PORTER 636-N Complete Overhaul

- hoffb77

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 53

- Thank you received: 21

01 Oct 2020 22:58 - 01 Oct 2020 23:07 #184521

by hoffb77

PORTER 636-N Complete Overhaul was created by hoffb77

We got this machine in 2009 out of a quilting frame factory in Wisconsin. I had no experience with NC anything but she came home. I sold all the innards and the DCM to fund single phase controls I had docs on. We managed to get a stepper system going with EMC2+Sound Logic+ Gecko 320's.

In 2019 I tore it down to bare frame and went through the machine top to bottom and gave her some new paint. Ball nuts, pillow blocks, stainless ballcage raceways on the Z....the whole 9!

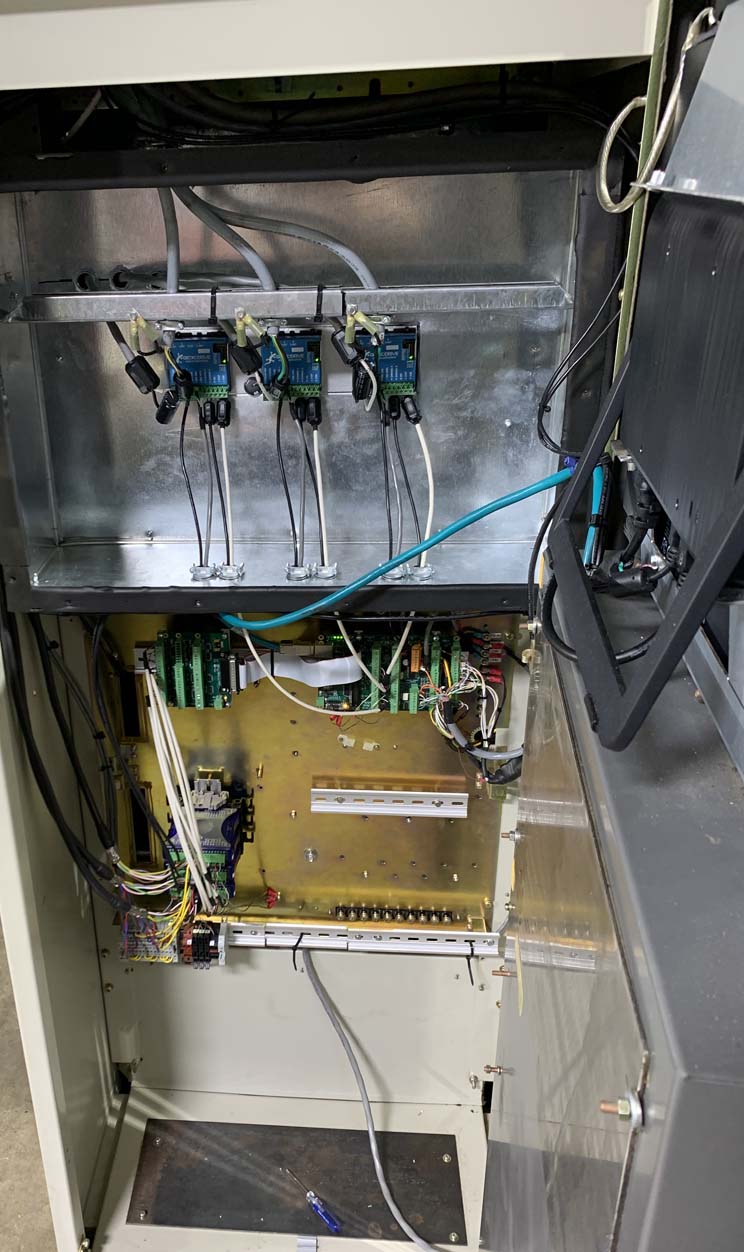

Mesa 7i76E+7i85+Gecko G320x's and I handle the Gecko #5 pin and all I/O logic through an Eaton ELC2 PLC.

I documented the whole process and would like to get something together and up on a server. I am by far done with this machine but it performs great with the new controls. A real spindle and tool changer are next but I have another machine to put the same controls on right now.......while this one is running

And I'd like to thank this community for the 2nd time in helping me gain the knowledge I needed to pull this off. I can say it would be nearly impossible to do this at my shop on top of a 365 maintenance job without this great group of people!

*****This machine was built on Oct 24 1979 by the Porter Machinery Co. Grand Rapids, MI*****

In 2019 I tore it down to bare frame and went through the machine top to bottom and gave her some new paint. Ball nuts, pillow blocks, stainless ballcage raceways on the Z....the whole 9!

Mesa 7i76E+7i85+Gecko G320x's and I handle the Gecko #5 pin and all I/O logic through an Eaton ELC2 PLC.

