DIY high soulder CNC with cad model.

- oficinerobotica

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 47

- Thank you received: 12

24 Jun 2021 06:16 #212784

by oficinerobotica

DIY high soulder CNC with cad model. was created by oficinerobotica

Hi to all, how's it going?

This is my first post here on the forum, I'm still a total noob regarding both LinuxCNC and cnc in general so please be patient with me. I'm slowly getting there. By looking at some forum posts around here I'm feeling like a dwarf in the middle of titans.

Anyway, to the point. As I'm kind of involved with the FreeCAD developers and community, this project was started as a test bench file for the modelling and assembly capabilities of the cad software. (for credibility points, the hexapod model on the splash screen of version 0.19 is one of my models).

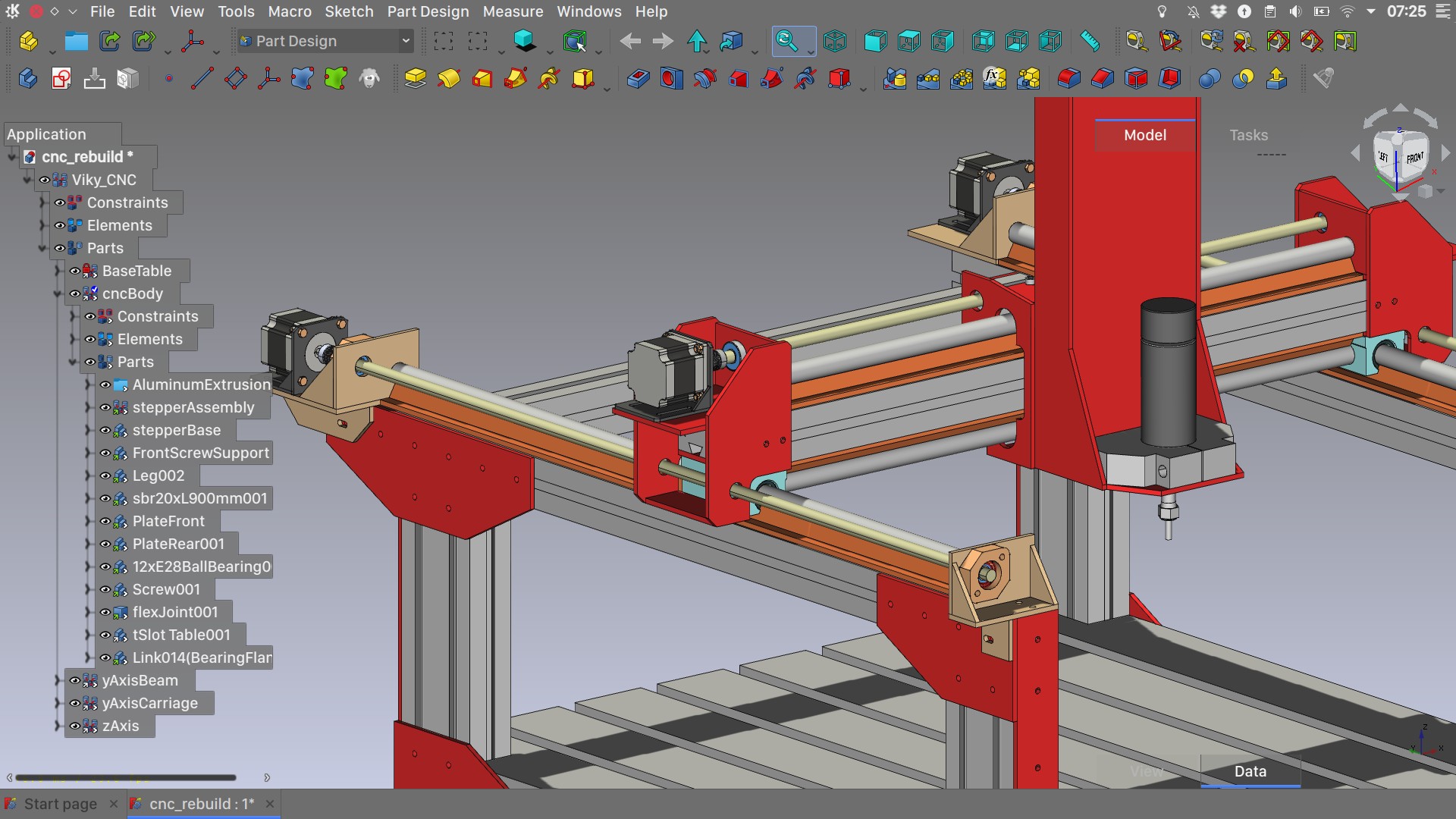

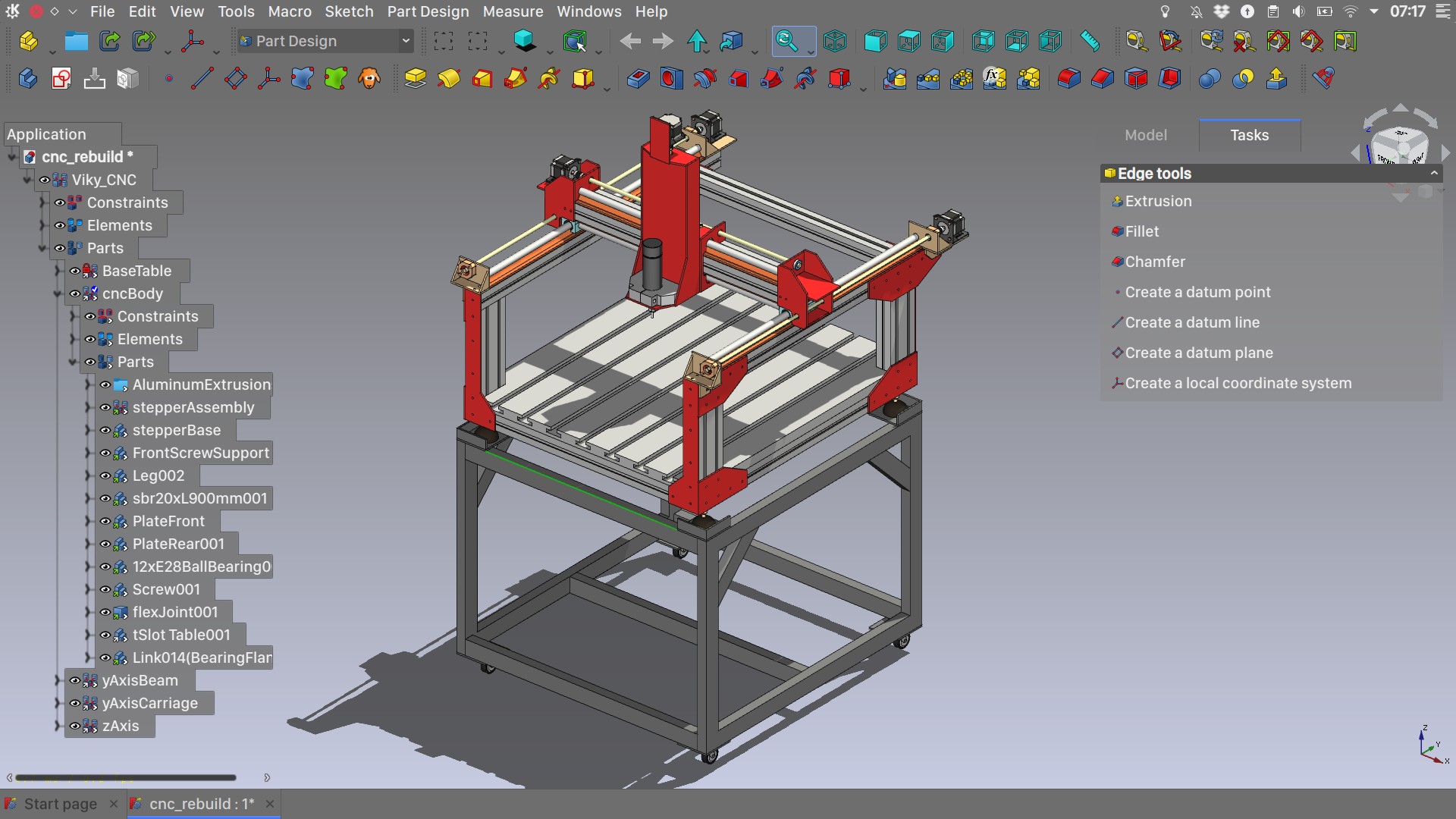

Some screenshots of the cad model inside freecad

Allot of the design decisions for this machine were driven by cost. I tried to get the best bang for the buck pretty much everywhere as this is a hobby project. Some design and material choices will make the hair rise on people around here that work with micron tolerances. My excuse is that I still have to buy a proper micrometer. It is all a learning experience.

