Bridgeport VMC760 retrofit

- spincycle

- Offline

- Junior Member

-

Less

More

- Posts: 33

- Thank you received: 6

29 May 2025 04:38 #329348

by spincycle

Replied by spincycle on topic Bridgeport VMC760 retrofit

Nope!

Mesa cards and servos are on there way though1 Ill make a more detailed post of my progress in the next day or two.

To answer your question. With a forklift.

Mesa cards and servos are on there way though1 Ill make a more detailed post of my progress in the next day or two.

To answer your question. With a forklift.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1549

- Thank you received: 572

03 Jun 2025 18:59 #329627

by RotarySMP

Replied by RotarySMP on topic Bridgeport VMC760 retrofit

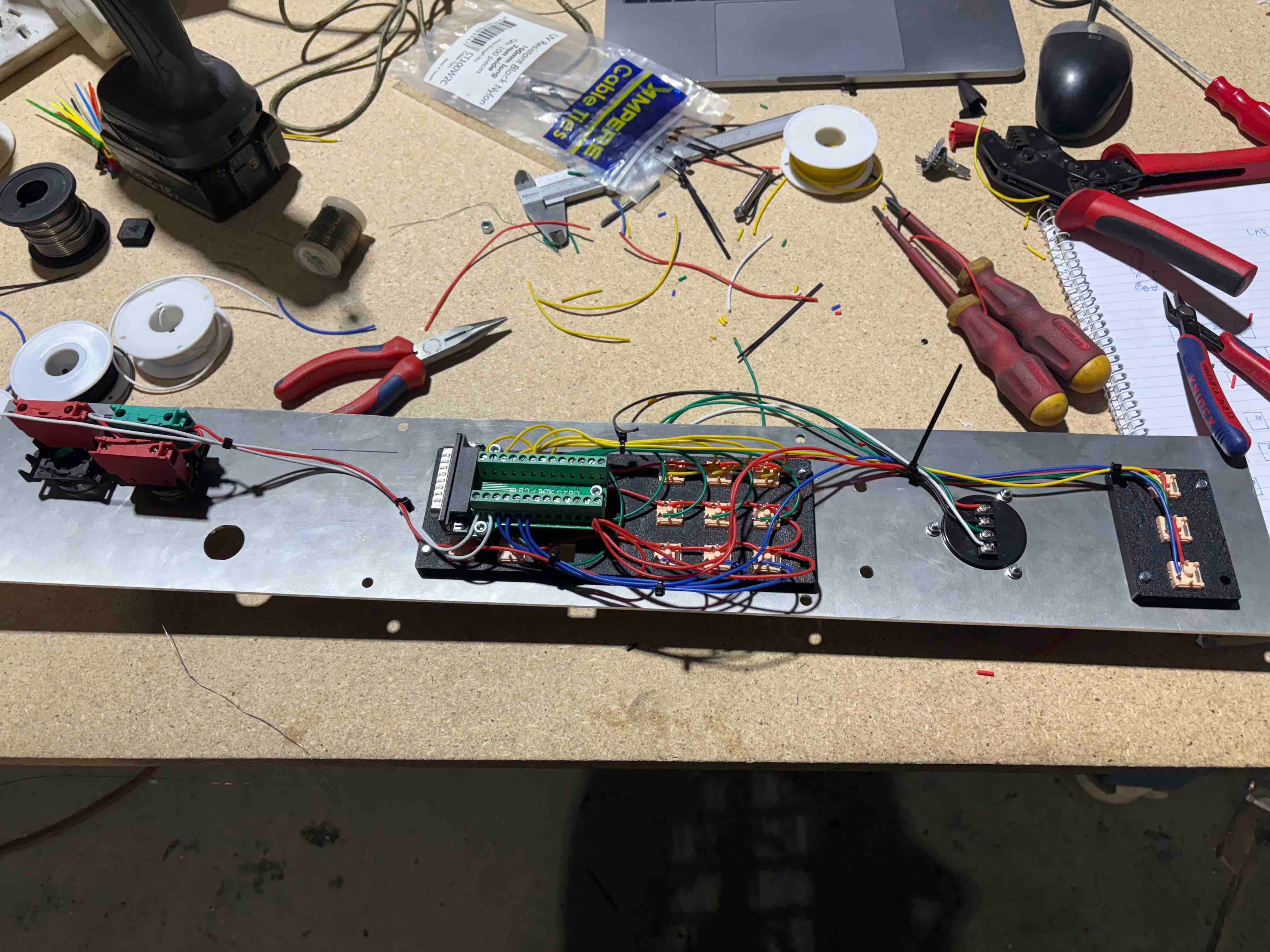

Nice welds on your control panel.

