- Configuring LinuxCNC

- Advanced Configuration

- Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

07 May 2025 09:25 #327932

by Aciera

Replied by Aciera on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

I'll try to open it in solidworks and reexport it as Ascii.

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 19

07 May 2025 10:41 #327936

by jochen91

Replied by jochen91 on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

In case it didn't work in solidworks here it is in ASCII format. In Fusion you have to take some extra steps to export it in ASCII format.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

07 May 2025 11:54 #327938

by Aciera

Replied by Aciera on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Worked fine (had to scale it 10x).

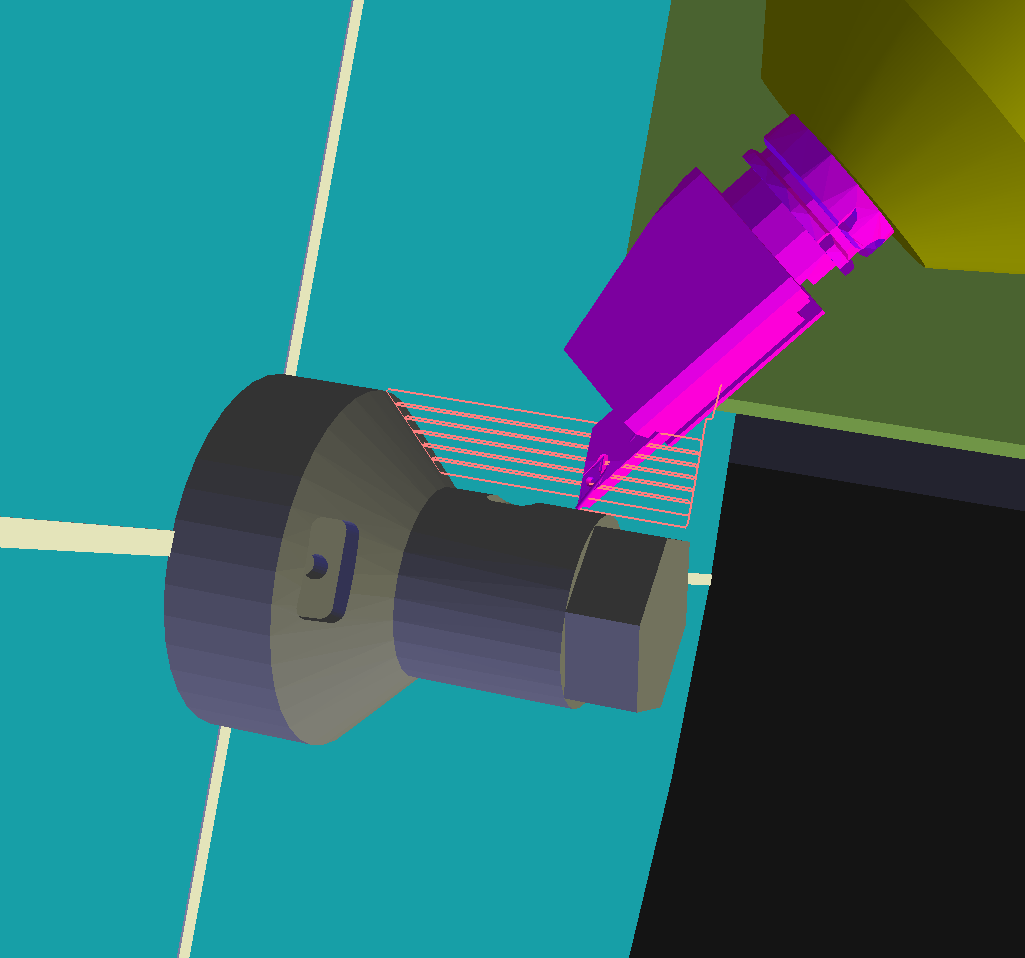

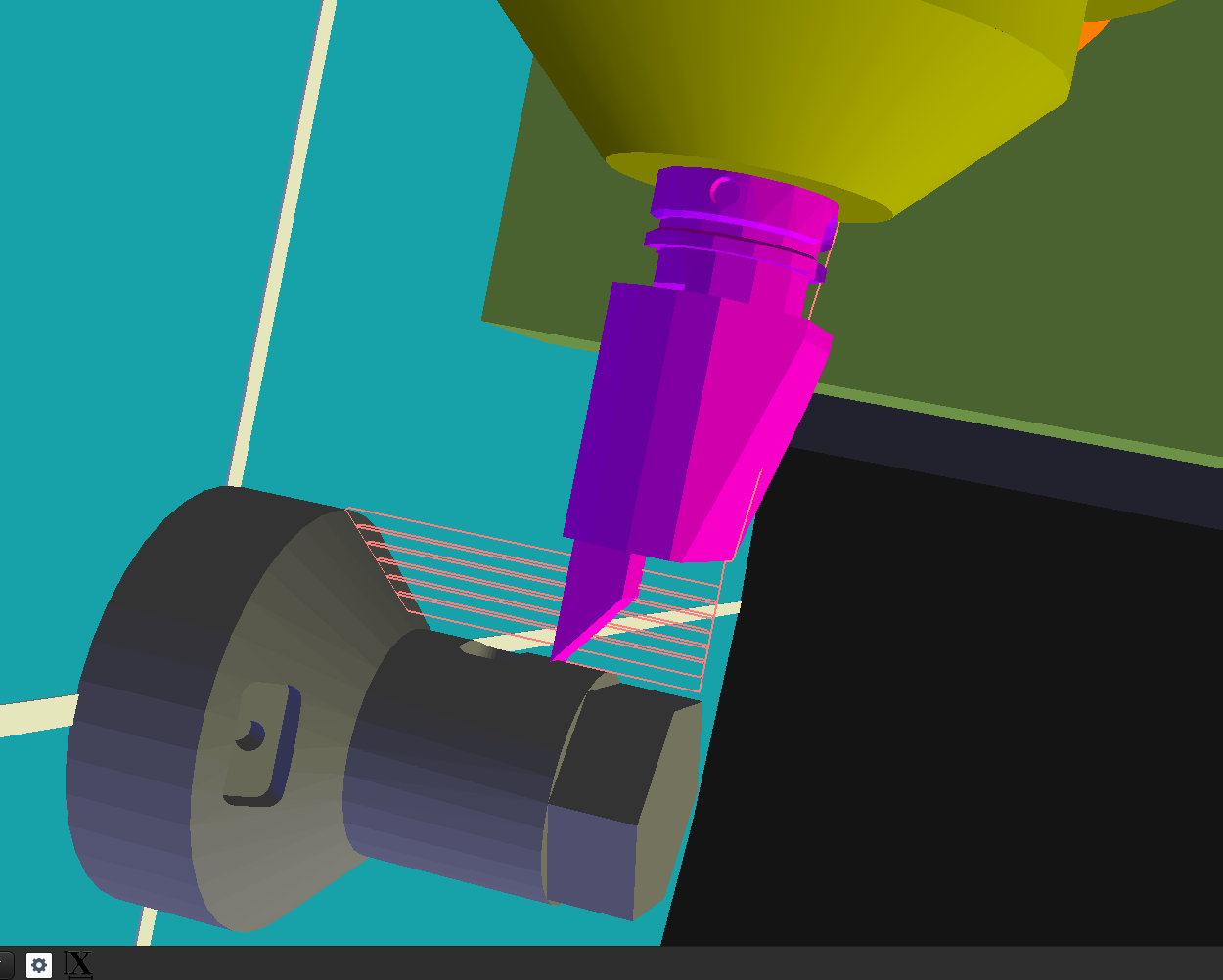

This is the modified turning operation (which works in TCP mode now).

;O1001

G0 G18 G21 G40 G54 G80 G99

g69

g7

;N1(TURNJNG)

G0 G53 X0 Y0 ;G0 G28 U0. V0.

G53 Z0 b0 c0 ;G53 Z0.

M429

;M90

G54

;G99 G18 M34

;G50 S5000

;T0200

m61 q101 g43 ;M6 T0200

;T0100 (NEXT TOOL)

;T0202

M8

G97 S374 M3 $0 ;P11

G0 B-40 ;G400 B0. I1. R3.

