THCAD selection including ohmic sensing

- calvin.d

- Offline

- Premium Member

-

Less

More

- Posts: 80

- Thank you received: 1

16 Mar 2020 03:09 #160385

by calvin.d

Replied by calvin.d on topic THCAD selection including ohmic sensing

well, I ordered a 300 and a 10

should I try to get a hold of mesa and have them just switch to 2 10's ?

I am going to end up making a few machines with the controller combo I am working out so I would rather take the time and do this first one right

Thank You

C

should I try to get a hold of mesa and have them just switch to 2 10's ?

I am going to end up making a few machines with the controller combo I am working out so I would rather take the time and do this first one right

Thank You

C

Please Log in or Create an account to join the conversation.

- jay1st

-

- Offline

- Premium Member

-

Less

More

- Posts: 127

- Thank you received: 17

16 Mar 2020 08:57 #160393

by jay1st

Replied by jay1st on topic THCAD selection including ohmic sensing

I'm jumping on this thread as i'm wondering if i add a Ohmic sensing or nat.

I have the THCAD-10 for the height control, and i'm thinking of using it for the Ohmic sensing as well.

I got the idea of using a relay connected to the same output as the torch on/off that will switch between a voltage supply and the torch on the THCAD-10 arc voltage input, but behind the voltage divider to get a highe r sensitivity

I have the THCAD-10 for the height control, and i'm thinking of using it for the Ohmic sensing as well.

I got the idea of using a relay connected to the same output as the torch on/off that will switch between a voltage supply and the torch on the THCAD-10 arc voltage input, but behind the voltage divider to get a highe r sensitivity

