Lead-in going beyond path

- fernandosf

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 69

- Thank you received: 17

07 Dec 2021 14:17 - 07 Dec 2021 14:29 #228532

by fernandosf

Lead-in going beyond path was created by fernandosf

Not sure where the problem is.

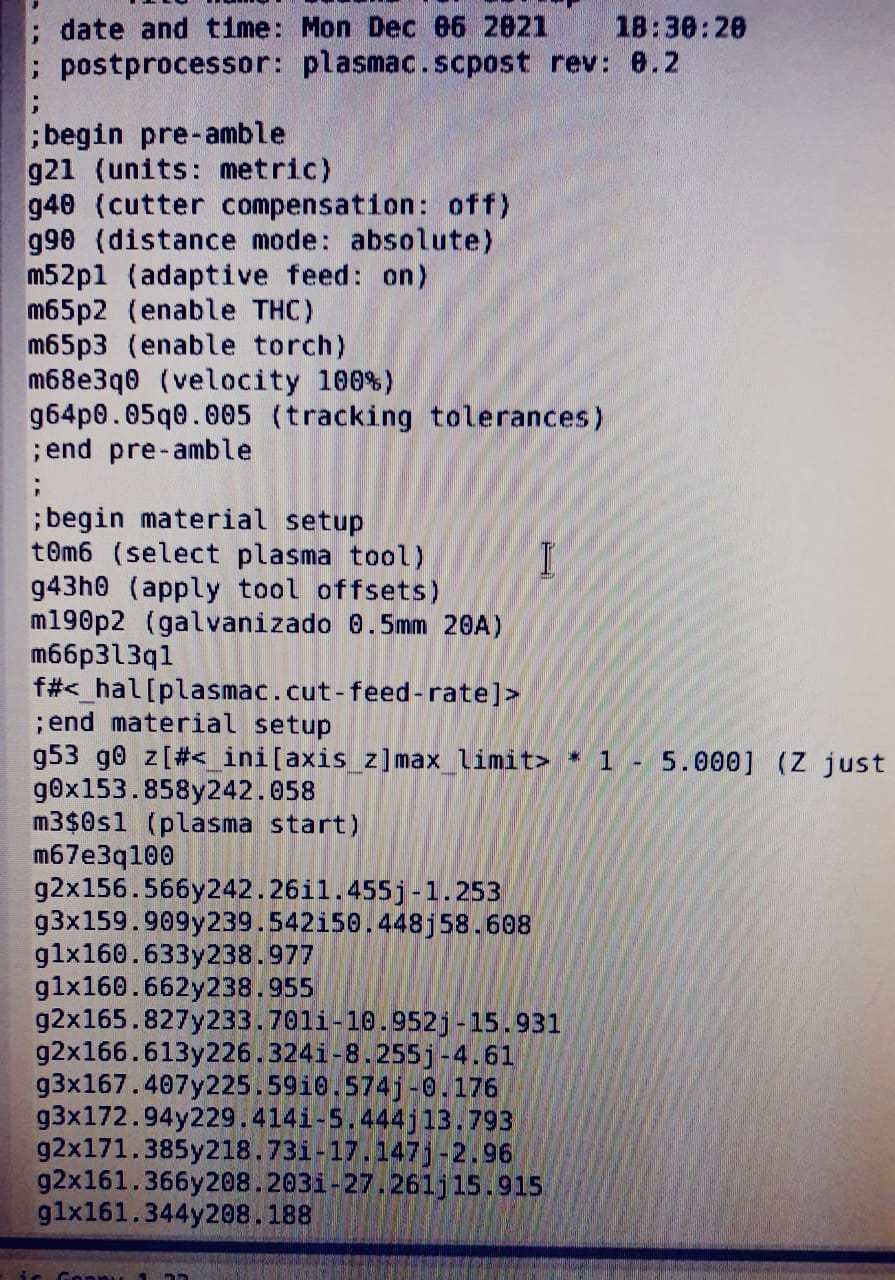

At the beggining of a cut, I did a Sheetcam arc lead in of 3mm. Looks good at sheetcam and QtplasmaC visualization. But I am getting this results:

I have done some testing, with/without THC, turn down g64 p to 0.05, slower feed rate, arc ok off, none seems to help.

My machine uses GT-2 10mm belts, it might be related to backlash (I can see a wiggle after a 90º turn).

How would you investigate such an issue ?

Thanks

At the beggining of a cut, I did a Sheetcam arc lead in of 3mm. Looks good at sheetcam and QtplasmaC visualization. But I am getting this results:

I have done some testing, with/without THC, turn down g64 p to 0.05, slower feed rate, arc ok off, none seems to help.

