Indramat 3trm2

- Sourabh3

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 1

02 Sep 2021 06:29 - 02 Sep 2021 09:46 #219407

by Sourabh3

Replied by Sourabh3 on topic Indramat 3trm2

So i have completed the homing cycle. And now I'm able to use MDI command. But when i put s1000 or s80 nothing happens. And when i click on spindle cw or ccw then the spindle 1k1/1k2 relay run directly along with star delta relays. But the gear change cycle doesn't take place. I'm just stuck at here.

Also it states error that detected running spindle while shifting, triggering emergency stop (but doesn't trigger the emergency stop in reality ). I tried activating and deactivating spindle steht relay but no luck.

Do i need to source the rip environment while running gmoccapy ? (did it need rip environment when compiling ?)

Also it states error that detected running spindle while shifting, triggering emergency stop (but doesn't trigger the emergency stop in reality ). I tried activating and deactivating spindle steht relay but no luck.

Do i need to source the rip environment while running gmoccapy ? (did it need rip environment when compiling ?)

Last edit: 02 Sep 2021 09:46 by Sourabh3.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1491

- Thank you received: 551

02 Sep 2021 14:00 #219437

by RotarySMP

Replied by RotarySMP on topic Indramat 3trm2

I asked my Linux guru mate who wrote the Comp...

read the LinuxCNC docs on how to compile comps I assume the instructions have changed in the newer version either they replaced that script with something else or renamed it or dunno, I'd have to google too in the version from back then rip-environment was located in linuxcnc/scripts so its not ours its part of linuxcnc I think he should also compile linuxcnc first the script gets created on the fly during their build as far as I can see

read the LinuxCNC docs on how to compile comps I assume the instructions have changed in the newer version either they replaced that script with something else or renamed it or dunno, I'd have to google too in the version from back then rip-environment was located in linuxcnc/scripts so its not ours its part of linuxcnc I think he should also compile linuxcnc first the script gets created on the fly during their build as far as I can see

The following user(s) said Thank You: Sourabh3

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 275

02 Sep 2021 17:09 #219443

by db1981

Replied by db1981 on topic Indramat 3trm2

if you don't have an RIP Install (run in place) you don't need to run rip-environment.

If your linuxcnc starts by simple type in "linuxcnc" then you have an normal package install, -> rip-environment is not neccesary.

If your linuxcnc starts by simple type in "linuxcnc" then you have an normal package install, -> rip-environment is not neccesary.

The following user(s) said Thank You: Sourabh3

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 275

02 Sep 2021 17:12 #219444

by db1981

Replied by db1981 on topic Indramat 3trm2

please post your actual hal and ini files. otherwise we are not able to help.

Please Log in or Create an account to join the conversation.

- Sourabh3

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 1

03 Sep 2021 13:08 #219515

by Sourabh3

Replied by Sourabh3 on topic Indramat 3trm2

So i had some trouble with pncconf and mark (white angel came down to earth to help me) and i shamelessly copied his hal and ini files.

forum.linuxcnc.org/12-milling/33035-retr...-maho-mh400e?start=0

The hal files in his first post are exactly the same in mine. I'm using 2.7.14 wheezy and my machine is exactly the same as mark's

forum.linuxcnc.org/12-milling/33035-retr...-maho-mh400e?start=0

The hal files in his first post are exactly the same in mine. I'm using 2.7.14 wheezy and my machine is exactly the same as mark's

Please Log in or Create an account to join the conversation.

- Sourabh3

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 1

03 Sep 2021 13:11 #219516

by Sourabh3

Replied by Sourabh3 on topic Indramat 3trm2

Thanks mark, I'm figuring out things now, learning the new way to compile. I'll update you as soon as I'm able to figure it out.

I don't understand German language much so can you tell me how the central lubrication works. The"p" and the "v" switches... What do they do? I guess p is the pressure switch and v?

I don't understand German language much so can you tell me how the central lubrication works. The"p" and the "v" switches... What do they do? I guess p is the pressure switch and v?