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11523

- Thank you received: 3859

16 Mar 2020 09:42 - 16 Mar 2020 09:43 #160401

by rodw

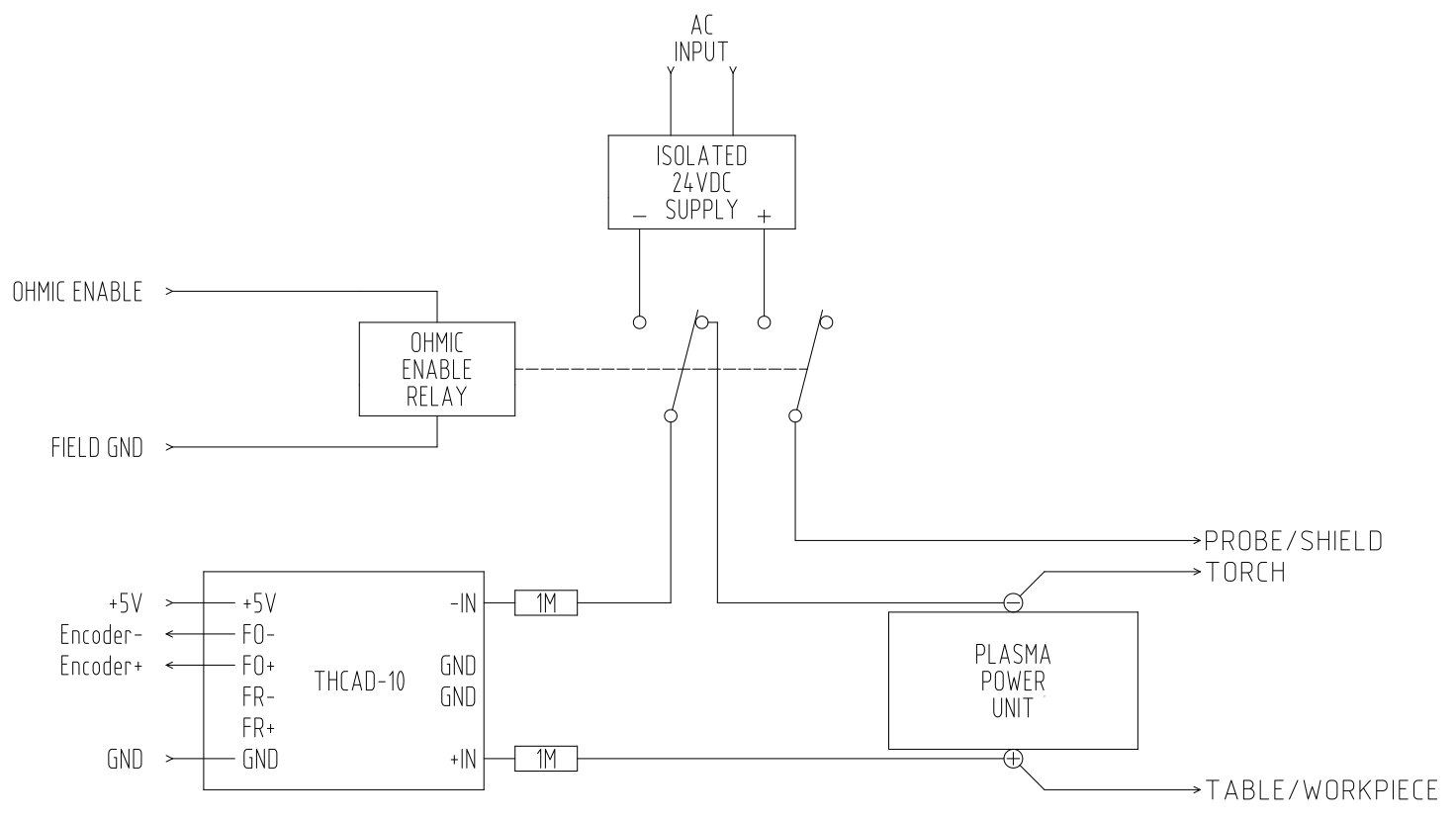

You might be able to do this without too much drama, With the hypersensing circuit, there is absolutely no need to keep the ohmic sensing circuit isolated from the arc voltage because the THCAD in conjunction with the Isolated power supply is impervious to the torch voltage. (both can handle over voltage of 500 volts)

Therefore, there is no reason to use a relay at all.

Because of this, there is no need to use Plasmac's Ohmic enable signal to switch the ohmic sensing circuit off. But in this scenario, it would be useful to know when its probing and when its not because if the probe was disabled we would know any voltage its seeing is the arc voltage.

I would have to think through this a bit and it might need a few mods to the component but it there was an out pin for voltage, it could be introduced to plasmac with scaling of 1.0. (Which is what I do now anyway from another component I had in place when I adopted plasmac which had a bug at the time).

But just say you calibrated a THCAD-10 to see 200 volts as full scale, 24 volts would be be at 1.2 volts on the 10 volt scale and that is probably enough to do the ohmic sensing. In fact, a lot of you you could probably calibrate the THCAD for somewhere around 150 volts depending on your plasma cutter. (my 120 amp machine has a maximum cutting voltage off 165 volts in the book speeds)

Its just that I never thought through this becasue I already had torch voltage sorted with a THCAD-10 when PCW donated a THCAD-5 to the cause so we could work this all out.

Replied by rodw on topic THCAD selection including ohmic sensing

I'm jumping on this thread as i'm wondering if i add a Ohmic sensing or nat.

I have the THCAD-10 for the height control, and i'm thinking of using it for the Ohmic sensing as well.

I got the idea of using a relay connected to the same output as the torch on/off that will switch between a voltage supply and the torch on the THCAD-10 arc voltage input, but behind the voltage divider to get a highe r sensitivity

You might be able to do this without too much drama, With the hypersensing circuit, there is absolutely no need to keep the ohmic sensing circuit isolated from the arc voltage because the THCAD in conjunction with the Isolated power supply is impervious to the torch voltage. (both can handle over voltage of 500 volts)

Therefore, there is no reason to use a relay at all.

Because of this, there is no need to use Plasmac's Ohmic enable signal to switch the ohmic sensing circuit off. But in this scenario, it would be useful to know when its probing and when its not because if the probe was disabled we would know any voltage its seeing is the arc voltage.

I would have to think through this a bit and it might need a few mods to the component but it there was an out pin for voltage, it could be introduced to plasmac with scaling of 1.0. (Which is what I do now anyway from another component I had in place when I adopted plasmac which had a bug at the time).

But just say you calibrated a THCAD-10 to see 200 volts as full scale, 24 volts would be be at 1.2 volts on the 10 volt scale and that is probably enough to do the ohmic sensing. In fact, a lot of you you could probably calibrate the THCAD for somewhere around 150 volts depending on your plasma cutter. (my 120 amp machine has a maximum cutting voltage off 165 volts in the book speeds)

Its just that I never thought through this becasue I already had torch voltage sorted with a THCAD-10 when PCW donated a THCAD-5 to the cause so we could work this all out.

Last edit: 16 Mar 2020 09:43 by rodw.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

16 Mar 2020 17:35 #160453

by islander261

Replied by islander261 on topic THCAD selection including ohmic sensing

Well it may not be quite that simple depending on ones actual hardware. In most case the arc voltage sensing (THC) is sensed between the torch electrode and the work piece. For ohmic sensing usually you want to measure the potential between the torch shield and the work piece.

