Hurco BMC30/M LinuxCNC Refit

- LinuxHurco

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 1

06 Feb 2022 13:52 - 06 Feb 2022 13:55 #234103

by LinuxHurco

Hurco BMC30/M LinuxCNC Refit was created by LinuxHurco

Hi everyone,

I would like to share my CNC build and where I am currently at with my project.

I am working on an old Hurco BMC30/M. Below is a photo of the BMC arriving at my home.

I have now stripped the machine down to just the column and bed, I am waiting for a crane to dismantle it further.

I now plan on splitting the column from the base and then stripping the paint and repainting the machine.

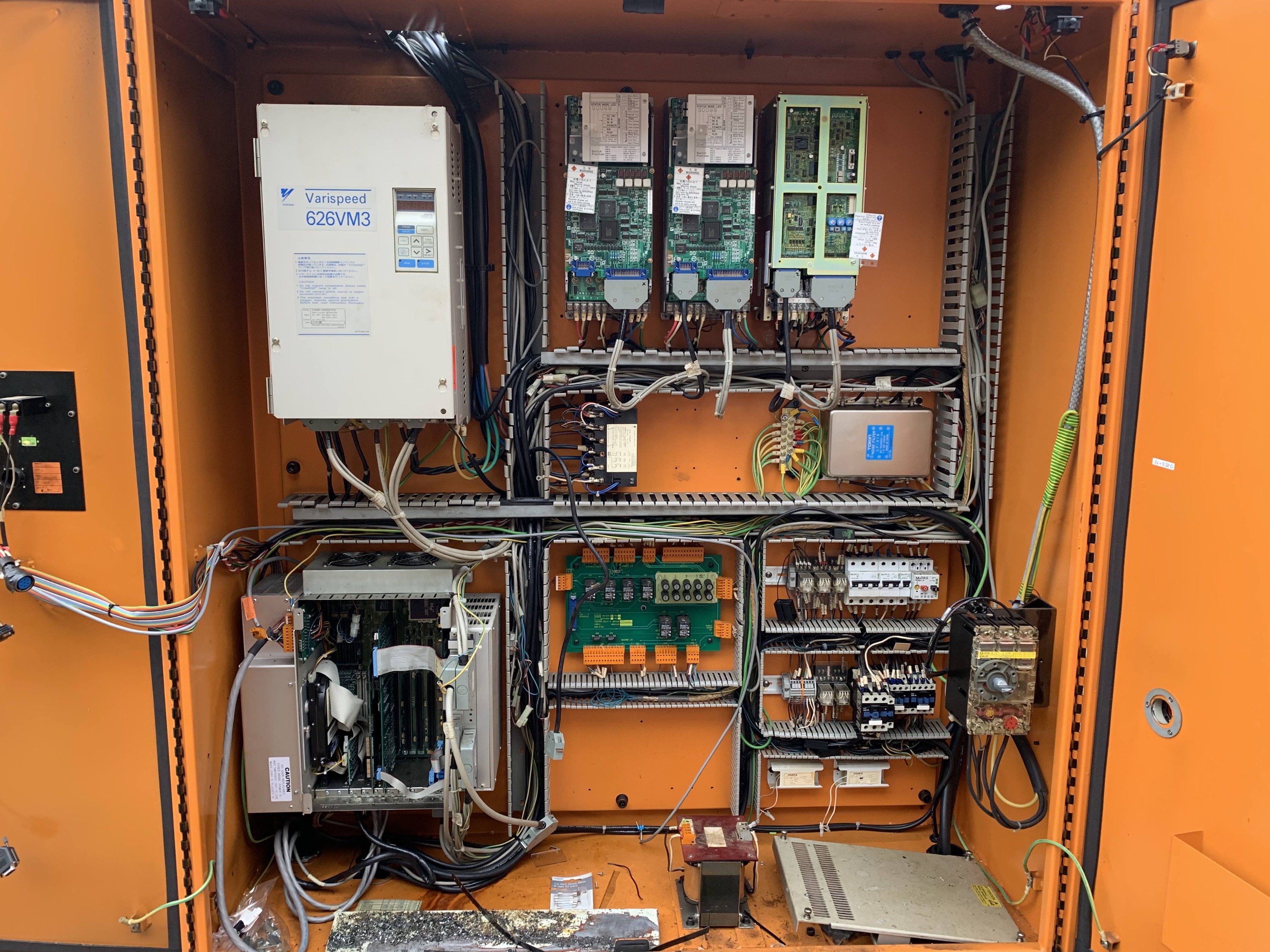

Below is an image of the old electrical cabinet, I am replacing all of the parts and am planning to make the machine a single phase machine.