Mark

Mark

Please Log in or Create an account to join the conversation.

- spincycle

- Offline

- Junior Member

-

Less

More

- Posts: 33

- Thank you received: 6

08 Jun 2025 04:31 #329929

by spincycle

Replied by spincycle on topic Bridgeport VMC760 retrofit

Cheers Mark.

I don't get to do as much ally as I'd like.

Bit of a progress update from the last couple weeks:

Control panel is at the powder coaters. I choose a dark matt charcoal. Mainly as my coater runs this Dulux colour often and Im impatient at the best of times! Should have this back on Tuesday.

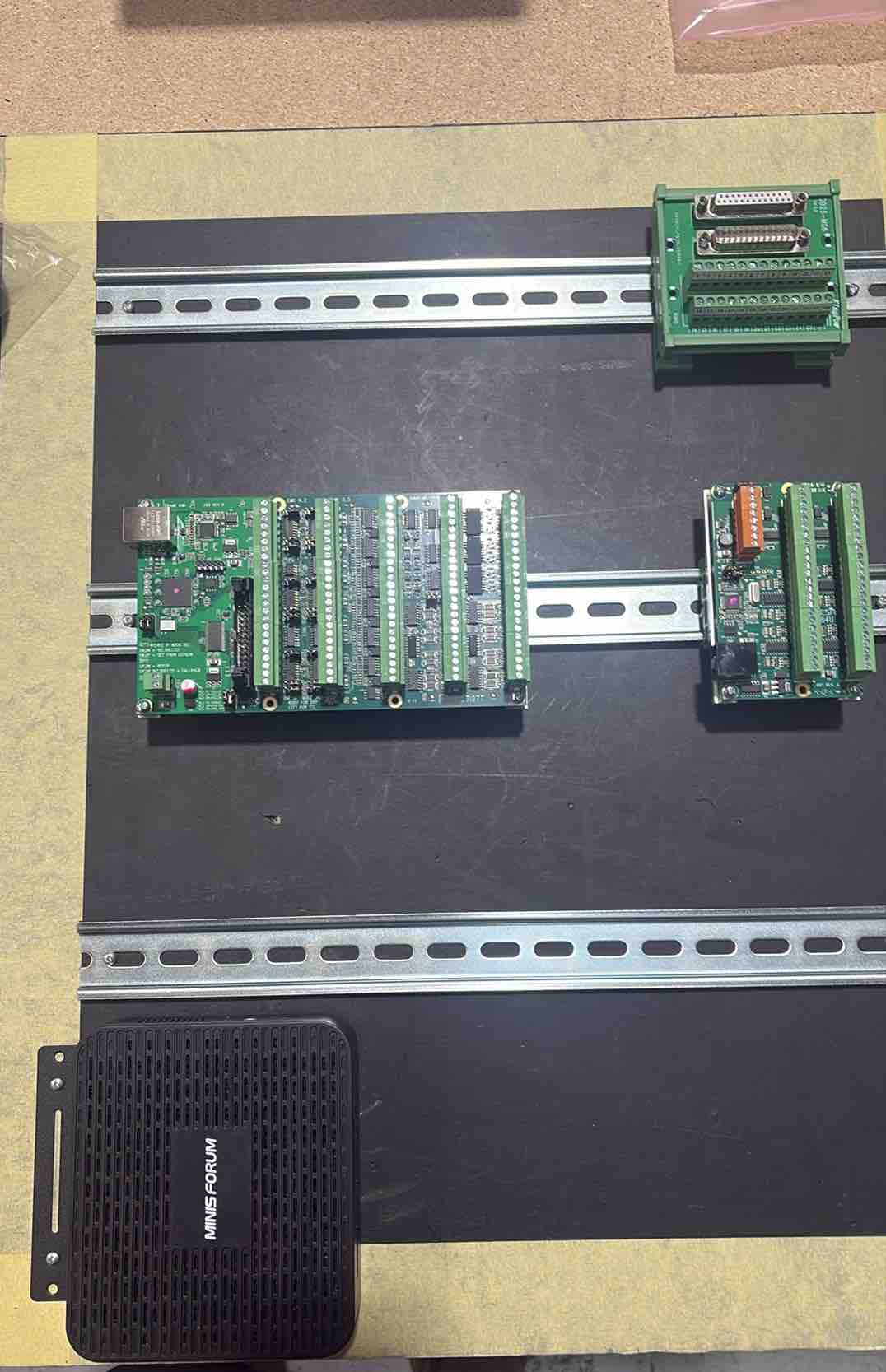

The custom control panel buttons are now 3d printed, along with the MX switch carriers. All wired up. These run into a DB25 breakout board and then will travel back the Mesa cards in the cabinet. I appreciate this isn't the nicest way to execute it, but I only require the 7i97t and 7i84u for all IO, and most IO terminates in the cabinet. I got cold feet on flashing the 7i97.... Pics below.

PC has been setup with linuxcnc. I chose a Coofun CK41 miniPC, which The Feral Engineer made some tests on YouTube with seemingly good results. Fingers crossed it works out. It's very compact and so was the price tag. Took me a few nights to get MesaCT and an updated Mesaflash running correctly to recognise the 7i97T. This is honestly due to my lack of unix (or IT in general!) skills. We got there in the end - I'm now able to run a draft linuxcnc config and toggle a coolant assigned output on the 7i97t with no dramas. I'll take that as a win. Yet to hook up the 7i84u.

Have to thank JT for the great MesaCT package!

I was and still am very daunted by the task of editing lines in the Hal/ini files.