G0 Z5.

X170. Y0.

G96 S200 M3 $0 ;P11

Z2.5

X140.

G1 Z-130.327 F1000

X150. Z-135.327

X152. Z-134.327

G0 Z2.5

X130.

G1 Z-125.327

X140. Z-130.327

X142. Z-129.327

G0 Z2.5

X120.

G1 Z-120.327

X130. Z-125.327

X132. Z-124.327

G0 Z2.5

X110.

G1 Z-115.327

X120. Z-120.327

X122. Z-119.327

G0 Z2.5

X100.

G1 Z-110.327

X110. Z-115.327

X112. Z-114.327

G0 Z2.5

X90.1

G1 Z-105.377

X100. Z-110.327

X102. Z-109.327

G0 Z2.5

X80.2

G1 Z-100.427

X90.1 Z-105.377

X92.1 Z-104.377

G0 X170.

Z5.

G97 S374 M3 $0 ;P11

M9

G0 G53 X0 Y0 ;G0 G28 U0. V0.

G53 Z0 ;G53 Z0.

g8

Note the tilted b-axis to compensate for the chosen tool:

Alternatively the operator could also orient to tool spindle 180° (m19 r180) and run it with b0 and the work spindle turning in the opposite direction:

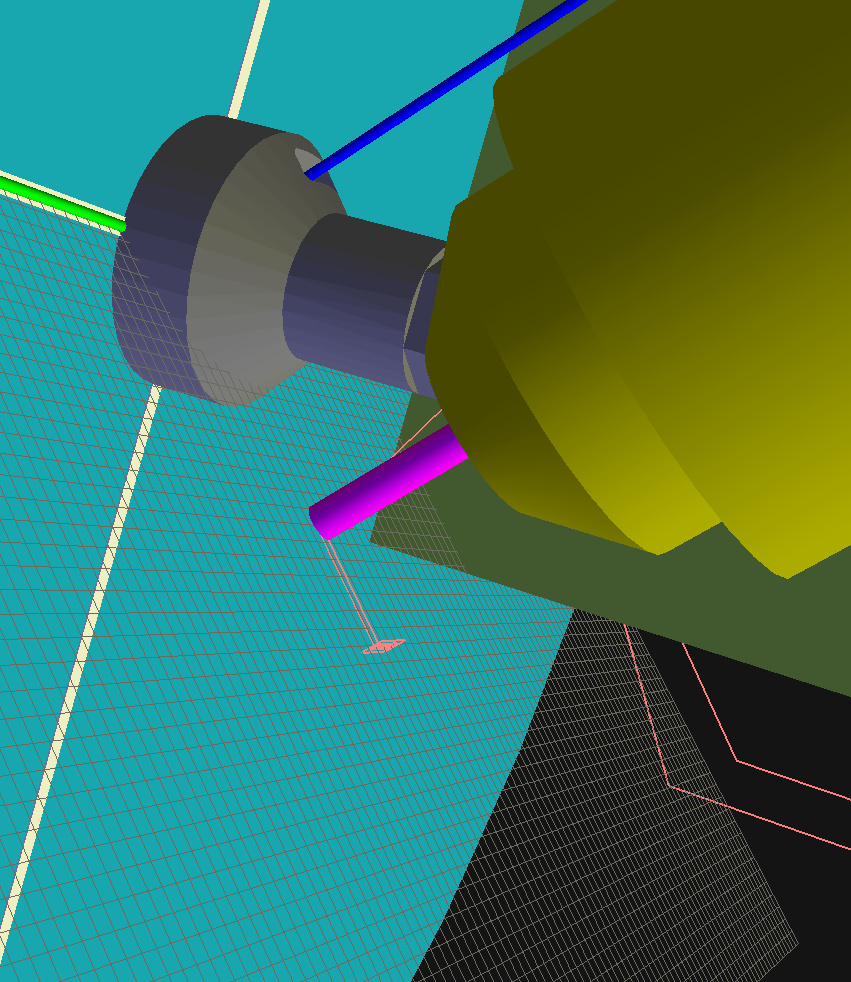

As already pointed out, the milling operation using 'G19' does not work:

Is there a way to change this to 'regular' G17 in the PP?

