HURCO KMB-1 Control Update

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 126

- Thank you received: 12

14 Mar 2025 19:49 - 14 Mar 2025 19:51 #323955

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

Delving into this in more detail, the AtoD conversion doesn't look very stable.

My digital voltmeter reads on a nominal mid position of XY feed pot a steady, non varying 1.666v

the 7i73 analog0 numbers flicker, not regularly, like on a timer, but with a fast random up and down.. With a slow-mo video

I actually get readings 1.565882,1.578824, 1.591756 the differences are exactly one bit. (3.3volts, 255 bits, ie 0.012941 volts per bit)

When the servos are on, then this flicker is actually audible.

Can you suggest anything that I can do to improve this please?

Thanks

My digital voltmeter reads on a nominal mid position of XY feed pot a steady, non varying 1.666v

the 7i73 analog0 numbers flicker, not regularly, like on a timer, but with a fast random up and down.. With a slow-mo video

I actually get readings 1.565882,1.578824, 1.591756 the differences are exactly one bit. (3.3volts, 255 bits, ie 0.012941 volts per bit)

When the servos are on, then this flicker is actually audible.

Can you suggest anything that I can do to improve this please?

Thanks

Last edit: 14 Mar 2025 19:51 by NT4Boy.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17478

- Thank you received: 5106

14 Mar 2025 23:36 #323970

by PCW

Replied by PCW on topic HURCO KMB-1 Control Update

You can low pass filter the outputs

Also for noise and stability I would

1. Run the pots from the 7I73s 3.3V if you can

(Since this is the 7I73s analog input reference the reading

will be ratiometric, so a change in the 3.3V will not change the reading)

2. Low pass filter the inputs at the 7I73 (say with a 0.1 uF capacitor to 7I73 ground)

3. Low pass filter the analog hal signal (a 1 LSB dither is expected with almost any

A-D at least at some (halfway between) input levels)

Also for noise and stability I would

1. Run the pots from the 7I73s 3.3V if you can

(Since this is the 7I73s analog input reference the reading

will be ratiometric, so a change in the 3.3V will not change the reading)

2. Low pass filter the inputs at the 7I73 (say with a 0.1 uF capacitor to 7I73 ground)

3. Low pass filter the analog hal signal (a 1 LSB dither is expected with almost any

A-D at least at some (halfway between) input levels)

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 126

- Thank you received: 12

15 Mar 2025 10:14 #323997

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

Thanks Pete,

Have looked at the trace with a scope now. The 0.1uF smooths out the sawtooth, but I still have this variable voltage flicker that's not caught on the meter, so something adrift with that power supply I think.

Have looked at the trace with a scope now. The 0.1uF smooths out the sawtooth, but I still have this variable voltage flicker that's not caught on the meter, so something adrift with that power supply I think.

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 126

- Thank you received: 12

02 May 2025 19:03 #327528

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

I think I have the system in control now, and have reached the point where I want to add an encoder to the spindle for rigid tapping and better speed control.

My plan had been to add a toothed wheel with a pair of hall effect sensors, one a few teeth away, but half a cycle out of phase for quadrature, and a third for an index. Then connect these directly into the 7i77 channel 5 encoder inputs. (some biasing resistors maybe required also)

The maximum spindle rpm is 3500. I was proposing 40 teeth, but on say an M6 thread with 1mm pitch, I think that's a possible pitch error of .00625mm, which is pretty small, but I guess 100 would be better. I'd appreciate others opinions on this choice please.

Secondly, because of the belt run and lack of clearance around the belt pulley, putting the index tooth on is a much bigger mission than I was expecting.

Can I simply delete it and use a missing tooth, or pair of missing teeth as the index?

What looks to me like it might not so simply work is the encoder quadrature when it reaches the missing tooth, or am I over thinking this?

Thanks

My plan had been to add a toothed wheel with a pair of hall effect sensors, one a few teeth away, but half a cycle out of phase for quadrature, and a third for an index. Then connect these directly into the 7i77 channel 5 encoder inputs. (some biasing resistors maybe required also)

The maximum spindle rpm is 3500. I was proposing 40 teeth, but on say an M6 thread with 1mm pitch, I think that's a possible pitch error of .00625mm, which is pretty small, but I guess 100 would be better. I'd appreciate others opinions on this choice please.

Secondly, because of the belt run and lack of clearance around the belt pulley, putting the index tooth on is a much bigger mission than I was expecting.

Can I simply delete it and use a missing tooth, or pair of missing teeth as the index?

What looks to me like it might not so simply work is the encoder quadrature when it reaches the missing tooth, or am I over thinking this?

Thanks

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17478

- Thank you received: 5106

02 May 2025 19:18 #327533

by PCW

Replied by PCW on topic HURCO KMB-1 Control Update

There is currently no "missing tooth index" support in hostmot2

(there is experimental firmware but no driver support currently)

(there is experimental firmware but no driver support currently)

The following user(s) said Thank You: NT4Boy

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 126

- Thank you received: 12

02 May 2025 19:20 #327534

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

Aha, many thanks for your speedy response.

