THCAD Configuration Problem

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21276

- Thank you received: 7265

01 Nov 2020 21:36 #188047

by tommylight

Replied by tommylight on topic THCAD Configuration Problem

Leave the PID settings at default, 10, 0, 0

do some short cuts with THC enabled and auto volts disabled :

if the torch starts to move upwards, lower the voltage in the run tab and try again

if the torch plunges into the material, raise the voltage in the run tab and try again

Change the cable going from THCAD to Mesa board, the signal (encoder) cable must be shielded and the shield connected to ground on the electronics side

change the THC delay to 0.1 or 0.2, leaving it at 1.5 is way to long for it to do nothing

do some short cuts with THC enabled and auto volts disabled :

if the torch starts to move upwards, lower the voltage in the run tab and try again

if the torch plunges into the material, raise the voltage in the run tab and try again

Change the cable going from THCAD to Mesa board, the signal (encoder) cable must be shielded and the shield connected to ground on the electronics side

change the THC delay to 0.1 or 0.2, leaving it at 1.5 is way to long for it to do nothing

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11706

- Thank you received: 3961

01 Nov 2020 21:43 #188050

by rodw

This is a function of the machine X/Y acceleration. Initially I found 1.5 was what was required but people like Tommy building rockets can do a lot less. Some halscope plots of voltage without THC will confirm.

Replied by rodw on topic THCAD Configuration Problem

change the THC delay to 0.1 or 0.2, leaving it at 1.5 is way to long for it to do nothing

This is a function of the machine X/Y acceleration. Initially I found 1.5 was what was required but people like Tommy building rockets can do a lot less. Some halscope plots of voltage without THC will confirm.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21276

- Thank you received: 7265

01 Nov 2020 23:08 #188064

by tommylight

Time to accelerate to cut speed = 0.0444 s

Distance to accelerate to cut speed = 1.4815 mm

1.5 second delay for THC = THC will start working exactly after passing 100mm of cut !

It was beyond my comprehension why then, it is still now, been using it for several years on several machines with no THC delay and it never fails.

I have it set at 0.1 so having the option to change that is really nice. It does work with 0 though.

Replied by tommylight on topic THCAD Configuration Problem

Cutting at 4000mm/m, acceleration set at 1500mm/s/s :

This is a function of the machine X/Y acceleration. Initially I found 1.5 was what was required but people like Tommy building rockets can do a lot less. Some halscope plots of voltage without THC will confirm.

Time to accelerate to cut speed = 0.0444 s

Distance to accelerate to cut speed = 1.4815 mm

1.5 second delay for THC = THC will start working exactly after passing 100mm of cut !

It was beyond my comprehension why then, it is still now, been using it for several years on several machines with no THC delay and it never fails.

I have it set at 0.1 so having the option to change that is really nice. It does work with 0 though.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11706

