Bridgeport VMC760 retrofit

- spincycle

- Offline

- Junior Member

-

- Posts: 33

- Thank you received: 6

The time has come!

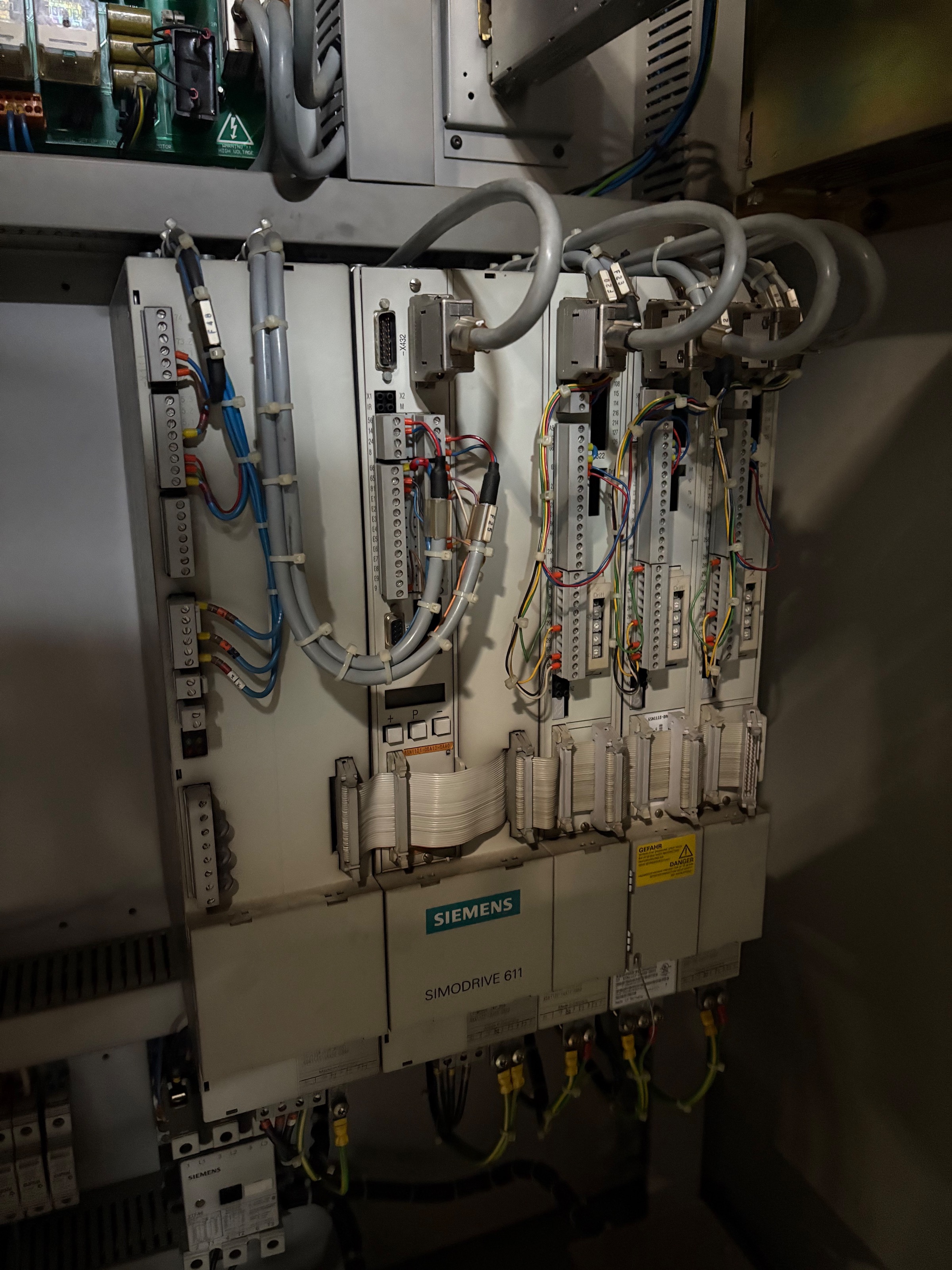

I've owned a Bridgeport VMC760 for the last 4 years. It's been used in my prototyping/fabrication shop here in Australia. The Heidenhain 370 control and Siemens drives have served me well in this time, up until yesterday, when one of the servo drives went bang.