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1491

- Thank you received: 551

04 Sep 2021 05:33 - 04 Sep 2021 07:55 #219577

by RotarySMP

Replied by RotarySMP on topic Indramat 3trm2

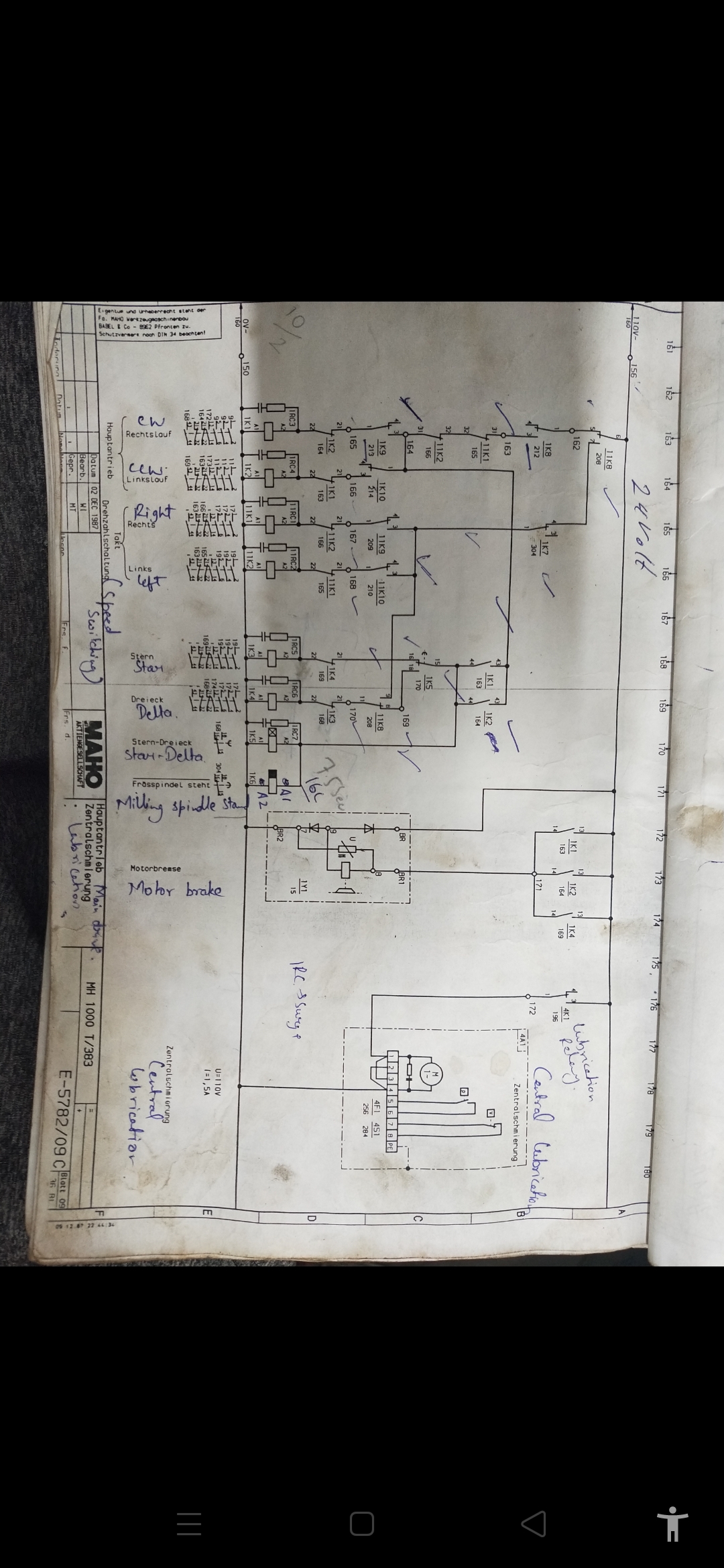