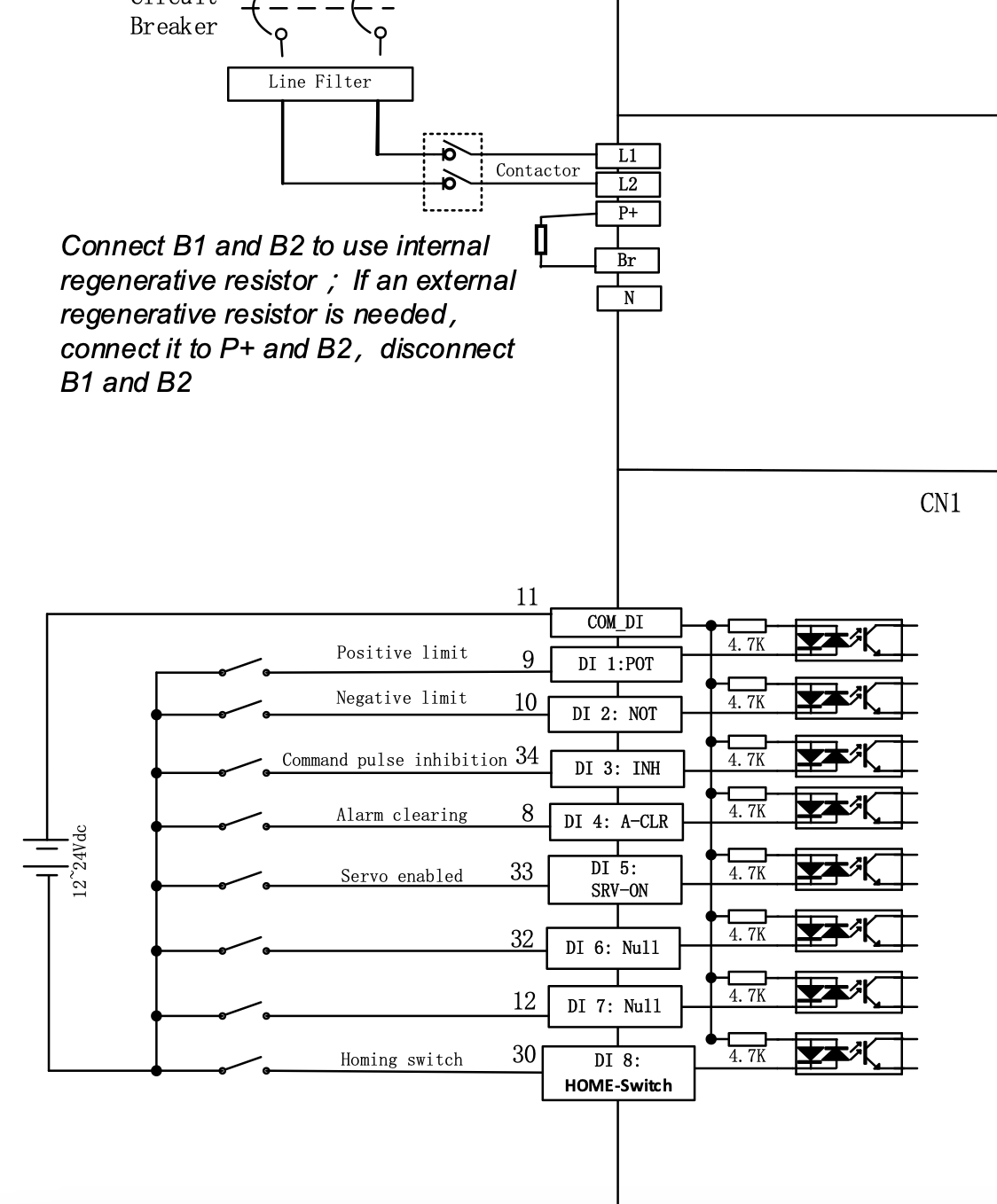

The servo drives are currently on their way from China. I went with Leadshine EL7 drives in the end. The price was decent and they're offered in 380-400v 3ph. Opted for analog/pulse control as these control methods appear to be well documented here, especially by Tommylight's guide. Ethercat looked