While I'm looking into replacing this drive, I'm also entertaining a retrofit. The machine is a 97' and I fear that I'll be tipping further money into the those drives at some stage. I've never tackled a retrofit of this level, but I've had experience building CNC machines in the past with my business. A couple of one-off 3/4 axis machines for client's specific manufacturing and a home-brew 'Datron' like router we used heavily before the VMC (and still use for high speed spindle applications).

Ideally the retrofit would look something like this:

New axis servos and drives (Interested in Leadshine's newer offerings, but I've had good experiences with DMM, Delta's and Clearpath in the past)

New spindle motor and drive (I've been looking at SVC VFD and encoders to handle orientation, rigid taping etc)

Preference to Ethercat communication for flexibility and wiring

Linux control with a touch screen and a few machine specific buttons up front

Full closed loop control on all axis

Very interested in running this from a Pi5

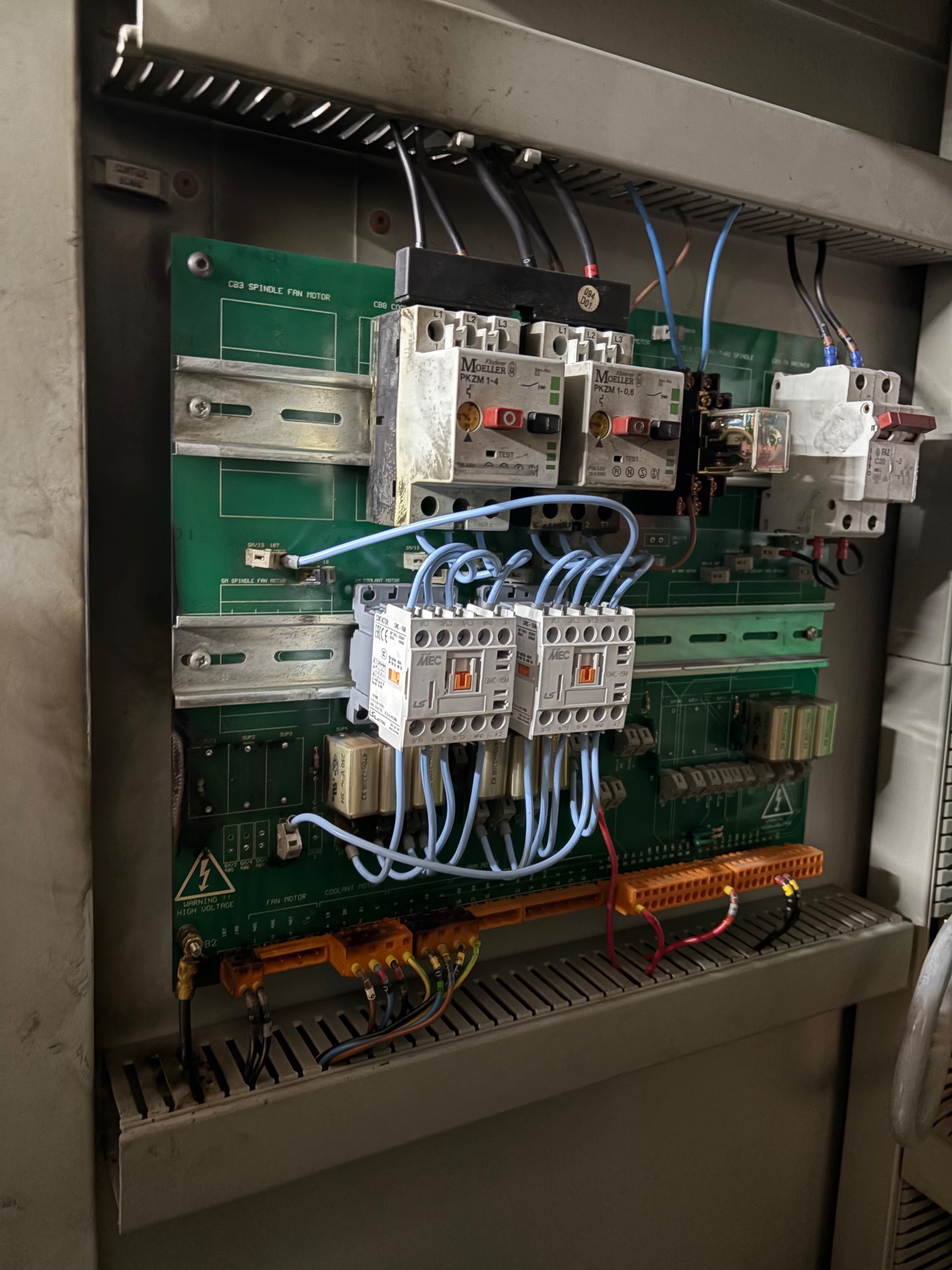

Ideally retain the original auxiliary control boards (the boards running the contactors for lube, coolant, tool change etc)

These boards look like the take simple logic signals from the Heidenhain.

