Shed plasma build

- Mud

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 25

30 Aug 2020 16:08 - 30 Aug 2020 18:34 #180086

by Mud

Replied by Mud on topic Shed plasma build

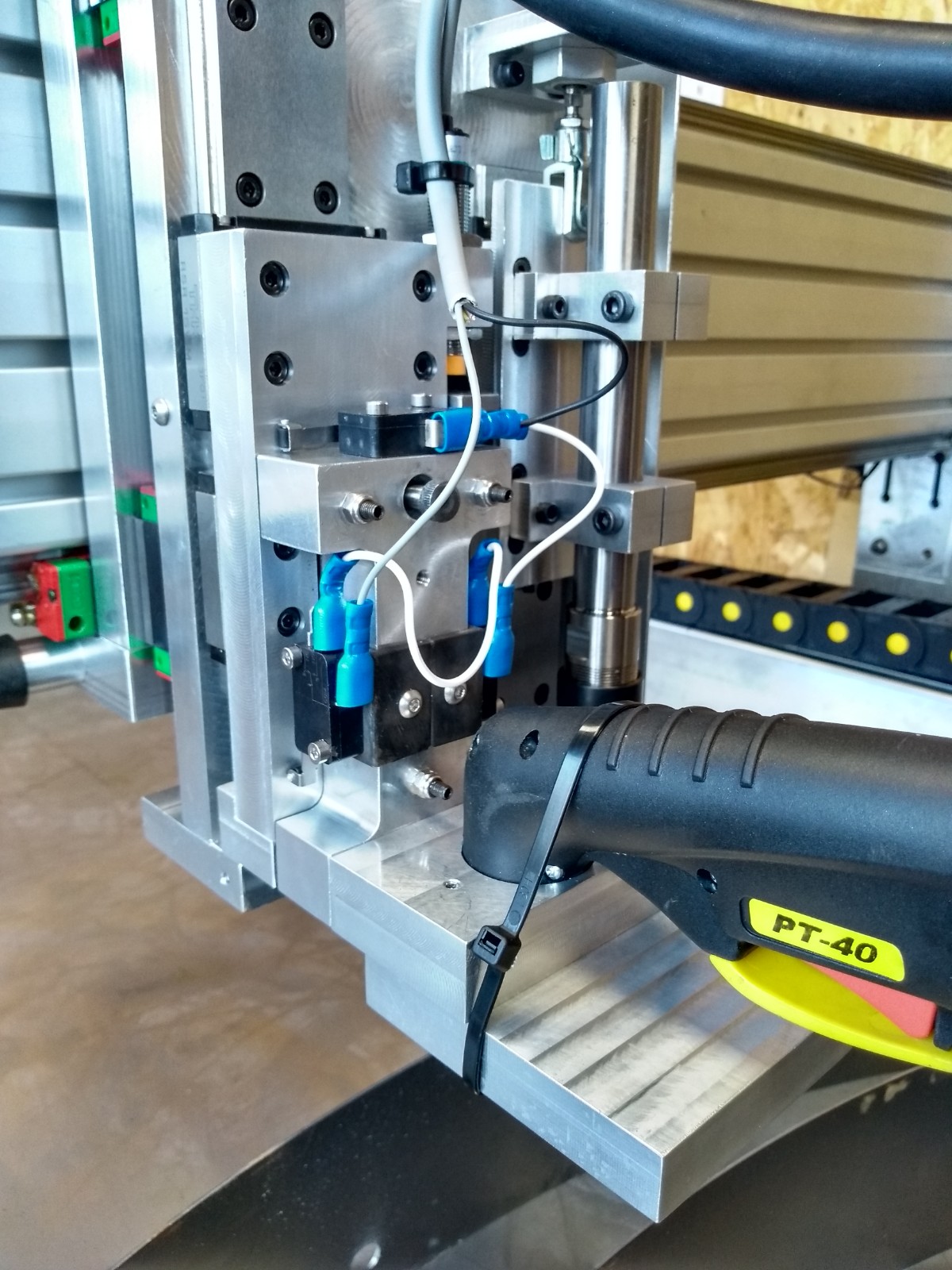

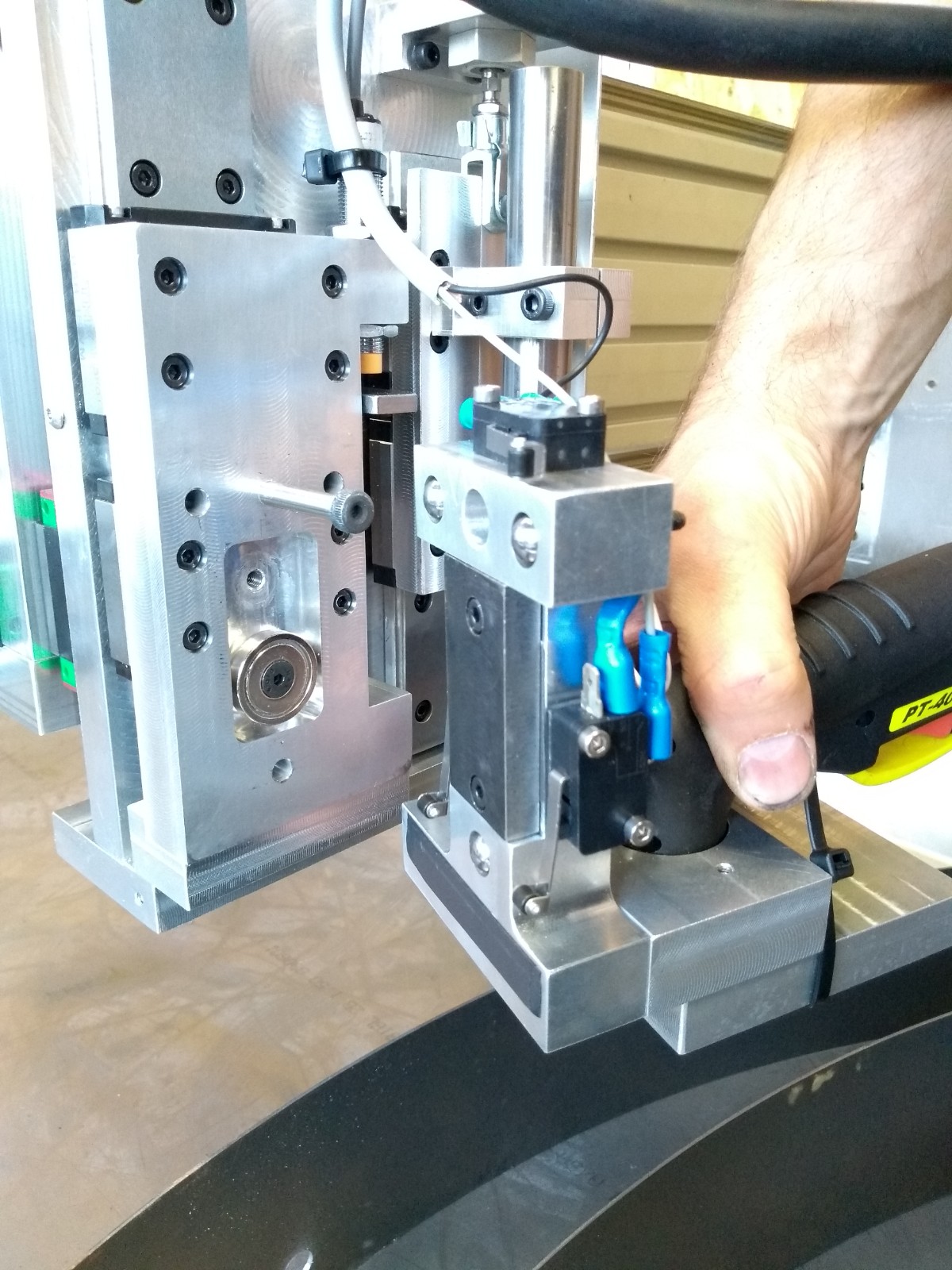

The machine is close to mechanically complete - I thought I would update with my breakaway solution. As much as I would have liked to have the magnets/interface in the horizontal plane I couldn't really make it work with the hand torch. I ended up with what I consider a very fussy solution, but after fine-tuning it seems to work. Obviously balancing the forces in all the directions with the different fulcrums is a pain, and the exponential drop-off of magnetic force with distance means make everything adjustable. The small bit of electrical tape makes up for a very slight rock which gave some locating variability (I think the M4-threaded 10mm balls I used aren't completely round...my hole locations were good to ~0.01mm  ).

).

I have nicer switches coming - the bolt pattern is pretty common.

I have nicer switches coming - the bolt pattern is pretty common.

Attachments:

Last edit: 30 Aug 2020 18:34 by Mud. Reason: spelling

The following user(s) said Thank You: phillc54, tommylight, Himarc3D

Please Log in or Create an account to join the conversation.

