Gmoccapy no valid configuration found

- harindugamlath

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 18

27 Nov 2022 14:03 #257733

by harindugamlath

Gmoccapy no valid configuration found was created by harindugamlath

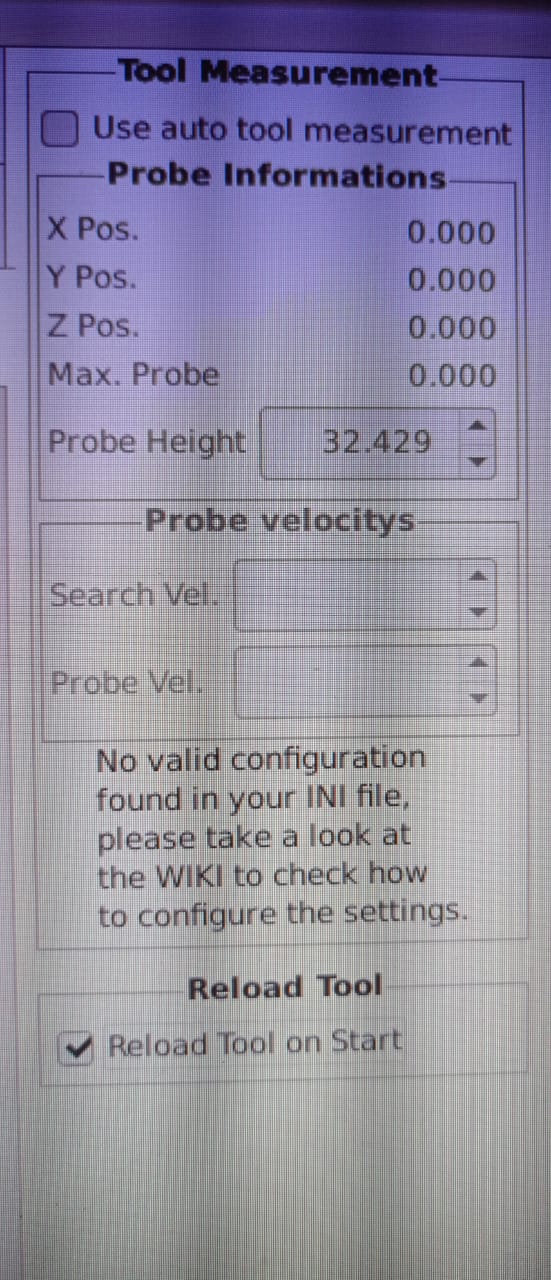

I'm getting this no valid configuration found when i try to use the auto tool measurement in gmoccapy.

Simulated versions run fine. But anything i create with the stepconf seems to miss something. I tried copying the postgui hal from gmoccapy sim to the directory and including everything from the sim ini to my ini file but can't seem to get this to work?

What am i missing here? What is a best path to create a proper gmoccapy configuration?

Any help is appreciated.

Simulated versions run fine. But anything i create with the stepconf seems to miss something. I tried copying the postgui hal from gmoccapy sim to the directory and including everything from the sim ini to my ini file but can't seem to get this to work?

What am i missing here? What is a best path to create a proper gmoccapy configuration?

Any help is appreciated.

Attachments:

Please Log in or Create an account to join the conversation.

- harindugamlath

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 18

27 Nov 2022 14:06 #257734

by harindugamlath

Replied by harindugamlath on topic Gmoccapy no valid configuration found

Here are my ini and hal files in case you need to see them

Attachments:

Please Log in or Create an account to join the conversation.

- harindugamlath

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 18

27 Nov 2022 17:27 - 27 Nov 2022 17:41 #257746

by harindugamlath

Replied by harindugamlath on topic Gmoccapy no valid configuration found

found it

Last edit: 27 Nov 2022 17:41 by harindugamlath.

Please Log in or Create an account to join the conversation.

