THC test mode to watch up and down movement

- Nick7251

- Offline

- Senior Member

-

Less

More

- Posts: 57

- Thank you received: 10

20 Jan 2021 20:44 #196019

by Nick7251

THC test mode to watch up and down movement was created by Nick7251

This is mainly an enhancement idea to the PlasmaC software as I did some searching and didn't find a way to do this. It would be nice to implement a test THC button that simulates voltages going above and below the set point that then in turn physically moves the torch up and down. My old Proma THC had a test mode that would do what I am thinking of. It was nice to ensure that voltage changes would indeed command the z axis without actually needing to burn metal.

I will ask at the same time as writing this software enhancement, is there already a way to do this?

Thanks,

Nick

I will ask at the same time as writing this software enhancement, is there already a way to do this?

Thanks,

Nick

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11566

- Thank you received: 3884

21 Jan 2021 09:40 #196071

by rodw

Replied by rodw on topic THC test mode to watch up and down movement

Pre-Plasmac, there was a pretty amazing SIM written by Dewey Garrett that did exactly that. He wrote it as part of the external offsets that Plasmac uses extensively. It included a simulated torch and the ability to change the voltage to follow a sine wave or square wave. The intent was to provide a SIM to allow you to tune a PID loop without wasting material as this is very common in industrial process control. eg tune the PID loop against a simulated environment. we could change all sorts of parameters on the fly and these features could be carried forward onto a real plasma table.

But the problem for Dewey is that the paradigm he devised for THC by External offsets did not work in the real world. I spent hundreds of hours trying to get it to work and providing Dewey feedback. Others got good results using external offsets in a different way that worked. Then along came Plasmac which I adopted very early in the piece before it even had a name!

It just worked out of the box and to this day, I have never needed to alter the Plasmac defaults. It just works! If you are not using a THCAD and a Mesa card, and are still using a Proma or similar THC (that Plasmac supports), I can't give any advice as I've never used anything like it. Except to say if you feel you need the feature you have prooposed, its time to upgrade to Mesa hardware.

But the problem for Dewey is that the paradigm he devised for THC by External offsets did not work in the real world. I spent hundreds of hours trying to get it to work and providing Dewey feedback. Others got good results using external offsets in a different way that worked. Then along came Plasmac which I adopted very early in the piece before it even had a name!

It just worked out of the box and to this day, I have never needed to alter the Plasmac defaults. It just works! If you are not using a THCAD and a Mesa card, and are still using a Proma or similar THC (that Plasmac supports), I can't give any advice as I've never used anything like it. Except to say if you feel you need the feature you have prooposed, its time to upgrade to Mesa hardware.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21079

- Thank you received: 7195

21 Jan 2021 13:03 #196083

by tommylight

Replied by tommylight on topic THC test mode to watch up and down movement

This is the third time i am reading this and still can not find any use for it.

Press pgdown - torch must go down, press pgup - torch must go up.

Set Proma THC to test mode, check the LED's on the Proma AND the on screen GUI, they should match.

End of setting.

There is no way of adjusting the THC without actually cutting.

Press pgdown - torch must go down, press pgup - torch must go up.

Set Proma THC to test mode, check the LED's on the Proma AND the on screen GUI, they should match.

End of setting.

There is no way of adjusting the THC without actually cutting.

Please Log in or Create an account to join the conversation.

- Nick7251

- Offline

- Senior Member

-

Less

More

- Posts: 57

- Thank you received: 10

21 Jan 2021 14:20 - 21 Jan 2021 14:37 #196091

by Nick7251

Replied by Nick7251 on topic THC test mode to watch up and down movement

I have since abandoned Proma. I now have Mesa 7i96 and THCAD-10. The reason for the request is that I tried to put a warped piece of metal on the table to see if the torch would indeed move up and down. It didn't seem to. So I thought this would serve as an idiot check.

I do think that in my experiment I was probably moving up a hill before the THC could establish a stable voltage. So I tweaked some parameters without any luck to get it to read and respond faster. So then I wondered if the controller was actually moving the torch as it received voltage changes.

