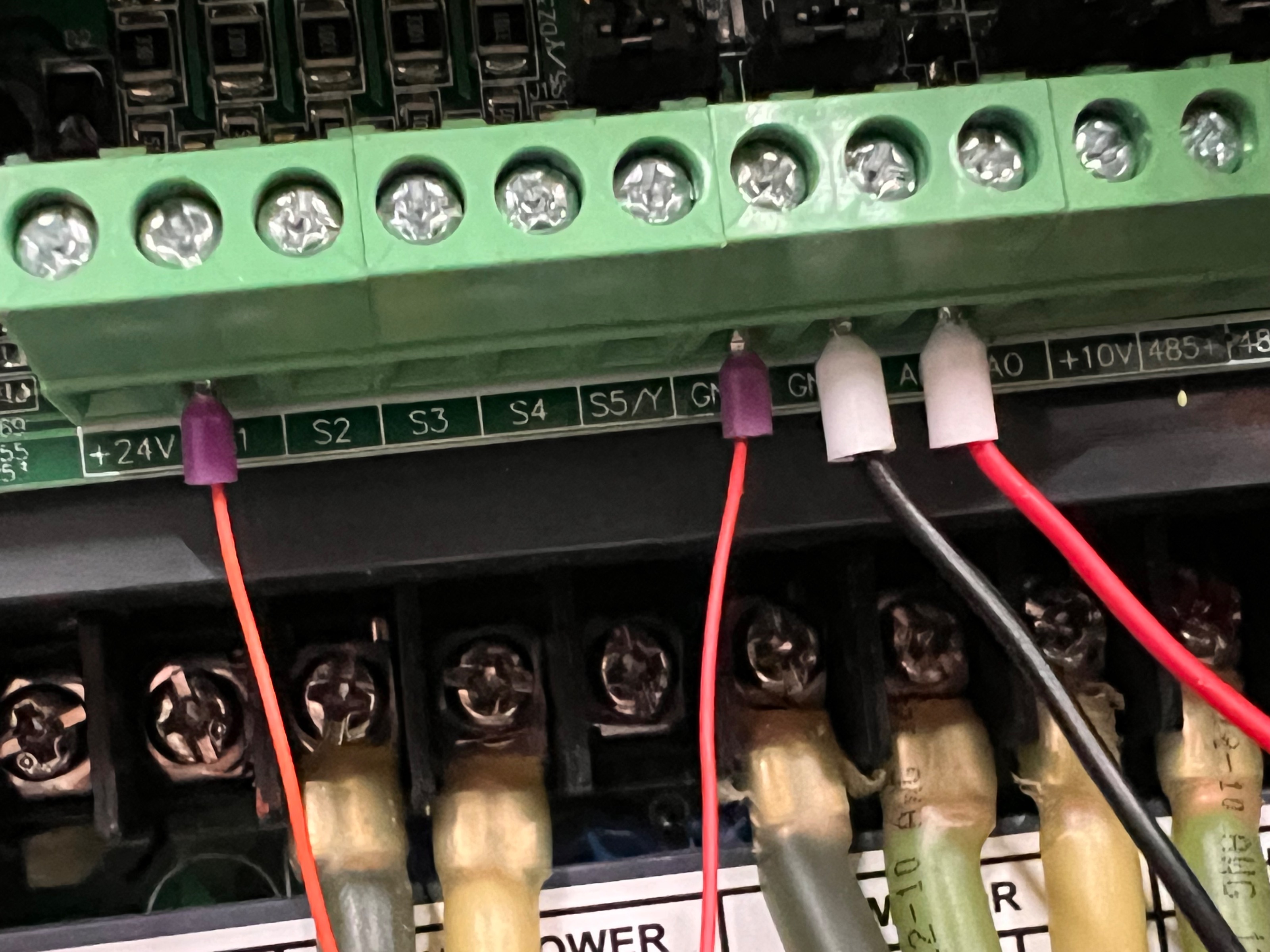

ok so heres a pic of the conns. i have verified everything all the way up to them is working. spindle start is on ssr.03, and all the wiring from the mesa to the vfd is tested. as best as i can tell P00.01 should switch between the keypad and remote switching. i can change the frequency from linuxcnc but thats about all.

the manual is here: www.huanyangvfd.com/wp-content/uploads/2.../FC01-Series-VFD.pdf

the manual is here: www.huanyangvfd.com/wp-content/uploads/2.../FC01-Series-VFD.pdf

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21205

- Thank you received: 7242

21 May 2025 15:23 #328863

by tommylight

Replied by tommylight on topic MesaCT problems with 7i96 pwm spindle

Manual, this section:

P05 group Input terminals

P05 group Input terminals

The following user(s) said Thank You: oddwick

Please Log in or Create an account to join the conversation.