I documented the whole process and would like to get something together and up on a server. I am by far done with this machine but it performs great with the new controls. A real spindle and tool changer are next but I have another machine to put the same controls on right now.......while this one is running

And I'd like to thank this community for the 2nd time in helping me gain the knowledge I needed to pull this off. I can say it would be nearly impossible to do this at my shop on top of a 365 maintenance job without this great group of people!

*****This machine was built on Oct 24 1979 by the Porter Machinery Co. Grand Rapids, MI*****

Last edit: 01 Oct 2020 23:07 by hoffb77. Reason: add info

The following user(s) said Thank You: tommylight, johnmc1, Aciera

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

02 Oct 2020 07:37 #184540

by thefabricator03

Replied by thefabricator03 on topic PORTER 636-N Complete Overhaul

Great work.

I really like how bare the inside of the original control cabinet is. Its funny how much space the old control hardware takes up. I have some robots from the early 90's and inside their cabinets is the same.

I really like how bare the inside of the original control cabinet is. Its funny how much space the old control hardware takes up. I have some robots from the early 90's and inside their cabinets is the same.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 19815

- Thank you received: 4614

02 Oct 2020 11:14 #184556

by andypugh

In the case of my lathe, I took out a bridge rectifier and had room for a PC motherboard and all the Mesa cards.

Replied by andypugh on topic PORTER 636-N Complete Overhaul

Its funny how much space the old control hardware takes up. I have some robots from the early 90's and inside their cabinets is the same.

In the case of my lathe, I took out a bridge rectifier and had room for a PC motherboard and all the Mesa cards.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- hoffb77

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 53

- Thank you received: 21

02 Oct 2020 13:34 #184572

by hoffb77

Replied by hoffb77 on topic PORTER 636-N Complete Overhaul

I’m glad to have kept the Fanuc cabinet around. I was able to keep the noisy and sensitive conductors isolated while leaving room for expansion. It has a heat exchange in the back door. It blows directly on my drive heatsink and I have had no need to wire up the fresh air intake thus far. It’s doubtful I ever will. Although I need to set up a temp monitor of some nature for the drives....just in case.

Attachments:

Please Log in or Create an account to join the conversation.

- hoffb77

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 53

- Thank you received: 21

02 Oct 2020 13:45 #184574

by hoffb77

Replied by hoffb77 on topic PORTER 636-N Complete Overhaul

The following user(s) said Thank You: tommylight, thefabricator03

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21376

- Thank you received: 7289

02 Oct 2020 17:15 #184588

by tommylight

Replied by tommylight on topic PORTER 636-N Complete Overhaul

Nice.

The following user(s) said Thank You: hoffb77

Please Log in or Create an account to join the conversation.