John

John

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11523

- Thank you received: 3859

16 Mar 2020 20:29 - 16 Mar 2020 20:34 #160469

by rodw

That makes sense. But it may be worth testing. I know on my machine the hypersensing circuit sees the Arc Voltage while cutting as a full scale reading on the THCAD but that is only 24.5 volts. Maybe there is some leakage. The component I created does have an output for the voltage output so it would be easy to see in halshow or halscope while cutting if the THCAD was scaled for the arc voltage.

In any case, there would be no need to switch circuits. Just connect both the shield and the arc voltage to the same THCAD terminal as we can depend on the isolation to keep things safe. We will know from the is probing signal what is happening (cutting or probing)

EDIT: And when cutting, an AC relay on the is probing pin can turn off the mains power to the isolated ohmic power supply so there is no voltage applied to the shield while cutting.

Replied by rodw on topic THCAD selection including ohmic sensing

Well it may not be quite that simple depending on ones actual hardware. In most case the arc voltage sensing (THC) is sensed between the torch electrode and the work piece. For ohmic sensing usually you want to measure the potential between the torch shield and the work piece.

John

That makes sense. But it may be worth testing. I know on my machine the hypersensing circuit sees the Arc Voltage while cutting as a full scale reading on the THCAD but that is only 24.5 volts. Maybe there is some leakage. The component I created does have an output for the voltage output so it would be easy to see in halshow or halscope while cutting if the THCAD was scaled for the arc voltage.

In any case, there would be no need to switch circuits. Just connect both the shield and the arc voltage to the same THCAD terminal as we can depend on the isolation to keep things safe. We will know from the is probing signal what is happening (cutting or probing)

EDIT: And when cutting, an AC relay on the is probing pin can turn off the mains power to the isolated ohmic power supply so there is no voltage applied to the shield while cutting.

Last edit: 16 Mar 2020 20:34 by rodw.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

16 Mar 2020 20:51 #160472

by islander261

Replied by islander261 on topic THCAD selection including ohmic sensing

Rod

I think you will find that your power supply will see an error condition with the shield connected to the electrode while cutting. Also I think the plasma arc will wander to the shield instead of the electrode while cutting. One of the firmware features on our vintage TD power supplies while using the automation torch is to check for the shield to contact the work piece and throw an error (#85). I defeated this feature on my machine by adding extra circuitry to control the solenoid in the torch.

John

I think you will find that your power supply will see an error condition with the shield connected to the electrode while cutting. Also I think the plasma arc will wander to the shield instead of the electrode while cutting. One of the firmware features on our vintage TD power supplies while using the automation torch is to check for the shield to contact the work piece and throw an error (#85). I defeated this feature on my machine by adding extra circuitry to control the solenoid in the torch.

John

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11523

- Thank you received: 3859

16 Mar 2020 21:17 #160475

by rodw

Replied by rodw on topic THCAD selection including ohmic sensing

Maybe. But we are not talking about connections at the plasma cutter, we are talking about making connections to the divided arc signal from the Plasma machine's voltage divider. Some of the better quality machines (eg. HT and TD) may have some isolation there.

Placing a relay on the wire between the THCAD and the shield may be required but that then defeats the whole simple design principle of the Hypersensing circuit which was to have no additional components in the sensing circuit.

Placing a relay on the wire between the THCAD and the shield may be required but that then defeats the whole simple design principle of the Hypersensing circuit which was to have no additional components in the sensing circuit.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17437

- Thank you received: 5085

16 Mar 2020 22:06 #160478

by PCW

Replied by PCW on topic THCAD selection including ohmic sensing

If you use a THCAD and an isolated power supply for Ohmic sensing, there _is_ no connection between the shield sense and the plasma voltage except the common work sense point. Adding a relay makes no sense

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2499

- Thank you received: 835

16 Mar 2020 23:29 #160484

by snowgoer540

Peter, I am looking to do this hypersensing on my table. I have been holding off on ordering a second THCAD, as I am unsure if firmware exists to do this with a 5i25 and a 7i76. Is that out there and I just missed it?

Thanks,

Greg

Replied by snowgoer540 on topic THCAD selection including ohmic sensing

If you use a THCAD and an isolated power supply for Ohmic sensing, there _is_ no connection between the shield sense and the plasma voltage except the common work sense point. Adding a relay makes no sense

Peter, I am looking to do this hypersensing on my table. I have been holding off on ordering a second THCAD, as I am unsure if firmware exists to do this with a 5i25 and a 7i76. Is that out there and I just missed it?

Thanks,

Greg

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

17 Mar 2020 00:21 #160492

by phillc54

Replied by phillc54 on topic THCAD selection including ohmic sensing

Attachments:

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.275 seconds