- Thank you received: 3961

01 Nov 2020 23:24 - 01 Nov 2020 23:32 #188067

by rodw

Replied by rodw on topic THCAD Configuration Problem

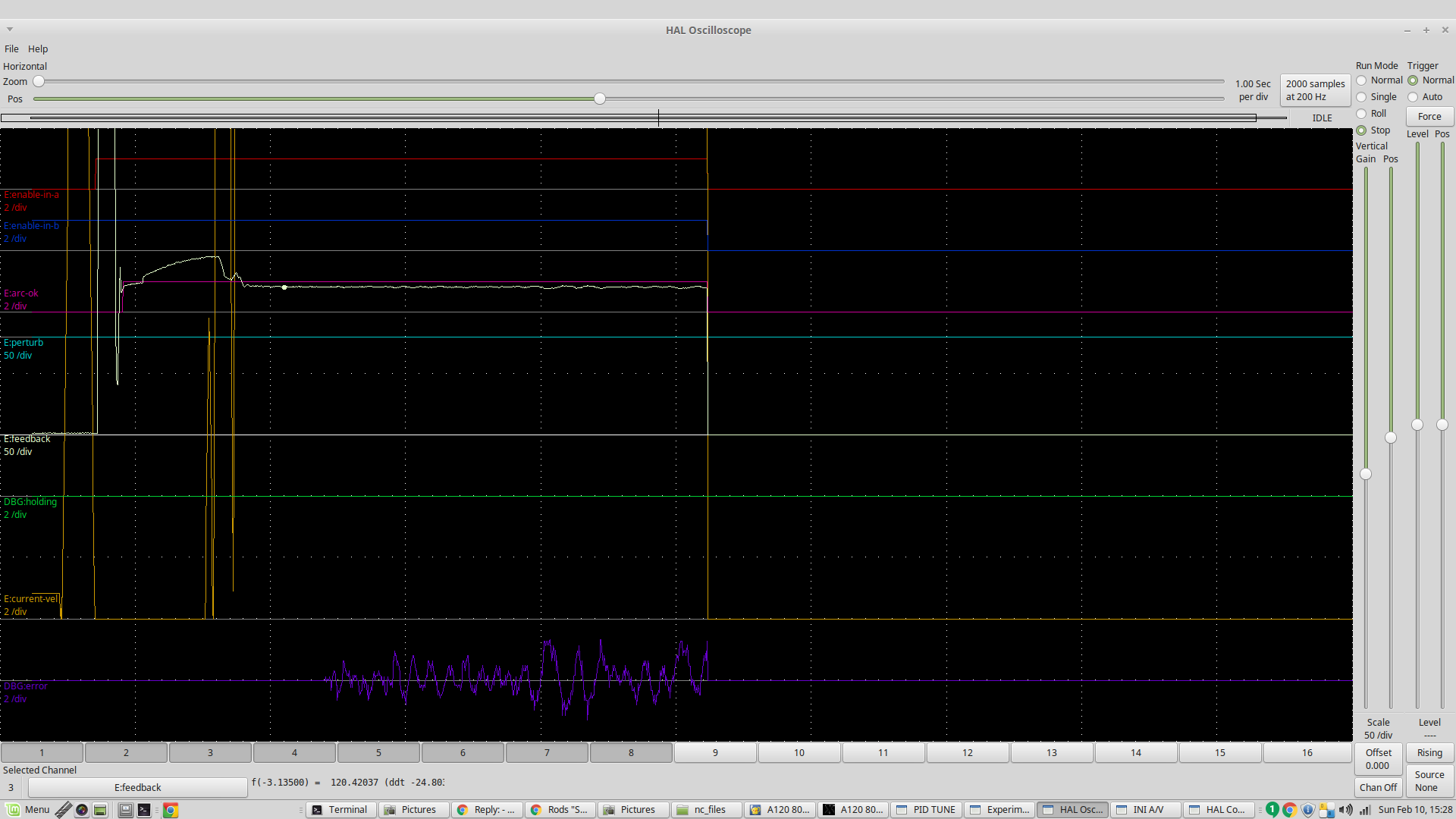

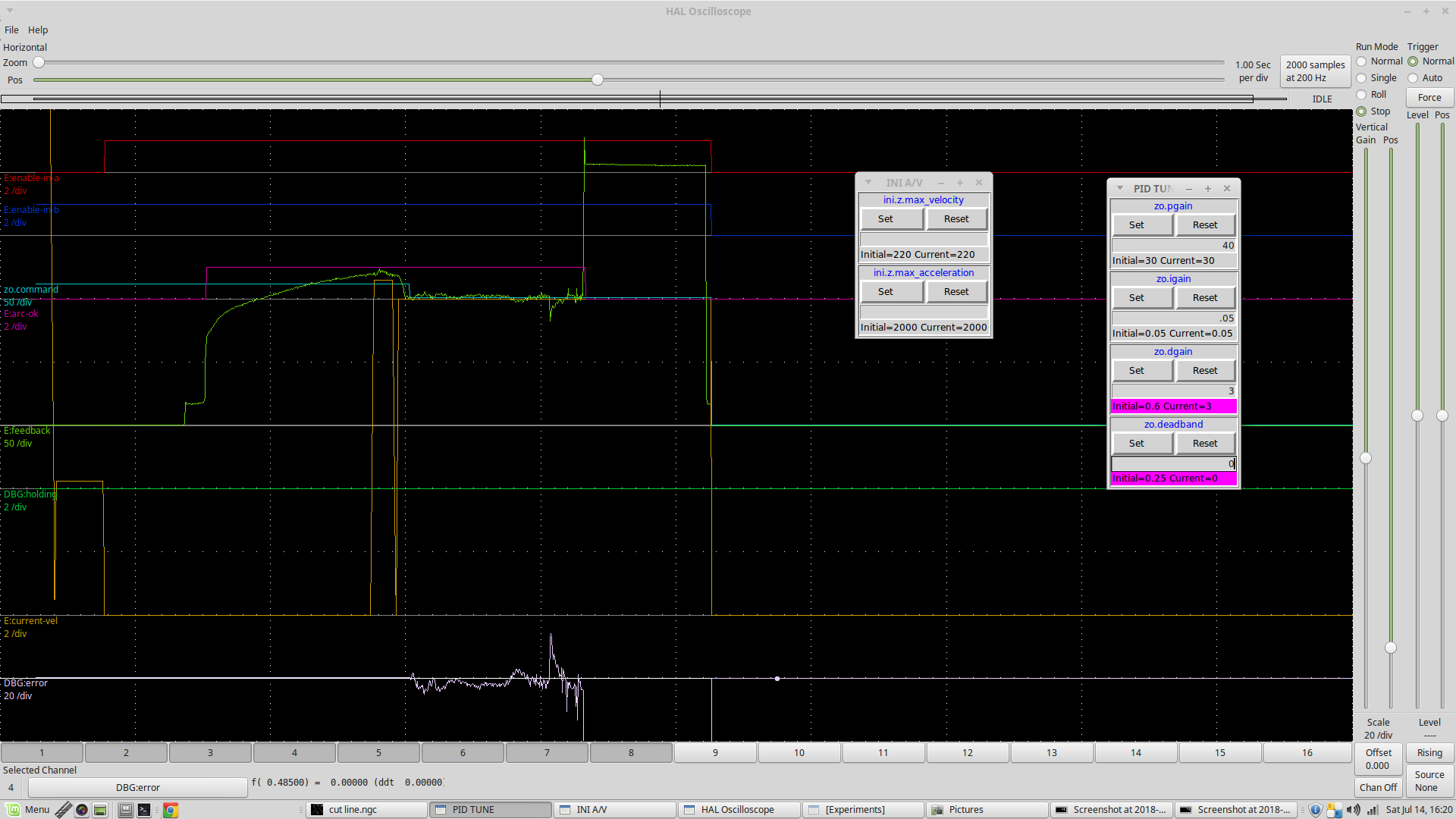

Tommy, I knew somebody would make me trawl through my plot collection! Look for ArcOK signals vs torch voltage. The voltage naturally peaks then falls back to cut volts without a THC.

Thermal Dynamics

About 1 second

Everlast

About 1.5 seconds

I wanted to experiment with waiting for constant velocity because I suspect that is a better indicator of when the arc should be stable than time.

Thermal Dynamics

About 1 second

Everlast

About 1.5 seconds

I wanted to experiment with waiting for constant velocity because I suspect that is a better indicator of when the arc should be stable than time.

Attachments:

Last edit: 01 Nov 2020 23:32 by rodw.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21276

- Thank you received: 7265

01 Nov 2020 23:42 #188071

by tommylight

Replied by tommylight on topic THCAD Configuration Problem

Yup i still remember those, but where are the new ones ?

Since you now own a very fast machine, you will have a new issue that will need all of these settings to be tuned to prevent the "pierce - not cut - cut" phenomena caused by the very fast move of the torch from stand still leaving a very small uncut part right after the pierce point. This is due to the small flex in the parts of the machine from the drive train to the torch tip.

Have fun, i know i did !

Since you now own a very fast machine, you will have a new issue that will need all of these settings to be tuned to prevent the "pierce - not cut - cut" phenomena caused by the very fast move of the torch from stand still leaving a very small uncut part right after the pierce point. This is due to the small flex in the parts of the machine from the drive train to the torch tip.

Have fun, i know i did !

The following user(s) said Thank You: snowgoer540

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11706

- Thank you received: 3961

01 Nov 2020 23:51 #188073

by rodw

Replied by rodw on topic THCAD Configuration Problem

I wish I had time to experiment but it will be a while.

