- Configuring LinuxCNC

- Advanced Configuration

- freelancer needed to create a routine for ATC tool change (rackchange)

freelancer needed to create a routine for ATC tool change (rackchange)

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 412

- Thank you received: 93

12 Dec 2025 00:44 - 12 Dec 2025 00:46 #339992

by Masiwood123

Replied by Masiwood123 on topic freelancer needed to create a routine for ATC tool change (rackchange)

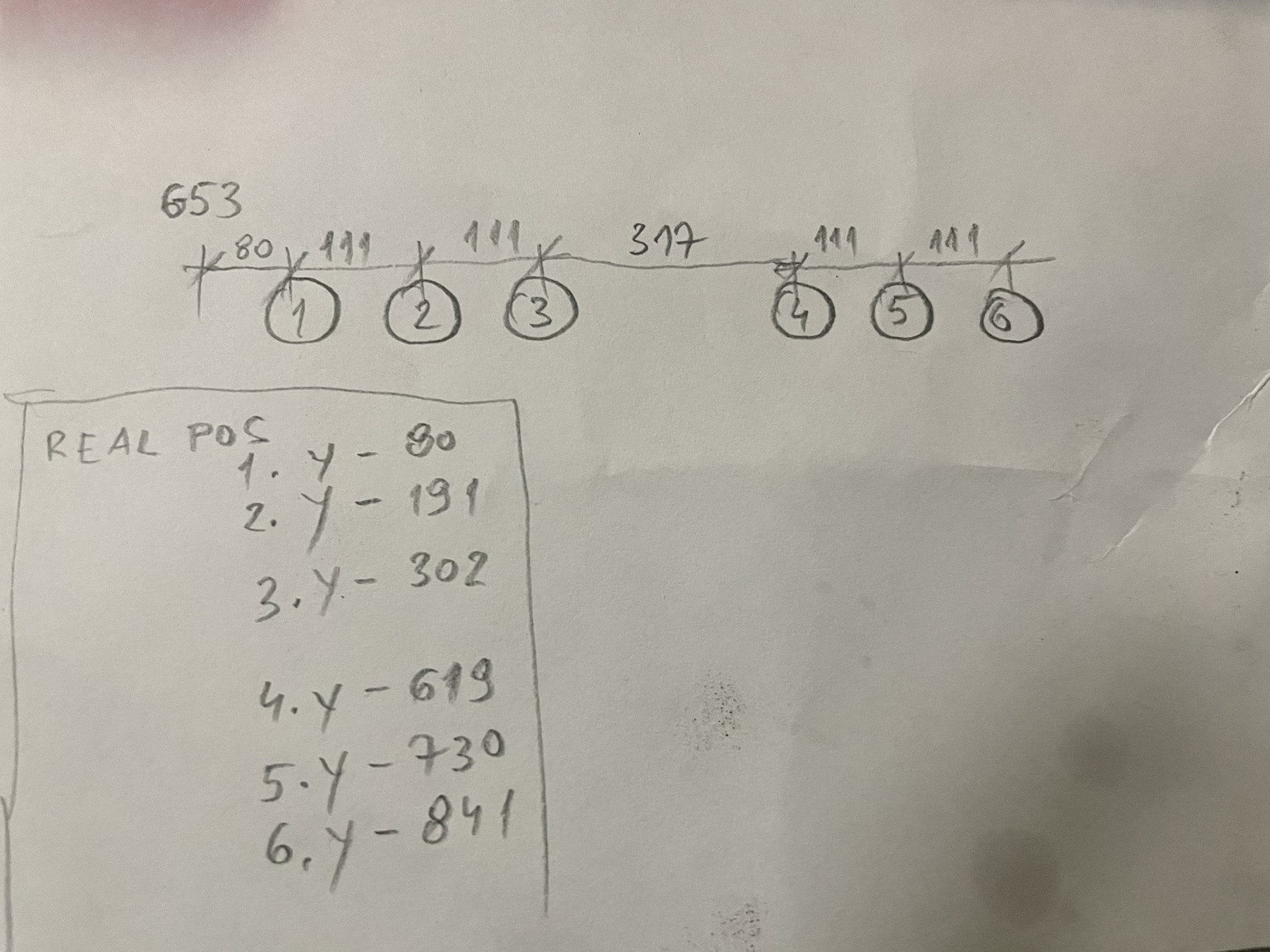

now, I don't know how to set the delta y for the second toolbox 4-5-6, because it has a gap between 123 456

youtube.com/shorts/nZJZBoi4e4g

youtube.com/shorts/nZJZBoi4e4g

Last edit: 12 Dec 2025 00:46 by Masiwood123.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21216

- Thank you received: 7246

12 Dec 2025 15:59 #340002

by tommylight

Replied by tommylight on topic freelancer needed to create a routine for ATC tool change (rackchange)

Is the gap a multiple of existing tool distances?

