Retrofitting a 1986 Maho MH400E

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

06 Oct 2017 13:00 - 06 Oct 2017 13:01 #100000

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Spindle at speed is an control input to LinuxCnc it is binary (1 or 0) if it is 0 than the LinuxCnc holds the feeds on all axis, if it is 1 than the motion is continued again. The encoder is fed directly to LinuxCnc, and LinuxCnc synchronizes the motion for every job that needs sinc motion with spindle.

John

John

Last edit: 06 Oct 2017 13:01 by drimaropoylos.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

06 Oct 2017 13:14 - 06 Oct 2017 13:23 #100001

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

The VFD has a relay output spindle at speed, I can connect it to mesa and connect the two signals with “and” in hall file, or in ladder. The maho originally I don’t think that it had speed at speed, I think it had timers on the controller.

Last edit: 06 Oct 2017 13:23 by drimaropoylos.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

06 Oct 2017 13:28 - 06 Oct 2017 13:29 #100003

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

I think that Spindle at speed is intended to be connected like this (to vfds), so LinuxCnc knows that the vfd has reached the commanded speed.

Last edit: 06 Oct 2017 13:29 by drimaropoylos.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

06 Oct 2017 15:23 - 06 Oct 2017 15:26 #100013

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

www.linuxcnc.org/docs/2.4/html/examples_...cha:Spindle-Feedback

loadrt encoder num_chan=1

addf encoder.update-counters base-thread

addf encoder.capture-position servo-thread

setp encoder.0.position-scale 100

net spindle-position encoder.0.position => motion.spindle-revs

net spindle-velocity encoder.0.velocity => motion.spindle-speed-in

net spindle-index-enable encoder.0.index-enable <=> motion.spindle-index-enable

net spindle-phase-a encoder.0.phase-A

net spindle-phase-b encoder.0.phase-B

net spindle-index encoder.0.phase-Z

net spindle-phase-a <= parport.0.pin-10-in

net spindle-index <= parport.0.pin-11-in

Can I put on the setp encoder.0.position-scale instead of a number, a signal that is connected to an output off ladder to scale correct the selected gear. And not connect the index

John

loadrt encoder num_chan=1

addf encoder.update-counters base-thread

addf encoder.capture-position servo-thread

setp encoder.0.position-scale 100

net spindle-position encoder.0.position => motion.spindle-revs

net spindle-velocity encoder.0.velocity => motion.spindle-speed-in

net spindle-index-enable encoder.0.index-enable <=> motion.spindle-index-enable

net spindle-phase-a encoder.0.phase-A

net spindle-phase-b encoder.0.phase-B

net spindle-index encoder.0.phase-Z

net spindle-phase-a <= parport.0.pin-10-in

net spindle-index <= parport.0.pin-11-in

Can I put on the setp encoder.0.position-scale instead of a number, a signal that is connected to an output off ladder to scale correct the selected gear. And not connect the index

John

Last edit: 06 Oct 2017 15:26 by drimaropoylos.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1548

- Thank you received: 572

07 Oct 2017 07:12 #100034

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks for the photos. Reminds me that I should also use my camera instead of the phone to post decent photos.

Why add encoders to the axis motors? Are you throwing out the Indramat?

If we need a spindle at speed signal to make the gearbox changing work, I'll just use a worst case time delay to simulate that, as I really dont want to get into replacing the MAHO relay based motor contro with a VFD at this time. Maybe down the road.

Mark

Why add encoders to the axis motors? Are you throwing out the Indramat?

If we need a spindle at speed signal to make the gearbox changing work, I'll just use a worst case time delay to simulate that, as I really dont want to get into replacing the MAHO relay based motor contro with a VFD at this time. Maybe down the road.

Mark

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

07 Oct 2017 14:32 #100042

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Say that we cut something and while the g code is running we estimate that the spindle speed is to low or to hi, and we move the spindle slider on the Gmoccapy. The ladder will see change in the commanded speed, and it will start gear change immediately. If the controller won’t stop feed on all axis and stop the motor, then either the gear box will be destroyed because the speed is very hi for gear change, or the tool will break because the spindle is not rotate to remove material.

When the slider for commanded speed is moved or a spindle speed commanded from the gcode than we have to ensure that the spindle will slow down to a stop and none of the axis is moving. I believe this is “what spindle at speed” signal is doing, it pause the program until the “spindle at speed” is true again. So when the ladder sees a change in commanded spindle speed, it makes the “spindle at speed” false wait for the estimated time needed for the spindle to come to a full stop, make the gear change and make the “spindle at speed” true again for the program to continue.

John

When the slider for commanded speed is moved or a spindle speed commanded from the gcode than we have to ensure that the spindle will slow down to a stop and none of the axis is moving. I believe this is “what spindle at speed” signal is doing, it pause the program until the “spindle at speed” is true again. So when the ladder sees a change in commanded spindle speed, it makes the “spindle at speed” false wait for the estimated time needed for the spindle to come to a full stop, make the gear change and make the “spindle at speed” true again for the program to continue.

