"From scraps were ye made, and scraps ye shall be!"

- pgf

- Offline

- Premium Member

-

Less

More

- Posts: 125

- Thank you received: 23

29 Apr 2025 11:57 #327285

by pgf

"From scraps were ye made, and scraps ye shall be!" was created by pgf

I've mentioned a few times that my DIY mill is very old (32 years), and probably some of you have looked at my pictures in the past. But bear with me -- this is the last post I'll likely make about this mill.

I'd been making a bunch of improvements lately (new RPi controller, mesa card interface, M3/M5 spindle control, M7/M9 vacuum control, some new hold-down techniques, automatic homing, better E-switch, probably some other stuff). It had been a while since I'd spent much time on it, so I was having a lot of fun.

My wife asked for help on a project, and I'm always happy to oblige, of course. We designed what she needed, and I set about cutting it. After a couple of false starts over a couple of days, the rough draft carve looked good. She needed two good copies, and the first of those looked great!

The second one, sadly, broke my Z axis. Not the project's fault, and not the mill's -- we'd have to blame the designer: me. Not only did the Z axis driven coupling come loose from the carriage, but because of the poor design, there was no way to fix it without a really huge amount of dis/reassembly. Which I really couldn't face. One too many times, straw that broke the camel, etc. I was done.

So I've ordered a new mill -- I'm expecting a Sainsmart Genmitsu 4040 Pro Max on my doorstep any day now. I'm very excited about it. And now if it breaks, I can blame someone else!

But I had to make space. This only took an hour or so, and it was actually very cathartic.

A note about the design. Using drawer slides to support the X/Y carriages, as the original plans called for, worked far better than you'd expect. High quality slides are specifically made to keep drawers from sagging... at all. So if you put them on their side, and use them over a shorter distance, they're not true "linear rail" quality, but they're very, very good, especially for a DIY'er. They didn't work well on the Z axis because unlike X and Y, Z undergoes forces in all directions, not just side to side. I eventually rebuilt that axis using actual linear rails, but the rest of the Z design wasn't so great. Ahem. As we've learned.)

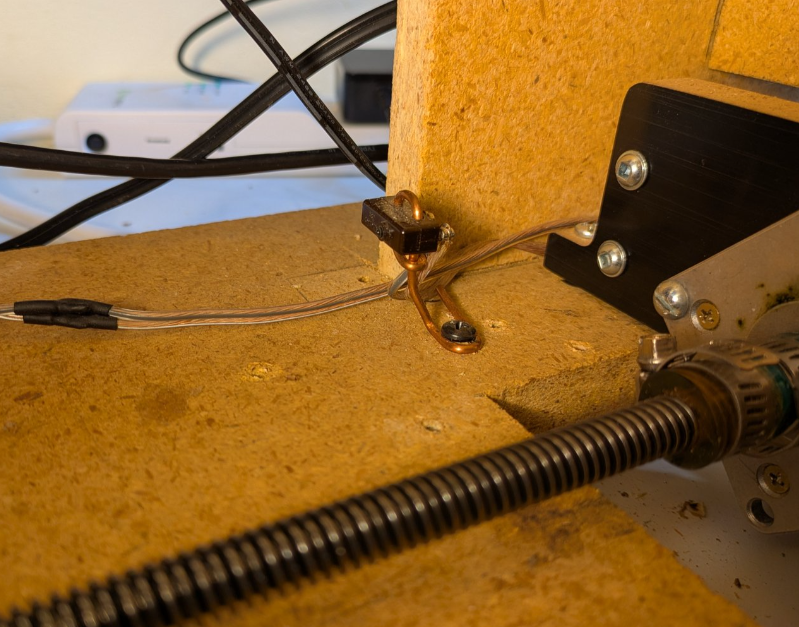

Anyway, I think one of the things I'll miss most about that mill is the limit switches. You've gotta admit, this is cute, right?

I'd been making a bunch of improvements lately (new RPi controller, mesa card interface, M3/M5 spindle control, M7/M9 vacuum control, some new hold-down techniques, automatic homing, better E-switch, probably some other stuff). It had been a while since I'd spent much time on it, so I was having a lot of fun.

My wife asked for help on a project, and I'm always happy to oblige, of course. We designed what she needed, and I set about cutting it. After a couple of false starts over a couple of days, the rough draft carve looked good. She needed two good copies, and the first of those looked great!

The second one, sadly, broke my Z axis. Not the project's fault, and not the mill's -- we'd have to blame the designer: me. Not only did the Z axis driven coupling come loose from the carriage, but because of the poor design, there was no way to fix it without a really huge amount of dis/reassembly. Which I really couldn't face. One too many times, straw that broke the camel, etc. I was done.

So I've ordered a new mill -- I'm expecting a Sainsmart Genmitsu 4040 Pro Max on my doorstep any day now. I'm very excited about it. And now if it breaks, I can blame someone else!

But I had to make space. This only took an hour or so, and it was actually very cathartic.

A note about the design. Using drawer slides to support the X/Y carriages, as the original plans called for, worked far better than you'd expect. High quality slides are specifically made to keep drawers from sagging... at all. So if you put them on their side, and use them over a shorter distance, they're not true "linear rail" quality, but they're very, very good, especially for a DIY'er. They didn't work well on the Z axis because unlike X and Y, Z undergoes forces in all directions, not just side to side. I eventually rebuilt that axis using actual linear rails, but the rest of the Z design wasn't so great. Ahem. As we've learned.)

Anyway, I think one of the things I'll miss most about that mill is the limit switches. You've gotta admit, this is cute, right?

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

29 Apr 2025 14:20 #327294

by tommylight

Replied by tommylight on topic "From scraps were ye made, and scraps ye shall be!"

The E-Stop was cool!

Please Log in or Create an account to join the conversation.

- pgf

- Offline

- Premium Member

-

Less

More

- Posts: 125

- Thank you received: 23

29 Apr 2025 15:28 #327299

by pgf

Replied by pgf on topic "From scraps were ye made, and scraps ye shall be!"

Thanks.  I was hoping to use the "emergency off" switch plate from our old oil burner, but I guess I tossed it at some point. So I "had" to paint another one red.

I was hoping to use the "emergency off" switch plate from our old oil burner, but I guess I tossed it at some point. So I "had" to paint another one red.

It's a double pole switch. One half turns off the spindle's outlet, the other half triggers an e-stop input on the Mesa.

It's a double pole switch. One half turns off the spindle's outlet, the other half triggers an e-stop input on the Mesa.

Please Log in or Create an account to join the conversation.

Time to create page: 0.155 seconds