Retrofit of 2 Messer Cortina DS Plasma cutting machines

- billykid

-

- Offline

- Platinum Member

-

Less

More

- Posts: 472

- Thank you received: 81

26 Nov 2022 17:10 #257689

by billykid

Replied by billykid on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

done quickly !!! What gear ratio are you using for the z axis? I put a small reducer but it has a small backlash and deceives the thcad... I'll have to put the toothed pulley and belt

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

26 Nov 2022 23:19 #257711

by tommylight

Replied by tommylight on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

26 Nov 2022 23:23 #257712

by tommylight

Replied by tommylight on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

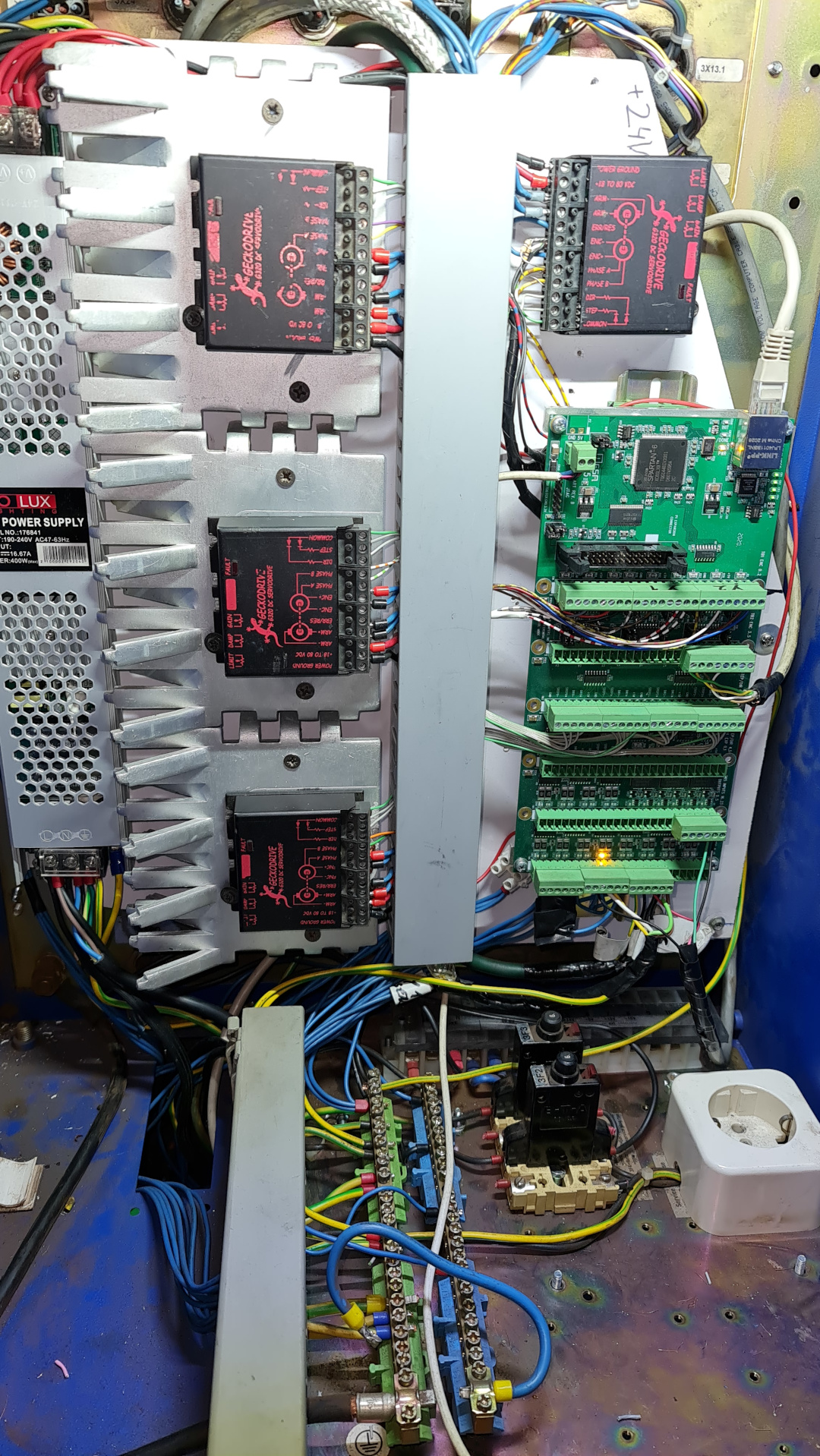

I used the existing DC servo motor and reduction, yanked out the tacho and bolted on an encoder. Also added another Gecko G320 as can be seen in the pictures to drive the Z axis.What gear ratio are you using for the z axis? I put a small reducer but it has a small backlash and deceives the thcad... I'll have to put the toothed pulley and belt

Please Log in or Create an account to join the conversation.

- billykid

-

- Offline

- Platinum Member

-

Less

More

- Posts: 472

- Thank you received: 81

27 Nov 2022 11:04 #257726

by billykid

Replied by billykid on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

You are on point!

your reducer will be zero backlash being expected for plasma with thc I think. I used the reducer from a miller spoolmatic torch... i have a dc motor with 512ppr encoder and mesa 7i30, i will do the reduction with pulley.

your reducer will be zero backlash being expected for plasma with thc I think. I used the reducer from a miller spoolmatic torch... i have a dc motor with 512ppr encoder and mesa 7i30, i will do the reduction with pulley.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

27 Nov 2022 22:13 #257776

by tommylight

Replied by tommylight on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

How much does the torch move up or down from that backlash?