John

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

07 Oct 2017 14:45 #100044

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1548

- Thank you received: 572

07 Oct 2017 17:07 - 07 Oct 2017 17:15 #100050

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Does your machine not have the Heidenhain LS403's and EXE? I heard that some MAHO's also have Phillips glass scales for which no one has yet produced a suitable A/D signal processor.

As long as I don't have a VFD installed, I was not going to activate LinuxCNC's spindle override capablity. If the spindle speed is wrong for a feature, I will only have the option of compensating with feed override, or pausing, backing out to a safe Z and changing gear.

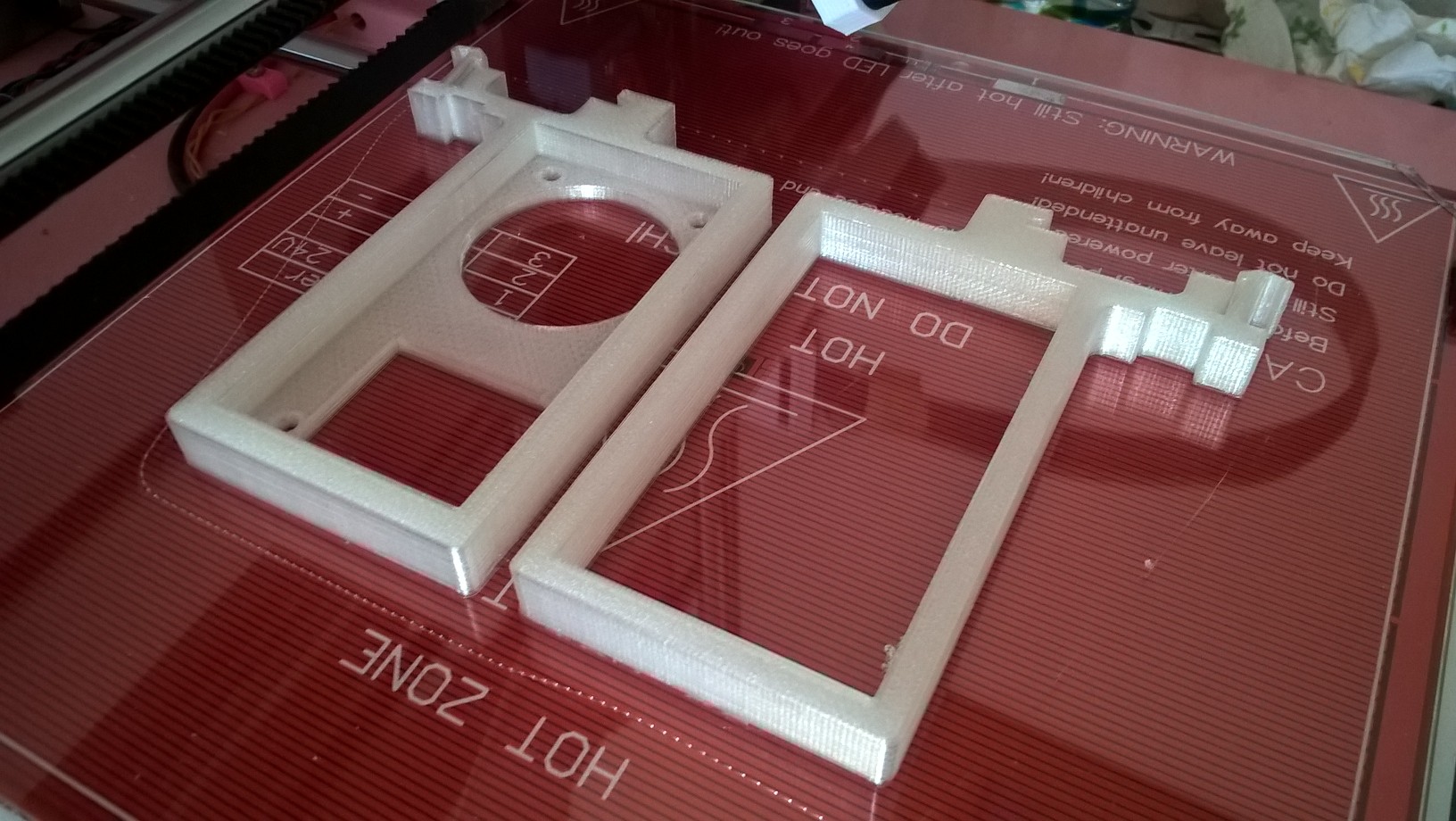

I printed out some brackets to mount the ITX PSU to DIN rail, but screwed up a couple of measurements and will have to print them again.

Mark

As long as I don't have a VFD installed, I was not going to activate LinuxCNC's spindle override capablity. If the spindle speed is wrong for a feature, I will only have the option of compensating with feed override, or pausing, backing out to a safe Z and changing gear.

I printed out some brackets to mount the ITX PSU to DIN rail, but screwed up a couple of measurements and will have to print them again.

Mark

Last edit: 07 Oct 2017 17:15 by RotarySMP.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

07 Oct 2017 17:14 #100051

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

I don’t know what scales had from the manufacturer, the previous owner had start the retrofit end had placed new scales with quadrature output.

John

John

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

07 Oct 2017 17:23 #100053

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

3d printer… nice thing to have.

John

John

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.334 seconds