- oddwick

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 19

22 May 2025 12:27 #328909

by oddwick

Replied by oddwick on topic MesaCT problems with 7i96 pwm spindle

thanks tom, i tried some changes in this section and those didnt work, but later on last evening i finally got it working, but i dont remember exactly which ones i changed. when i get back to the shop later today, i will log all the keys i modified and put a list together for anyone with this model of vfd. also, there was some keys where i could adjust the scale of the pwm so at the anything under 5v gives me 12k rpm and i get 400mhz at 9.45v

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- oddwick

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 19

29 May 2025 16:18 #329376

by oddwick

Replied by oddwick on topic MesaCT problems with 7i96 pwm spindle

So it was a busy week, but here is the list of keys that I modified to get the spindle running. Some of the values are specific to the spindle itself. My spindle is 2.2kw air cooled, so my max rpm is 24000 and the minimum rpm is 12000. also my pwm range is from about 5v to around 9.6, so i adjusted the values is the 5 section to make my max voltage equal 24000 rpm. the values in the parenthesis are the values that i used, but will vary depending on your spindle

P00.01 - 1

P00.03 - [MAX OUTPUT FREQUENCY] (400)

P00.04 - [MAX RUNNING FREQUENCY] (400)

P00.05 - [MIN RUNNING FREQUENCY] (200)

P00.06 - 2 [ANALOG INPUT 2]

P00.07 - 1

P00.10 - 60

P00.11 - 6 (seconds to accelerate)

P00.12 - 6 (seconds to decelerate)

P00.14 - 4.0 (2.2 KW)

P02.01 - [MOTOR RATED POWER] (2.2)

P02.02 - [MOTOR FREQUENCY] (400)

P02.03 - [MAX RPM] (24000)

P02.04 - [MOTOR VOLTAGE] (220)

P03.05 - [MOTOR RATED AMPS] (6)

with this section, anything under 5v will also give me 50% power, so the spindle can never run less than 12k rpm. just to be on the safe side, i also set the AI2 settings to the same values (37-40)

P05.32 - 5.00

P05.33 - 50.00

P05.34 - 9.6

P05.35 - 100.0

P05.37 - 5.00

P05.38 - 50.00

P05.39 - 9.6

P05.40 - 100.0

This allows me to use the stop key to override the spindle in case of emergency

P07.04 - 3

P00.01 - 1

P00.03 - [MAX OUTPUT FREQUENCY] (400)

P00.04 - [MAX RUNNING FREQUENCY] (400)

P00.05 - [MIN RUNNING FREQUENCY] (200)

P00.06 - 2 [ANALOG INPUT 2]

P00.07 - 1

P00.10 - 60

P00.11 - 6 (seconds to accelerate)

P00.12 - 6 (seconds to decelerate)

P00.14 - 4.0 (2.2 KW)

P02.01 - [MOTOR RATED POWER] (2.2)

P02.02 - [MOTOR FREQUENCY] (400)

P02.03 - [MAX RPM] (24000)

P02.04 - [MOTOR VOLTAGE] (220)

P03.05 - [MOTOR RATED AMPS] (6)

with this section, anything under 5v will also give me 50% power, so the spindle can never run less than 12k rpm. just to be on the safe side, i also set the AI2 settings to the same values (37-40)

P05.32 - 5.00

P05.33 - 50.00

P05.34 - 9.6

P05.35 - 100.0

P05.37 - 5.00

P05.38 - 50.00

P05.39 - 9.6

P05.40 - 100.0

This allows me to use the stop key to override the spindle in case of emergency

P07.04 - 3

Please Log in or Create an account to join the conversation.

Time to create page: 0.096 seconds