If yes, set it as tool (4 i think in your case) and just do not use tool 4 in post, and even if someone asks for tool 4 no damage should be done as the spindle does not go that low.

If yes, set it as tool (4 i think in your case) and just do not use tool 4 in post, and even if someone asks for tool 4 no damage should be done as the spindle does not go that low.

The following user(s) said Thank You: Masiwood123

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 412

- Thank you received: 93

12 Dec 2025 17:14 - 12 Dec 2025 17:29 #340007

by Masiwood123

Replied by Masiwood123 on topic freelancer needed to create a routine for ATC tool change (rackchange)

The space between 3 and 4 do not agree to say that it is possible to divide by 111I would like all 6 tools to work, the delta between 1,2,3 is 111mm, so there is a gap, so the same delta raster between 4,5,6 is also 111mm, so the distance between 3 and 4 is 317mm...I will post the script for the first 3 tools later...if I copy and put an additional [change position delta 2]' in the ini file with ``if<current_tool GT 3>`` it doesn't work

Last edit: 12 Dec 2025 17:29 by Masiwood123.

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 412

- Thank you received: 93

12 Dec 2025 18:36 #340010

by Masiwood123

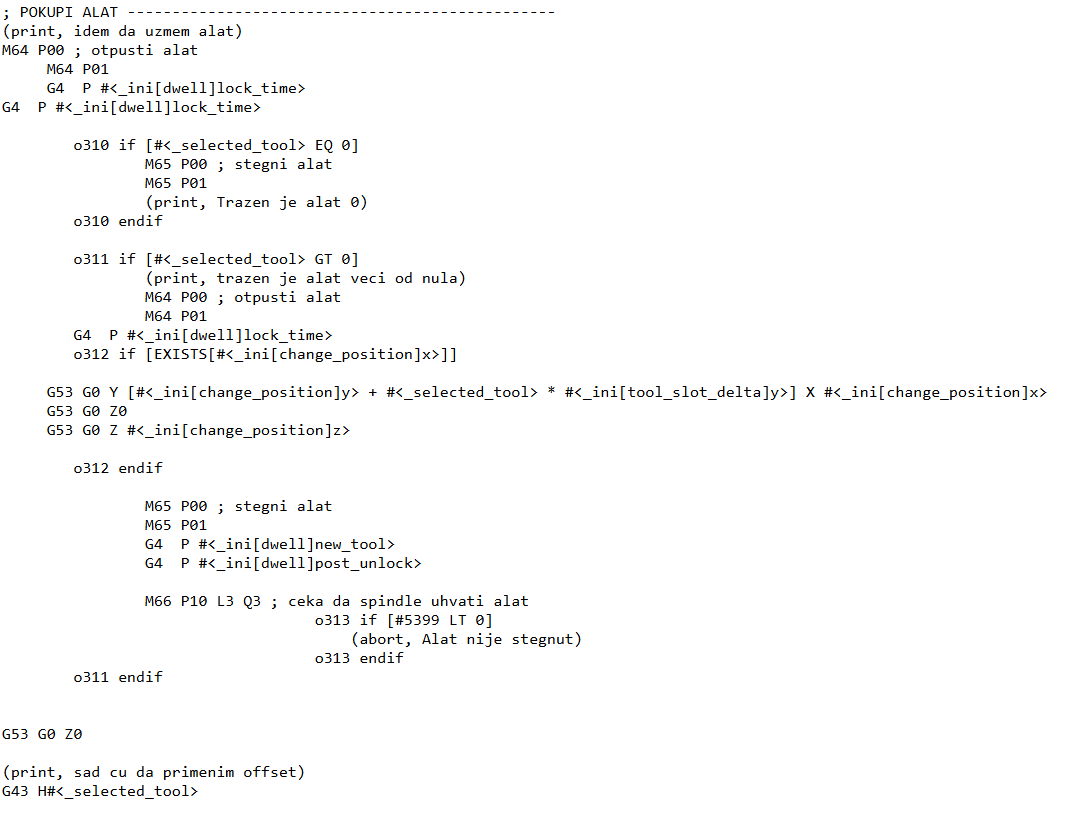

if someone know to edit ini and rack_change.ngc files according to my y positions for tool 4,5,6 here are my files.thank you

Replied by Masiwood123 on topic freelancer needed to create a routine for ATC tool change (rackchange)

if someone know to edit ini and rack_change.ngc files according to my y positions for tool 4,5,6 here are my files.thank you

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11657

- Thank you received: 3924

12 Dec 2025 20:43 #340017

by rodw

Replied by rodw on topic freelancer needed to create a routine for ATC tool change (rackchange)

The distance between 3&4 = 317 and its therefore 206mm more than the delta. (111_206 - 306)

I think I would save this gap in the ini file as a seperate variable and calculate the tool position and do something like

#tool_pos = #<_current_tool> * #<_ini[tool_slot_delta]y>]

if #<current_tool GT 3>

#tool_pos = #tool_pos + 206

G53 G0 Y [#<_ini[change_position]y> + #tool_pos X [#<_ini[change_position]x>]

I'll leave it to you to sort out the syntax as gcode is not my strong point. We have postprocessors for that!