appealing, but given my lack of IT skills I thought it safe to stick with the aforementioned.

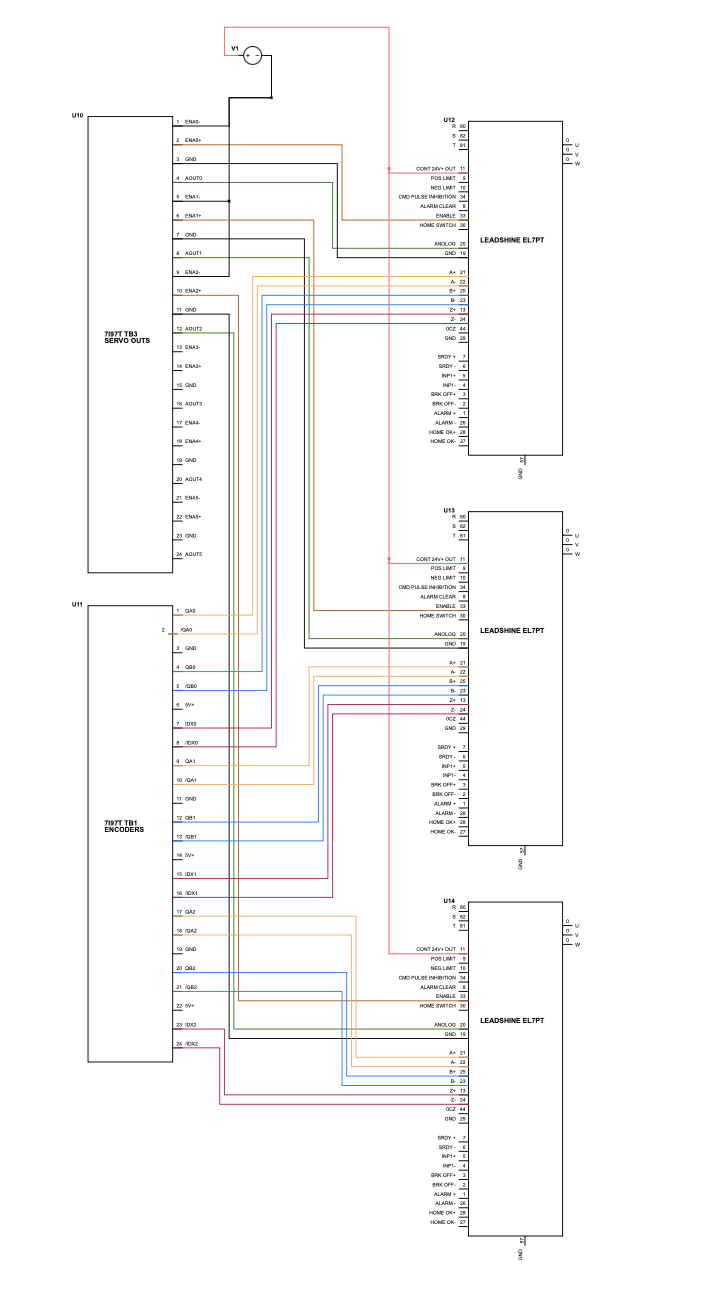

This weekend I started drafting the wiring diagrams between the Mesa boards, original Bridgeport control/distrubution board and new servo drives. The free schematic cad on DigiKey.com ist great btw! Would recommend.