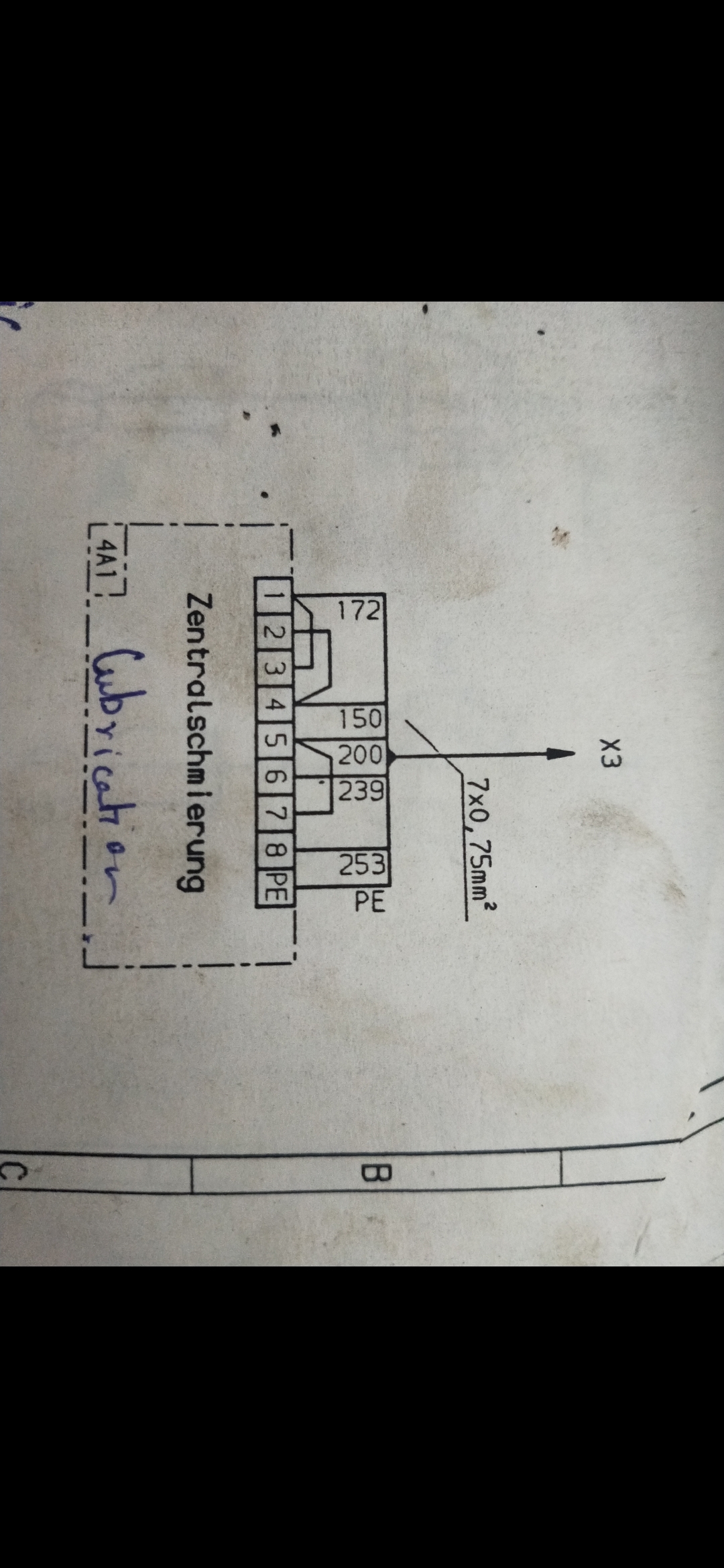

Please post a schematic of your lubrication unit, so I know what you are talking about.

Mark

Mark

Last edit: 04 Sep 2021 07:55 by RotarySMP.

Please Log in or Create an account to join the conversation.

