- Configuring LinuxCNC

- Configuration Tools

- StepConf Wizard

- Looking for advice? Is my DB25-1205 breakout board faulty?

×

Forum Header

Looking for advice? Is my DB25-1205 breakout board faulty?

- uptown47

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 1

21 Nov 2018 20:36 #121173

by uptown47

Replied by uptown47 on topic Looking for advice? Is my DB25-1205 breakout board faulty?

Hi Rodw,

The Arduino is just controlling the manual functions and that side of it works well. It's just the control from the PC via the breakout board that I'm struggling with.

But you're right about the active low. I seem to remember something about that when I was setting it up.

Thanks for your help.

The Arduino is just controlling the manual functions and that side of it works well. It's just the control from the PC via the breakout board that I'm struggling with.

But you're right about the active low. I seem to remember something about that when I was setting it up.

Thanks for your help.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

21 Nov 2018 20:42 #121174

by rodw

Replied by rodw on topic Looking for advice? Is my DB25-1205 breakout board faulty?

In the brief play I had with the device, I patched some of the inputs and observed the pins in halshow to confirm it worked. I can't remember if I patched to GND or the +V rail. Too long ago.

The following user(s) said Thank You: uptown47

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

22 Nov 2018 00:06 #121194

by phillc54

Replied by phillc54 on topic Looking for advice? Is my DB25-1205 breakout board faulty?

The motor specification you linked to states 1.8 degrees per step so Motor Steps Per Revolution should be 200.

With 10 microsteps, a 1:1 ratio and a 5mm pitch you should end up with a scale value of 400. (200 x 10 x (1/1) x (1/5))

Cheers, Phill

With 10 microsteps, a 1:1 ratio and a 5mm pitch you should end up with a scale value of 400. (200 x 10 x (1/1) x (1/5))

Cheers, Phill

The following user(s) said Thank You: uptown47

Please Log in or Create an account to join the conversation.

- uptown47

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 1

22 Nov 2018 07:48 #121207

by uptown47

Replied by uptown47 on topic Looking for advice? Is my DB25-1205 breakout board faulty?

That's great Phil. Thanks for that (and showing how it is worked out).

I've found another breakout board in my stash of bits 'n bobs so I'll try and change my old one when I get chance (hopefully tonight) and then report back.

Will also update the settings as per your formula.

Thanks again

John

I've found another breakout board in my stash of bits 'n bobs so I'll try and change my old one when I get chance (hopefully tonight) and then report back.

Will also update the settings as per your formula.

Thanks again

John

Please Log in or Create an account to join the conversation.

- uptown47

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 1

22 Nov 2018 08:27 #121208

by uptown47

Just another question regarding this. My drivers (www.wantmotor.com/product/dq860ma.html) have dip switches on them to allow me to select the number of 'microsteps'. Should I be selecting 200 on here to reflect the Motor Steps Per Rev figure? Or can I select as many as I want on here and it will split the 200 per rev down to whatever number I select in order to add more resolution??

Also, should the "Driver Microstepping" value in LinuxCNC reflect whatever I've selected on the Dip Switches of my driver?

Thanks

Replied by uptown47 on topic Looking for advice? Is my DB25-1205 breakout board faulty?

The motor specification you linked to states 1.8 degrees per step so Motor Steps Per Revolution should be 200.

With 10 microsteps, a 1:1 ratio and a 5mm pitch you should end up with a scale value of 400. (200 x 10 x (1/1) x (1/5))

Cheers, Phill

Just another question regarding this. My drivers (www.wantmotor.com/product/dq860ma.html) have dip switches on them to allow me to select the number of 'microsteps'. Should I be selecting 200 on here to reflect the Motor Steps Per Rev figure? Or can I select as many as I want on here and it will split the 200 per rev down to whatever number I select in order to add more resolution??

Also, should the "Driver Microstepping" value in LinuxCNC reflect whatever I've selected on the Dip Switches of my driver?

Thanks

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

22 Nov 2018 09:38 #121209

by rodw

Replied by rodw on topic Looking for advice? Is my DB25-1205 breakout board faulty?

The speed of your base thread (and the break out board) will put a finite limit on the maximum frequency your motors can run at. I'd start with 10x microstepping and see how it goes. That means it will do 2000 steps per motor rev. or as Phil said 2000/5 (400) steps per mm on a 5mm ball screw. All Linuxcnc cares about is the number of steps per device unit (mm or inch). Thats what goes in the ini file, anything else is a convenience in stepconf (which I've never used).

The following user(s) said Thank You: uptown47

Please Log in or Create an account to join the conversation.

- uptown47

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 1

22 Nov 2018 09:46 #121210

by uptown47

Replied by uptown47 on topic Looking for advice? Is my DB25-1205 breakout board faulty?