Which brings me to my next question:

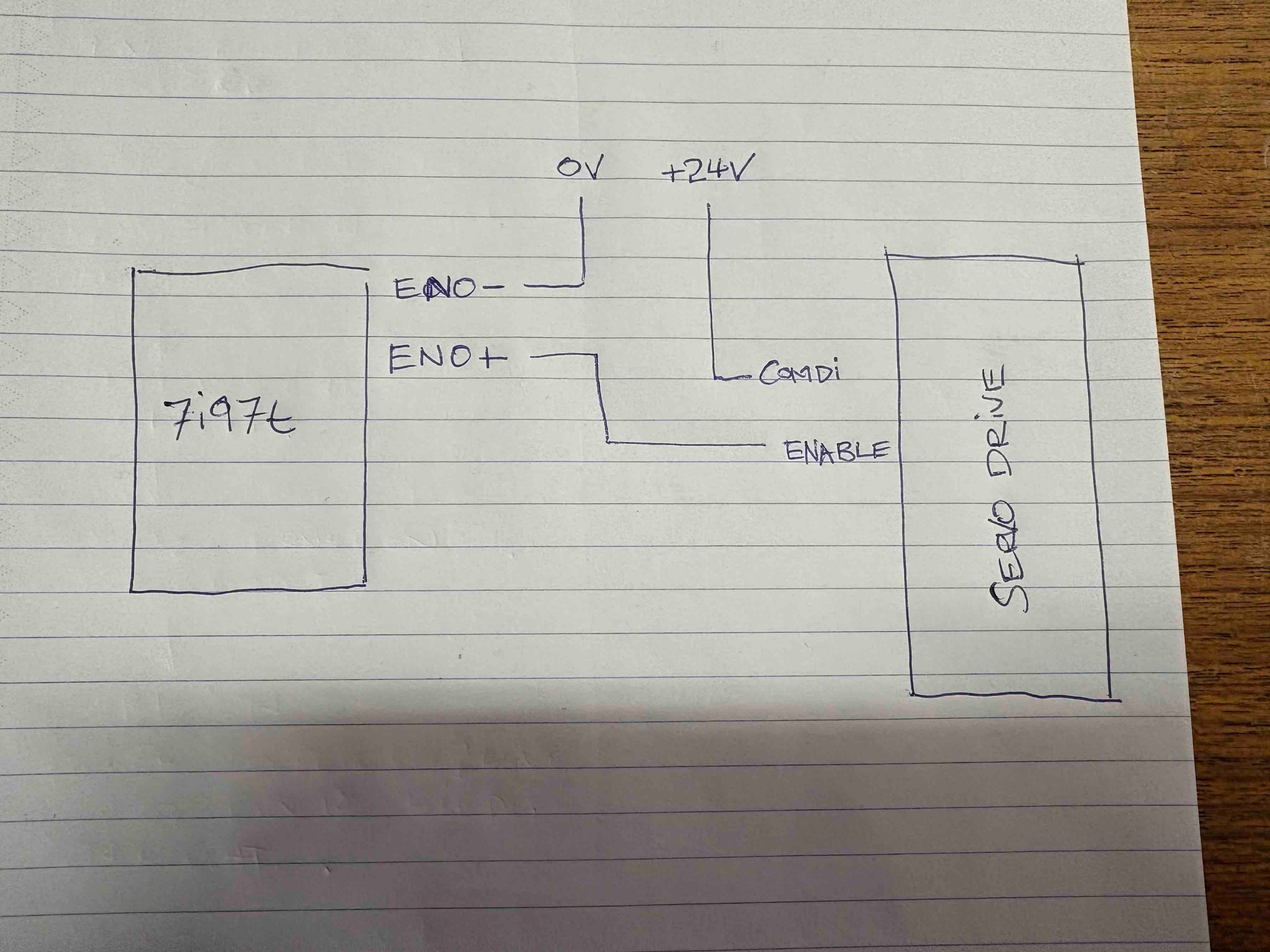

I assume I can run the enable controls from the 7i97t to drives without a relay? I believe I've drawn this with the correct polarity directions, but any insight are most appreciated.

More updates to come!

Cheers,

j

I don't get to do as much ally as I'd like.