Here is my thinking. Because I wrote a component that senses when each joint is at constant velocity for the Lam boost feature, I should be able to detect when we are at constant X & Y velocity but I need to give that some more thought.

So if that enabled an output pin that was used to enable or disable the THC, the arc volts should be at cut volts becasue the pierce is over and torch is up to velocity. Such a method might render obsolete the concept of a THC time delay except it might require a small delay past that point.

Here is my thinking. Because I wrote a component that senses when each joint is at constant velocity for the Lam boost feature, I should be able to detect when we are at constant X & Y velocity but I need to give that some more thought.

So if that enabled an output pin that was used to enable or disable the THC, the arc volts should be at cut volts becasue the pierce is over and torch is up to velocity. Such a method might render obsolete the concept of a THC time delay except it might require a small delay past that point.

Please Log in or Create an account to join the conversation.

- Riggorous

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 2

02 Nov 2020 02:40 #188085

by Riggorous

Replied by Riggorous on topic THCAD Configuration Problem

tommy and rod thank you both for the quick and thorough answers! It is late here currently but I will test what y'all recommended tomorrow. What you're saying definitely makes sense and hopefully tomorrow I can get a little more progress done. I will report back tomorrow afternoon with the results of my testing

also, to the both of you thank you very much for your thorough write ups in the past. I referenced a ton of your material and posts as I was building and sourcing this machine. Rod, your "spaceship" build was one of the build that encouraged me to build a second machine that used Mesa Hardware. So thank you both!

also, to the both of you thank you very much for your thorough write ups in the past. I referenced a ton of your material and posts as I was building and sourcing this machine. Rod, your "spaceship" build was one of the build that encouraged me to build a second machine that used Mesa Hardware. So thank you both!