- Sourabh3

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 1

05 Sep 2021 14:41 - 06 Sep 2021 05:46 #219673

by Sourabh3

Replied by Sourabh3 on topic Indramat 3trm2

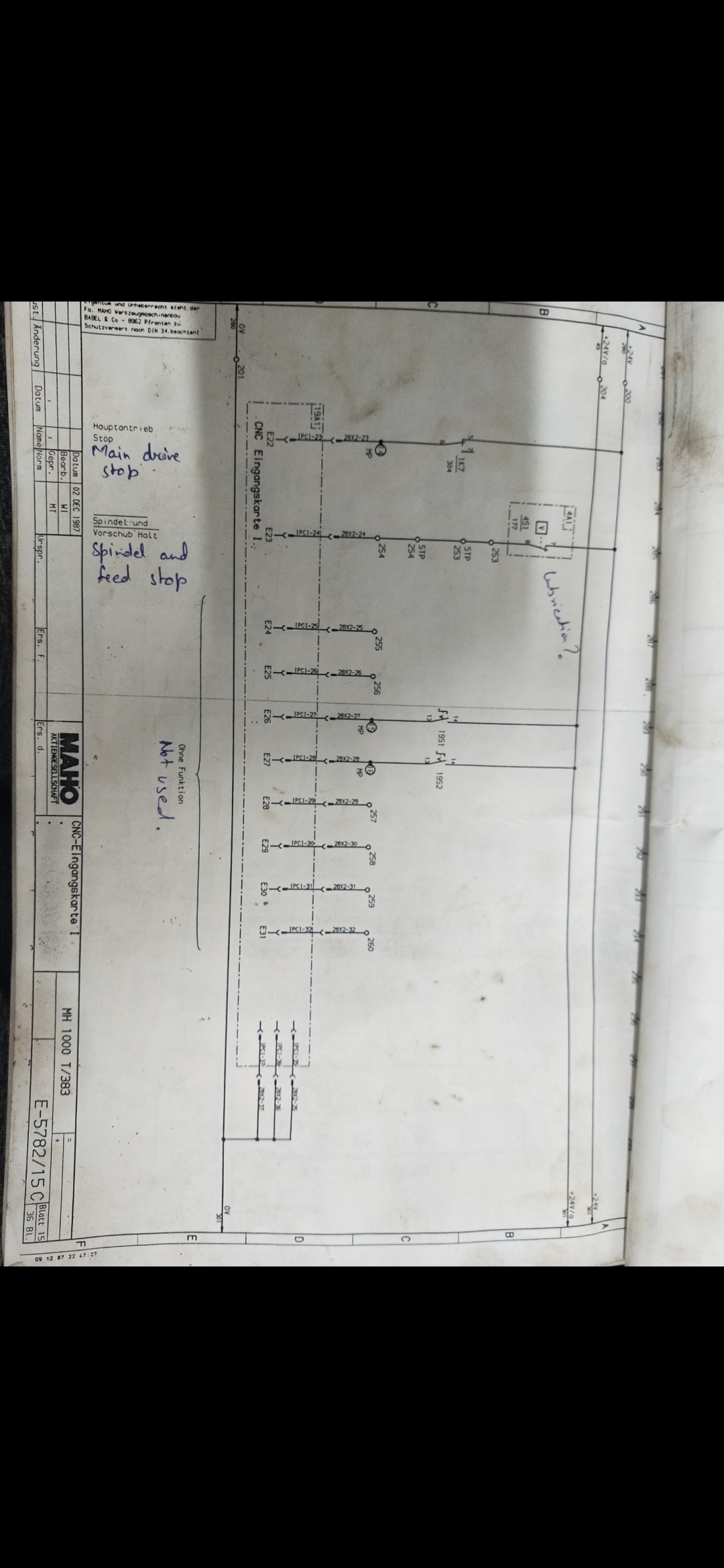

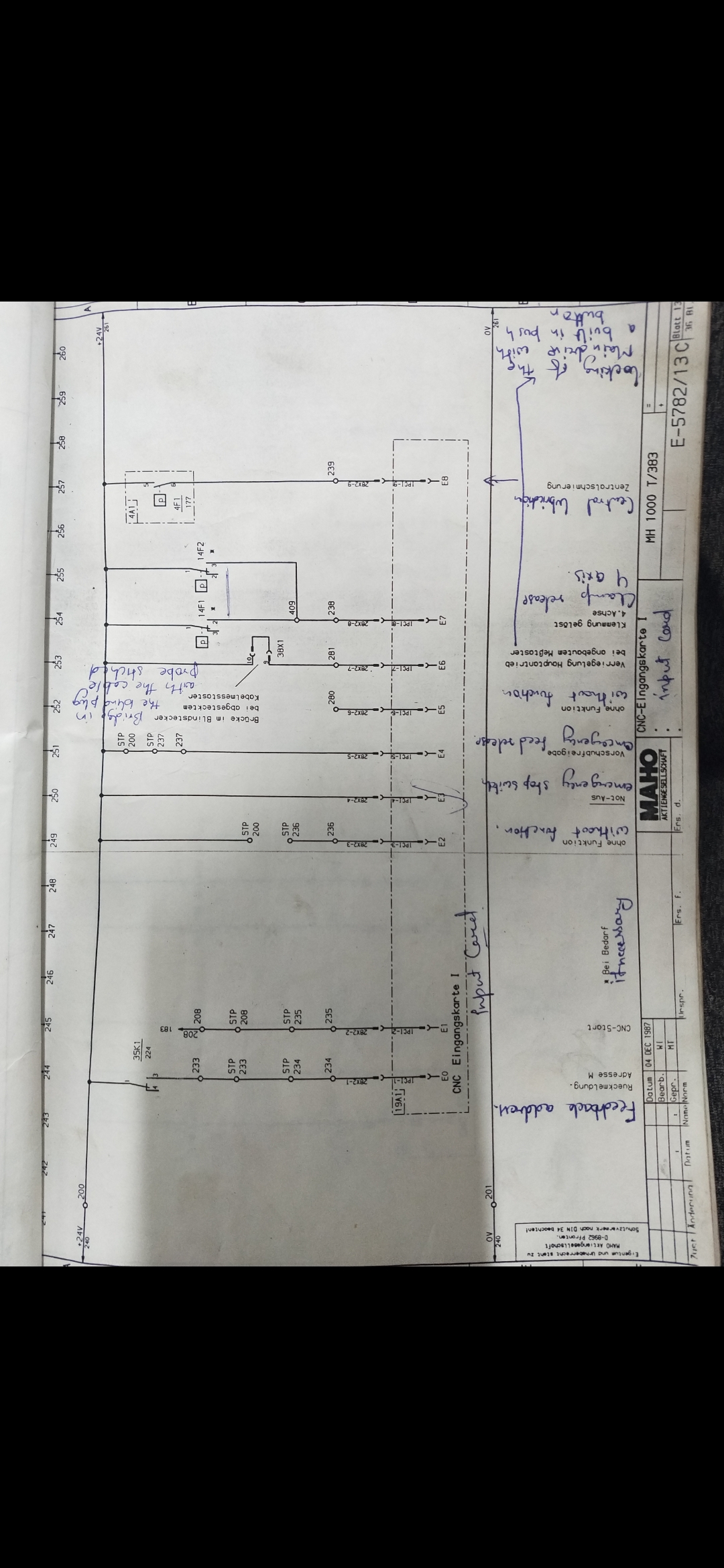

Sorry for the late reply mark, I've had some trouble at work. Here are the diagrams of the central lubrication system.