This is the modified turning operation (which works in TCP mode now).

Warning: Spoiler!

;O1001

G0 G18 G21 G40 G54 G80 G99

g69

g7

;N1(TURNJNG)

G0 G53 X0 Y0 ;G0 G28 U0. V0.

G53 Z0 b0 c0 ;G53 Z0.

M429

;M90

G54

;G99 G18 M34

;G50 S5000

;T0200

m61 q101 g43 ;M6 T0200

;T0100 (NEXT TOOL)

;T0202

M8

G97 S374 M3 $0 ;P11

G0 B-40 ;G400 B0. I1. R3.

G0 Z5.

X170. Y0.

G96 S200 M3 $0 ;P11

Z2.5

X140.

G1 Z-130.327 F1000

X150. Z-135.327

X152. Z-134.327

G0 Z2.5

X130.

G1 Z-125.327

X140. Z-130.327

X142. Z-129.327

G0 Z2.5

X120.

G1 Z-120.327

X130. Z-125.327

X132. Z-124.327

G0 Z2.5

X110.

G1 Z-115.327

X120. Z-120.327

X122. Z-119.327

G0 Z2.5

X100.

G1 Z-110.327

X110. Z-115.327

X112. Z-114.327

G0 Z2.5

X90.1

G1 Z-105.377

X100. Z-110.327

X102. Z-109.327

G0 Z2.5

X80.2

G1 Z-100.427

X90.1 Z-105.377

X92.1 Z-104.377

G0 X170.

Z5.

G97 S374 M3 $0 ;P11

M9

G0 G53 X0 Y0 ;G0 G28 U0. V0.

G53 Z0 ;G53 Z0.

g8

Note the tilted b-axis to compensate for the chosen tool:

Alternatively the operator could also orient to tool spindle 180° (m19 r180) and run it with b0 and the work spindle turning in the opposite direction:

As already pointed out, the milling operation using 'G19' does not work:

Is there a way to change this to 'regular' G17 in the PP?

Attachments:

The following user(s) said Thank You: besriworld, jochen91

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

07 May 2025 12:12 #327942

by Aciera

Replied by Aciera on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Attachments:

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 19

07 May 2025 12:13 #327943

by jochen91

Replied by jochen91 on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

I think in regards to modifying the PP we are totally free. I've just used to Doosan PP to have something at hand. It definitely needs to be modified and if that includes G17... than that's the way it has to be.

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 19

07 May 2025 12:15 - 07 May 2025 12:19 #327944

by jochen91

Replied by jochen91 on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

"makes me wonder if you can get the CAM so use 'D0':"

Should be no problem.

For now it needs to be done manually. I have a contact at hand who can modify the PP to our preferences. We just need to get the LCNC side going.

I do list all the changes that need to be done to the Doosan PP. My contact will then implement everything.

Should be no problem.

For now it needs to be done manually. I have a contact at hand who can modify the PP to our preferences. We just need to get the LCNC side going.

I do list all the changes that need to be done to the Doosan PP. My contact will then implement everything.

Last edit: 07 May 2025 12:19 by jochen91.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