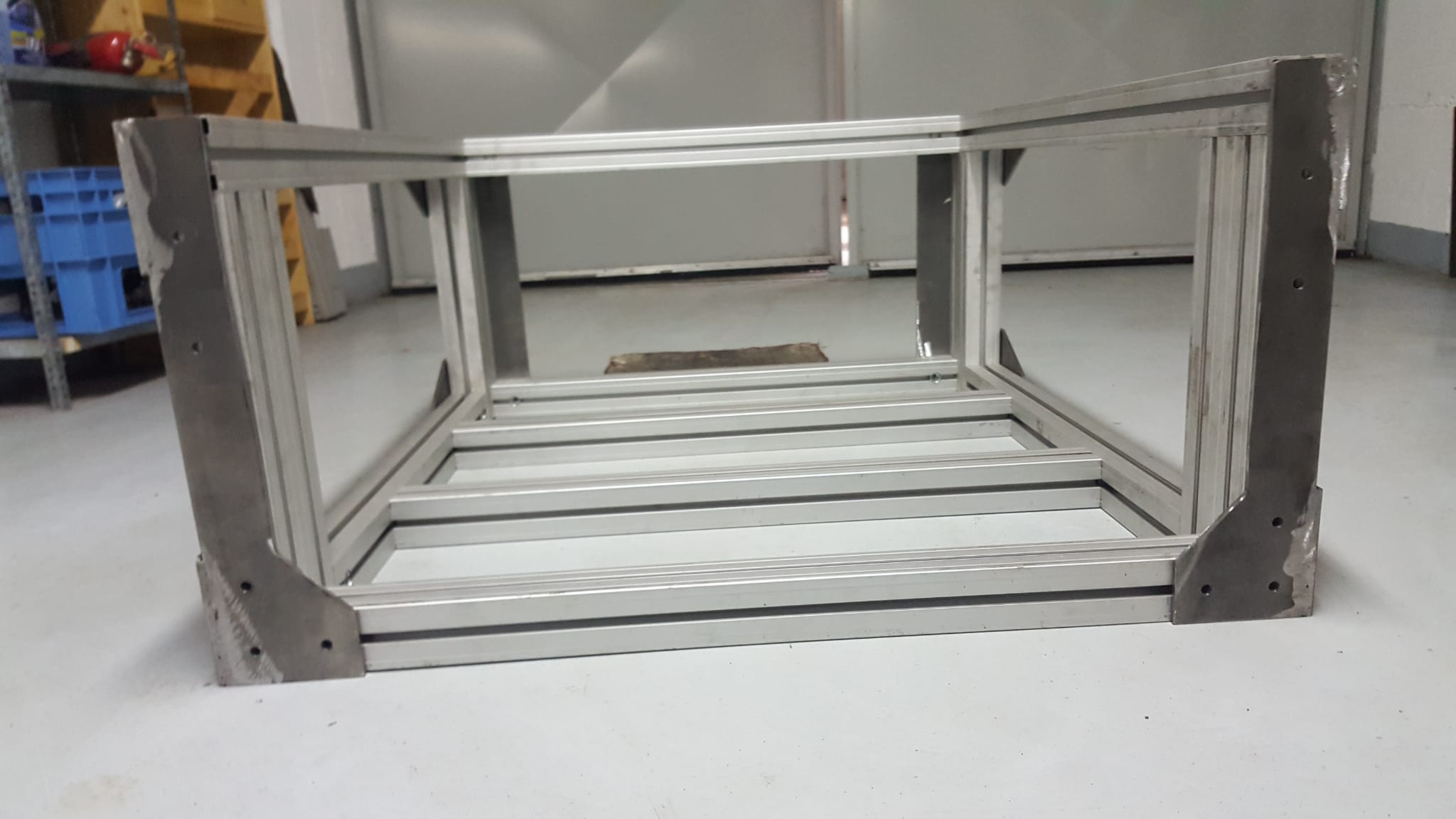

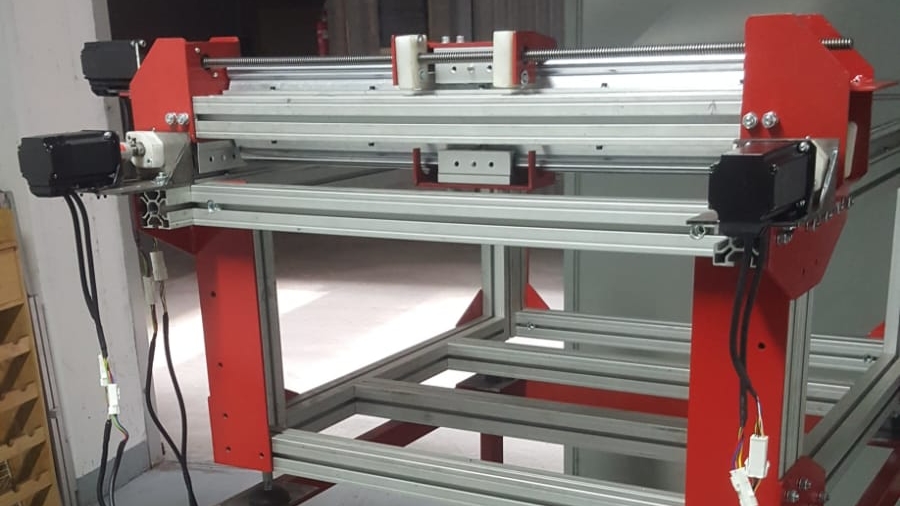

The frame is out of 50x50 or 50x100 aluminum extrusion that I was lucky enough to recover from some dismissed industrial machines. The aluminum extrusions were reinforced with 5mm cold rolled steel bolted to the frame. These reinforcements were cuted and driled by hand with allot sweat and tears. None the less I think they came out pretty good.

After learning that cold rolled steel is tough to work with by hand I decided to laser cut some of the components that were missing.

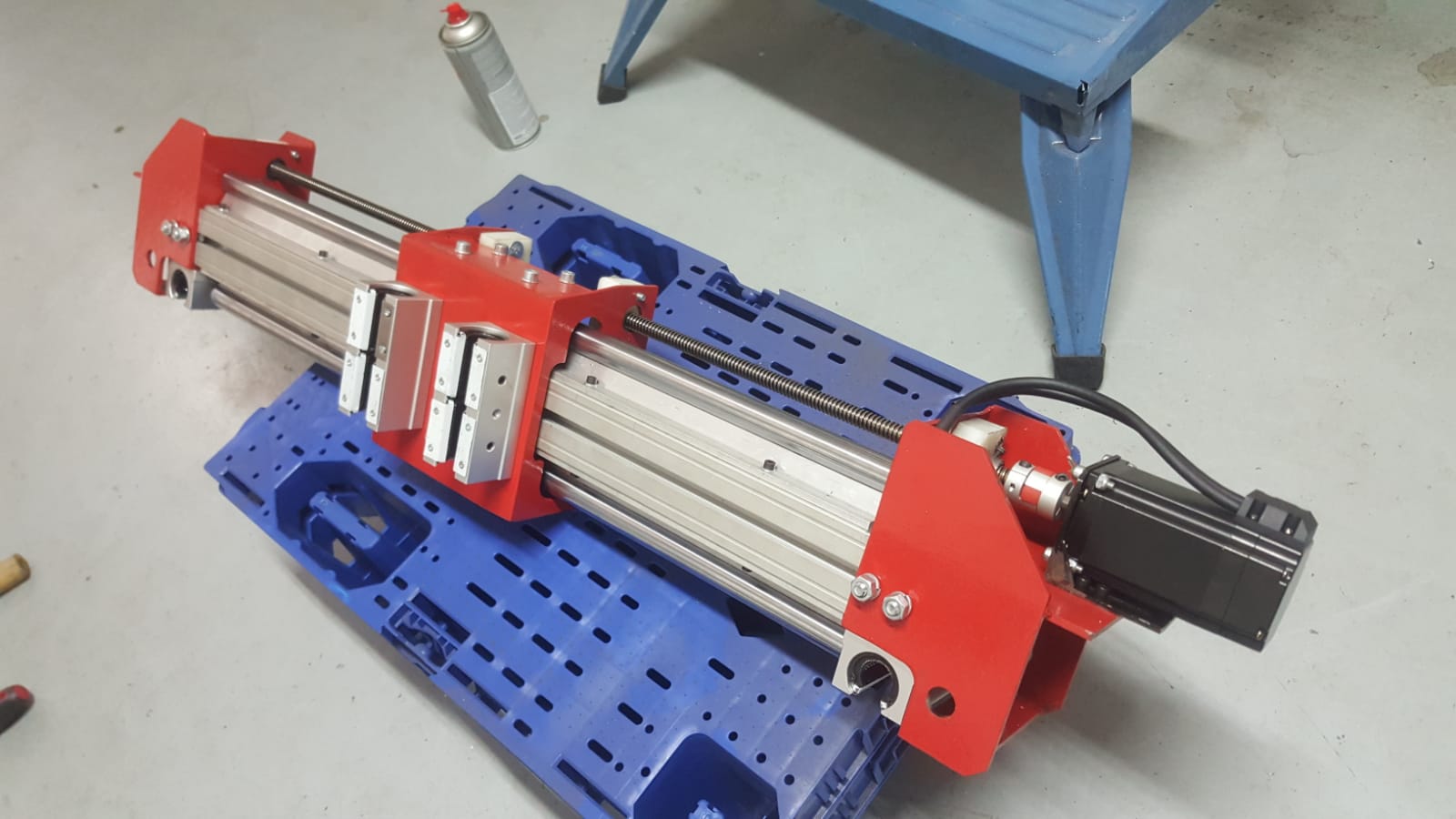

And this is the X axis after a bit of work

This is my first post here on the forum, I'm still a total noob regarding both LinuxCNC and cnc in general so please be patient with me. I'm slowly getting there. By looking at some forum posts around here I'm feeling like a dwarf in the middle of titans.

Anyway, to the point. As I'm kind of involved with the FreeCAD developers and community, this project was started as a test bench file for the modelling and assembly capabilities of the cad software. (for credibility points, the hexapod model on the splash screen of version 0.19 is one of my models).

Some screenshots of the cad model inside freecad

Allot of the design decisions for this machine were driven by cost. I tried to get the best bang for the buck pretty much everywhere as this is a hobby project. Some design and material choices will make the hair rise on people around here that work with micron tolerances. My excuse is that I still have to buy a proper micrometer. It is all a learning experience.