Retain full operation of the carousel tool changer. Fairly typical Geneva drive style of the time with AC motors and inductive sensors.

The major gaps in my knowledge (I'm sure there are plenty to be honest) are regarding the following points:

I've never worked with Ethercat, but flexibility and lack of wiring are intriguing. Can an Ethercat system run full closed loop control?

Spindle sytem. Originally this machine had 9kw of continuous (11kw peak) power and 76Nm of torque (93Nm peak), 6000rpm max. I'd like to keep such performance. Is a large SVC VFD AC setup with linux/software based spindle synchronisation the right avenue?

Running LinuxCNC on a raspberry Pi. I've only every run it on old scrap PC's with parallel ports back in the hobby days. Latency was always an issue!

I understand most people would suggest binning the machine or just fixing what's there. CNC machines, even on the secondhand market are not as plentiful or cheap here in Australia. It's a decent sized machine that's produced some great work for us in the past and most importantly, it's already in our workshop!

I'll post some pictures when I'm in the workshop later today.

Any input on these topics is very welcomed and appreciated!!

Thanks,

John

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21301

- Thank you received: 7274

By Nikola Tesla.The induction motor is a very, very old invention.

Please Log in or Create an account to join the conversation.

- spincycle

- Offline

- Junior Member

-

- Posts: 33

- Thank you received: 6

Good to know that a beefed up PC is a better choice than the Pi.

The thought did cross my mind to keep the motors and replace drivers. I would assume I'd need to get drivers that work with the Siemens encoders or replace the encoders with ones that match the drives.

Does anyone have any experience with this?

Thanks,

J

Please Log in or Create an account to join the conversation.

- spincycle

- Offline

- Junior Member

-

- Posts: 33

- Thank you received: 6

The induction motor is a very, very old invention.

By Nikola Tesla.

Hahaha, so true

Please Log in or Create an account to join the conversation.

- spincycle

- Offline

- Junior Member

-

- Posts: 33

- Thank you received: 6

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21301

- Thank you received: 7274

If you mean the induction motor, no, no one even tried it before him. He knew his s#it, for sure.Lots of other men contributed to its discovery and invention too.

Induction motor has no magnets, no rotor coils, no brushes, yet it works!

It has been the single most important discovery that pushed civilization and the industrial complex forward.

Please Log in or Create an account to join the conversation.

- spincycle

- Offline

- Junior Member

-

- Posts: 33

- Thank you received: 6

I'm a little apprehensive about cheap drivers as I've struggled with the manuals and particularly tuning in the past.

How was your experience setting up and tuning the servos?

Surface finish and accuracy are rather important to me on this machine

Please Log in or Create an account to join the conversation.

- spincycle

- Offline

- Junior Member

-

- Posts: 33

- Thank you received: 6

Yep! I'm keen to reuse the majority of the control contractors, breakers and transformers. I've got the full schematics for the machine, so ideally I would splice the original contractor boards into Linux control.I refurbished a 30-year-old CNC router machine at my school.

The original drivers were E-waste.

The original motors are great.

The original transformer (that powers the drivers) is also great (though it's terrifyingly powerful).

The original rectifer bridge + capacitor were also E-waste.

But most of the original switches are still good (one switch got welded contacts due to overcurrent).

Mechanical things outlive electrical things.

Thanks for the input!

Please Log in or Create an account to join the conversation.

- spincycle

- Offline

- Junior Member

-

- Posts: 33

- Thank you received: 6

Very impressive. Here I was thinking he just invented Tesla coils!

Lots of other men contributed to its discovery and invention too.

If you mean the induction motor, no, no one even tried it before him. He knew his s#it, for sure.

Induction motor has no magnets, no rotor coils, no brushes, yet it works!

It has been the single most important discovery that pushed civilization and the industrial complex forward.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21301

- Thank you received: 7274

Analog servos? Velocity mode?

How was your experience setting up and tuning the servos?

forum.linuxcnc.org/10-advanced-configura...ning-detailed-how-to

Please Log in or Create an account to join the conversation.