Bit of a progress update from the last couple weeks:

Control panel is at the powder coaters. I choose a dark matt charcoal. Mainly as my coater runs this Dulux colour often and Im impatient at the best of times! Should have this back on Tuesday.

The custom control panel buttons are now 3d printed, along with the MX switch carriers. All wired up. These run into a DB25 breakout board and then will travel back the Mesa cards in the cabinet. I appreciate this isn't the nicest way to execute it, but I only require the 7i97t and 7i84u for all IO, and most IO terminates in the cabinet. I got cold feet on flashing the 7i97.... Pics below.

PC has been setup with linuxcnc. I chose a Coofun CK41 miniPC, which The Feral Engineer made some tests on YouTube with seemingly good results. Fingers crossed it works out. It's very compact and so was the price tag. Took me a few nights to get MesaCT and an updated Mesaflash running correctly to recognise the 7i97T. This is honestly due to my lack of unix (or IT in general!) skills. We got there in the end - I'm now able to run a draft linuxcnc config and toggle a coolant assigned output on the 7i97t with no dramas. I'll take that as a win. Yet to hook up the 7i84u.

Have to thank JT for the great MesaCT package!

I was and still am very daunted by the task of editing lines in the Hal/ini files.

The servo drives are currently on their way from China. I went with Leadshine EL7 drives in the end. The price was decent and they're offered in 380-400v 3ph. Opted for analog/pulse control as these control methods appear to be well documented here, especially by Tommylight's guide. Ethercat looked appealing, but given my lack of IT skills I thought it safe to stick with the aforementioned.

This weekend I started drafting the wiring diagrams between the Mesa boards, original Bridgeport control/distrubution board and new servo drives. The free schematic cad on DigiKey.com ist great btw! Would recommend.

Which brings me to my next question:

I assume I can run the enable controls from the 7i97t to drives without a relay? I believe I've drawn this with the correct polarity directions, but any insight are most appreciated.

More updates to come!

Cheers,

j

Attachments:

Please Log in or Create an account to join the conversation.

- spincycle

- Offline

- Junior Member

-

Less

More

- Posts: 33

- Thank you received: 6

12 Jun 2025 05:57 #330194

by spincycle

Replied by spincycle on topic Bridgeport VMC760 retrofit

Alrighty!

Drives and motors arrived. Setup a bench test rig.

I've made it as far as getting the encoders to read in LCNC (scale seems right). Unfortunately I'm getting following errors when I try enabling the drive. I can hear the drive enable relay latch very briefly.

I've followed Tommylights guide, but can't get too far when it errors straight out of the gate. Im also getting a "could not switch machine on, is limit switch activated". I currently have no IO assigned.

I suspect my wiring is at fault or I'm really missing the mark with my initial PID numbers - I've tried a bunch so far, even with giant max f errors.

Schematic below. Any thoughts would be greatly appreciated!

Thanks,

J

Drives and motors arrived. Setup a bench test rig.

I've made it as far as getting the encoders to read in LCNC (scale seems right). Unfortunately I'm getting following errors when I try enabling the drive. I can hear the drive enable relay latch very briefly.

I've followed Tommylights guide, but can't get too far when it errors straight out of the gate. Im also getting a "could not switch machine on, is limit switch activated". I currently have no IO assigned.

I suspect my wiring is at fault or I'm really missing the mark with my initial PID numbers - I've tried a bunch so far, even with giant max f errors.

Schematic below. Any thoughts would be greatly appreciated!

Thanks,

J

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17708

- Thank you received: 5180

12 Jun 2025 19:43 #330228

by PCW

Replied by PCW on topic Bridgeport VMC760 retrofit

You need to set large min-ferror and ferror limits (an inch / 25mm or so) so you can see

the motor behavior (you have about a 50% chance of the wrong feedback direction and

runaway so of course this needs to be addressed first.)

Also make sure you have working drive enables or motors disconnected from linear axis

as a runaway linear axis can be dangerous/destructive.

the motor behavior (you have about a 50% chance of the wrong feedback direction and

runaway so of course this needs to be addressed first.)

Also make sure you have working drive enables or motors disconnected from linear axis

as a runaway linear axis can be dangerous/destructive.

Please Log in or Create an account to join the conversation.

- spincycle

- Offline

- Junior Member

-

Less

More

- Posts: 33

- Thank you received: 6

13 Jun 2025 02:59 #330240

by spincycle

Replied by spincycle on topic Bridgeport VMC760 retrofit

Thank you for your replies PCW and langdons,

You were on the money PCW! I had my MIN-Ferror set way too small - this made sense in my head, but clearly didn't work. Also swapped my A,B and Z polarities at the mesa. Thank you greatly for the tip!!