The frame is out of 50x50 or 50x100 aluminum extrusion that I was lucky enough to recover from some dismissed industrial machines. The aluminum extrusions were reinforced with 5mm cold rolled steel bolted to the frame. These reinforcements were cuted and driled by hand with allot sweat and tears. None the less I think they came out pretty good.

After learning that cold rolled steel is tough to work with by hand I decided to laser cut some of the components that were missing.

And this is the X axis after a bit of work

Attachments:

Please Log in or Create an account to join the conversation.

- oficinerobotica

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 47

- Thank you received: 12

24 Jun 2021 06:49 #212786

by oficinerobotica

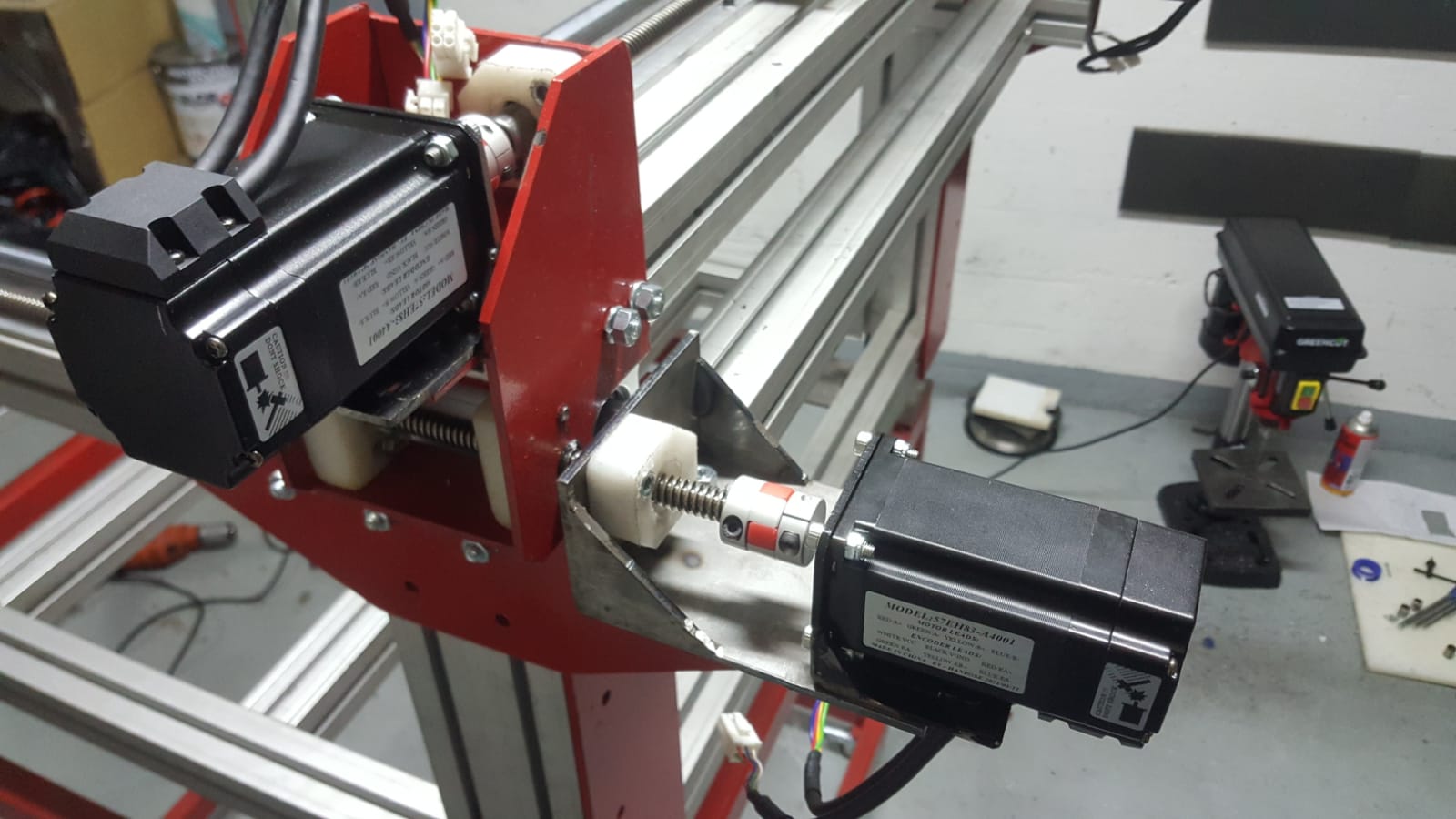

The machine electronics choice is Mesa7i96 Etherenet card coupled with cheapo closed loop nema 23 steppers from AliExpress (they seem to work allot better than expected tough). I had a really hard time wiring them because I NEED TO PAY ATTENTION TO WHAT I AM DOING. While testing the first motor and after loosing countless hours on the internets thinking I have wired wrong the mesa card or the encoders I realized that i have inverted one of the coils wires. These motors are pretty much plug and play. With that solved i went ahead and wired the tandem Y axis too

