Retrofit of 2 Messer Cortina DS Plasma cutting machines

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

11 Nov 2022 12:35 #256424

by tommylight

Retrofit of 2 Messer Cortina DS Plasma cutting machines was created by tommylight

Here we go again, two retrofits at once:

-both are Messer Cortina machines made in 2000 and 2004 respectively,

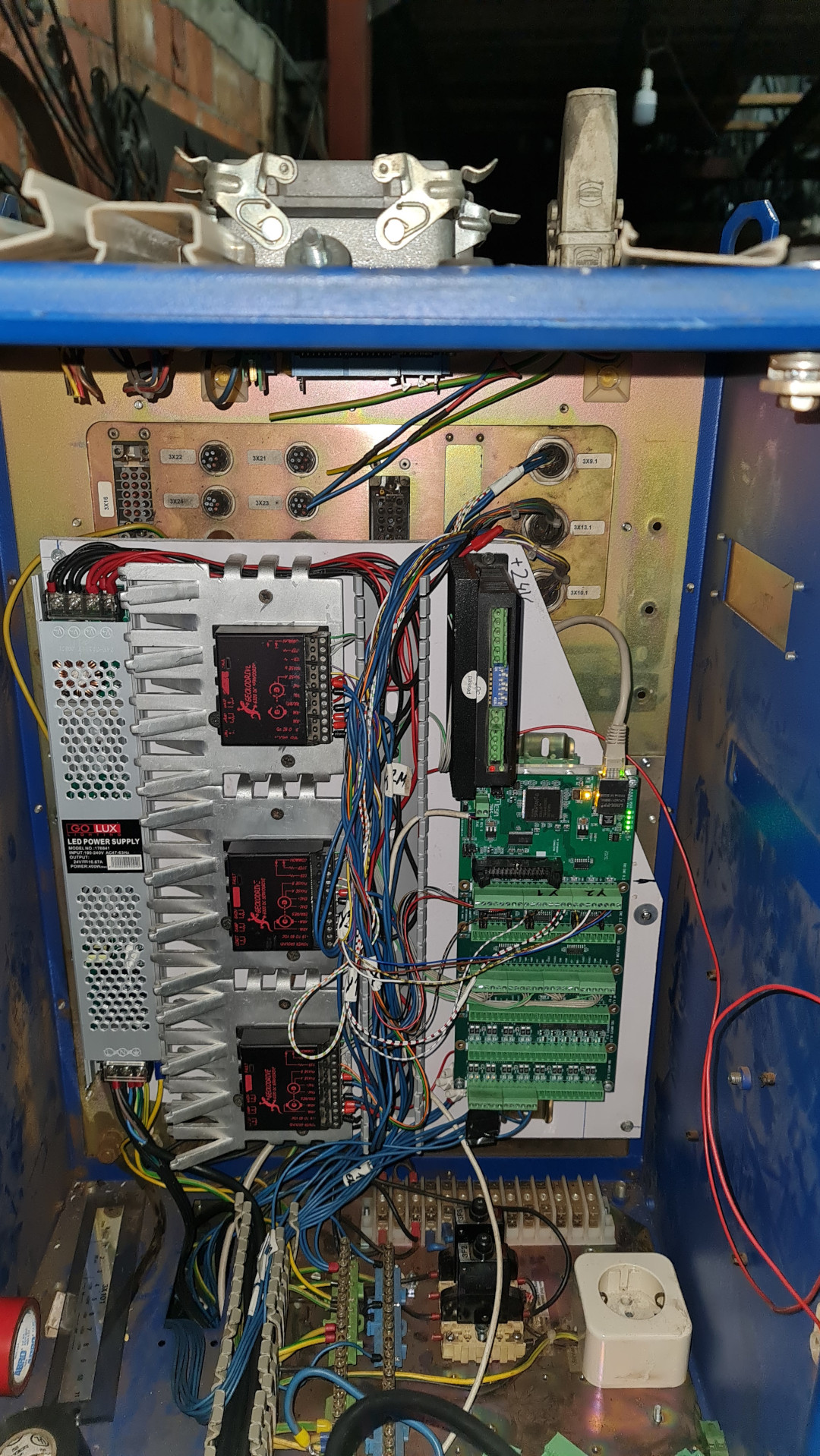

--one is 4X2 meters that has another 3 meters added so now it becomes 7X2 meters, last two pictures, it was bought as non working so everything is yanked out already, retrofitting it with Mesa 7i95, 3 of Gecko 320 DC servo drives and a stepper drive and motor for Z axis, will try to use encoders for both the drives and Mesa and report back how that works out. It had a Hypertherm 3070 Plasma system with O2 and N2 that will not be used, instead a Hypertherm PowerMax 45 will be installed with a Mesa THCAD.

