Rods "Spaceship" Scratch built Plasma Cutter build

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11691

- Thank you received: 3942

23 Mar 2017 12:41 #90116

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Tommy, thanks, the welding worries me a bit but I am a bit far in to change it significantly now. My Plan B is to add some levelling grub screws or shim the mounting plate to square it up. I guess I could drill and tap some holes and bolt the RHS on. I'll think about that. 4mm thick steel should be enough to hold a thread.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11691

- Thank you received: 3942

24 Mar 2017 10:44 #90182

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Well , the ongoing conspiracy to delay completion of my Plasma table continues.

I guess I can't really complain. Its just that you guys continue to force me not to take shortcuts and improve the design of my plasma table.

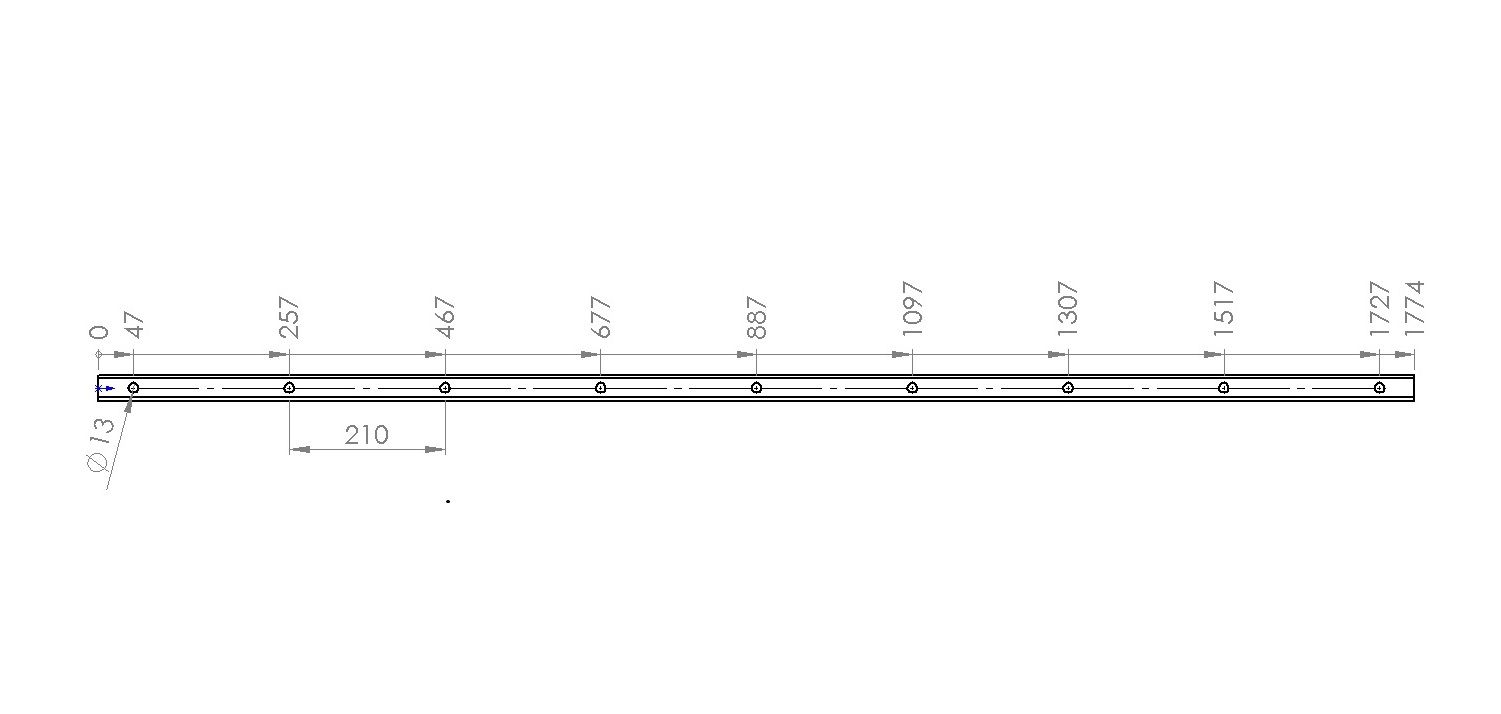

So for Tommy's benefit and in response to his word of advice, I worked out a way to bolt the linear rail support to the table to avoid welding and possible warping. I'm planning on using M12 x 1.25mm bolts at 210mm intervals (9 bolts per side) as shown below