I hope to do an update on the build when it has progressed a bit further.

Thanks for looking!!

I would like to share my CNC build and where I am currently at with my project.

I am working on an old Hurco BMC30/M. Below is a photo of the BMC arriving at my home.

I have now stripped the machine down to just the column and bed, I am waiting for a crane to dismantle it further.

I now plan on splitting the column from the base and then stripping the paint and repainting the machine.

Below is an image of the old electrical cabinet, I am replacing all of the parts and am planning to make the machine a single phase machine.

I hope to do an update on the build when it has progressed a bit further.

Thanks for looking!!

Attachments:

Last edit: 06 Feb 2022 13:55 by LinuxHurco.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21297

- Thank you received: 7273

06 Feb 2022 18:06 #234138

by tommylight

Replied by tommylight on topic Hurco BMC30/M LinuxCNC Refit

I would try to use the existing drives, they are very good as long as they work properly, especially i would use the spindle drive, anything close in performance costs in high 4 figures. Also has spindle orient built in.

They are also very easy to tune, like 3 minutes in total.

The only bad thing is they use proprietary encoders so if changing the drives, they must also go, not easy to remove them at all.

Also do not remove the green relay/fuse board, that is the tool changer control with interlocks.

They are also very easy to tune, like 3 minutes in total.

The only bad thing is they use proprietary encoders so if changing the drives, they must also go, not easy to remove them at all.

Also do not remove the green relay/fuse board, that is the tool changer control with interlocks.

The following user(s) said Thank You: LinuxHurco

Please Log in or Create an account to join the conversation.

- LinuxHurco

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 1

06 Feb 2022 18:54 #234150

by LinuxHurco

Replied by LinuxHurco on topic Hurco BMC30/M LinuxCNC Refit

Hi Tommy, Thank you for the advice but I plan on making the machine single phase and selling the components such as servopacks, motors and spindle-drive.

I hope that this plan sounds okay and will provide me with a very rigid and inexpensive machine, even if it does mean losing some of the power that the machine once had.

I hope that this plan sounds okay and will provide me with a very rigid and inexpensive machine, even if it does mean losing some of the power that the machine once had.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21297

- Thank you received: 7273

06 Feb 2022 22:06 #234182

by tommylight

Replied by tommylight on topic Hurco BMC30/M LinuxCNC Refit

Yeah about that, i doubt you can make it a single phase, or to put it better, you can make it single phase if you lower the spindle power a lot and never use all 3 axis at the same time.

My 20P had 0.75KW motors and a 5.5KW spindle, and a very large transformer from 3X380V to 3X220V.

That can not be run on a single phase.

De-rating the spindle to 2KW and motors to 0.5KW might just bring it to single phase, but .....

My 20P had 0.75KW motors and a 5.5KW spindle, and a very large transformer from 3X380V to 3X220V.

That can not be run on a single phase.

De-rating the spindle to 2KW and motors to 0.5KW might just bring it to single phase, but .....

Please Log in or Create an account to join the conversation.

- LinuxHurco

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 1

06 Feb 2022 22:21 #234184

by LinuxHurco

Replied by LinuxHurco on topic Hurco BMC30/M LinuxCNC Refit

Thats the plan with downgrading the spindle motor and replacing out the servos, currently it's a 7.5 kW Yaskawa motor (which is more power than I need) I was thinking of downgrading it to a 2-3kW spindle which I can run off a VFD.

I hope that a 32 amp single phase connection will be enough for this, if not then I will have to reconsider.

I hope that a 32 amp single phase connection will be enough for this, if not then I will have to reconsider.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21297

- Thank you received: 7273

06 Feb 2022 22:48 #234190

by tommylight

Replied by tommylight on topic Hurco BMC30/M LinuxCNC Refit

Just to be sure, are you sure you can run 32A on a single phase and neutral?

We can run 16A single phase + neutral, but we can run 32A on any and all of the 3 phases without neutral.

We can run 16A single phase + neutral, but we can run 32A on any and all of the 3 phases without neutral.

Please Log in or Create an account to join the conversation.

- LinuxHurco

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 1

06 Feb 2022 23:02 #234193

by LinuxHurco

Replied by LinuxHurco on topic Hurco BMC30/M LinuxCNC Refit

Yeah in the UK we have 32A 2P+E single phase, I currently use this socket connector for my MIG welder.

I have some sizable Nema 34 motors laying about from a previous project so hopefully I can make up an adaptor plate this week and see how fast the feed rates are and they accuracy on the X axis with the heavy table.

I have some sizable Nema 34 motors laying about from a previous project so hopefully I can make up an adaptor plate this week and see how fast the feed rates are and they accuracy on the X axis with the heavy table.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.238 seconds