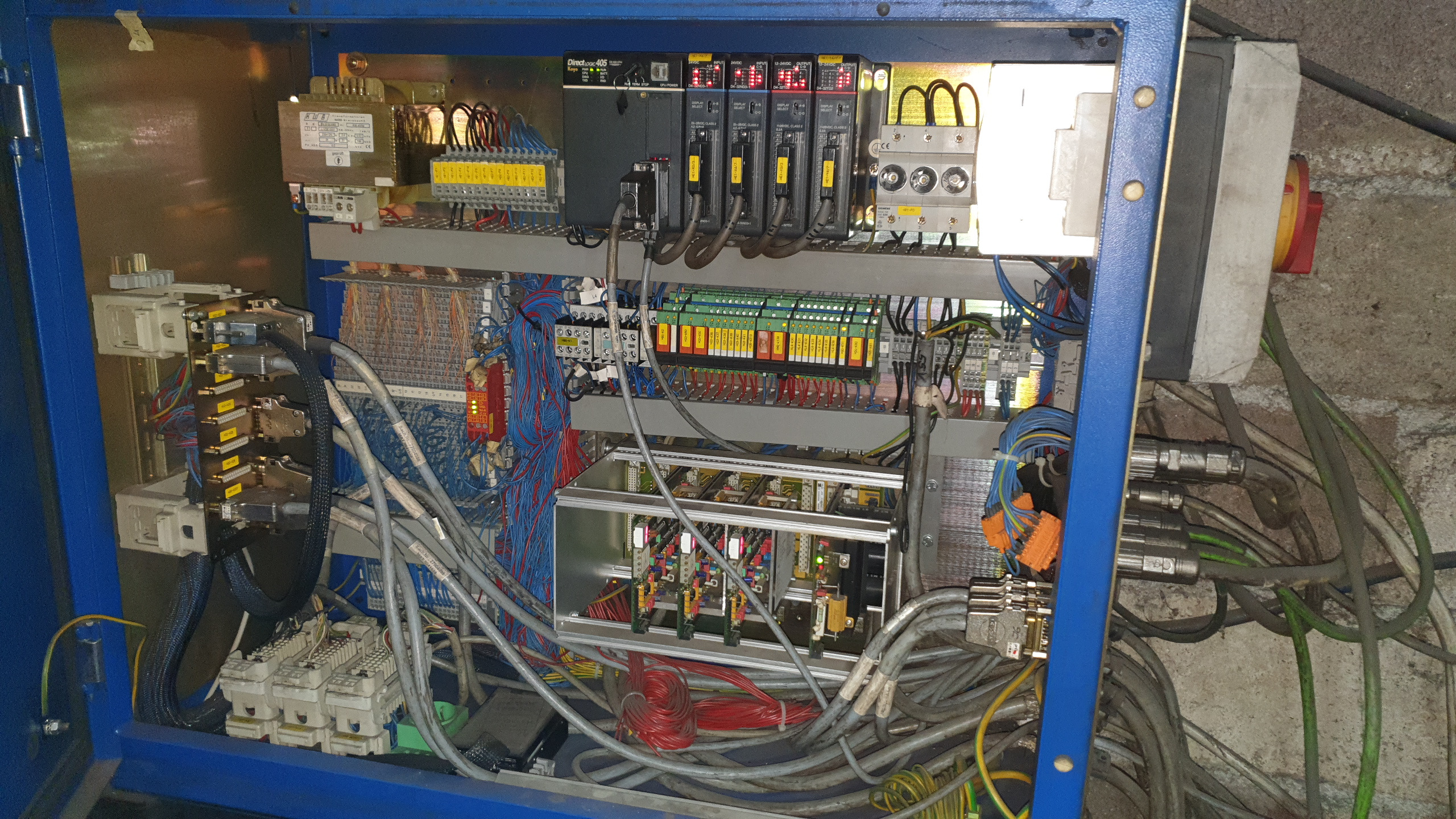

--The big monstrosity is also a Messer Cortina that was 12X3 meters but 3 meters of length went to the first machine so now it is 9X3M, it has a 400 Amp Hypertherm HT4400 that can not be used at full power due to power grid, also has Oxy Acetylene cutting, has at a guess about one metric ton of cabling and that is not exaggerated! It is in working order, it was fitted with a new Hypertherm PowerMax 45 lately ( imagine that ! ), old software and hardware causes more trouble than it is worth, so everything will be yanked out except the drives and motors. Will be retrofitted with Mesa 7i92 and Mesa 7i77 and THCAD. The first picture is just the main control box where the drives are, there are another 6 or more boxes of stuff around it. Oxy everything will also be removed. The PowerMax 45 will go to the first machine and this one will be fitted with PowerMax 65.