I think I would save this gap in the ini file as a seperate variable and calculate the tool position and do something like

#tool_pos = #<_current_tool> * #<_ini[tool_slot_delta]y>]

if #<current_tool GT 3>

#tool_pos = #tool_pos + 206

G53 G0 Y [#<_ini[change_position]y> + #tool_pos X [#<_ini[change_position]x>]

I'll leave it to you to sort out the syntax as gcode is not my strong point. We have postprocessors for that!

The following user(s) said Thank You: Masiwood123

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 412

- Thank you received: 93

12 Dec 2025 20:59 #340018

by Masiwood123

Replied by Masiwood123 on topic freelancer needed to create a routine for ATC tool change (rackchange)

thanks Rodw, I can try ``it in the air'' but that would also be ok if I get a change for slot 4, but since slot 5 and 6 are also bigger than GT3, then I will get some other distance for 5 and 6, unless I make additional lines again, ``if GT4`` is bigger than 4, then again only delta y will work, which is 111mm?

Attachments:

Please Log in or Create an account to join the conversation.

- MaHa

- Offline

- Platinum Member

-

Less

More

- Posts: 504

- Thank you received: 211

12 Dec 2025 22:24 - 13 Dec 2025 01:21 #340020

by MaHa

Replied by MaHa on topic freelancer needed to create a routine for ATC tool change (rackchange)

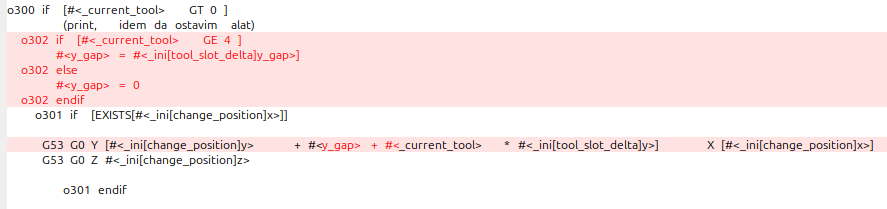

I see you got replys already, while preparing this. My idea to solve that, by adding the gap value for tool 4 to 6. Extend the ini entry for [TOOL_SLOT_DELTA] by y_gap, then apply that value for tool 4 to 6

in o<rack_change> sub

in .ini

Edit:

AS the 'tool_slot_delta' is always added, the 'y_gap' should be reduced by 111 to 206

in o<rack_change> sub

o300 if [#<_current_tool> GT 0 ]

(print, idem da ostavim alat)

o302 if [#<_current_tool> GE 4 ]

#<y_gap> = #<_ini[tool_slot_delta]y_gap>]

o302 else

#<y_gap> = 0

o302 endif

o301 if [EXISTS[#<_ini[change_position]x>]]

G53 G0 Y [#<_ini[change_position]y> + #<y_gap> + #<_current_tool> * #<_ini[tool_slot_delta]y>] X [#<_ini[change_position]x>]

G53 G0 Z #<_ini[change_position]z>

o301 endif in .ini

[TOOL_SLOT_DELTA]

X = 0

Y = -111

Z = 0

y_gap = 317Edit:

AS the 'tool_slot_delta' is always added, the 'y_gap' should be reduced by 111 to 206

Attachments:

Last edit: 13 Dec 2025 01:21 by MaHa.

The following user(s) said Thank You: tommylight, Masiwood123

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 412

- Thank you received: 93

12 Dec 2025 22:28 #340021

by Masiwood123

Replied by Masiwood123 on topic freelancer needed to create a routine for ATC tool change (rackchange)

thanks a lot i can try this tomorrow

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 412

- Thank you received: 93

13 Dec 2025 16:44 - 13 Dec 2025 16:52 #340060

by Masiwood123

Replied by Masiwood123 on topic freelancer needed to create a routine for ATC tool change (rackchange)

.this does not work, maybe because you entered the parameters in the routine in the section of returning the current tool to its place, also o302 already exists, so I changed it to o303, but the same thing happens when selecting T4 M6(spindle goes 111mm from tool 3). you should somehow add it to the section of the file where it says ``POKUPI ALAT'',- means that is, ``selected tool'' down in routine, if you are able to edit that part. Thank you very much

.

.