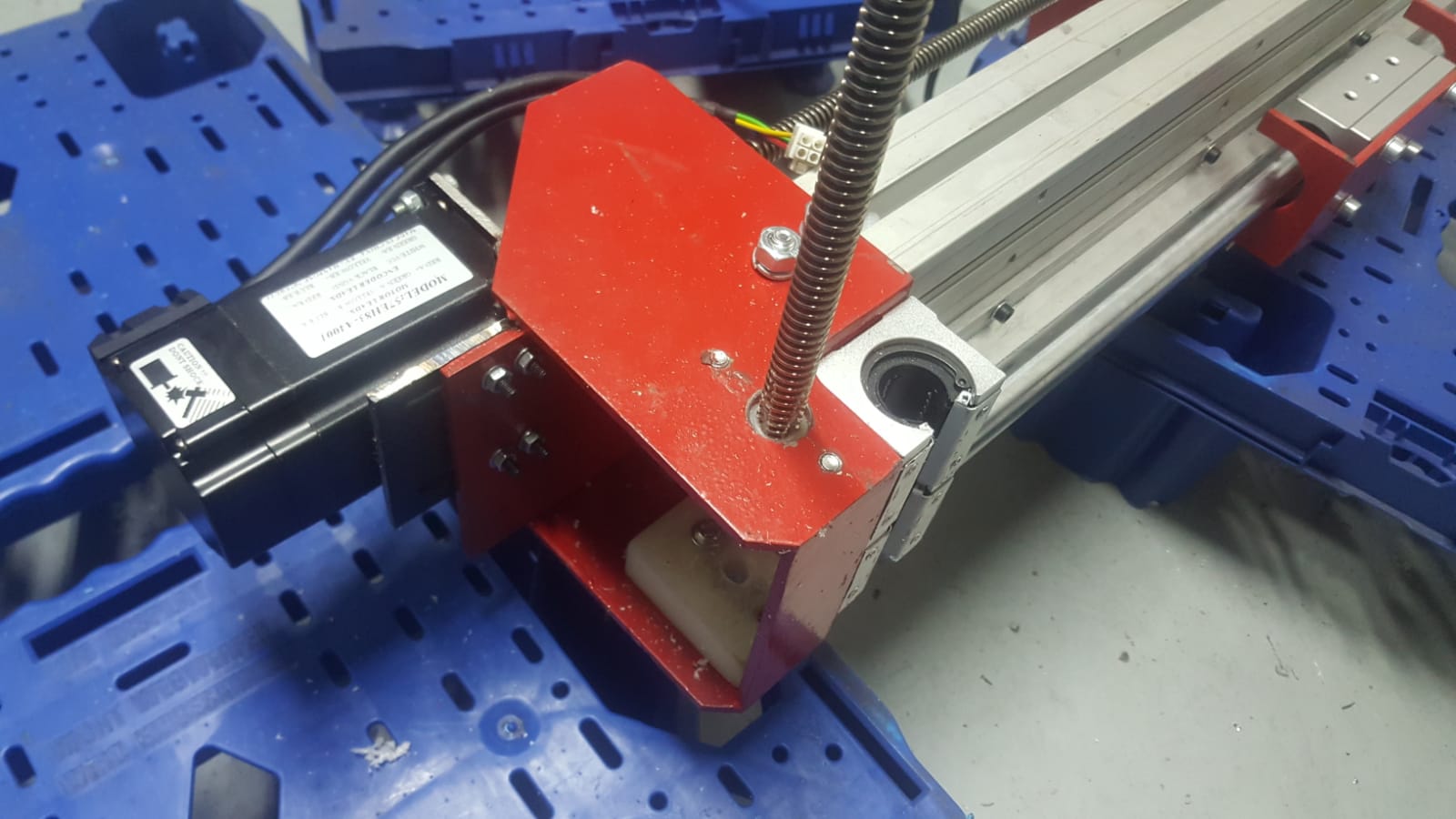

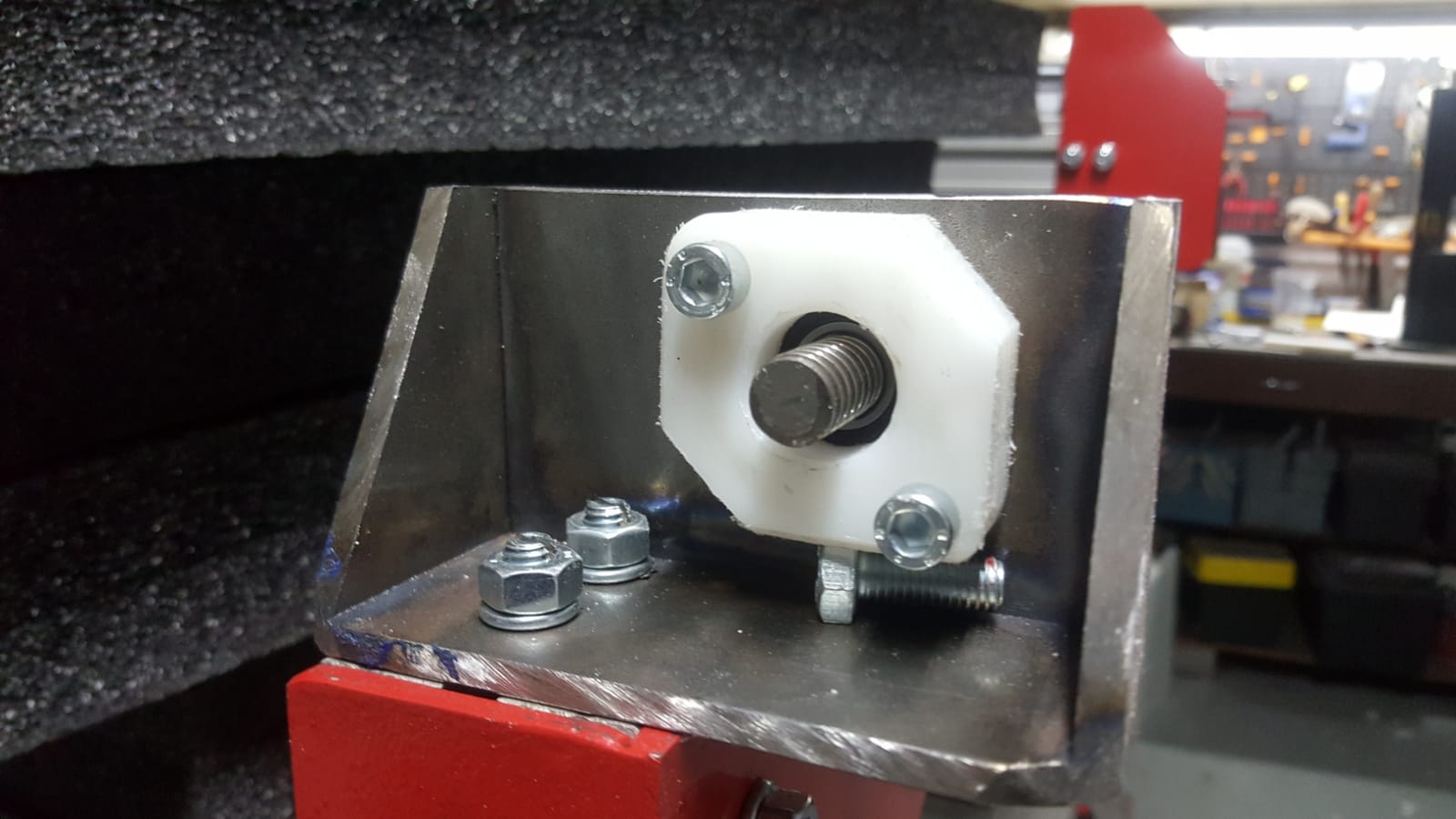

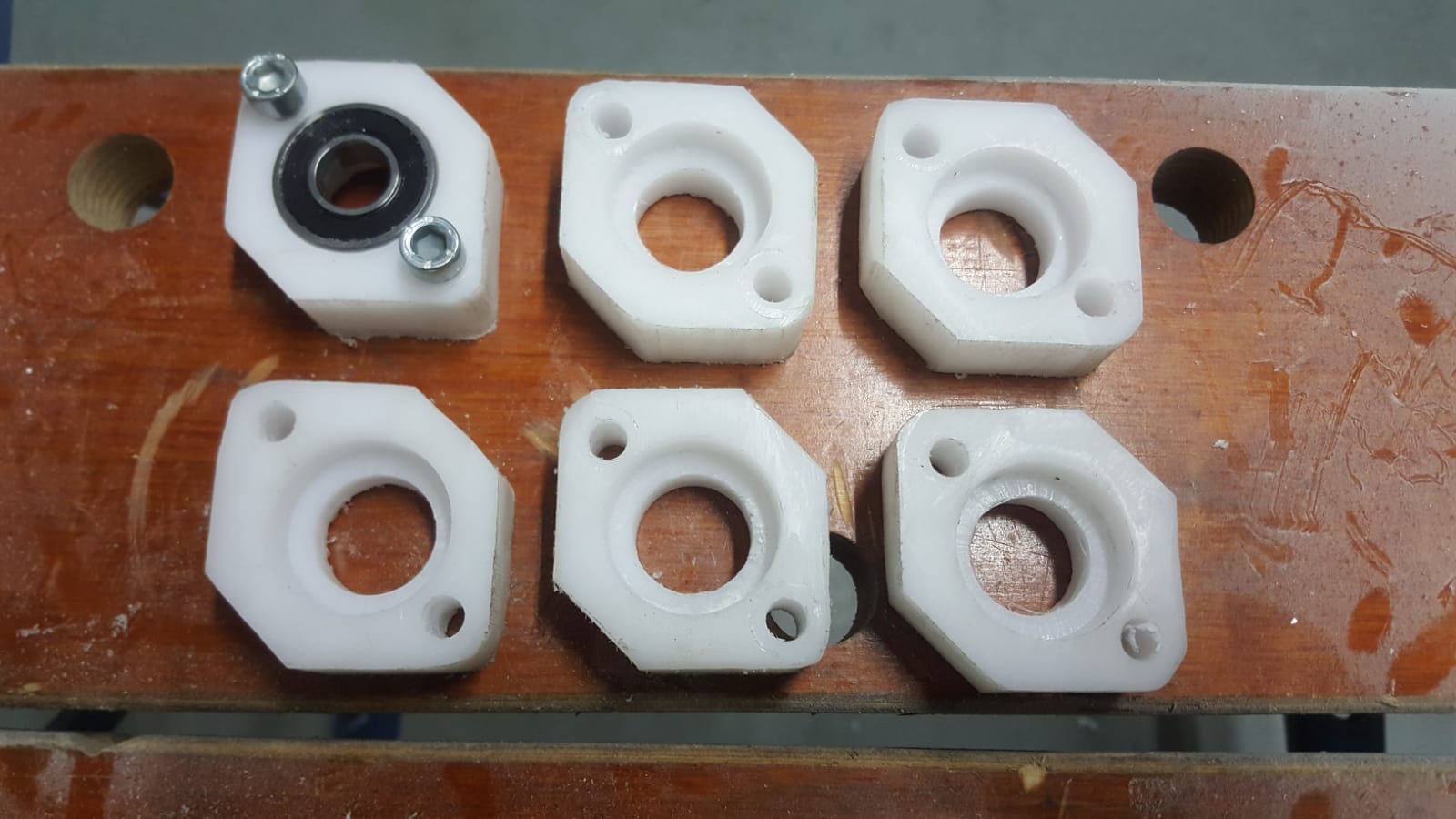

As previously stated, allot of the design decisions for this machine were driven by cost. One of those decisions was to use trapezoidal screws instead of higher quality ball screws. The design is made so that thees can be added at a later time.

Now for the problem: the trapezoidal screws are not strait. It seems they arrived curved and this is a HUGE problem. Now I don't want to wait for another set of screws and I'm pretty sure that misalignments, wrong design choices or wrong parts will happen again in the future. If the build doesn't continue I will never know where the problems are.

The intention is to buy precision ball screws at a later moment and modify the machine accordingly. Lukly that will be easily done but at the moment I decided it is time to spend no more money on this type of motion and to self fabricate the trapezoidal nuts in Teflon.

Replied by oficinerobotica on topic DIY high soulder CNC with cad model.

The machine electronics choice is Mesa7i96 Etherenet card coupled with cheapo closed loop nema 23 steppers from AliExpress (they seem to work allot better than expected tough). I had a really hard time wiring them because I NEED TO PAY ATTENTION TO WHAT I AM DOING. While testing the first motor and after loosing countless hours on the internets thinking I have wired wrong the mesa card or the encoders I realized that i have inverted one of the coils wires. These motors are pretty much plug and play. With that solved i went ahead and wired the tandem Y axis too

As previously stated, allot of the design decisions for this machine were driven by cost. One of those decisions was to use trapezoidal screws instead of higher quality ball screws. The design is made so that thees can be added at a later time.

Now for the problem: the trapezoidal screws are not strait. It seems they arrived curved and this is a HUGE problem. Now I don't want to wait for another set of screws and I'm pretty sure that misalignments, wrong design choices or wrong parts will happen again in the future. If the build doesn't continue I will never know where the problems are.

The intention is to buy precision ball screws at a later moment and modify the machine accordingly. Lukly that will be easily done but at the moment I decided it is time to spend no more money on this type of motion and to self fabricate the trapezoidal nuts in Teflon.

Attachments:

Please Log in or Create an account to join the conversation.

