long part cutting problems

- paulsao

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 22

27 Feb 2022 02:11 - 27 Feb 2022 02:12 #235888

by paulsao

long part cutting problems was created by paulsao

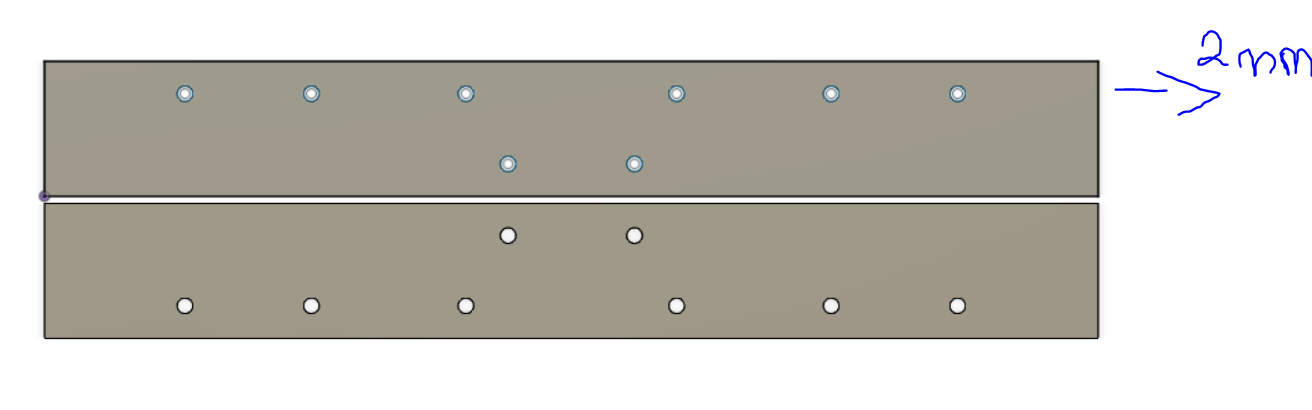

Someone who has experience in plasma cutting who can help me solve this problem. I cut the following pieces that can be seen in the image, the metal sheet has a thickness of 4mm, and the pieces to be cut have an approximate length of 1 meter, first I make the holes and then the outer part, when I finish the cut I saw that the first piece measures approximately 2 mm more, I suppose that it must be due to thermal deformation since I do not have a water table to cool, but I also began to think that the table is out of square. Could someone explain to me what is happening?

Attachments:

Last edit: 27 Feb 2022 02:12 by paulsao.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

27 Feb 2022 03:29 #235890

by thefabricator03

Replied by thefabricator03 on topic long part cutting problems

Do you have a way of checking if your gantry is square? Do you home the gantry against homing switches that square up your gantry?

I would say the problem would be thermal expansion, If I was to cut those long cuts, I would allow at least 25mm of plate on the outside of the part to hold the plate straight as it cuts. I have learnt the hard way that long cuts distort the material around it, so it needs to be held by more material.

I would say the problem would be thermal expansion, If I was to cut those long cuts, I would allow at least 25mm of plate on the outside of the part to hold the plate straight as it cuts. I have learnt the hard way that long cuts distort the material around it, so it needs to be held by more material.

Please Log in or Create an account to join the conversation.

- Clive S

- Away

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

27 Feb 2022 08:19 #235896

by Clive S

Replied by Clive S on topic long part cutting problems

First I would check that if you commanded 1000mm without cutting does the torch move exactly 1000mm or 1002mm .

The following user(s) said Thank You: paulsao

Please Log in or Create an account to join the conversation.

- daiman444

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 8

12 Apr 2022 17:38 #240062

by daiman444

Replied by daiman444 on topic long part cutting problems

Greetings. It seems to me that you are right that the problem lies in the thermal deformations of the metal during cutting. this problem is most noticeable when cutting long parts. to solve this problem, I use jumpers and this solves the problem 99%. jumpers can be made in gcode or conventional metal welding with tacks no more than 1-2 cm in increments that will divide the length of your part into at least 3 parts, but not more than 500mm. for me, such techniques are equally relevant both for a thickness of 1-3 mm and for a thickness of 40-50mm

The following user(s) said Thank You: paulsao

Please Log in or Create an account to join the conversation.

- paulsao

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 22

12 Apr 2022 18:14 #240066

by paulsao

Replied by paulsao on topic long part cutting problems

Thanks for your suggestions, apply this technique in the next cuts, my main problem was that the table was very out of square from 2 to 4 mm, but it is already solved.

The following user(s) said Thank You: snowgoer540

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

12 Apr 2022 22:01 #240087

by thefabricator03

Replied by thefabricator03 on topic long part cutting problems

In the future, when you have solved your issue, could you post what you did to solve it. These post come up when new people search for them so having a solved solution can help many people.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.095 seconds