), old software and hardware causes more trouble than it is worth, so everything will be yanked out except the drives and motors. Will be retrofitted with Mesa 7i92 and Mesa 7i77 and THCAD. The first picture is just the main control box where the drives are, there are another 6 or more boxes of stuff around it. Oxy everything will also be removed. The PowerMax 45 will go to the first machine and this one will be fitted with PowerMax 65.

Both will be used for cutting 3mm thick sheets, and with those heavy gantries that will be quite a challenge! Will be removing everything not in use any more to lighten up as much as possible.

-both are Messer Cortina machines made in 2000 and 2004 respectively,

--one is 4X2 meters that has another 3 meters added so now it becomes 7X2 meters, last two pictures, it was bought as non working so everything is yanked out already, retrofitting it with Mesa 7i95, 3 of Gecko 320 DC servo drives and a stepper drive and motor for Z axis, will try to use encoders for both the drives and Mesa and report back how that works out. It had a Hypertherm 3070 Plasma system with O2 and N2 that will not be used, instead a Hypertherm PowerMax 45 will be installed with a Mesa THCAD.

--The big monstrosity is also a Messer Cortina that was 12X3 meters but 3 meters of length went to the first machine so now it is 9X3M, it has a 400 Amp Hypertherm HT4400 that can not be used at full power due to power grid, also has Oxy Acetylene cutting, has at a guess about one metric ton of cabling and that is not exaggerated! It is in working order, it was fitted with a new Hypertherm PowerMax 45 lately ( imagine that !

Both will be used for cutting 3mm thick sheets, and with those heavy gantries that will be quite a challenge! Will be removing everything not in use any more to lighten up as much as possible.

Attachments:

The following user(s) said Thank You: besriworld, zz912

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

11 Nov 2022 15:10 #256441

by Clive S

Replied by Clive S on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

11 Nov 2022 20:57 - 17 Mar 2024 14:18 #256463

by tommylight

Replied by tommylight on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

Pipes, some cabling, the O2/N2 equipment and valves, torch cable and torch, from the smaller one are alredy in my shop!

Hypertherm 3070 will come at a later date.

Not the machines though, both of them will not fit in my new shop even if it was empty!

Anyone interested in the Hypertherm HT4400 ? It is a 400 amp monster, probably weighs a ton.

I will try to take some pictures of the cabling and pipes just for gigless, it has half a meter wide cable chains, filled to the brim.

Gona have a blast removing all that!

Edit:

Attached configs for both machines, both use LinuxCNC 2.8.4

Hypertherm 3070 will come at a later date.

Not the machines though, both of them will not fit in my new shop even if it was empty!

Anyone interested in the Hypertherm HT4400 ? It is a 400 amp monster, probably weighs a ton.

I will try to take some pictures of the cabling and pipes just for gigless, it has half a meter wide cable chains, filled to the brim.

Gona have a blast removing all that!

Edit:

Attached configs for both machines, both use LinuxCNC 2.8.4

Last edit: 17 Mar 2024 14:18 by tommylight.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

15 Nov 2022 19:48 #256796

by tommylight

Replied by tommylight on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

The encoders are A/B/Z incremental ones with diferential outputs, so that made wiring to both Mesa and Gecko very easy, one side as single ended to Mesa, the other side has to be single ended to the Geckos, and left the indexes as diferential to Mesa 7i95, just in case.

A bit of tuning and all 3 joints/both axis are moving and tracking perfectly. This also helped with tuning Geckos better using the scope after setting feedback to encoders, one of them had a tad bit much Damp.

On to changing the Z motors on both machines...

A bit of tuning and all 3 joints/both axis are moving and tracking perfectly. This also helped with tuning Geckos better using the scope after setting feedback to encoders, one of them had a tad bit much Damp.

On to changing the Z motors on both machines...

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

16 Nov 2022 16:11 #256868

by tommylight

Replied by tommylight on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

I was told by the owner both machines have the same Z axis and same motors, they do not!

Big one has two Z axis that i have to yank out tomorrow to check what is inside, making reduction and mounts for new motors takes a lot of time, time i do not have.

Sorry for the lack of pictures, but the lighting conditions are pitifull there so everything looks terrible.

Big one has two Z axis that i have to yank out tomorrow to check what is inside, making reduction and mounts for new motors takes a lot of time, time i do not have.

Sorry for the lack of pictures, but the lighting conditions are pitifull there so everything looks terrible.

The following user(s) said Thank You: billykid

Please Log in or Create an account to join the conversation.

- billykid

-

- Offline

- Platinum Member

-

Less

More

- Posts: 472

- Thank you received: 81

20 Nov 2022 10:32 #257150

by billykid

Replied by billykid on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

Hi Tom you don't miss the fun! they are very demanding jobs that require time, a few years ago I did a similar job with a friend's two-axis cnc lathe with a 12-tool motorized turret but it took us 2 months!