I've got the test motor running now, and am able to tune it with Tommylight's guide on the bench within 0.003mm ferror. Couple of questions for the next stage though:

- I assume I would get a baseline tune on the bench for all motors. Then instal motors, run the inertia calculator in the motor software (adust these parameters where fit), then finally re-tune/adjust my position tuning with motors under real loads?

Regarding wiring - I plan to use twisted pairs on the ANOout/GND control and each encoder channel. Can I have the 3 encoder twisted pairs in one shielded cable and the analog control in a seperate one? Or can I put them all in a common shielded cable?

Or do all encoder pairs need to be in seperate shielded cables as well?

Currently I'm just using some CAT6 cable for the encoder link and some shielded twin core audio cable for the analog voltage on the bench. However, I'd like to order the right stuff for the next stage of wiring.

Many thanks,

J

You were on the money PCW! I had my MIN-Ferror set way too small - this made sense in my head, but clearly didn't work. Also swapped my A,B and Z polarities at the mesa. Thank you greatly for the tip!!

I've got the test motor running now, and am able to tune it with Tommylight's guide on the bench within 0.003mm ferror. Couple of questions for the next stage though:

- I assume I would get a baseline tune on the bench for all motors. Then instal motors, run the inertia calculator in the motor software (adust these parameters where fit), then finally re-tune/adjust my position tuning with motors under real loads?

Regarding wiring - I plan to use twisted pairs on the ANOout/GND control and each encoder channel. Can I have the 3 encoder twisted pairs in one shielded cable and the analog control in a seperate one? Or can I put them all in a common shielded cable?

Or do all encoder pairs need to be in seperate shielded cables as well?

Currently I'm just using some CAT6 cable for the encoder link and some shielded twin core audio cable for the analog voltage on the bench. However, I'd like to order the right stuff for the next stage of wiring.

Many thanks,

J

Please Log in or Create an account to join the conversation.

- spincycle

- Offline

- Junior Member

-

Less

More

- Posts: 33

- Thank you received: 6

24 Jun 2025 05:37 #330789

by spincycle

Replied by spincycle on topic Bridgeport VMC760 retrofit

Thanks for your input Langdons.

I used shielded on the encoder feed and analog control lead. The IO's I left unshielded. These looms are wired up and ready to go.

Little bit of progress. Got the control panel assembled with touchscreen and computer. It's definitely not a small screen....

The DB37 breakout units arrived, which will allow me to use the existing Heidenhain control cables to feed the relay board from the Mesa cards.