07 May 2025 15:27 - 07 May 2025 16:05 #327950

by Aciera

Replied by Aciera on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

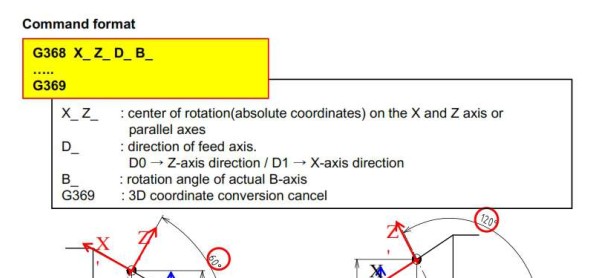

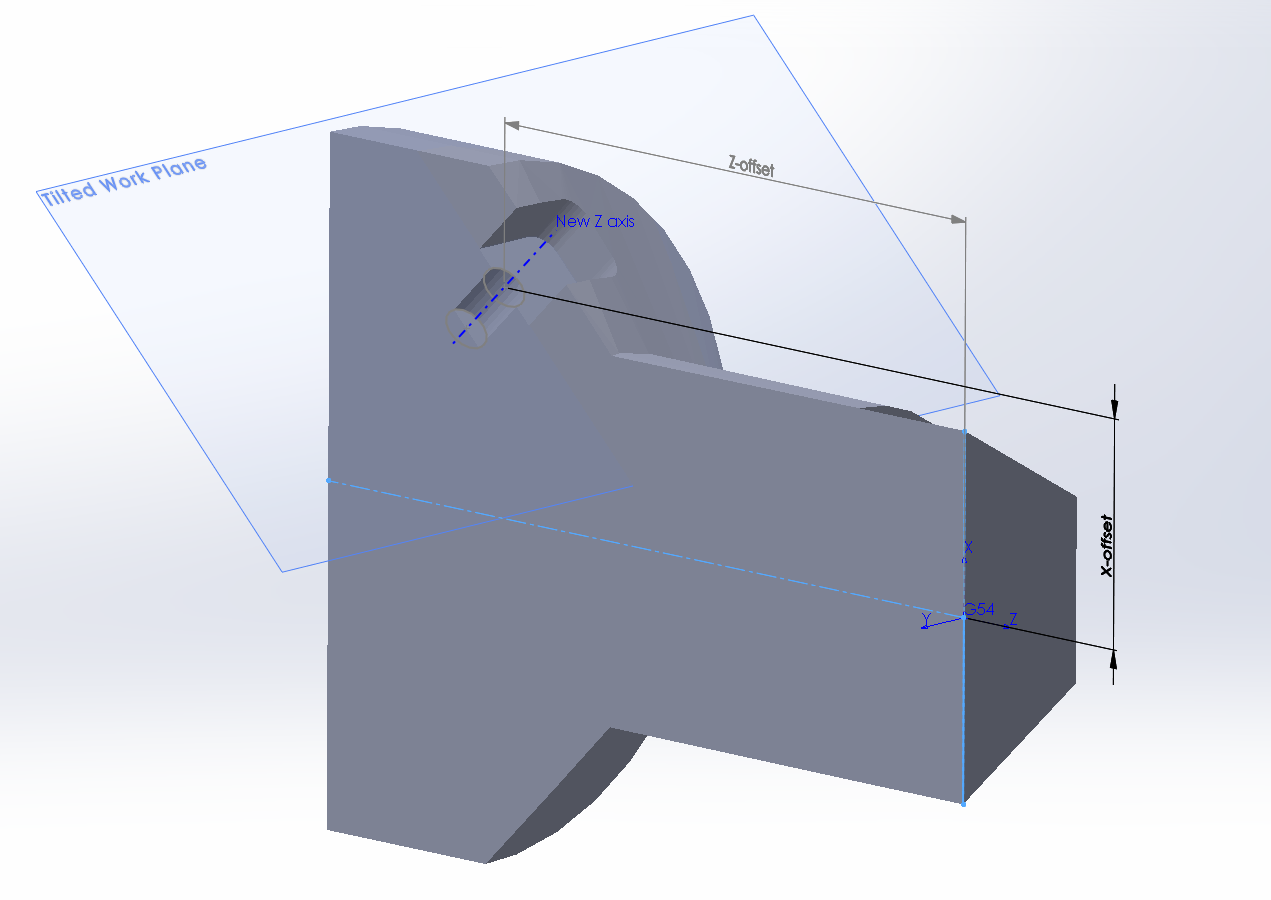

I see. I'm not very familiar with editing post processors so I have no idea what's possible. I've made a sketch to give you an idea of how Tilted Work Plane (TWP) would work in the example part.

What we need is the offset from the current WCS (G54) to the new origin of the TWP. After that we can use regular 3axis gcode to mill the feature on the inclined plane.

Note that the g68.3 command accepts an optional 'R' word to change the direction of the new X axis.

What we need is the offset from the current WCS (G54) to the new origin of the TWP. After that we can use regular 3axis gcode to mill the feature on the inclined plane.

Note that the g68.3 command accepts an optional 'R' word to change the direction of the new X axis.