I have always liked cnc machines, in the 80s as soon as I started working I reassembled two used boring machines with cnc olivetti CNZ huge all transistor plates and a delay line as memory, punched tapes and contraves for the quotas. inductosyn as a measure sometimes some chips cut them and I redid the connection with a wire. in the mid 90s they closed and I started a new assistance job for welding machines and plasma generators but at home I made a small cnc and now that I'm retired I also have a plasma and a 3d printer. good work

I have always liked cnc machines, in the 80s as soon as I started working I reassembled two used boring machines with cnc olivetti CNZ huge all transistor plates and a delay line as memory, punched tapes and contraves for the quotas. inductosyn as a measure sometimes some chips cut them and I redid the connection with a wire. in the mid 90s they closed and I started a new assistance job for welding machines and plasma generators but at home I made a small cnc and now that I'm retired I also have a plasma and a 3d printer. good work

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

20 Nov 2022 12:02 #257159

by tommylight

Replied by tommylight on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

Yea, these are going slow for my liking as i can work only 2 to 4 hours a day there.

Just removing cables took 5 of those short days, another day to tidy up the remaing ones.

The small one is fully installed, both axis tuned, loop closed in LinuxCNC as i never trusted Geckos G320 with their 128 encoder counts error bandwidth.

Limit switches are wired but i have to add some load to them, they are 2 wire ones.

And Z axis, mount a new motor or add an encoder to the existing motor.

In a few days, the work on the big one starts, way more cables to remove!

More fun!

Just removing cables took 5 of those short days, another day to tidy up the remaing ones.

The small one is fully installed, both axis tuned, loop closed in LinuxCNC as i never trusted Geckos G320 with their 128 encoder counts error bandwidth.

Limit switches are wired but i have to add some load to them, they are 2 wire ones.

And Z axis, mount a new motor or add an encoder to the existing motor.

In a few days, the work on the big one starts, way more cables to remove!

More fun!

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

22 Nov 2022 02:13 #257285

by tommylight

On the smaller one, took the Z motor out, removed the tacho, adding a 100PPR encoder, and installing another Gecko 320, tomorrow, had a headache today, i can not do complicated stuff while head is hurting.

Replied by tommylight on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

Surprise, surprise, both have what look like rolled ballscrews, 16mm ones! Daymn, those just have the chance of being very easy to replace the motors.Big one has two Z axis that i have to yank out tomorrow to check what is inside, .....

On the smaller one, took the Z motor out, removed the tacho, adding a 100PPR encoder, and installing another Gecko 320, tomorrow, had a headache today, i can not do complicated stuff while head is hurting.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

23 Nov 2022 02:55 #257421

by tommylight

Replied by tommylight on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

How the hell is Samsung Note 20 Ultra able to take such good pictures, it was to damn dark there.

I took the fist picture in the original post at day time with a Note 9, they look like cr@p.

Got the sensors wired today, homing, tandem axis/joints, limits, all done. Work area got to be 2450x6550mm with the extension they did.

Also mounted the existing servo motor on the Z axis and added an encoder, it was a very tight fit, but we did shoehorn it there!

They were extremely happy today jogging the machine around, had to drag the younger one from the machine just to take pictures.

I took the fist picture in the original post at day time with a Note 9, they look like cr@p.

Got the sensors wired today, homing, tandem axis/joints, limits, all done. Work area got to be 2450x6550mm with the extension they did.

Also mounted the existing servo motor on the Z axis and added an encoder, it was a very tight fit, but we did shoehorn it there!

They were extremely happy today jogging the machine around, had to drag the younger one from the machine just to take pictures.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

25 Nov 2022 10:37 #257602

by tommylight

Replied by tommylight on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

The first/smaller one is almost done, need to add voltage dividers and zener diodes to newly installed encoder on Z axis, and add 2 of 1MOhm resistors for THCAD.

All the sensors are wired and tested, float, breakaway, both Z limits, both X limits, both Y limits.

Hypertherm is also wired, torch on works, arc ok works, but some dumb a$$ yanked out the divider and wired the torch voltage, i have only THCAD 10's.

There were sparks as we tested arc ok by holding a plate near the torch, so the only thing left is more sparks tomorrow!

Regards,

Tom.

All the sensors are wired and tested, float, breakaway, both Z limits, both X limits, both Y limits.

Hypertherm is also wired, torch on works, arc ok works, but some dumb a$$ yanked out the divider and wired the torch voltage, i have only THCAD 10's.

There were sparks as we tested arc ok by holding a plate near the torch, so the only thing left is more sparks tomorrow!

Regards,

Tom.

Please Log in or Create an account to join the conversation.

Time to create page: 0.342 seconds