Spindle Encoder Mesa 7I76?

- Rhine_Labs

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 79

- Thank you received: 11

08 Aug 2016 07:18 - 08 Aug 2016 07:29 #78480

by Rhine_Labs

Spindle Encoder Mesa 7I76? was created by Rhine_Labs

I have a Encoder On the Lathe and getting my wiring plan done for the 7I76 will be using Path Pilot with a Hitachi WJ200 VFD.

My Encoder is Driven 1:1 to the Spindle.

Options For Wiring On The Encoder.

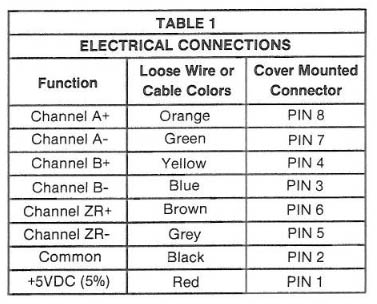

Whats the recommended wiring for a Quadrature Encoder on a Mesa 7I76 for Turning & Accurate Threading? Searching gives conflicting/confusing info but most say all ya need is A+, ZR+, Common, & +5V Some say B+ Also? Some say just A+, A- and Some sites say if reversing motor for left hand threading/tapping Connect All? Confusing! Figured idd post this for the experts here to weigh in for correct info.

Also From the Model & Data Sheet Below this encoder appears to be Sq/wave Single Ended so I am assuming I want to also set jumpers W4,5,&6 to the left in single ended mode so if this is the cases my answer is in the manual!

Encoder Spec's From Data Sheet .

Model M21AASoDB4D-2000

SO Servo Mount

D : Cover Connector

B : Supply Voltage +5VDC

4 : Zero Reference Full Cycle

D : Sq/wave Single Ended

2000 : Cycle Per Shaft Rev.

My Encoder is Driven 1:1 to the Spindle.

Options For Wiring On The Encoder.

Whats the recommended wiring for a Quadrature Encoder on a Mesa 7I76 for Turning & Accurate Threading? Searching gives conflicting/confusing info but most say all ya need is A+, ZR+, Common, & +5V Some say B+ Also? Some say just A+, A- and Some sites say if reversing motor for left hand threading/tapping Connect All? Confusing! Figured idd post this for the experts here to weigh in for correct info.

Also From the Model & Data Sheet Below this encoder appears to be Sq/wave Single Ended so I am assuming I want to also set jumpers W4,5,&6 to the left in single ended mode so if this is the cases my answer is in the manual!

When used with single ended encoders, the ENCA+, ENCB+ and IDX+ signals are wired to the encoder and the ENCA-,ENCB-,and IDX- terminal left unconnected.

Encoder Spec's From Data Sheet .

Model M21AASoDB4D-2000

SO Servo Mount

D : Cover Connector

B : Supply Voltage +5VDC

4 : Zero Reference Full Cycle

D : Sq/wave Single Ended

2000 : Cycle Per Shaft Rev.

Last edit: 08 Aug 2016 07:29 by Rhine_Labs.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17732

- Thank you received: 5187

08 Aug 2016 14:44 #78491

by PCW

Replied by PCW on topic Spindle Encoder Mesa 7I76?

For threading you can get by with A and index only but you will get 4 times the resolution by using A and B (and index)

For rigid tapping you need A and B and Index

So if your encoder has A and B and index, use them all

If your encoder is single ended (= TTL) jumper the 7I76 encoder input for single ended

(your chart shows differential signals = a pair of signals for A,B and index))

For rigid tapping you need A and B and Index

So if your encoder has A and B and index, use them all

If your encoder is single ended (= TTL) jumper the 7I76 encoder input for single ended

(your chart shows differential signals = a pair of signals for A,B and index))

Please Log in or Create an account to join the conversation.

Time to create page: 0.175 seconds