Last edit: 13 Dec 2025 16:52 by Masiwood123.

Please Log in or Create an account to join the conversation.

- MaHa

- Offline

- Platinum Member

-

Less

More

- Posts: 504

- Thank you received: 211

13 Dec 2025 18:52 - 13 Dec 2025 20:07 #340064

by MaHa

Replied by MaHa on topic freelancer needed to create a routine for ATC tool change (rackchange)

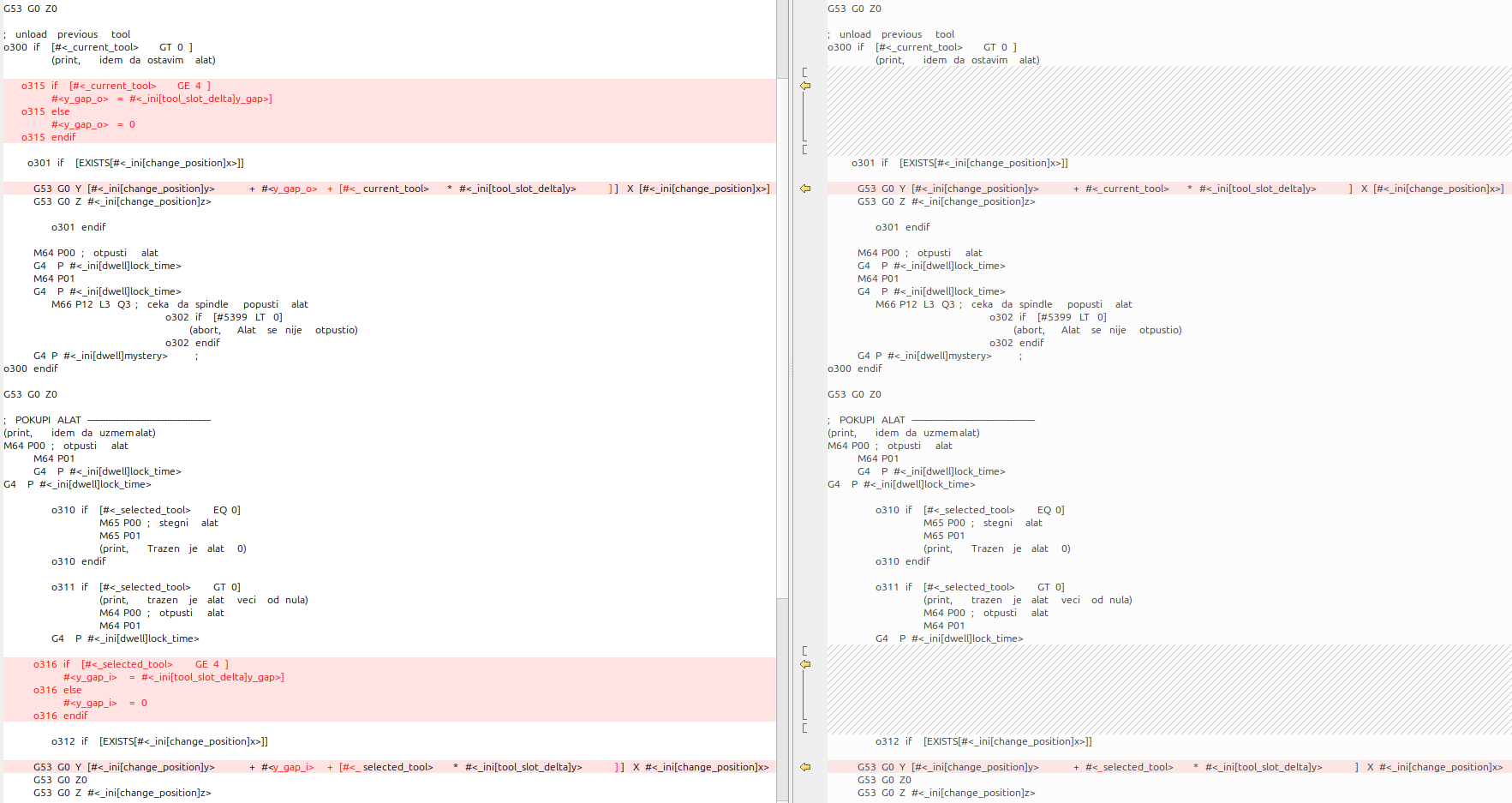

I modified the routine for unload and load, o315 and o 316 used. In .ini file the value for 'y_gap' should be 206, not 317 The diff shows the modification

Attachments:

Last edit: 13 Dec 2025 20:07 by MaHa. Reason: updated file

The following user(s) said Thank You: Masiwood123

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Advanced Configuration

- freelancer needed to create a routine for ATC tool change (rackchange)

Time to create page: 0.222 seconds