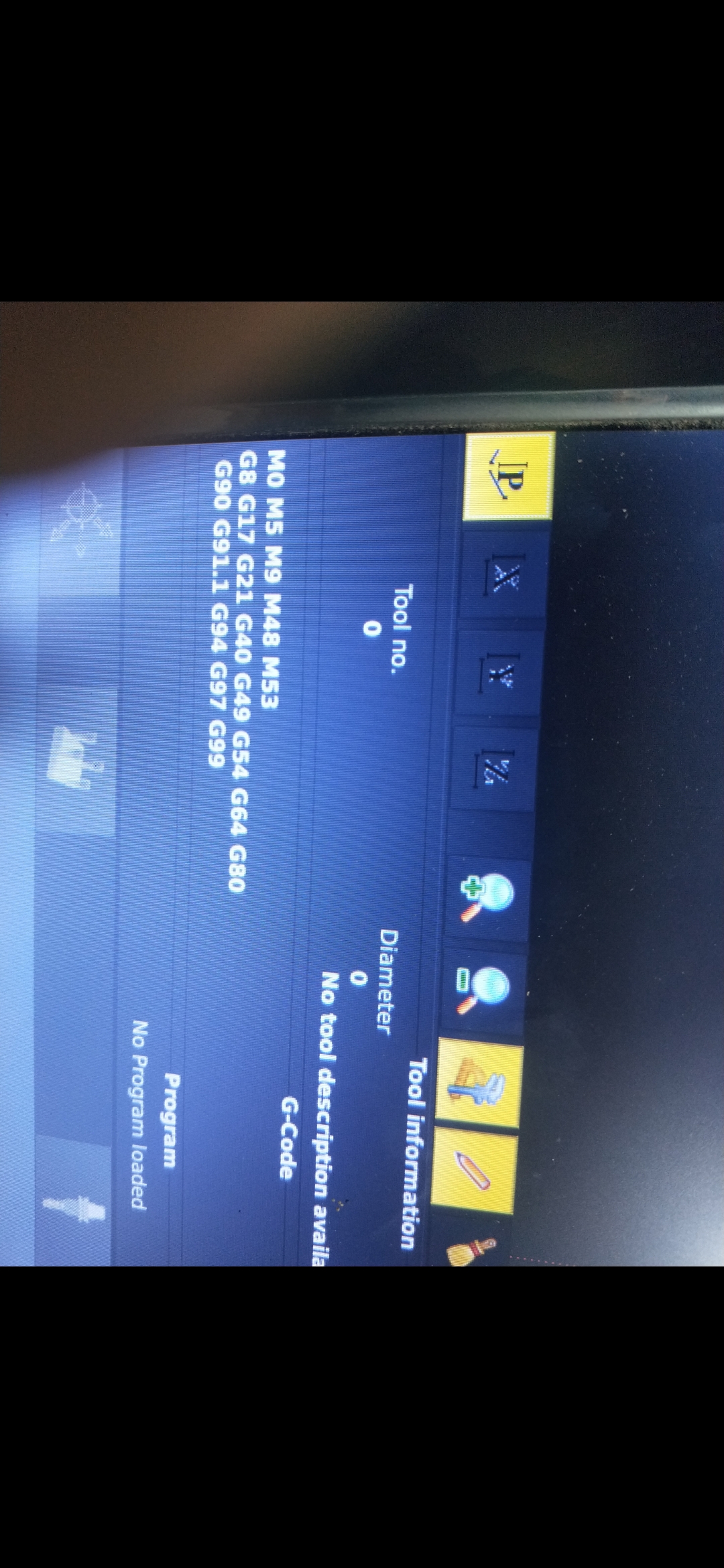

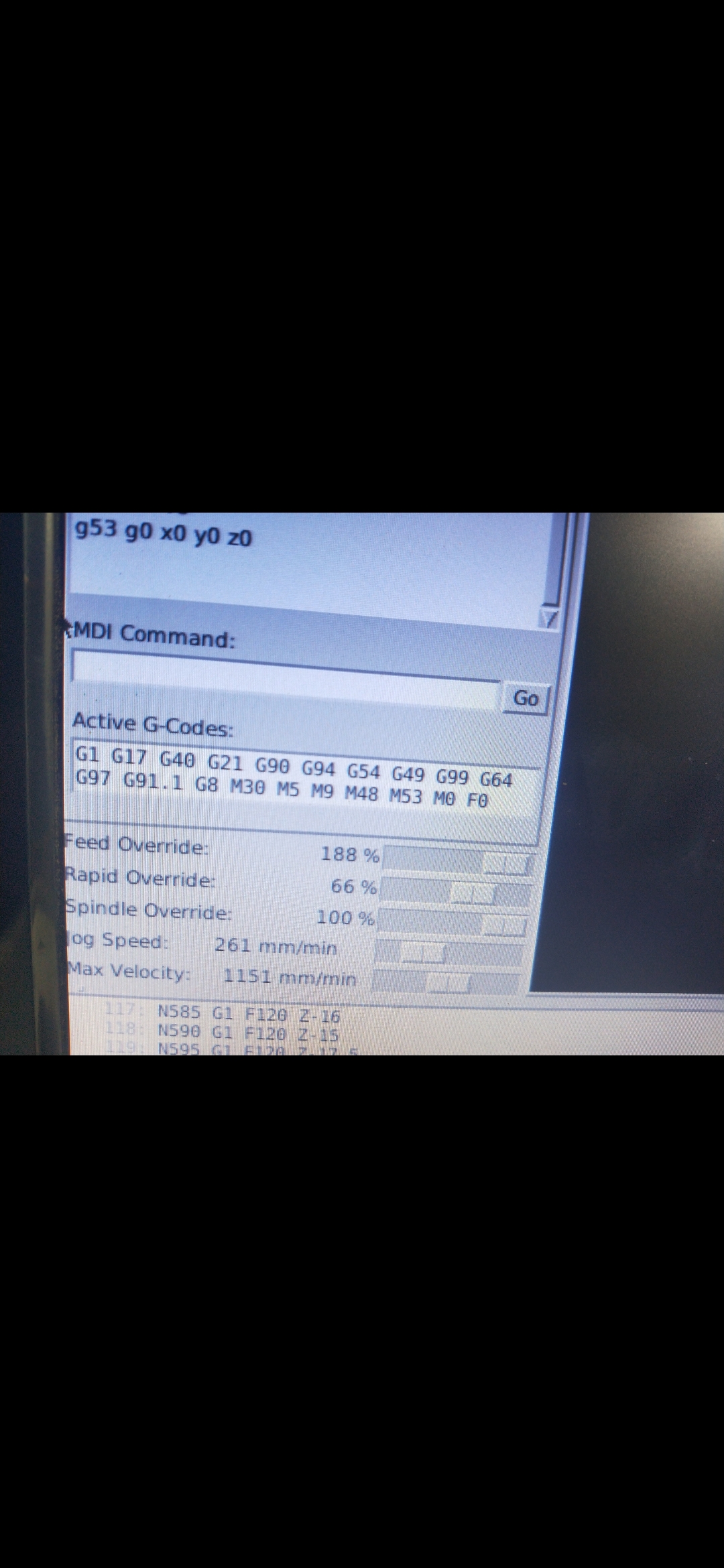

There is another thing that i want to discuss. Doesn't gmoccapy support G33 gcode? I saw a tab named as gcode in gmoccapy screen that stated a few gcodes(i guess the supported gcodes by gmoccapy) same i noticed in axis gui(I'm attaching pictures). And also i tried to run gmoccapy with G33 gcode and the machine didn't respond to it (became stationary) without generating any error. Can you tell me if it's possible to run G33 gcode and some basic gcodes on gmoccapy (G33).

There is another thing that i want to discuss. Doesn't gmoccapy support G33 gcode? I saw a tab named as gcode in gmoccapy screen that stated a few gcodes(i guess the supported gcodes by gmoccapy) same i noticed in axis gui(I'm attaching pictures). And also i tried to run gmoccapy with G33 gcode and the machine didn't respond to it (became stationary) without generating any error. Can you tell me if it's possible to run G33 gcode and some basic gcodes on gmoccapy (G33).