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 126

- Thank you received: 12

02 Jun 2025 10:06 - 02 Jun 2025 10:17 #329540

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

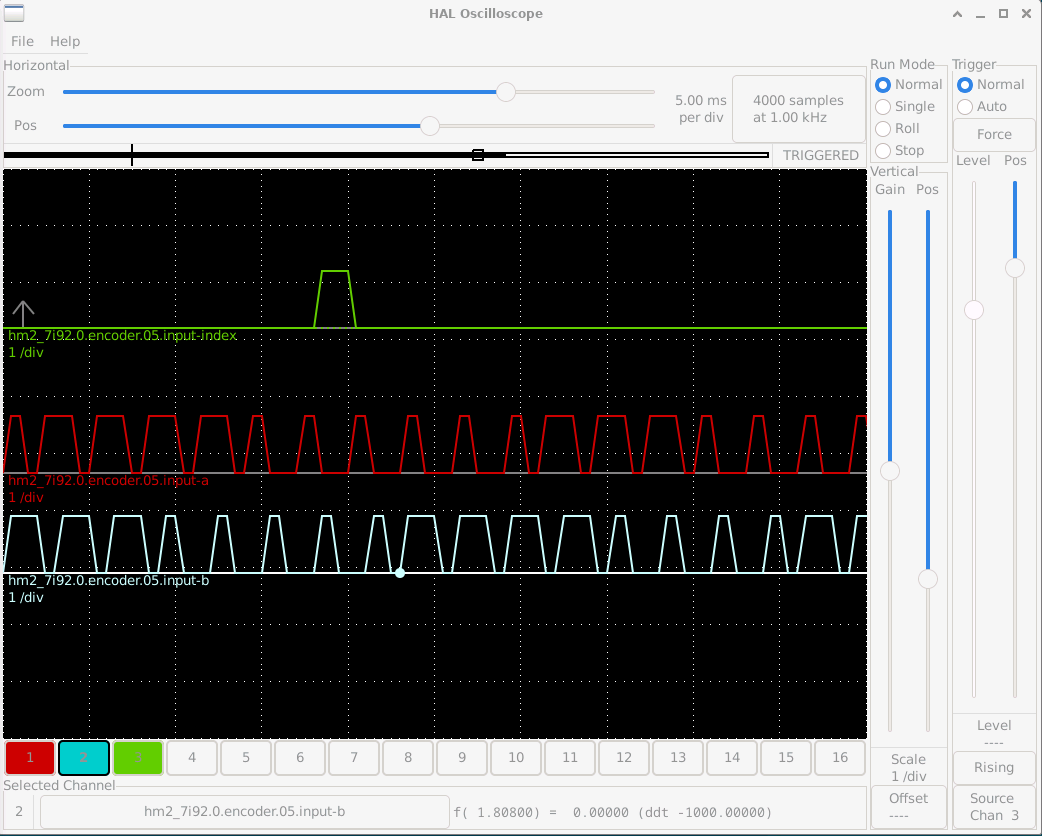

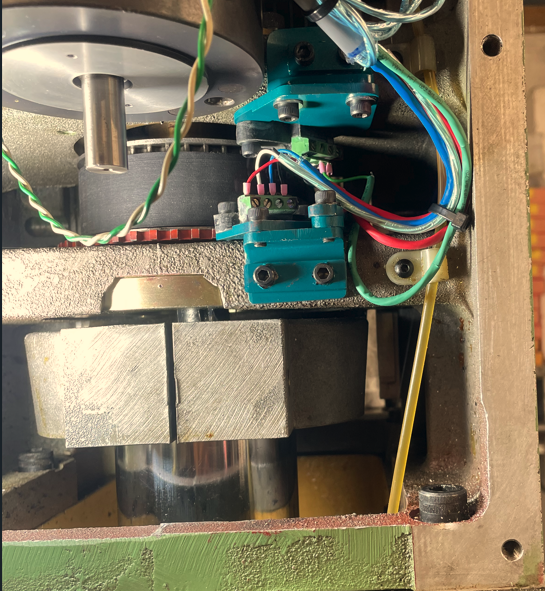

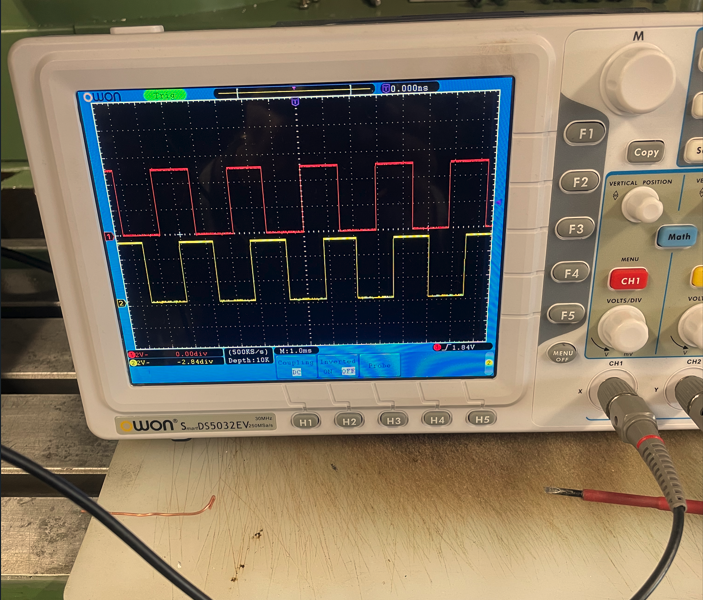

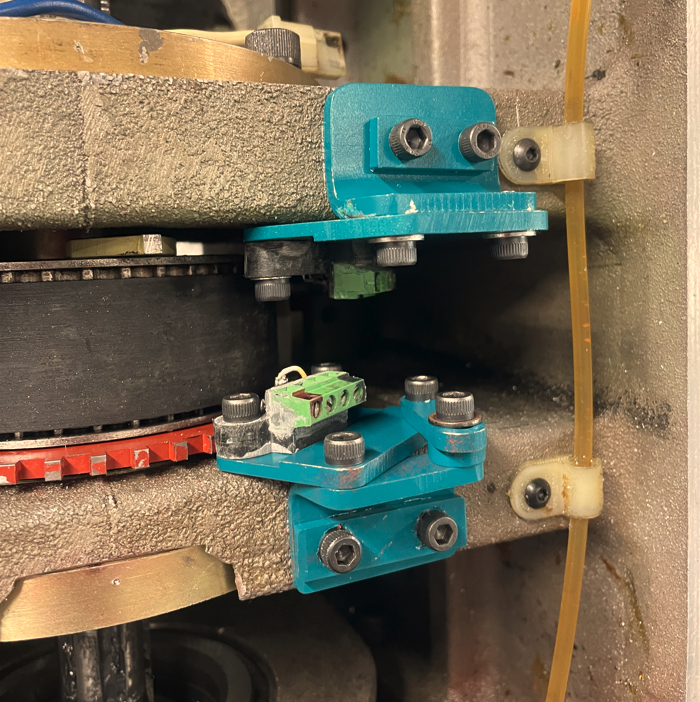

What I hope will be the last part of my adventure, is to add a spindle encoder for rigid tapping etc.Mission now achieved. 48 teeth on the lower side of the drive pully as well as an index tooth on the upper side, (complete with counterbalance weight).Have used ATS616LSG hall effects, with 10k biasing resistors which produce at the 7i77 encoder 05 inputs, good clean 5volt signals.I have yet to get properly to grips with the hal side of things, but at first sight, the hal scope doesn’t look right.

Attachments:

Last edit: 02 Jun 2025 10:17 by NT4Boy. Reason: Made a mess with images.

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 126

- Thank you received: 12

02 Jun 2025 12:35 #329549

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

I think this is a raspberry PI issue as there is no fast sample rate option in the halscope.

Hopefully won't affect what I am doing, other than spoil my pictures.

Hopefully won't affect what I am doing, other than spoil my pictures.

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 126

- Thank you received: 12

05 Jun 2025 16:54 #329756

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

Hello, This is likely the wrong spot to ask this question, but as its one of the first things I've machined using linuxcnc on the machine...