Attachments:

Last edit: 07 May 2025 16:05 by Aciera.

The following user(s) said Thank You: jochen91

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 19

07 May 2025 19:49 - 09 May 2025 05:22 #327955

by jochen91

Replied by jochen91 on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

I talked with my contact and he said its possible (he even did it before).

Edit: I attached a G-Code sample from him, that was generated by one of his posts.

Edit: I attached a G-Code sample from him, that was generated by one of his posts.

Last edit: 09 May 2025 05:22 by jochen91.

The following user(s) said Thank You: Aciera

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

10 May 2025 16:14 - 11 May 2025 19:17 #328156

by Aciera

Replied by Aciera on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Here is the promised sim config:

To test:

1. unzip

2. 'halcompile --install' the enclosed 'mazak_integrex_200y_kins.comp'

3. start 'mazak-integrex-200y' config and run the preloaded gcode program

If you have any questions, which is likely, just ask.

Text from the enclosed README file:

To test:

1. unzip

2. 'halcompile --install' the enclosed 'mazak_integrex_200y_kins.comp'

3. start 'mazak-integrex-200y' config and run the preloaded gcode program

If you have any questions, which is likely, just ask.

Text from the enclosed README file:

Experimental simulation of a 5axis Mill/Turn machine (eg MAZAK Integrex 200Y)

Implemented Gcodes:

- 'G67 B': Moves the B-axis to the 'B'-word position and activates 'HALF TCP Lathe' mode.

- 'G68 B (X Y Z)': Moves the B-axis to the 'B'-word position then defines and activates a work plane perpendicular the this current tool orientation with the origin at the current WCS (optionally offset by any [X,Y,Z]-Words). This will change WCS to 'G59' where the transformed work offset values have been written to (ie the prior values stored in G59 will be lost!).

- 'G68.1 (X Y Z)': Defines and activates a work plane perpendicular the the current tool orientation with the origin at the current WCS (optionally offset by any [X,Y,Z]-Words). For change to WCS see 'G68'

- 'G69': Cancels the work plane set by 'G68' and (currently) switches back to 'G54'.

NOTES:

- This config defines the work-spindle as '$0' and the tool-spindle as '$1'. Example: 'M19 $1 R90' will orient the tool-spindle to 90°. (For real hardware it is recommended to use the spindle encoder-position instead of using 'spindle.1.orient-angle'.)

- 'HALF/FULL TCP MILL/LATHE' modes include tracking of tool-spindle rotation.

- 'HALF TCP MILL/LATHE' modes do not track the work spindle rotation, this is intended behavior.

- 'FULL TCP MILL' mode will track all rotations.

- Tool-offsets must only be changed in 'Identity' mode as it may cause sudden joint movements otherwise.

- Lathe tools must only be used in 'Identity' or 'HALF TCP Lathe' mode.

- Mill tools must only be used in 'HALF/FULL TCP Mill' or 'TWP' mode.

- Due to easier abort handling we currently restrict the use of twp to G54 as LinuxCNC seems to revert to G54 as the default system.

Abort behavior can be handled by using a subroutine defined in the ini file under [RS274NGC]ON_ABORT_COMMAND'.

- The TWP remap code in this config does not implement virtual rotations (ie no optional 'R' word).Attachments:

Last edit: 11 May 2025 19:17 by Aciera. Reason: Edit 2: Bring back the TWP button on the panel for tool retraction

The following user(s) said Thank You: tommylight, besriworld, jochen91

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

11 May 2025 09:17 - 11 May 2025 09:21 #328193

by Aciera

Replied by Aciera on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Please note the update regarding tool-spindle orientation in the post above.

Also note that there is a sim config for fanuc style tool change and tool-wear, which you may find interesting:

github.com/LinuxCNC/linuxcnc/tree/master...im/axis/lathe-fanucy

Also note that there is a sim config for fanuc style tool change and tool-wear, which you may find interesting:

github.com/LinuxCNC/linuxcnc/tree/master...im/axis/lathe-fanucy

Last edit: 11 May 2025 09:21 by Aciera.

The following user(s) said Thank You: jochen91

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Advanced Configuration

- Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Time to create page: 0.257 seconds