As you say Tommy, it probably isn't needed if page up and page down keys work, which they do. Just a paradigm shift in thinking for me on the way I was used to things working when I was using Proma.

I do think that in my experiment I was probably moving up a hill before the THC could establish a stable voltage. So I tweaked some parameters without any luck to get it to read and respond faster. So then I wondered if the controller was actually moving the torch as it received voltage changes.

As you say Tommy, it probably isn't needed if page up and page down keys work, which they do. Just a paradigm shift in thinking for me on the way I was used to things working when I was using Proma.

Last edit: 21 Jan 2021 14:37 by Nick7251.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21079

- Thank you received: 7195

21 Jan 2021 17:00 #196104

by tommylight

Replied by tommylight on topic THC test mode to watch up and down movement

Not sure what version of PlasmaC you are using but some older versions had the THC delay set to 1.5 seconds and that is to much for anything useful as on fast machines they can travel several CM during that time without adjustments.

To adjust the THC:

-a piece of scrap 5 or 6mm thick

-set the jog rate to 500mm/m

-fire the torch with F9

-look at the GUI for the ARCOK and Up/Down LED's

-after the pierce the torch will start to move down towards the material

-jog X or Y axis by small amounts and look at the torch, it should go higher while moving and go lower when not moving.

How is the Z axis moved ?

To adjust the THC:

-a piece of scrap 5 or 6mm thick

-set the jog rate to 500mm/m

-fire the torch with F9

-look at the GUI for the ARCOK and Up/Down LED's

-after the pierce the torch will start to move down towards the material

-jog X or Y axis by small amounts and look at the torch, it should go higher while moving and go lower when not moving.

How is the Z axis moved ?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11566

- Thank you received: 3884

21 Jan 2021 19:27 #196131

by rodw

Replied by rodw on topic THC test mode to watch up and down movement

The THC needs to be enabled in the GUI. Too often I find mine is not. I watch the Z axis ball screw nut to see if it moves to confirm operation.

Try the GUI settings for enabled and auto. I always had to select enabled once but yesterday on a more recent version auto worked too

The GUI has LEDS the show if the THC is enabled and when it moves up or down.

It certainly works as shown in this early video

I'll let you in on a secret though. I started cutting on the high side so that the material sloped downwards away from the torch on the start of cut to lessen the chance of a collision. That was deliberate!

Try the GUI settings for enabled and auto. I always had to select enabled once but yesterday on a more recent version auto worked too

The GUI has LEDS the show if the THC is enabled and when it moves up or down.

It certainly works as shown in this early video

I'll let you in on a secret though. I started cutting on the high side so that the material sloped downwards away from the torch on the start of cut to lessen the chance of a collision. That was deliberate!

Please Log in or Create an account to join the conversation.

- Nick7251

- Offline

- Senior Member

-

Less

More

- Posts: 57

- Thank you received: 10

24 Jan 2021 18:28 #196443

by Nick7251

Replied by Nick7251 on topic THC test mode to watch up and down movement

Sorry I haven't responded. My Linux OS decided to lock me out. It was a stuck process running in the background that caused the SDD to report 100% full. At any rate I'm having to start all over with the install and machine configuration. You know what they say "it always goes better the second time"

Thanks for your help and suggestions. Once I'm back up and running I'll test the THC.

Thanks for your help and suggestions. Once I'm back up and running I'll test the THC.

Please Log in or Create an account to join the conversation.

- Nick7251

- Offline

- Senior Member

-

Less

More

- Posts: 57

- Thank you received: 10

12 Feb 2021 15:45 #198544

by Nick7251

Replied by Nick7251 on topic THC test mode to watch up and down movement

Finally did some testing last night.THC seems to be working great.

Tommy - when I go into the set the THC delay it says 1.5. what number would you recommend? I want a delay long enough to give me a reliable sample for auto THC, but I don't want it so long that it cuts several inches before turning on.

Tommy - when I go into the set the THC delay it says 1.5. what number would you recommend? I want a delay long enough to give me a reliable sample for auto THC, but I don't want it so long that it cuts several inches before turning on.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21079

- Thank you received: 7195

12 Feb 2021 16:58 #198547

by tommylight

Replied by tommylight on topic THC test mode to watch up and down movement

Depends on what thickness and velocity and amperage it is cutting.