The weight of the torch should be enough to keep it always pressed against the teeth, so i see not reason for it now working, at any backlash amount.

The weight of the torch should be enough to keep it always pressed against the teeth, so i see not reason for it now working, at any backlash amount.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

27 Nov 2022 22:20 #257779

by tommylight

Replied by tommylight on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

The finished machine was busy today cutting 10mm thick plate all day long, not a single hiccup.

Meanwhile i was yanking out everything from the control box and the power box on the second/bigger machine, turns out i might be better off just yanking out the servo drive box/holder and mounting it on the back of the control panel.

Otherwise, again, the amount of useless wiring on this machine is astonishing, example, encoder wires go from motors that are on the gantry to the power box with 25 meter long cables, go in through connectors, reroute to other connectors and from those go through other 25 meter long cables to the control panel ... that is on the GANTRY!!!!

This is gona be a hoot !

-

We sell wires, we sell lots and lots of wires.....

Meanwhile i was yanking out everything from the control box and the power box on the second/bigger machine, turns out i might be better off just yanking out the servo drive box/holder and mounting it on the back of the control panel.

Otherwise, again, the amount of useless wiring on this machine is astonishing, example, encoder wires go from motors that are on the gantry to the power box with 25 meter long cables, go in through connectors, reroute to other connectors and from those go through other 25 meter long cables to the control panel ... that is on the GANTRY!!!!

This is gona be a hoot !

-

We sell wires, we sell lots and lots of wires.....

The following user(s) said Thank You: billykid

Please Log in or Create an account to join the conversation.

- billykid

-

- Offline

- Platinum Member

-

Less

More

- Posts: 472

- Thank you received: 81

28 Nov 2022 12:39 #257846

by billykid

Replied by billykid on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

the backlash is about 0.12mm about 1 volt of voltage. at low gain it works ok but is slow to respond, if you turn it up a little it starts to rock up and down. the next few days, I put the pulleys and via the reducer, I'm sure I'll solve it.

it's true once it was all full of cables, even my friend's lathe once finished left a box of cables.

it's true once it was all full of cables, even my friend's lathe once finished left a box of cables.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

09 Dec 2022 12:22 #258994

by tommylight

Replied by tommylight on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

Took the drives from the smaller machine to my shop, found out the wiring for everything, mounted the Mesa 7i77 on one side of the drive box and 2 power supplies to the other side as the drives need 24V and +-15V to work, Mesa 6i25 is on the PC, installed everything inside the existing console but it is getting tight!

Had to cut the motor, encoder, and sensor wires and reroute them to the console, so today a lot of wiring ahead.

Will take some pictures and post here later.

Had to cut the motor, encoder, and sensor wires and reroute them to the console, so today a lot of wiring ahead.

Will take some pictures and post here later.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

11 Dec 2022 20:31 #259218

by tommylight

Replied by tommylight on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

Wires are cut, a bunch is removed, the drive box with Mesa 7i77 and 2 power supplies attached to it is also installed inside the existing console, PC with Mesa 6i25 installed and everything wired and tested, so today was encoder wiring and tuning day!

Took some running back and forth over the machine to disengage and engage the Y2 motor twice, but all three drives are tuned and running!

Was a good day for tuning, also managed to tune the Mazak X and Z motors drives.

Tomorrow more "removing cabling" and extending one of the encoder cables, i cut it to short, shame on me, then removing the existing Z axis motors (has 2 Z axis), trying to shoehorn a stepper motor, add a drive for it and another power supply, wire in the THCAD... hmmm with 2 to 4 hour days, to much???

I should do some pictures and videos, i think...

Took some running back and forth over the machine to disengage and engage the Y2 motor twice, but all three drives are tuned and running!

Was a good day for tuning, also managed to tune the Mazak X and Z motors drives.

Tomorrow more "removing cabling" and extending one of the encoder cables, i cut it to short, shame on me, then removing the existing Z axis motors (has 2 Z axis), trying to shoehorn a stepper motor, add a drive for it and another power supply, wire in the THCAD... hmmm with 2 to 4 hour days, to much???

I should do some pictures and videos, i think...

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

27 Jan 2023 12:30 #263002

by tommylight

Replied by tommylight on topic Retrofit of 2 Messer Cortina DS Plasma cutting machines

Sorry for the delay, the second one was finished quite a while back in 2022, but still waiting for the plasma source to do the final tuning and testing.

Also, the machine has been moved to another place in the shop, so aligning the rails is taking forever for them. I did warn them that the rails were off by quite a bit in the old place as i did notice that during tuning of the tandem axis.

Anyone need a 400A Hypertherm plasma source for cheap in Europe?

Also, the machine has been moved to another place in the shop, so aligning the rails is taking forever for them. I did warn them that the rails were off by quite a bit in the old place as i did notice that during tuning of the tandem axis.

Anyone need a 400A Hypertherm plasma source for cheap in Europe?

Please Log in or Create an account to join the conversation.

Time to create page: 0.151 seconds