Threading on a Boxford TCL lathe

- john11668

- Offline

- Elite Member

-

Less

More

- Posts: 199

- Thank you received: 10

19 May 2021 16:47 #209528

by john11668

Replied by john11668 on topic Threading on a Boxford TCL lathe

Spindle revs is increasing by one at each rev, and increases continually when running.

Spindle at speed stays false and and spindle index stays at false .

I cant get the true speed to match the speed called for because they stay in ratio so I would seem to need to alter the ratio to bring the two into line .

And Yes G21 is active

Spindle at speed stays false and and spindle index stays at false .

I cant get the true speed to match the speed called for because they stay in ratio so I would seem to need to alter the ratio to bring the two into line .

And Yes G21 is active

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

19 May 2021 18:52 #209536

by andypugh

Replied by andypugh on topic Threading on a Boxford TCL lathe

spindle.0.index-enable will only be true very briefly. The problem would be if it was staying high.

What drives spindle-at-speed? Note that it only has to indicate "true" to the system, it doesn't actually need to be true.

But, really, you should get the spindle speed to match the requested speed. It's probably just one number to change in the INI (or possibly directly in the HAL)

What drives spindle-at-speed? Note that it only has to indicate "true" to the system, it doesn't actually need to be true.

But, really, you should get the spindle speed to match the requested speed. It's probably just one number to change in the INI (or possibly directly in the HAL)

The following user(s) said Thank You: john11668

Please Log in or Create an account to join the conversation.

- john11668

- Offline

- Elite Member

-

Less

More

- Posts: 199

- Thank you received: 10

19 May 2021 22:06 - 19 May 2021 22:17 #209555

by john11668

Replied by john11668 on topic Threading on a Boxford TCL lathe

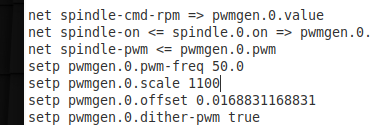

Attachments:

Last edit: 19 May 2021 22:17 by john11668.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

19 May 2021 22:27 #209559

by andypugh

Yes, but it can be made automatic.

Can you think of a way for the system to know which ratio is active? Maybe laser / sensor pairs to tell where the belt is?

(not expensive - www.amazon.co.uk/WayinTop-Photoresistor-...sistor/dp/B07PHFSR2B)

Once the information is in to HAL then you can use a mux component to set the correct pwmgen scale.

Replied by andypugh on topic Threading on a Boxford TCL lathe

i suspect that I will have to change this figure for every belt ratio though.

Yes, but it can be made automatic.

Can you think of a way for the system to know which ratio is active? Maybe laser / sensor pairs to tell where the belt is?

(not expensive - www.amazon.co.uk/WayinTop-Photoresistor-...sistor/dp/B07PHFSR2B)

Once the information is in to HAL then you can use a mux component to set the correct pwmgen scale.

Please Log in or Create an account to join the conversation.

- john11668

- Offline

- Elite Member

-

Less

More

- Posts: 199

- Thank you received: 10

19 May 2021 22:43 #209564

by john11668

Replied by john11668 on topic Threading on a Boxford TCL lathe

I suspect I will use only two belt positions ,

One for speeds up to say 2500revs , and one low speed option like a back gear , ( I doubt if my motor will reliably produce enough torque at low speed, so I will probably have to manually change belt position along with a tool change for threading. Then suppose I can add a simple switch to say I am in back gear mode to prompt the software selection.

One for speeds up to say 2500revs , and one low speed option like a back gear , ( I doubt if my motor will reliably produce enough torque at low speed, so I will probably have to manually change belt position along with a tool change for threading. Then suppose I can add a simple switch to say I am in back gear mode to prompt the software selection.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

19 May 2021 23:00 #209574

by andypugh

Replied by andypugh on topic Threading on a Boxford TCL lathe

Does the lathe have an _actual_ back gear?

It makes no sense to preclude the use of any gears that you have. Configure this once, and do it right.

It is possible to infer the gear selected from the ratio of motor speed and spindle speed: forum.linuxcnc.org/47-hal-examples/27071...gear-detection#39583

It makes no sense to preclude the use of any gears that you have. Configure this once, and do it right.