- oficinerobotica

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 47

- Thank you received: 12

24 Jun 2021 08:00 - 24 Jun 2021 09:31 #212793

by oficinerobotica

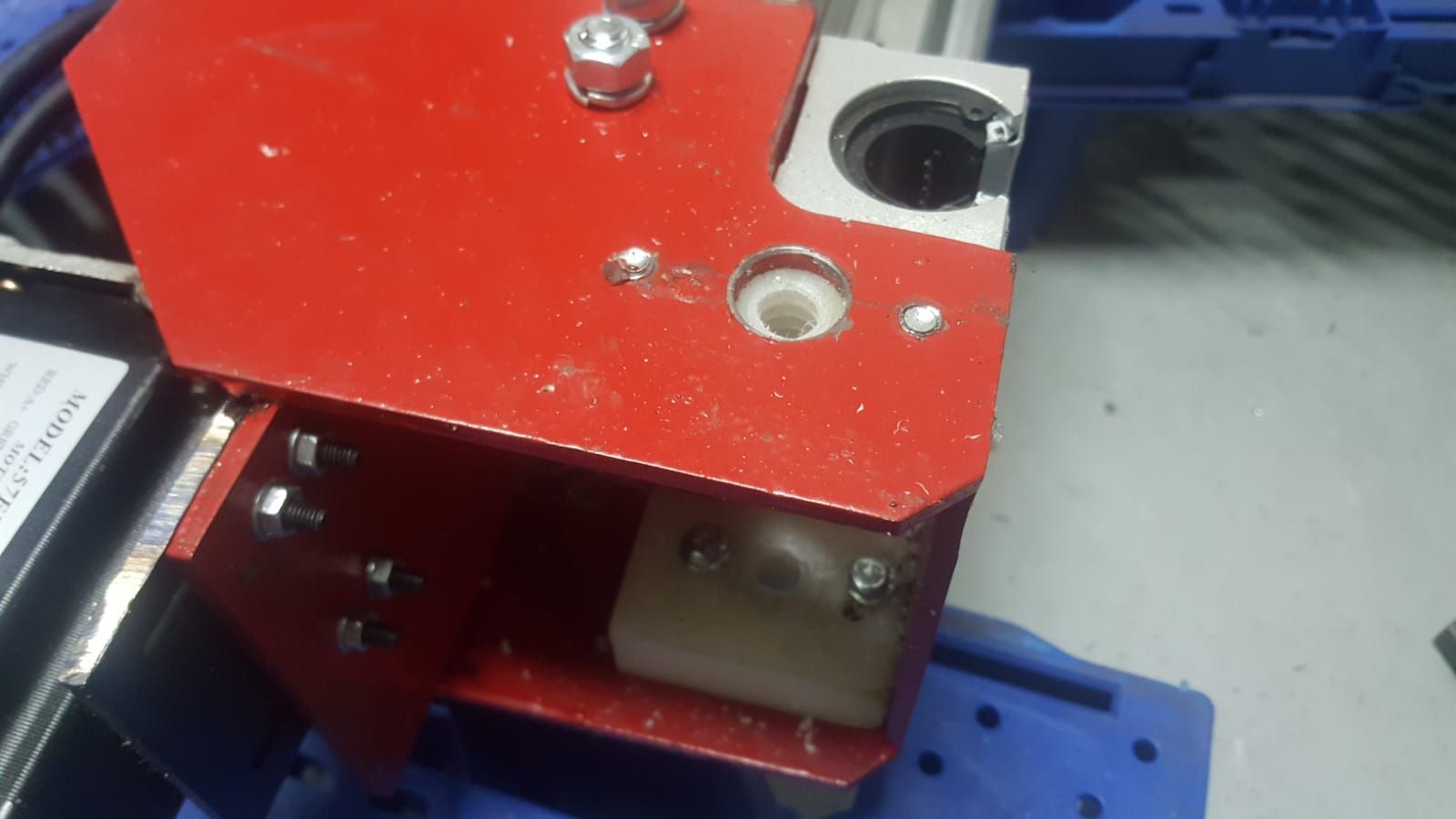

With the awareness that I will need to swap the motion with higher quality screws , I fabricated my self some teflon bearing holders in order to finally see some motion.

And low and behold we have motion. This is where my LinuxCNC adventure is starting.

Motor test video link

X axis motion video link

Now for the cad model. I will create a GitHUB repo where all the files will be uploaded and updated based on the modifications done down the road. As this project was spawned from the FreeCAD development road , there is a series of tutorials on how to model the thing and this is the first part:

CNC FreeCAD tutorial video link

Of course, all the files will be under a CC license, all in the spirit of open source.

Replied by oficinerobotica on topic DIY high soulder CNC with cad model.

With the awareness that I will need to swap the motion with higher quality screws , I fabricated my self some teflon bearing holders in order to finally see some motion.

And low and behold we have motion. This is where my LinuxCNC adventure is starting.

Motor test video link

X axis motion video link

Now for the cad model. I will create a GitHUB repo where all the files will be uploaded and updated based on the modifications done down the road. As this project was spawned from the FreeCAD development road , there is a series of tutorials on how to model the thing and this is the first part:

CNC FreeCAD tutorial video link

Of course, all the files will be under a CC license, all in the spirit of open source.

Attachments:

Last edit: 24 Jun 2021 09:31 by oficinerobotica. Reason: Added video links as embeded isn't displayed in the forum

The following user(s) said Thank You: phillc54, Clive S

Please Log in or Create an account to join the conversation.

- oficinerobotica

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 47

- Thank you received: 12

24 Jun 2021 08:41 - 24 Jun 2021 08:51 #212794

by oficinerobotica

Replied by oficinerobotica on topic DIY high soulder CNC with cad model.

Now for the first noob dillema I'm facing. Using the axis gui and after I have setted up Y as tandem in PncConf how on earth do I jog the x axis for homing? Before homing it seems that I can only jog each motor independently not together. Unfortunately I have the axis mounted on the machine at the opposite side of the home position.

I have tried to jog the axis in PncConf with the test axis utility but even there only one motor is used instead of the tandem.

I know that there might be many information missing from this question for anyone to help but if someone could give a suggestion of where to start to troubleshoot this issue I will be forever grateful.

Also, somehow I am not able to embed Youtube video links in the forum. I am using the small "movie strip" icon at the top of the mesage editor then "video" inserting the link at the pop up. Am I doing something wrong?

I have tried to jog the axis in PncConf with the test axis utility but even there only one motor is used instead of the tandem.

I know that there might be many information missing from this question for anyone to help but if someone could give a suggestion of where to start to troubleshoot this issue I will be forever grateful.

Also, somehow I am not able to embed Youtube video links in the forum. I am using the small "movie strip" icon at the top of the mesage editor then "video" inserting the link at the pop up. Am I doing something wrong?

Last edit: 24 Jun 2021 08:51 by oficinerobotica. Reason: Adde info

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7231

24 Jun 2021 09:20 #212800

by tommylight

Replied by tommylight on topic DIY high soulder CNC with cad model.

For youtube just paste the link as normal text.

For tandem axis there are some setting that have to be set for it to work, like having negative value for "home sequence" in the ini file, pncconf should take care of it, but to be sure attach your hal and ini files.

For tandem axis there are some setting that have to be set for it to work, like having negative value for "home sequence" in the ini file, pncconf should take care of it, but to be sure attach your hal and ini files.