The tapped holes will be in 4mm steel so that should give me a bit over 3 threads per bolt which should be adequate.

I'm only guessing at this stage but I think the total weight being supported by 18 bolts will be in the vicinity of 150kg so each bolt only has to support less than 10 kg.

Is a 210mm bolt spacing OK do you think?

I guess I can't really complain. Its just that you guys continue to force me not to take shortcuts and improve the design of my plasma table.

So for Tommy's benefit and in response to his word of advice, I worked out a way to bolt the linear rail support to the table to avoid welding and possible warping. I'm planning on using M12 x 1.25mm bolts at 210mm intervals (9 bolts per side) as shown below

The tapped holes will be in 4mm steel so that should give me a bit over 3 threads per bolt which should be adequate.

I'm only guessing at this stage but I think the total weight being supported by 18 bolts will be in the vicinity of 150kg so each bolt only has to support less than 10 kg.

Is a 210mm bolt spacing OK do you think?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

24 Mar 2017 10:53 #90183

by andypugh

What is the spacing of the holes in the actual rails?

Replied by andypugh on topic Rods "Spaceship" Scratch built Plasma Cutter build

Is a 210mm bolt spacing OK do you think?

What is the spacing of the holes in the actual rails?

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11691

- Thank you received: 3942

24 Mar 2017 11:07 #90184

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Andy, I'm not 100% sure what you mean, but here goes.

This part is 65mm x 35mm x 4mm wall RHS

The "Rail Mounting Plate" in the diagram posted last night (see forum.linuxcnc.org/show-your-stuff/32029...uild?start=110#90111) will be secured to this by M10 bolts on 100 mm centres.

The Hiwin 25mm linear rail is bolted to the "Rail Mounting Plate" on 60mm centres. I'm pretty sure the Hiwin docs say it is not necessary to use every mounting hole. I'll check their docs and see if I can find that.

This part is 65mm x 35mm x 4mm wall RHS

The "Rail Mounting Plate" in the diagram posted last night (see forum.linuxcnc.org/show-your-stuff/32029...uild?start=110#90111) will be secured to this by M10 bolts on 100 mm centres.

The Hiwin 25mm linear rail is bolted to the "Rail Mounting Plate" on 60mm centres. I'm pretty sure the Hiwin docs say it is not necessary to use every mounting hole. I'll check their docs and see if I can find that.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

24 Mar 2017 11:14 #90186

by andypugh

Replied by andypugh on topic Rods "Spaceship" Scratch built Plasma Cutter build

What I was actually wondering about was whether you would have a "vernier" problem.

Or maybe I mean: xkcd.com/1814/

You have bolts on 100mm, 210mm and 60mm centres. And you probably don't want them all in exactly the same place as each other.

Or maybe I mean: xkcd.com/1814/

You have bolts on 100mm, 210mm and 60mm centres. And you probably don't want them all in exactly the same place as each other.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11691

- Thank you received: 3942

24 Mar 2017 11:35 #90189

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Andy, sometimes you speak in riddles. I had a look at my CAD files and none of the hole patterns line up with other patterns if that was your concern.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11691

- Thank you received: 3942

25 Mar 2017 10:19 #90242

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

I still have no idea what a "vernier" problem is but in the absence of any feedback to the contary, I am going with 210mm bolt spacing. We had a bit of a chat about it at work and the consensus was that that was probably overkill.