Hi Rod,

Thanks for the advice. So am I setting the dip switches on my stepper drivers to be 400 then? Or am I setting them to 2000?

Sorry if this is a stupid question but I'm just getting a bit confused between the settings on LinuxCNC and the settings on the stepper driver?

Thanks for your patience.

John

Thanks for the advice. So am I setting the dip switches on my stepper drivers to be 400 then? Or am I setting them to 2000?

Sorry if this is a stupid question but I'm just getting a bit confused between the settings on LinuxCNC and the settings on the stepper driver?

Thanks for your patience.

John

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

22 Nov 2018 09:55 #121211

by rodw

Replied by rodw on topic Looking for advice? Is my DB25-1205 breakout board faulty?

Both your hardware and Linuxcnc need to be in sync.

Your stepper is a bit confusing but its all based on the 200 steps/rev (1.8 deg/step).

1x stepping = 200 and is not supported

2x stepping = 400

10x stepping = 2,000

So its 2,000 is what you need.

Your stepper is a bit confusing but its all based on the 200 steps/rev (1.8 deg/step).

1x stepping = 200 and is not supported

2x stepping = 400

10x stepping = 2,000

So its 2,000 is what you need.

The following user(s) said Thank You: uptown47

Please Log in or Create an account to join the conversation.

- uptown47

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 1

22 Nov 2018 09:57 #121212

by uptown47

Replied by uptown47 on topic Looking for advice? Is my DB25-1205 breakout board faulty?

Excellent Rod. Thank you!

I'm going to have another stab at it either tonight or tomorrow.

I've got another breakout board to try as well so hopefully I'll be able to get it sorted.

I really appreciate everyone's help on this. I'll report back as to how I get on

I'm going to have another stab at it either tonight or tomorrow.

I've got another breakout board to try as well so hopefully I'll be able to get it sorted.

I really appreciate everyone's help on this. I'll report back as to how I get on

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

22 Nov 2018 11:43 #121213

by phillc54

Replied by phillc54 on topic Looking for advice? Is my DB25-1205 breakout board faulty?

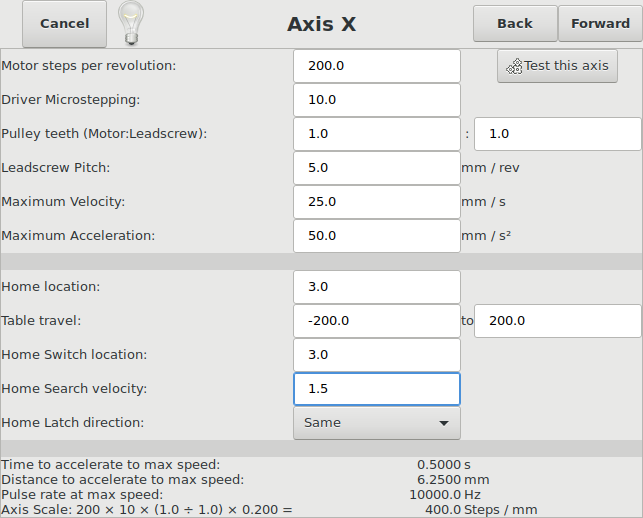

If you are using stepconf for your above settings you need to enter as in the attached screenshot.

Motor steps is the actual physical motor steps, for your motor it is 200.

Driver Microstepping is the number of microsteps per motor step, for your setup it is 10.

Some drivers confuse the issue by saying 2000, when they actually mean 2000 total steps per rev. (200 x 10).

If you enter this confusing value in stepconf for the motor revs then you need to enter 1 for the microsteps as this is the total number of steps required per rev.

If you look at the bottom of the screenshot the Axis Scale is 400, this is what is transferred into your ini file as Scale. This is the important value and it also shows how it is calculated using the top four rows of the screenshot, the 0.2 being 1mm/5mm because we are calculating the number of steps required to move 1mm.

Cheers, Phill.

Motor steps is the actual physical motor steps, for your motor it is 200.

Driver Microstepping is the number of microsteps per motor step, for your setup it is 10.

Some drivers confuse the issue by saying 2000, when they actually mean 2000 total steps per rev. (200 x 10).

If you enter this confusing value in stepconf for the motor revs then you need to enter 1 for the microsteps as this is the total number of steps required per rev.

If you look at the bottom of the screenshot the Axis Scale is 400, this is what is transferred into your ini file as Scale. This is the important value and it also shows how it is calculated using the top four rows of the screenshot, the 0.2 being 1mm/5mm because we are calculating the number of steps required to move 1mm.

Cheers, Phill.

The following user(s) said Thank You: uptown47

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Configuration Tools

- StepConf Wizard

- Looking for advice? Is my DB25-1205 breakout board faulty?

Time to create page: 0.105 seconds