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- Riggorous

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 2

03 Nov 2020 00:16 #188164

by Riggorous

Replied by Riggorous on topic THCAD Configuration Problem

For those following along. I got the THC working and the machine fully working.

Plasmac started with the PID settings at 50,0,0 respectively. Based on Tommy's input I adjust the P setting to 10,0,0 respectively. This made the THC start to behave somewhat predictably from their I was able to turn off auto volts and play with the voltage numbers until I was receiving THC as desired. I also adjusted the THC response time to 1.0 seconds which is slower than Tommy's but my machine does not move quite as fast so this is acceptable to me.

After doing some more test cuts and small circles and squares I got all of the settings dialed! Rod, I did also confirm the Everlast was set to 16:1 from factory, based on the "Port Erratta" post you linked I adjusted my settings to reflect 24:1 instead which seems to work. I am still receiving some erroneous voltage readings that I attribute to noise within the enclosure, I will install the filter when I receive it and do a better job of shielding all the THC wires while I am in there.

Thanks for all the help, now to just play with it some more to really make it efficient

Plasmac started with the PID settings at 50,0,0 respectively. Based on Tommy's input I adjust the P setting to 10,0,0 respectively. This made the THC start to behave somewhat predictably from their I was able to turn off auto volts and play with the voltage numbers until I was receiving THC as desired. I also adjusted the THC response time to 1.0 seconds which is slower than Tommy's but my machine does not move quite as fast so this is acceptable to me.

After doing some more test cuts and small circles and squares I got all of the settings dialed! Rod, I did also confirm the Everlast was set to 16:1 from factory, based on the "Port Erratta" post you linked I adjusted my settings to reflect 24:1 instead which seems to work. I am still receiving some erroneous voltage readings that I attribute to noise within the enclosure, I will install the filter when I receive it and do a better job of shielding all the THC wires while I am in there.

Thanks for all the help, now to just play with it some more to really make it efficient

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11706

- Thank you received: 3961

03 Nov 2020 00:30 #188166

by rodw

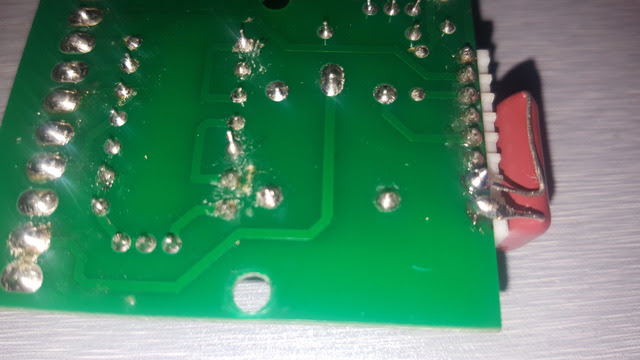

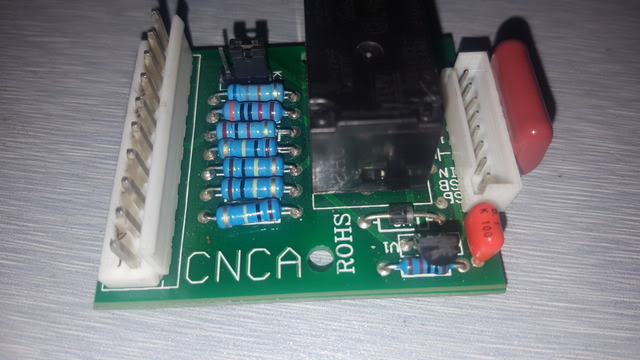

I ended up buying a cheap USB oscilloscope to investigate the noise issue and concluded that most of it was entering by the mains ground wire when the plasma was turned on. The filter made a huge difference and was a 10 minute job to fit.

The other thing you can do (as advised by Everlast) is add a capacitor to the divider board. Sorry but I don't have the capacitor spec anymore. But I don't think this will be necessary.

Replied by rodw on topic THCAD Configuration Problem

Rod, I did also confirm the Everlast was set to 16:1 from factory, based on the "Port Erratta" post you linked I adjusted my settings to reflect 24:1 instead which seems to work. I am still receiving some erroneous voltage readings that I attribute to noise within the enclosure, I will install the filter when I receive it and do a better job of shielding all the THC wires while I am in there.

I ended up buying a cheap USB oscilloscope to investigate the noise issue and concluded that most of it was entering by the mains ground wire when the plasma was turned on. The filter made a huge difference and was a 10 minute job to fit.

The other thing you can do (as advised by Everlast) is add a capacitor to the divider board. Sorry but I don't have the capacitor spec anymore. But I don't think this will be necessary.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.258 seconds