The profile I've machined is essentially circular and should be symmetrical, and the bore clocks in at X0,Y0.

issuing a G0 X0, Y0 gets me back over the bore and it repeatably clocks in.

The finished machined part has a Y offset of 0.2mm.

This may be a programming issue, but I have noticed a random Y -28.11 offset in the tool table for the tool used.

If that entry was doing what I thought it should, then the mis-machining would have been 28.11 and not 0.2. However, could this entry have caused the issue?

On a three axis mill, is there a purpose for the X and Y offsets in the table?

Thanks

The profile I've machined is essentially circular and should be symmetrical, and the bore clocks in at X0,Y0.

issuing a G0 X0, Y0 gets me back over the bore and it repeatably clocks in.

The finished machined part has a Y offset of 0.2mm.

This may be a programming issue, but I have noticed a random Y -28.11 offset in the tool table for the tool used.

If that entry was doing what I thought it should, then the mis-machining would have been 28.11 and not 0.2. However, could this entry have caused the issue?

On a three axis mill, is there a purpose for the X and Y offsets in the table?

Thanks

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 126

- Thank you received: 12

11 Jun 2025 13:12 #330146

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

By experimentation, the Y and X offsets can be entered pressing tool touch off with the wrong axis selected. On a 3 axis mill, as far as I can tell numbers in these columns are ignored.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.305 seconds