I buy M12 x 1.25 x 90mm bolts 100 at a time. They will work but something a bit shorter would be better but my contract bolt pricing is probably cheaper...

Today, I also cut a couple of short pieces of 50mm x 75mm x 6mm angle iron from a very rusty length and linished the rust off. Tomorrow morning, I'm going to drill some holes in them so I can mount them to the linear carriages and with a bit of luck I'll get one rail mounted up tomorrow. Its become a bit complicated now because I took all of the table parts back to work ready to weld up so I've got 2 sites I'm working at so I'll be ferrying a few parts around.

I buy M12 x 1.25 x 90mm bolts 100 at a time. They will work but something a bit shorter would be better but my contract bolt pricing is probably cheaper...

Today, I also cut a couple of short pieces of 50mm x 75mm x 6mm angle iron from a very rusty length and linished the rust off. Tomorrow morning, I'm going to drill some holes in them so I can mount them to the linear carriages and with a bit of luck I'll get one rail mounted up tomorrow. Its become a bit complicated now because I took all of the table parts back to work ready to weld up so I've got 2 sites I'm working at so I'll be ferrying a few parts around.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11691

- Thank you received: 3942

01 Apr 2017 14:35 #90706

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

I had a bit of fun tonight writing my first HAL component. I got far enough to know it works, but it needs some tidying up before I share it.

The component is designed to scale voltages for the Mesa THCAD cards. If you are using one with a 10 volt range like I am, its messy to display voltages on the screen when say 4.5 volts represented in a specific frequency really means 95 volts.

So what this component does is let you input your calibration data, , THCAD voltage range (10v or 300v), THCAD frequency divider setting and torch voltage divider ratio. It then has outputs for both the THCAD voltage derived from the encoder frequency and the corresponding calculated torch arc voltage.

Additionally, it has an input for commanded torch voltage that outputs a correctly scaled encoder frequency value for use in a THC module. I'll share my scalethcad.comp in the plasma section once I add a bit more documentation. I'm sure this won't be the last component I write so I guess I need to learn more about github so I can maintain my own development branch for this stuff.

The component is designed to scale voltages for the Mesa THCAD cards. If you are using one with a 10 volt range like I am, its messy to display voltages on the screen when say 4.5 volts represented in a specific frequency really means 95 volts.

So what this component does is let you input your calibration data, , THCAD voltage range (10v or 300v), THCAD frequency divider setting and torch voltage divider ratio. It then has outputs for both the THCAD voltage derived from the encoder frequency and the corresponding calculated torch arc voltage.

Additionally, it has an input for commanded torch voltage that outputs a correctly scaled encoder frequency value for use in a THC module. I'll share my scalethcad.comp in the plasma section once I add a bit more documentation. I'm sure this won't be the last component I write so I guess I need to learn more about github so I can maintain my own development branch for this stuff.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11691

- Thank you received: 3942

04 Apr 2017 09:57 #90858

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Finally, we are welding up the table..

We have a large jig at work we use to square up tray bodies for trucks, pickups and as we call them in Australia, utes. It was perfect for building the table top. You can see the crossmember that is bolted to the linear rails on either side and with one side fixed in position, and the other clamped into position. I could push it full length with one finger so it was a credit to Lee's fabrication skills. Its only tacked up for now. Hopefully, by the weekend it will be welded out and on its feet. I was feeling very excited today.

We have a large jig at work we use to square up tray bodies for trucks, pickups and as we call them in Australia, utes. It was perfect for building the table top. You can see the crossmember that is bolted to the linear rails on either side and with one side fixed in position, and the other clamped into position. I could push it full length with one finger so it was a credit to Lee's fabrication skills. Its only tacked up for now. Hopefully, by the weekend it will be welded out and on its feet. I was feeling very excited today.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21243

- Thank you received: 7251

04 Apr 2017 18:12 #90872

by tommylight

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

I do not see any beer there?

Please Log in or Create an account to join the conversation.

Time to create page: 0.179 seconds