- hoffb77

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 53

- Thank you received: 21

02 Oct 2020 20:39 #184619

by hoffb77

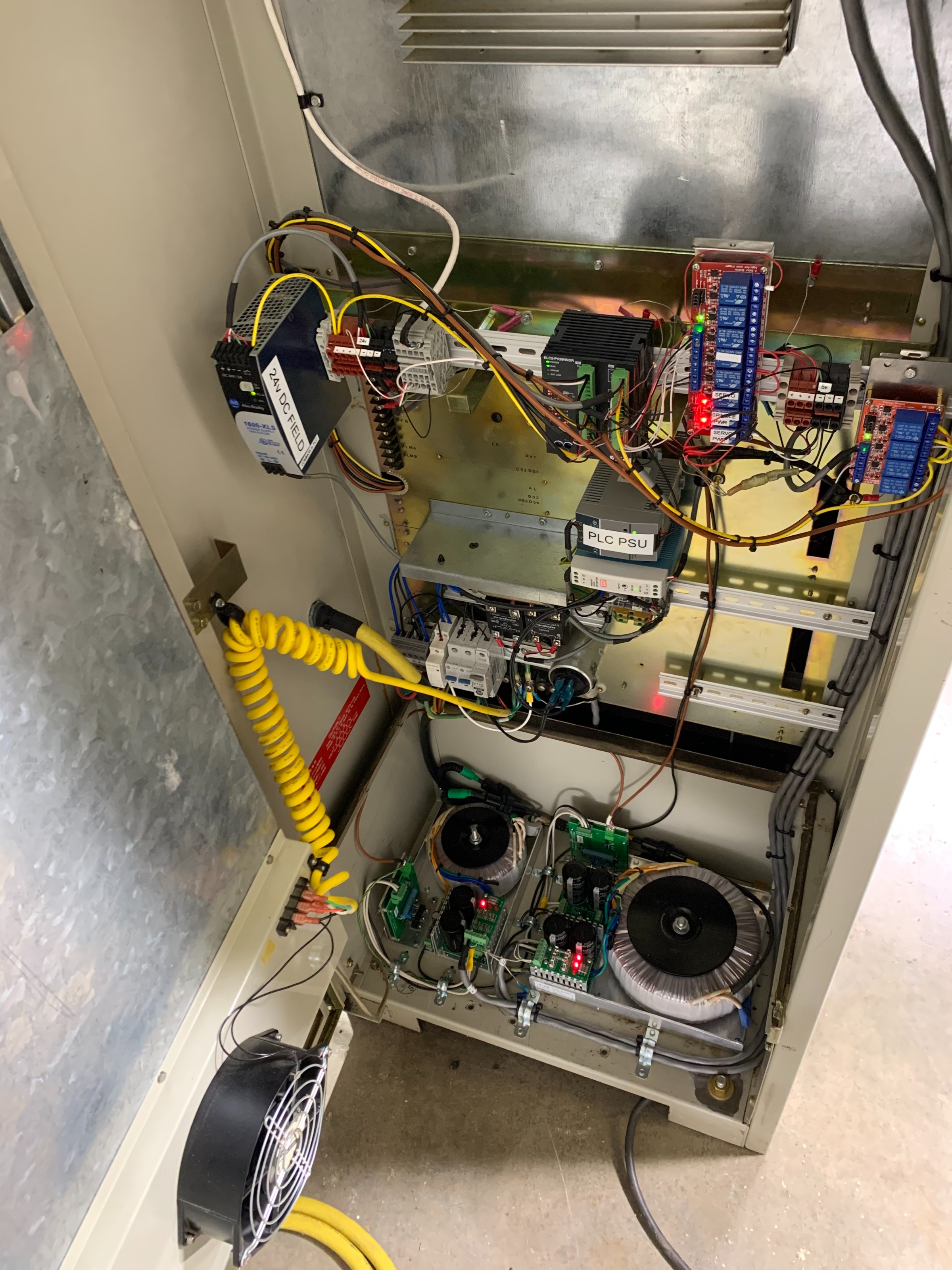

That's a slick conversion. I have two cabinets that size on my current project. Its a Millennium 4200 (Tree J-425). I had it running with the OEM analog drives with a 7i77. They were made by MSI, whom got gobbled up in the 90's. Rather than waste time and money on them I decided to put the exact same setup in the Millennium that have in the Porter. Except the Millennium has a 6i25+7i76=7i85. The only difference between my two mills as far as hal is concerned is i/o.....

The old controls were Anilam1400. There is 120v everywhere for the draw bar solenoid, oil pump, PLC, PC.... I want to get some of it separated for noise concerns but Id rather not re-wire the whole machine. My noisy components will be on the other side and the drives will be in a box again. I hope that's enough.

Have any of you had noise issues during an integration?

Replied by hoffb77 on topic PORTER 636-N Complete Overhaul

Its funny how much space the old control hardware takes up. I have some robots from the early 90's and inside their cabinets is the same.

In the case of my lathe, I took out a bridge rectifier and had room for a PC motherboard and all the Mesa cards.

That's a slick conversion. I have two cabinets that size on my current project. Its a Millennium 4200 (Tree J-425). I had it running with the OEM analog drives with a 7i77. They were made by MSI, whom got gobbled up in the 90's. Rather than waste time and money on them I decided to put the exact same setup in the Millennium that have in the Porter. Except the Millennium has a 6i25+7i76=7i85. The only difference between my two mills as far as hal is concerned is i/o.....

The old controls were Anilam1400. There is 120v everywhere for the draw bar solenoid, oil pump, PLC, PC.... I want to get some of it separated for noise concerns but Id rather not re-wire the whole machine. My noisy components will be on the other side and the drives will be in a box again. I hope that's enough.

Have any of you had noise issues during an integration?

Please Log in or Create an account to join the conversation.

- hoffb77

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 53

- Thank you received: 21

28 Jun 2021 16:41 #213159

by hoffb77

Replied by hoffb77 on topic PORTER 636-N Complete Overhaul

I decided to replace the servo drives with Mach BRC's. They allow me to run the Fanuc servos at full voltage and set the step resolution. The Geckos are limited to 80v and the step resolution has to match the feedback. Those two features were enough for me but the Mach Drives have much more to offer. Once that was done I put on a real spindle. Its a RATTM - RTM100-30-24 - 3.0KW, 24,000RPM@400hz, with a BT30 taper. This setup has been running very well for the past few months and I couldn't be happier with the results.

Attachments:

The following user(s) said Thank You: johnmc1, thefabricator03

Please Log in or Create an account to join the conversation.

Time to create page: 0.419 seconds