I have it set at 0.1 as i do not use autovolts and cut 3mm sheet at 4m/m.

Start at 0.2 and work your way up to see what works for you best.

Did some cutting today, some gussets and some rounds from 3mm sheet, am still frozen !

I have it set at 0.1 as i do not use autovolts and cut 3mm sheet at 4m/m.

Start at 0.2 and work your way up to see what works for you best.

Did some cutting today, some gussets and some rounds from 3mm sheet, am still frozen !

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11566

- Thank you received: 3884

12 Feb 2021 21:21 - 12 Feb 2021 21:22 #198583

by rodw

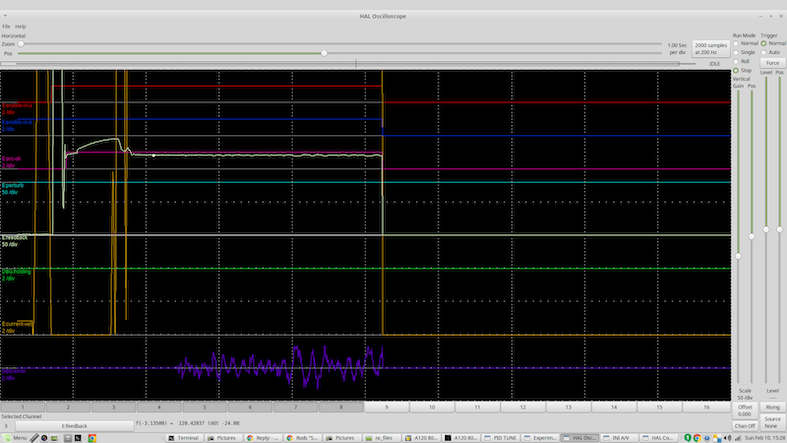

0.1 second is far too soon even if not using auto volts. There is no way the torch voltage has settled to cut volts in that time. Please study the plot below from the plasma primer (green line). Each vertical line is one second apart.

linuxcnc.org/docs/devel/html/plasma/plas...imer.html#_thc_delay

This shows the pierce delay does not subside for 1.1 seconds. I appreciate a faster accellerating machine may perform better. but never to 0.1 seconds.

Tommy even if you are accelerating at 0.5 G (5 m/s/s), your machine is going to take 0.13 seconds to get to cut velocity.

If you enable the THC too early, you will be trying to control the torch height when the voltage is not at cut velocity and you'll be forcing the torch below the cut height at the start of the cut.

There is no need to guess here. All you need to do is use halscope to plot torch volts like I have here and pick the time that suits your table. I dd not see any appreciable difference between 2mm and 16mm plate.

In the absence of actually measuring it, I would start at 1.5 seconds and work backwards. 0.1 seconds at a time.

Getting this right and auto sampling makes life so much easier.

Replied by rodw on topic THC test mode to watch up and down movement

I have it set at 0.1 as i do not use autovolts and cut 3mm sheet at 4m/m.

0.1 second is far too soon even if not using auto volts. There is no way the torch voltage has settled to cut volts in that time. Please study the plot below from the plasma primer (green line). Each vertical line is one second apart.

linuxcnc.org/docs/devel/html/plasma/plas...imer.html#_thc_delay

This shows the pierce delay does not subside for 1.1 seconds. I appreciate a faster accellerating machine may perform better. but never to 0.1 seconds.

Tommy even if you are accelerating at 0.5 G (5 m/s/s), your machine is going to take 0.13 seconds to get to cut velocity.

If you enable the THC too early, you will be trying to control the torch height when the voltage is not at cut velocity and you'll be forcing the torch below the cut height at the start of the cut.

There is no need to guess here. All you need to do is use halscope to plot torch volts like I have here and pick the time that suits your table. I dd not see any appreciable difference between 2mm and 16mm plate.

In the absence of actually measuring it, I would start at 1.5 seconds and work backwards. 0.1 seconds at a time.

Getting this right and auto sampling makes life so much easier.

Last edit: 12 Feb 2021 21:22 by rodw.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.074 seconds