Mini lathe conversion to CNC

- tml

- Offline

- Junior Member

-

- Posts: 34

- Thank you received: 0

My plan is to use one proximity sensor for limit and homing function for each axis. I still have to wait for some more parts before I can get that going.

Please Log in or Create an account to join the conversation.

- verticalperformance

-

- Offline

- Senior Member

-

- Posts: 55

- Thank you received: 11

Interesting. That homing process sounds pretty straight forward and should give repeatable results as well. The only issue I can see with that is some stepper motor/servo have a tendency to jitter or move slightly when it's first powered on. If that happens then it would throw off your last home position that you saved. Have you ever experienced that?

If I'm chasing accurate diameters, I always chuck some scrap and confirm that the diameter Linux CNC thinks it's making is the diameter it's actually making. Then I touch off X on the measured just machined diameter to compensate for the x=0 in machine coordinates being a little off.

Every now an then I'll do the above, command the machine to X=0 in part coordinates, turn off the drives, then command the machine to X=0 in machine coordinates and re-home.

I always command the lathe back to the home location when I'm done, so it starts up pretty close to x=0, as you noted sometimes the axis jiggles a little on startup. Having a real home switch on the X would be a real timesaver though!

Please Log in or Create an account to join the conversation.

- tml

- Offline

- Junior Member

-

- Posts: 34

- Thank you received: 0

- Tim

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

- Posts: 19802

- Thank you received: 4609

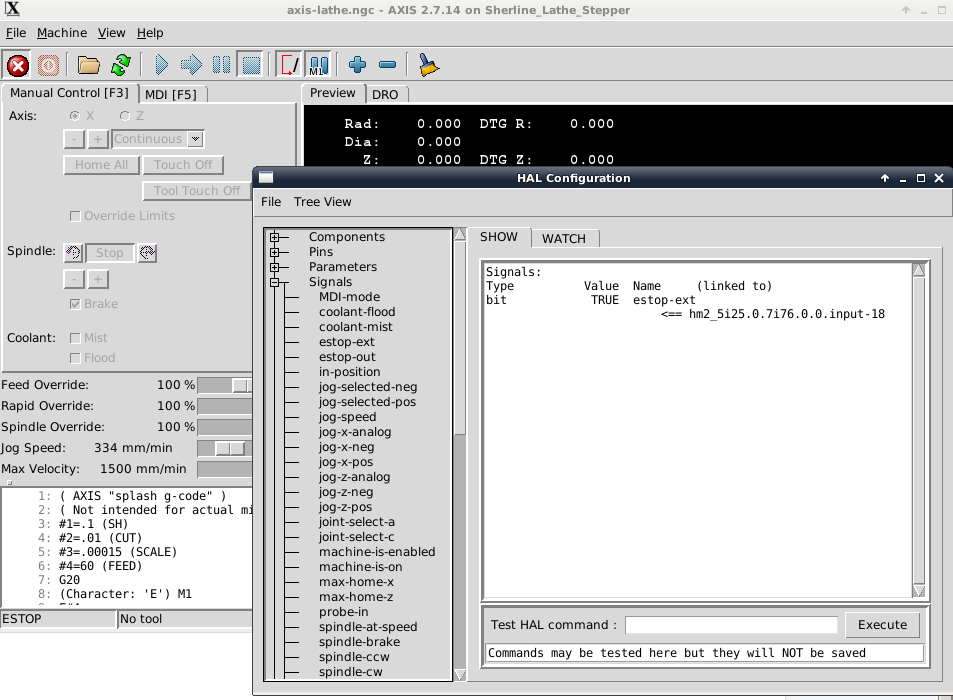

I don't know if the Mesa 7i76 board has some terminals I should hook up the e-stop wiring to, to notify it when the button is pushed .

Nothing specifically for that job.

On my lathe I use an auxiliary terminal on the main contactor to indicate an e-stop has been pressed. The e-stop breaks the coil current, the contactor drops out and the auxiliary contact opens to inform LinuxCNC.

On the mill I used a second switch block on the E-stop button, NC breaks to turn off the contactor, NO makes to inform LinuxCNC.

Please Log in or Create an account to join the conversation.

- tml

- Offline

- Junior Member

-

- Posts: 34

- Thank you received: 0

I have another N.C. contact block that I can use to connect to the 7i76. Am I right in thinking that my +24V goes to the E-stop switch, then run the other wire from the switch to one of the 7i76's field input connectors?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

- Posts: 19802

- Thank you received: 4609

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

- Posts: 3990

- Thank you received: 994

gnipsel.com/linuxcnc/configs/7i77.html

JT

Please Log in or Create an account to join the conversation.

- tml

- Offline

- Junior Member

-

- Posts: 34

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

- Posts: 19802

- Thank you received: 4609

Please Log in or Create an account to join the conversation.

- tml

- Offline

- Junior Member

-

- Posts: 34

- Thank you received: 0

Please Log in or Create an account to join the conversation.