My machine uses GT-2 10mm belts, it might be related to backlash (I can see a wiggle after a 90º turn).

How would you investigate such an issue ?

Thanks

Attachments:

Last edit: 07 Dec 2021 14:29 by fernandosf. Reason: posted incomplete first time

Please Log in or Create an account to join the conversation.

- fernandosf

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 69

- Thank you received: 17

07 Dec 2021 14:40 #228534

by fernandosf

Replied by fernandosf on topic Lead-in going beyond path

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21342

- Thank you received: 7283

07 Dec 2021 16:33 #228543

by tommylight

Replied by tommylight on topic Lead-in going beyond path

Sharp corners wobbling is for sure due to flex/slop/loose stuff, always mechanical on stepper systems.

You can try lowering acceleration, it helps a lot but only to a certain point.

Using GT2 belt on a 20 KG gantry is manageable and works OK, but on a 70 KG gantry nothing helps short of slowing it to a crawl.

You can try lowering acceleration, it helps a lot but only to a certain point.

Using GT2 belt on a 20 KG gantry is manageable and works OK, but on a 70 KG gantry nothing helps short of slowing it to a crawl.

Please Log in or Create an account to join the conversation.

- fernandosf

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 69

- Thank you received: 17

07 Dec 2021 16:52 - 07 Dec 2021 17:06 #228548

by fernandosf

Replied by fernandosf on topic Lead-in going beyond path

Yes, I will check for mechanical issues. And try to lower accel. Thanks.

I think my gantry is near 18kg, never weighted it.

Have seen this topic (forum.linuxcnc.org/38-general-linuxcnc-q...ad-in-on-inside-cuts) and additional info follows:

PARAMETERS > THC > SPEED: 10%

PARAMETERS > THC > VAD THRESHOLD: 90%

PARAMETERS > MATERIAL > PAUSE AT THE END: 0

PARAMETERS > MATERIAL > CUT HEIGHT: 1.5mm

PARAMETERS > MATERIAL > CUT FEED RATE: 2400mm/s

I have tested and the "divot" happens at the start, not at the end of cut (when there is less material around the plasma).

I have set negative overcut of 1.4mm (on Sheetcam) and it didn't help.

EDIT: I have MAIN > CONTROL > VELOCITY ANTI-DIVE checked and it lights several times when cutting (not sure if it has any relation to the problem

I think my gantry is near 18kg, never weighted it.

Have seen this topic (forum.linuxcnc.org/38-general-linuxcnc-q...ad-in-on-inside-cuts) and additional info follows:

PARAMETERS > THC > SPEED: 10%

PARAMETERS > THC > VAD THRESHOLD: 90%

PARAMETERS > MATERIAL > PAUSE AT THE END: 0

PARAMETERS > MATERIAL > CUT HEIGHT: 1.5mm

PARAMETERS > MATERIAL > CUT FEED RATE: 2400mm/s

I have tested and the "divot" happens at the start, not at the end of cut (when there is less material around the plasma).

I have set negative overcut of 1.4mm (on Sheetcam) and it didn't help.

EDIT: I have MAIN > CONTROL > VELOCITY ANTI-DIVE checked and it lights several times when cutting (not sure if it has any relation to the problem

Last edit: 07 Dec 2021 17:06 by fernandosf. Reason: gantry weigth

Please Log in or Create an account to join the conversation.

- fernandosf

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 69

- Thank you received: 17

07 Dec 2021 17:21 #228553

by fernandosf

Replied by fernandosf on topic Lead-in going beyond path

Would this have anything to do with FERROR and MIN_FERROR ?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21342

- Thank you received: 7283

07 Dec 2021 17:37 #228556

by tommylight

Replied by tommylight on topic Lead-in going beyond path

See above, if stepper system = mechanical issues.

From the cuts i am fairly certain it is a stepper system.

From the cuts i am fairly certain it is a stepper system.

The following user(s) said Thank You: fernandosf

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

07 Dec 2021 20:14 #228571

by rodw

Replied by rodw on topic Lead-in going beyond path

Can you try a perpendicular leadin? That is the recommended method.

Its either your choice of leadin or mechanical issues.

Its either your choice of leadin or mechanical issues.

Please Log in or Create an account to join the conversation.

- fernandosf

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 69

- Thank you received: 17

08 Dec 2021 19:41 #228643

by fernandosf

Replied by fernandosf on topic Lead-in going beyond path

It was mechanical, one of my pillows had a loosen screw that adjusts it around the rod.

I have set lower accel and the wobbling is gone.

Thanks guys.

I have set lower accel and the wobbling is gone.

Thanks guys.

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.221 seconds