- Mud

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 25

02 Sep 2020 19:36 #180459

by Mud

Replied by Mud on topic Shed plasma build

Scribe dry run - very easy to add

The following user(s) said Thank You: rodw, snowgoer540

Please Log in or Create an account to join the conversation.

- Mud

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 25

04 Sep 2020 12:43 #180676

by Mud

Replied by Mud on topic Shed plasma build

My pushrod solution - not pretty, but appears to work. I have ~0.9mm of hysteresis.

The following user(s) said Thank You: phillc54, Clive S

Please Log in or Create an account to join the conversation.

- Mud

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 25

09 Sep 2020 17:59 #181477

by Mud

Replied by Mud on topic Shed plasma build

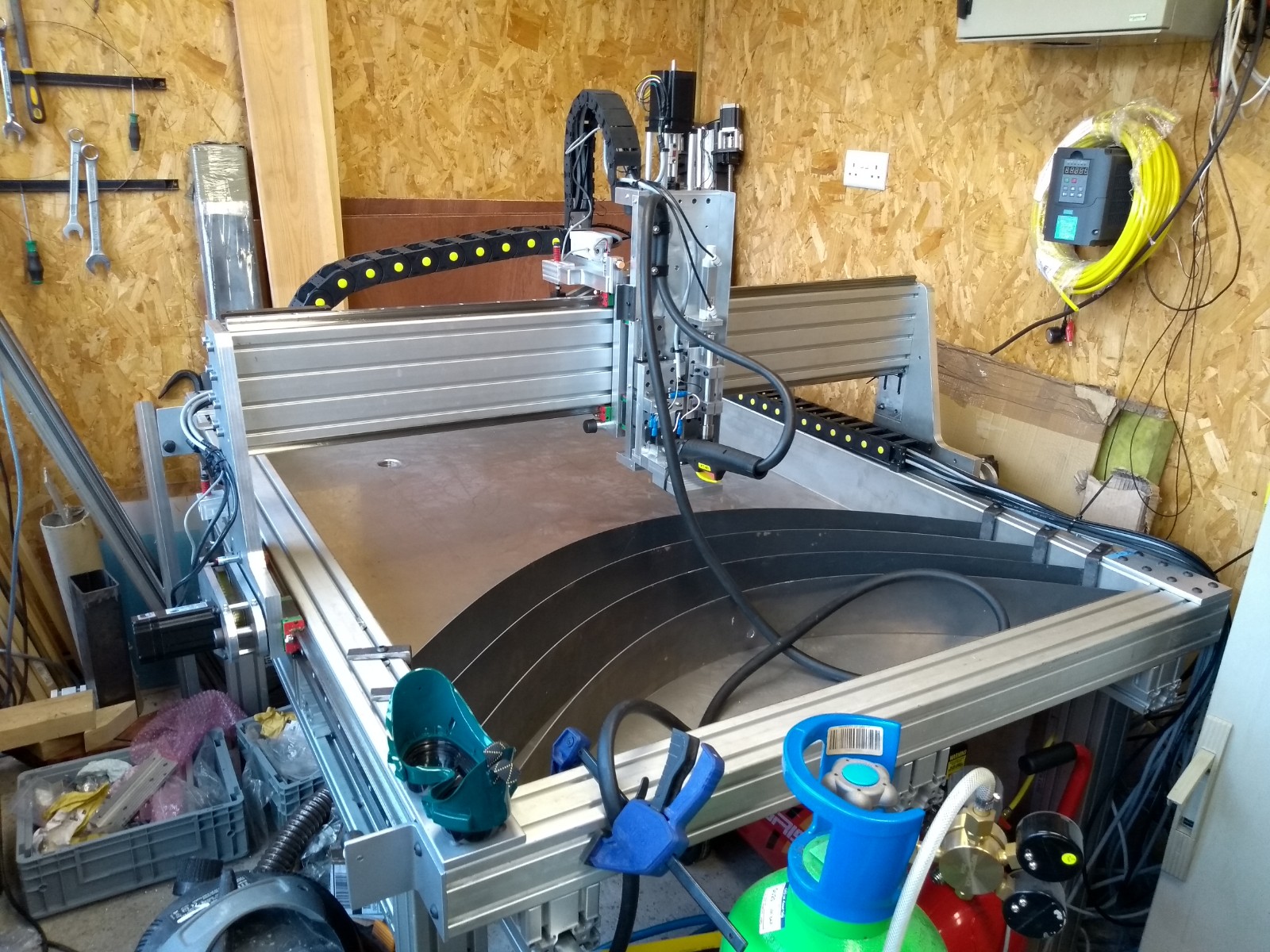

Getting closer to usable - got the drive alarms wired in, cabinet button for machine on, made some more slats, etc.

