CNC Baseboard Coping Machine

- thadwald

- Offline

- Premium Member

-

Less

More

- Posts: 111

- Thank you received: 10

02 Apr 2023 01:21 - 02 Apr 2023 02:08 #268039

by thadwald

CNC Baseboard Coping Machine was created by thadwald

Here's a look at a small CNC machine that I've been working on. It's a device that copes baseboard. I do believe I invented it but let me know if you think otherwise.

The hardware is mostly self-built. It consists of a pair small belt-driven xy cantilevered axes built around a compact Dewalt router. For metrology it uses a Keyence laser displacement sensor.

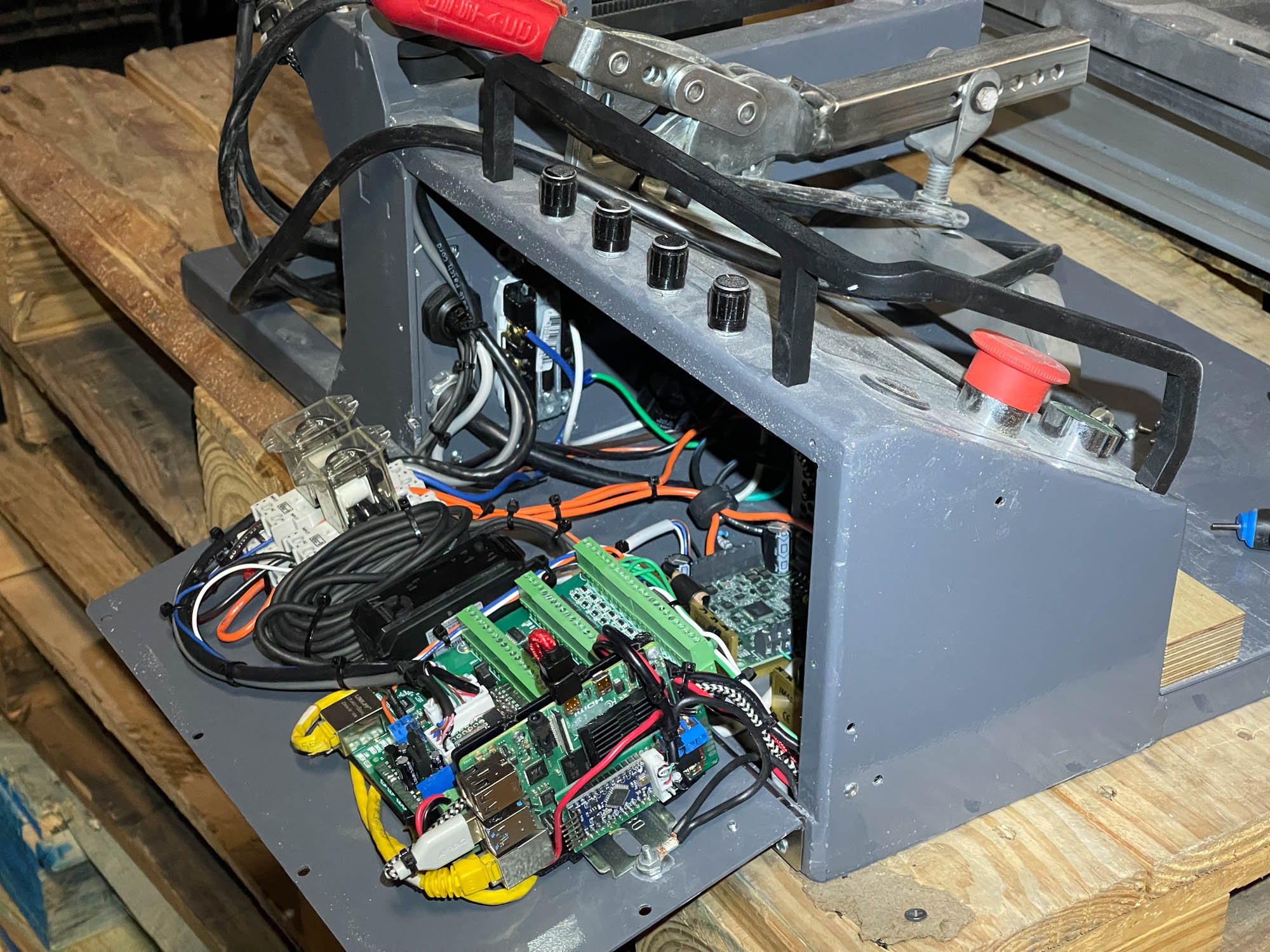

The system is run by a Pi-4 and MESA 7i96, and a pair of stepper drivers. A pair of relays controls power to motor drivers and to a 110v receptacle for running the Dewalt router and a vacuum. It includes a voltage-frequency converter for interfacing the displacement sensor. 5V power for the Pi and the MESA board is controlled by an Arduino that monitors the power switch and operates a P-channel MOSFET.

The UI includes a 7-inch touchscreen, several small (finger-sized) MPGs, start button, estop, and power switch.

The gcode for the coping profile is generated on-board by scanning a piece of baseboard with a precision laser displacement sensor. After scanning, geometry is presented in a custom UI for some simple smoothness tuning, end treatment, and optional gouging to compensate for profile features that cannot be accommodated by the cutter diameter.

Once the profile is built, vertical and angle offsets can be set on the fly via the MPGs to compensate for tipped baseboard.

Thanks to all the people on this forum who helped me with this project.

ToDo: add a 45° router adjustment so it can also cope crown moulding.

The hardware is mostly self-built. It consists of a pair small belt-driven xy cantilevered axes built around a compact Dewalt router. For metrology it uses a Keyence laser displacement sensor.

The system is run by a Pi-4 and MESA 7i96, and a pair of stepper drivers. A pair of relays controls power to motor drivers and to a 110v receptacle for running the Dewalt router and a vacuum. It includes a voltage-frequency converter for interfacing the displacement sensor. 5V power for the Pi and the MESA board is controlled by an Arduino that monitors the power switch and operates a P-channel MOSFET.

The UI includes a 7-inch touchscreen, several small (finger-sized) MPGs, start button, estop, and power switch.

The gcode for the coping profile is generated on-board by scanning a piece of baseboard with a precision laser displacement sensor. After scanning, geometry is presented in a custom UI for some simple smoothness tuning, end treatment, and optional gouging to compensate for profile features that cannot be accommodated by the cutter diameter.

Once the profile is built, vertical and angle offsets can be set on the fly via the MPGs to compensate for tipped baseboard.

Thanks to all the people on this forum who helped me with this project.

ToDo: add a 45° router adjustment so it can also cope crown moulding.

Attachments:

Last edit: 02 Apr 2023 02:08 by thadwald. Reason: Edit: added some detail of the inside

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21287

- Thank you received: 7267

02 Apr 2023 01:37 #268043

by tommylight

Replied by tommylight on topic CNC Baseboard Coping Machine

Very nice, indeed, thank you.

But, you really should have not used "invented" as nothing there is invented, just modified to fit your needs and you did a great job with that.

I absolutely and unequivocally know for sure nothing was invented since Nikola Tesla died.

But, you really should have not used "invented" as nothing there is invented, just modified to fit your needs and you did a great job with that.

I absolutely and unequivocally know for sure nothing was invented since Nikola Tesla died.

Please Log in or Create an account to join the conversation.

Time to create page: 0.107 seconds