Tool Change, Probe relationships and the Z

- Gaunt1969

- Offline

- Senior Member

-

Less

More

- Posts: 45

- Thank you received: 8

02 Nov 2019 18:25 #149433

by Gaunt1969

Tool Change, Probe relationships and the Z was created by Gaunt1969

OK just when i start to think i remotely have a grasp i find i don have a clue.

First let me give the setup.

My Z axis has 8.75 inches of travel I have the top as home 0.0. all the way to the bottom is -8.75 from all i have read this is the preferred way things should be set up or am I wrong?

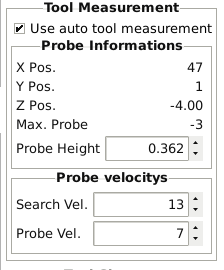

my Tool measurements in Gmoccapy look like this

The way I am understanding this is as follows. ZPos is the level at where Gmoccapy rapids down too, and then starts "Search Vel" in my case at -4. inches from the top of my Zaxis and continues to look for a Probe for the next -3.0 inches to a max depth of -7.00. if a probe is not encountered it will error.

This my be where I am getting confused on some of the relationships with how things are getting handled.

"A couple of questions"

(1) So i should be able to set Max Probe to number that as long as when it's combined value with ZPos does not exceed my maximum travel of -8.75 inches? Say for instance ZPos is -5 and Max probe is -3. it should start Search Vel at a positon of Z -5.0 and probe down for a maximum Z position of Z -8 and as long as it encounters the probe there should be no problem with that?

(2) Does probe height factor into to this portion of the calculations and if so in what way?

(3) I think what I ever it is i am not understanding correctly is causing my issue below.

What my system is currently doing is after i set my X and Y offset and the Blockheight i load my program and hit start. XYZ all to go tool change location, it ask for the tool, i hit ok it rapids down and touches off twice like it is supposed to and Z moves up then Back down and crashes the tool thru my probe and takes off toward the work piece.

I added gcode to change.ngc befor the end of the Sub routine to tell it to return Z to the top and then go to the XY G54 offset. it does this now without crashing and starts the program but it still starts workiing at well below the Block Height

First let me give the setup.

My Z axis has 8.75 inches of travel I have the top as home 0.0. all the way to the bottom is -8.75 from all i have read this is the preferred way things should be set up or am I wrong?

my Tool measurements in Gmoccapy look like this

The way I am understanding this is as follows. ZPos is the level at where Gmoccapy rapids down too, and then starts "Search Vel" in my case at -4. inches from the top of my Zaxis and continues to look for a Probe for the next -3.0 inches to a max depth of -7.00. if a probe is not encountered it will error.

This my be where I am getting confused on some of the relationships with how things are getting handled.

"A couple of questions"

(1) So i should be able to set Max Probe to number that as long as when it's combined value with ZPos does not exceed my maximum travel of -8.75 inches? Say for instance ZPos is -5 and Max probe is -3. it should start Search Vel at a positon of Z -5.0 and probe down for a maximum Z position of Z -8 and as long as it encounters the probe there should be no problem with that?

(2) Does probe height factor into to this portion of the calculations and if so in what way?

(3) I think what I ever it is i am not understanding correctly is causing my issue below.

What my system is currently doing is after i set my X and Y offset and the Blockheight i load my program and hit start. XYZ all to go tool change location, it ask for the tool, i hit ok it rapids down and touches off twice like it is supposed to and Z moves up then Back down and crashes the tool thru my probe and takes off toward the work piece.

I added gcode to change.ngc befor the end of the Sub routine to tell it to return Z to the top and then go to the XY G54 offset. it does this now without crashing and starts the program but it still starts workiing at well below the Block Height

Attachments:

The following user(s) said Thank You: ikkuh

Please Log in or Create an account to join the conversation.

- Gaunt1969

- Offline

- Senior Member

-

Less

More

- Posts: 45

- Thank you received: 8

02 Nov 2019 23:02 - 02 Nov 2019 23:25 #149453

by Gaunt1969

Replied by Gaunt1969 on topic Tool Change, Probe relationships and the Z

On observation it looks like while things are working in the change.ngc things are going well but watching the display when it completes and exits the subroutine the offsets shift. the work piece and plane move approximately the amount that it is off. it maybe clearing the change to the tool offset.

Apparently this is my exact problem with the crashing after looking thru the code my post processor is is inserting a G49 into the mix. this undid everything happening in the auto tool change.

All in all i am lucky AIRGAS was not open today because after the last week and half with this thing i would have replaced the OX and ACL tanks sitting in the corner and would be selling scrap metal on Monday.

Apparently this is my exact problem with the crashing after looking thru the code my post processor is is inserting a G49 into the mix. this undid everything happening in the auto tool change.

All in all i am lucky AIRGAS was not open today because after the last week and half with this thing i would have replaced the OX and ACL tanks sitting in the corner and would be selling scrap metal on Monday.

Last edit: 02 Nov 2019 23:25 by Gaunt1969.

Please Log in or Create an account to join the conversation.

- newbynobi

-

- Offline

- Moderator

-

Less

More

- Posts: 1930

- Thank you received: 394

02 Nov 2019 23:09 #149455

by newbynobi

Replied by newbynobi on topic Tool Change, Probe relationships and the Z

Post you remap code and a sample program

There must be a problem on your code.

Norbert

There must be a problem on your code.

Norbert

The following user(s) said Thank You: Gaunt1969

Please Log in or Create an account to join the conversation.

- Gaunt1969

- Offline

- Senior Member

-

Less

More

- Posts: 45

- Thank you received: 8

02 Nov 2019 23:22 - 02 Nov 2019 23:26 #149457

by Gaunt1969

Replied by Gaunt1969 on topic Tool Change, Probe relationships and the Z

Norbert

There was a problem in my initial GCode my Post processor from my cad program had a G49 in the code, The remap and all seemed to work. As soon as it finished the subroutine for change.ngc It then jumped back into the GCode to run and it encountered the G49 this cleared everything done with the tool offsets placed there in change.ngc.

thanks Craig

There was a problem in my initial GCode my Post processor from my cad program had a G49 in the code, The remap and all seemed to work. As soon as it finished the subroutine for change.ngc It then jumped back into the GCode to run and it encountered the G49 this cleared everything done with the tool offsets placed there in change.ngc.

thanks Craig

Last edit: 02 Nov 2019 23:26 by Gaunt1969.

The following user(s) said Thank You: ikkuh, centreline

Please Log in or Create an account to join the conversation.

Moderators: newbynobi, HansU

Time to create page: 0.130 seconds