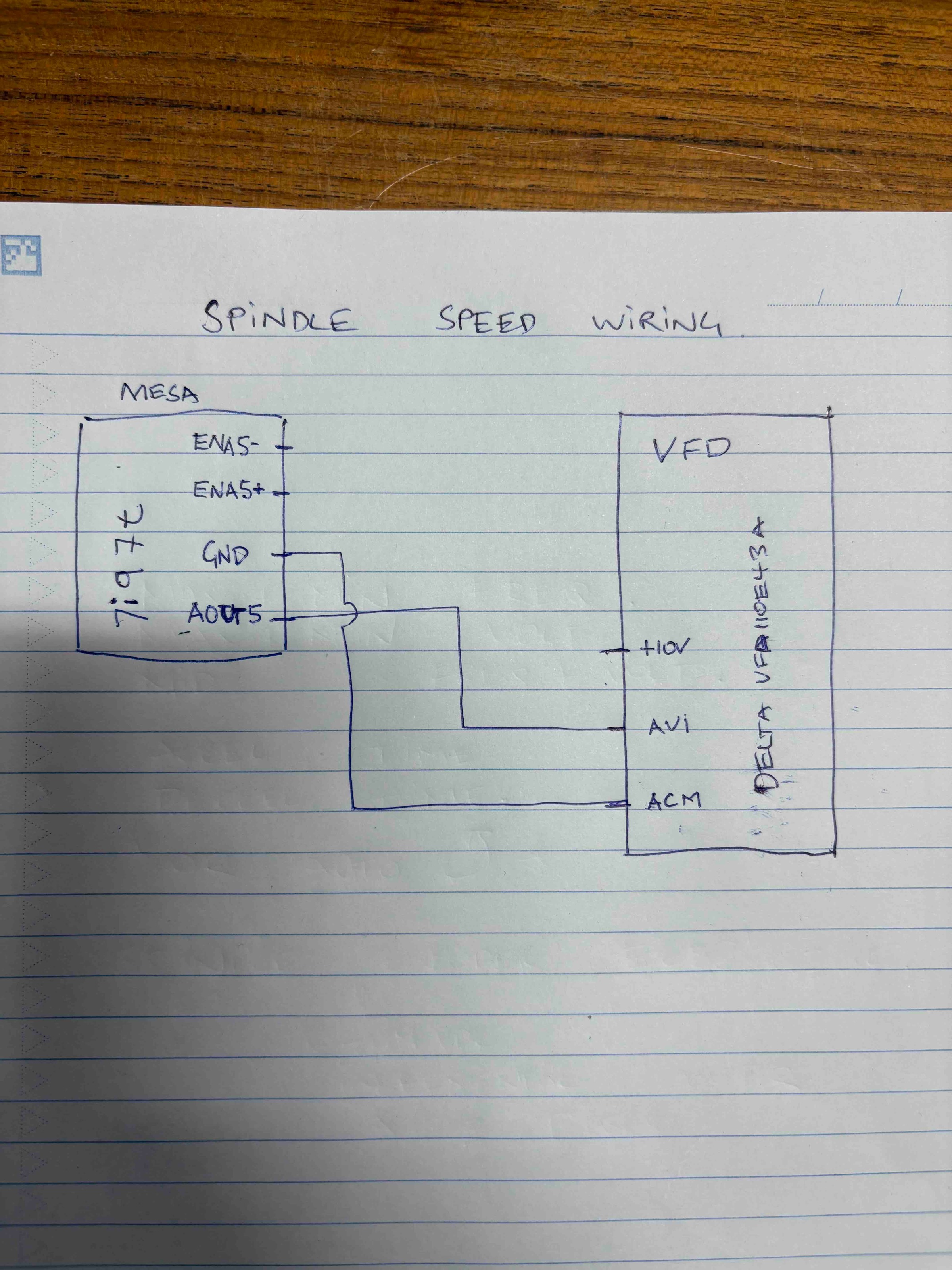

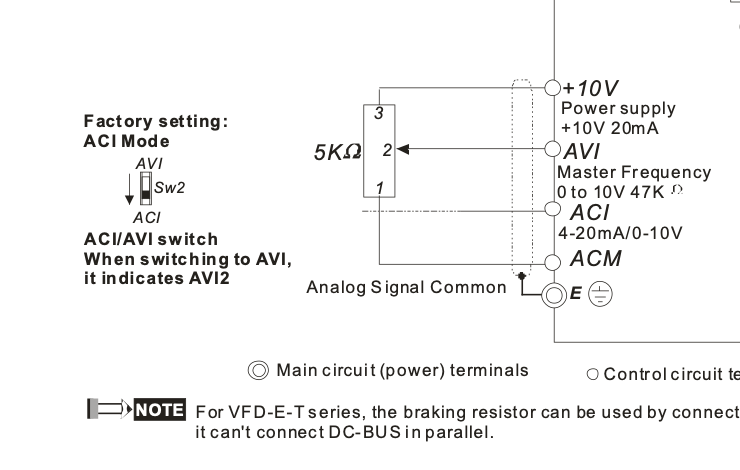

I just wanted to check VFD speed control wiring. The Delta data sheet only shows external speed control using a potentiometer. Can I wire it like below, using the axis 4 or 5 on the 7i97t to control it?

I'll activate the FWD/STOP, REV/STOP and OUTPUT SHUTDOWN via outputs on the 7i97t.

Thanks!

J

I used shielded on the encoder feed and analog control lead. The IO's I left unshielded. These looms are wired up and ready to go.

Little bit of progress. Got the control panel assembled with touchscreen and computer. It's definitely not a small screen....

The DB37 breakout units arrived, which will allow me to use the existing Heidenhain control cables to feed the relay board from the Mesa cards.

I just wanted to check VFD speed control wiring. The Delta data sheet only shows external speed control using a potentiometer. Can I wire it like below, using the axis 4 or 5 on the 7i97t to control it?

I'll activate the FWD/STOP, REV/STOP and OUTPUT SHUTDOWN via outputs on the 7i97t.

Thanks!

J

Attachments:

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.291 seconds