- harindugamlath

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 18

27 Nov 2022 17:42 #257748

by harindugamlath

Replied by harindugamlath on topic Gmoccapy no valid configuration found

Ok. Got it to work. These are the steps if anyone finds themselves in a similar situation.

By this time I have created a working Gmoccapy config with stepconf (pnconf will have the same issue i guess)

1. Create a simulation config of Gmoccapy-tool_sensor from linuxcnc sims.

2. After the folders are created for the simulation config, Copy the folling to your machine config folder

By this time I have created a working Gmoccapy config with stepconf (pnconf will have the same issue i guess)

1. Create a simulation config of Gmoccapy-tool_sensor from linuxcnc sims.

2. After the folders are created for the simulation config, Copy the folling to your machine config folder

- macros folder

- python folder

- gmoccapy_tool_sensor.para

- tool_sensor.hal

3.Then copy these lines to your machine ini file from the Gmoccapy-tool_sensor ini file under the correct section. Ex- [DISPLAY]

[DISPLAY] PREFERENCE_FILE_PATH = gmoccapy_tool_sensor.para

[RS274NGC]

RS274NGC_STARTUP_CODE = G17 G21 G40 G43H0 G54 G64P0.005 G80 G90 G94 G97 M5 M9

PARAMETER_FILE = linuxcnc.var

SUBROUTINE_PATH = macros

# optional features - a bit mask to selectively turn on experimental/dubious features

# see

# RETAIN_G43 0x00000001

# OWORD_N_ARGS 0x00000002

# INI_VARS 0x00000004

# HAL_PIN_VARS 0x00000008

# NO_DOWNCASE_OWORD 0x00000010

# turn on all optional features

# turn on optional features in this case just INI reading

FEATURES=12

ON_ABORT_COMMAND=O <on_abort> call

# parameters exposed by change_prolog/evaluated by change_epilog:

# #<tool_in_spindle>

# #<selected_tool>

# #<current_pocket>

# #<selected_pocket>

REMAP=M6 modalgroup=6 prolog=change_prolog ngc=change epilog=change_epilog

# (this is probably already there) [HAL]

POSTGUI_HALFILE = custom_postgui.hal

**Under [EMCIO] if you have the following lines or similar please delete them.

TOOL_CHANGE_POSITION = 100 100 -10

TOOL_CHANGE_QUILL_UP = 1

(Documentation describes the variables used are called differently to avoid any unwanted interactions, but they seems to interfere.)

Finally at the end copy this to your ini. (change your locations accordingly)

# section for main IO controller parameters

[TOOLSENSOR]

X = 00

Y = 20

Z = 0

# abort change if no toolsensor contact after this probe distance

MAXPROBE = -20

# this is not named TOOL_CHANGE_POSITION on purpose - canon uses it and will

# interfere

[CHANGE_POSITION]

X = 50

Y = 0

Z = 0

# the Python plugins serves interpreter and task

[PYTHON]

PATH_PREPEND = python

TOPLEVEL = python/toplevel.py

LOG_LEVEL = 8

# Motion control section

4. Then in you hal file you will probably have something similar if you have a manual tool change selected.

loadusr -W hal_manualtoolchange

net tool-change iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-changed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

5. remove those lines from your hal file and add these to your custopm_postgui hal file.

loadusr -W hal_manualtoolchange

net tool-change iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-changed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

net tooloffset-z gmoccapy.tooloffset-z <= motion.tooloffset.z

6. After that hopefully Gmoccapy will happily to a auto touch off when you do a manual tool change.

This was the first time i came across such a thing and this was my solution to it. People who understand better will be able to do a better explanation. What I did was tried to figure out how the auto touch off worked and then pieced it together like a caveman.

In case if you need here are my hal and ini files.

Attachments:

The following user(s) said Thank You: andypugh, HansU

Please Log in or Create an account to join the conversation.

Moderators: newbynobi, HansU

Time to create page: 0.090 seconds