Attachments:

Last edit: 06 Sep 2021 05:46 by Sourabh3.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1491

- Thank you received: 551

06 Sep 2021 15:37 - 06 Sep 2021 15:39 #219767

by RotarySMP

Replied by RotarySMP on topic Indramat 3trm2

I am pretty sure the bigger Maho's have the lubrication tank low level switch as an inhibit. My little 400E doesn't. Looks like the switch V is an inhibit for the main spindle (probably the tank low level float switch), and P is the power switch to the lube unit used to command a squirt of way oil. My lube unit is self-contained and has no connection to the LinuxCNC controller. It has an internal timer relay, and gives a 5 sec squirt of oil at start up and then every 20 minutes.

On larger more complicated machines, the way oiling is often more complicated. For example if you are 3D contouring with a lot of short back and forth motion, there is a greater risk of galling a way. Since you have that P switch, you can easily connect that to LinuxCNC, and make the lubrication interval as simple (timer) or as complicated (distance ways have travelled, lines of code read etc) as you like. Search the forum, I am pretty sure a variety of solutions have been done on other machines.

Gmoccapy is only a GUI. The G codes which can be run are all which LinuxCNC supports. The section of the GUI you showed is a the list of currently active codes. For example, if you type a line with G00 you do not need to keep writing G0 on following lines. It stays in rapid mode, until you write a G1 (or G2, G3, G33 etc - any code from the same modal group). See here... Paragraph 11 and 13.

linuxcnc.org/docs/html/gcode/overview.ht...ds_and_machine_modes

G33 is supported, but you need a spindle encoder for LinuxCNC to sync the motion to. If you send a G33, without an encoder, it is probably waiting in an infinite loop for spindle motion to sync to. I have an encoder on the mini lathe spindle, and will use the one on the Schaublin, but have none on the Maho.

That is why I use the Tapmatic on the Maho. It is designed for manual machines. I just program a G1 plunging move with the feedrate of RPM x Metric pitch. Once the depth is reached, you need a rapid retract for a few mm to reverse it's gearbox (not needed on a through hole). Then I retract to about 10mm above the stock, with another G1 at a feedrate of RPM x metric pitch x 1.75, as the internal reversing gearbox of the tapmatic increases he rpm by 1.75 when it reverses.

Mark

On larger more complicated machines, the way oiling is often more complicated. For example if you are 3D contouring with a lot of short back and forth motion, there is a greater risk of galling a way. Since you have that P switch, you can easily connect that to LinuxCNC, and make the lubrication interval as simple (timer) or as complicated (distance ways have travelled, lines of code read etc) as you like. Search the forum, I am pretty sure a variety of solutions have been done on other machines.

Gmoccapy is only a GUI. The G codes which can be run are all which LinuxCNC supports. The section of the GUI you showed is a the list of currently active codes. For example, if you type a line with G00 you do not need to keep writing G0 on following lines. It stays in rapid mode, until you write a G1 (or G2, G3, G33 etc - any code from the same modal group). See here... Paragraph 11 and 13.

linuxcnc.org/docs/html/gcode/overview.ht...ds_and_machine_modes

G33 is supported, but you need a spindle encoder for LinuxCNC to sync the motion to. If you send a G33, without an encoder, it is probably waiting in an infinite loop for spindle motion to sync to. I have an encoder on the mini lathe spindle, and will use the one on the Schaublin, but have none on the Maho.

That is why I use the Tapmatic on the Maho. It is designed for manual machines. I just program a G1 plunging move with the feedrate of RPM x Metric pitch. Once the depth is reached, you need a rapid retract for a few mm to reverse it's gearbox (not needed on a through hole). Then I retract to about 10mm above the stock, with another G1 at a feedrate of RPM x metric pitch x 1.75, as the internal reversing gearbox of the tapmatic increases he rpm by 1.75 when it reverses.

Mark

Last edit: 06 Sep 2021 15:39 by RotarySMP.

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.236 seconds