The following user(s) said Thank You: oficinerobotica

Please Log in or Create an account to join the conversation.

- oficinerobotica

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 47

- Thank you received: 12

24 Jun 2021 09:38 #212804

by oficinerobotica

Replied by oficinerobotica on topic DIY high soulder CNC with cad model.

Thank you so much. Atm I'm not near the machine but I have the laptop with the configuration. I'm attaching the hal and ini files and as soon as I will get near the machine I will try the suggestions .

P.S. we have the same problem in the FreeCAD forum with embeded videos after a forum upgrade. I now have to try there also to see if simply pasting a video link will work. Thank you again for the tip

P.S. we have the same problem in the FreeCAD forum with embeded videos after a forum upgrade. I now have to try there also to see if simply pasting a video link will work. Thank you again for the tip

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7231

24 Jun 2021 10:21 #212811

by tommylight

Replied by tommylight on topic DIY high soulder CNC with cad model.

There are no homing entries in the attached ini file.

Please Log in or Create an account to join the conversation.

- oficinerobotica

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 47

- Thank you received: 12

24 Jun 2021 11:29 - 24 Jun 2021 11:32 #212815

by oficinerobotica

Replied by oficinerobotica on topic DIY high soulder CNC with cad model.

Thank you so much for your support.

This is what PncConf gave me and I double checked that I attached the correct files. I don't want to waste your time so when I will be back next to the machine I will fire again the configuration paying more attention so I don't miss any steps then I'll get back here.

Just as a clarification, perhaps I explained my self wrong, Essentially the configuration works but I have no way of moving the tandem axis to the home position prior to ..... homing, in the Axis gui, the 2 joints/motors. If I click "home" in the gui for the 4 joints I am then able to use the tandem correctly. The problem is moving the axis to home prior to homing in the gui because , prior to that I have no way of jogging the 2 motors together. And now, physically the axis is at the opposite end of the machine in respect to the home position. Just as info, I have no limit switches yet installed on the cnc.

Thank you again and I will get back with better info to manage to set up the machine.

This is what PncConf gave me and I double checked that I attached the correct files. I don't want to waste your time so when I will be back next to the machine I will fire again the configuration paying more attention so I don't miss any steps then I'll get back here.

Just as a clarification, perhaps I explained my self wrong, Essentially the configuration works but I have no way of moving the tandem axis to the home position prior to ..... homing, in the Axis gui, the 2 joints/motors. If I click "home" in the gui for the 4 joints I am then able to use the tandem correctly. The problem is moving the axis to home prior to homing in the gui because , prior to that I have no way of jogging the 2 motors together. And now, physically the axis is at the opposite end of the machine in respect to the home position. Just as info, I have no limit switches yet installed on the cnc.

Thank you again and I will get back with better info to manage to set up the machine.

Last edit: 24 Jun 2021 11:32 by oficinerobotica.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7231

24 Jun 2021 13:38 #212820

by tommylight

Replied by tommylight on topic DIY high soulder CNC with cad model.

Oh well, was in a hurry,

There are no limit switches set in hal also, tandem axis will not work without them (well it can but not a good idea any way you look ta it), so you can use PncConf and edit the existing config to add limit switches and homing stuff, no need to redo everything.

So if you do not plan to use the gantry squaring and homing switches, do a new config with no tandem axis, but choose steppgen0 (or whatever the tandem axis uses) and steppgen1 as X axis, basically have to outputs for the same axis.

There are no limit switches set in hal also, tandem axis will not work without them (well it can but not a good idea any way you look ta it), so you can use PncConf and edit the existing config to add limit switches and homing stuff, no need to redo everything.

So if you do not plan to use the gantry squaring and homing switches, do a new config with no tandem axis, but choose steppgen0 (or whatever the tandem axis uses) and steppgen1 as X axis, basically have to outputs for the same axis.

The following user(s) said Thank You: oficinerobotica

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

24 Jun 2021 16:15 #212832

by Clive S

Re: the ini file. You need something like this:-

# final home position machine -unit/sec

HOME = -20 This is the final home position

# use this to square the gantry

HOME_OFFSET = 0.0

# machine-units per sec next 2 lines

HOME_SEARCH_VEL = 50 changing the sign will alter the direction

HOME_LATCH_VEL = -2 This is to back off the switch slowly and as above

HOME_FINAL_VEL = 50 This is the speed to the home position

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

HOME_SEQUENCE = -2 This has to be -ve number and the same for both tandem axis

You will need physical home switches wired in the hal file

Mine are

# --- MIN-HOME-Y ---Right side---

net min-home-y <= [HMOT](CARD0).gpio.006.in

# --- MIN-HOME-Y2 ---Left side----

net min-home-y2 <= [HMOT](CARD0).gpio.005.in

Replied by Clive S on topic DIY high soulder CNC with cad model.

Thank you so much for your support.

This is what PncConf gave me and I double checked that I attached the correct files. I don't want to waste your time so when I will be back next to the machine I will fire again the configuration paying more attention so I don't miss any steps then I'll get back here.

Just as a clarification, perhaps I explained my self wrong, Essentially the configuration works but I have no way of moving the tandem axis to the home position prior to ..... homing, in the Axis gui, the 2 joints/motors. If I click "home" in the gui for the 4 joints I am then able to use the tandem correctly. The problem is moving the axis to home prior to homing in the gui because , prior to that I have no way of jogging the 2 motors together. And now, physically the axis is at the opposite end of the machine in respect to the home position. Just as info, I have no limit switches yet installed on the cnc.

Thank you again and I will get back with better info to manage to set up the machine.

Re: the ini file. You need something like this:-

# final home position machine -unit/sec

HOME = -20 This is the final home position

# use this to square the gantry

HOME_OFFSET = 0.0

# machine-units per sec next 2 lines

HOME_SEARCH_VEL = 50 changing the sign will alter the direction

HOME_LATCH_VEL = -2 This is to back off the switch slowly and as above

HOME_FINAL_VEL = 50 This is the speed to the home position

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

HOME_SEQUENCE = -2 This has to be -ve number and the same for both tandem axis

You will need physical home switches wired in the hal file

Mine are

# --- MIN-HOME-Y ---Right side---

net min-home-y <= [HMOT](CARD0).gpio.006.in

# --- MIN-HOME-Y2 ---Left side----

net min-home-y2 <= [HMOT](CARD0).gpio.005.in

The following user(s) said Thank You: oficinerobotica

Please Log in or Create an account to join the conversation.

Time to create page: 0.843 seconds