Any tips on getting complete penetration on those first linear cuts? Adding pierce delay and lowering the pierce height didn't seem to make much difference. This is 1mm steel. The star looks a bit wavy, so will have to work out if that's machine stiffness or process parameter related.

Any tips on getting complete penetration on those first linear cuts? Adding pierce delay and lowering the pierce height didn't seem to make much difference. This is 1mm steel. The star looks a bit wavy, so will have to work out if that's machine stiffness or process parameter related.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11646

- Thank you received: 3919

09 Sep 2020 19:52 #181496

by rodw

Replied by rodw on topic Shed plasma build

I would lower the cut velocity by 20% and see how you go with cutting through.

Please Log in or Create an account to join the conversation.

- Mud

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 25

09 Sep 2020 19:58 #181497

by Mud

Replied by Mud on topic Shed plasma build

The square was at 6000mm/min (vs. 8500mm/min on the star) and it had the same issue.

Looking at the star, I think it looks wavier in the gantry traverse direction - I've upped the preload on the pinion.

Looking at the star, I think it looks wavier in the gantry traverse direction - I've upped the preload on the pinion.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11646

- Thank you received: 3919

09 Sep 2020 20:05 #181501

by rodw

What plasma cutter? what is the book speed?

Don't use Hypertherm speeds on any other brand of machine. They are way too fast.

1mm mild steel on my Thermal Dynamic is 3266 mm/min at 40 amps with shielded consumables.

A star is a really tough test.

Replied by rodw on topic Shed plasma build

The square was at 6000mm/min (vs. 8500mm/min on the star) and it had the same issue.

Looking at the star, I think it looks wavier in the gantry traverse direction - I've upped the preload on the pinion.

What plasma cutter? what is the book speed?

Don't use Hypertherm speeds on any other brand of machine. They are way too fast.

1mm mild steel on my Thermal Dynamic is 3266 mm/min at 40 amps with shielded consumables.

A star is a really tough test.

The following user(s) said Thank You: Mud

Please Log in or Create an account to join the conversation.

- Mud

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 25

09 Sep 2020 20:37 #181504

by Mud

Replied by Mud on topic Shed plasma build

As a starter I had indeed scaled some Hypertherm values (by 40/45 since my GYS 40FV has a lower current capability). The book values are limited/non-existant and since it's a hand torch it recommends I go to 10A for such thin metal (I was going full whack). I'll try scaling way back, but you can see it's close to doing something handy!

Yes, the star is a bit of a stress test. If it has identified insufficient preload on one pinion then I'm happy I did it.

With hindsight, I'm tempted to see what more air pressure does (was at 4 bar, but can go to ~8 bar from memory). I suspect it may be worse, but interested to try. I should also move the clamp onto the work for troubleshooting I guess.

Yes, the star is a bit of a stress test. If it has identified insufficient preload on one pinion then I'm happy I did it.

With hindsight, I'm tempted to see what more air pressure does (was at 4 bar, but can go to ~8 bar from memory). I suspect it may be worse, but interested to try. I should also move the clamp onto the work for troubleshooting I guess.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- Mud

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 25

10 Sep 2020 15:45 - 11 Sep 2020 08:53 #181648

by Mud

~3500mm/min is actually pretty spot-on for my machine for 1mm steel @40A - are you able to share any more settings Rod?

edit: saw your complete plasma make/model in another thread and found the manual. I notice the working and pierce heights are relatively high for the TD - I'll have a play and see how it fares

Replied by Mud on topic Shed plasma build

The square was at 6000mm/min (vs. 8500mm/min on the star) and it had the same issue.

Looking at the star, I think it looks wavier in the gantry traverse direction - I've upped the preload on the pinion.

What plasma cutter? what is the book speed?

Don't use Hypertherm speeds on any other brand of machine. They are way too fast.

1mm mild steel on my Thermal Dynamic is 3266 mm/min at 40 amps with shielded consumables.

A star is a really tough test.

~3500mm/min is actually pretty spot-on for my machine for 1mm steel @40A - are you able to share any more settings Rod?

edit: saw your complete plasma make/model in another thread and found the manual. I notice the working and pierce heights are relatively high for the TD - I'll have a play and see how it fares

Last edit: 11 Sep 2020 08:53 by Mud.

Please Log in or Create an account to join the conversation.

Time to create page: 0.186 seconds