It is possible to infer the gear selected from the ratio of motor speed and spindle speed: forum.linuxcnc.org/47-hal-examples/27071...gear-detection#39583

Please Log in or Create an account to join the conversation.

- john11668

- Offline

- Elite Member

-

Less

More

- Posts: 199

- Thank you received: 10

20 May 2021 10:07 #209632

by john11668

Replied by john11668 on topic Threading on a Boxford TCL lathe

The lathe does not have a back gear , only belts,, but I do find that for most turning operations one belt ratio, along with the Sprint electronic drive unit (which varies the spindle speed quite effectively under pwm control) covers the speeds needed for most turning operations.

A change of belt ratio only therefore becomes necessary for high torque demands like threading.

The TCL is not a sophisticated machine . It is by definition a Training school lathe , and I see it my introduction to lathe CNC. As such it is unlikely to be producing complicated components.

It is probable therefore that I will only need two ratios .

I am guessing therefore that a much simpler piece of code to that outlined in the thread above would suffice for me. My problem is that with my current experience , that piece of code is beyond my capability..

Is it possible that such automatic speed detection will be added to linuxCNC?

Meanwhile I may try to find a single belt ratio which covers my current needs yet still provides enough torque at low speeds to permit threading with lighter cuts . (along with of course a suitable pwmgen scale number)

Thanks for your assistance on this problem so far.

A change of belt ratio only therefore becomes necessary for high torque demands like threading.

The TCL is not a sophisticated machine . It is by definition a Training school lathe , and I see it my introduction to lathe CNC. As such it is unlikely to be producing complicated components.

It is probable therefore that I will only need two ratios .

I am guessing therefore that a much simpler piece of code to that outlined in the thread above would suffice for me. My problem is that with my current experience , that piece of code is beyond my capability..

Is it possible that such automatic speed detection will be added to linuxCNC?

Meanwhile I may try to find a single belt ratio which covers my current needs yet still provides enough torque at low speeds to permit threading with lighter cuts . (along with of course a suitable pwmgen scale number)

Thanks for your assistance on this problem so far.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

20 May 2021 11:48 #209639

by andypugh

There is a HAL component for the 2-speed case:

linuxcnc.org/docs/2.8/html/man/man9/gearchange.9.html

And another for more gears:

linuxcnc.org/docs/2.8/html/man/man9/spindle.9.html

Or, in your case, you could do it all with a mux4. But the question is how you would prefer to indicate the current gear to the system?

Replied by andypugh on topic Threading on a Boxford TCL lathe

Do you have enough IO pins for a physical switch or sensor to tell the system which gear it is in?I am guessing therefore that a much simpler piece of code to that outlined in the thread above would suffice for me. My problem is that with my current experience , that piece of code is beyond my capability..

There is a HAL component for the 2-speed case:

linuxcnc.org/docs/2.8/html/man/man9/gearchange.9.html

And another for more gears:

linuxcnc.org/docs/2.8/html/man/man9/spindle.9.html

Or, in your case, you could do it all with a mux4. But the question is how you would prefer to indicate the current gear to the system?

Please Log in or Create an account to join the conversation.

- john11668

- Offline

- Elite Member

-

Less

More

- Posts: 199

- Thank you received: 10

21 May 2021 18:32 #209775

by john11668

Replied by john11668 on topic Threading on a Boxford TCL lathe

Hi Andy and thanks

I have chosen a ratio which gives me speeds of 50 to 2000 rpm and I have found a pwmgen . scale figure which suits this, and gives me pretty close control in the low end of this range . It is nearly spot on at around 300 - 400 revs and does not impede the threading cycle ,

This gets me going for now (until the next snag comes along)

I will bookmark this thread so I can come back the the above links .

Thanks again

I have chosen a ratio which gives me speeds of 50 to 2000 rpm and I have found a pwmgen . scale figure which suits this, and gives me pretty close control in the low end of this range . It is nearly spot on at around 300 - 400 revs and does not impede the threading cycle ,

This gets me going for now (until the next snag comes along)

I will bookmark this thread so I can come back the the above links .

Thanks again

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

21 May 2021 19:41 #209787

by andypugh

Replied by andypugh on topic Threading on a Boxford TCL lathe

Making it work for all ratios isn't hard, if you ever want to get back to it. It's exactly the sort of thing that HAL is good at.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.348 seconds