New CAM tutorial with Free Software

- alan_3301

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 22

12 Nov 2018 18:53 #120503

by alan_3301

Replied by alan_3301 on topic New CAM tutorial with Free Software

Try to get a hobby license for fusion 360, you can model the u-channel for a stock model, and then program the toolpaths for the holes and slots. There are many videos explaining how to use the cam software.

If you are modeling more than a couple of these, I think it would be the easiest way to do it. If you just have one to program, by hand may be the easiest.

you can use an m0 or m1 in the gcode to insert pauses wherever you want.

linuxcnc.org/docs/html/gcode/m-code.html#mcode:m0-m1

If you are modeling more than a couple of these, I think it would be the easiest way to do it. If you just have one to program, by hand may be the easiest.

you can use an m0 or m1 in the gcode to insert pauses wherever you want.

linuxcnc.org/docs/html/gcode/m-code.html#mcode:m0-m1

Please Log in or Create an account to join the conversation.

- hatch789

-

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 0

12 Nov 2018 19:15 #120505

by hatch789

Replied by hatch789 on topic New CAM tutorial with Free Software

I can try to get a hobby license for Fusion 360 as you suggest, but is that because the CAM in F360 is so good that it's worth the hassle? Or is there other CAM software out there that would also be good for me to try. As stated I already use OnShape which lets me design my parts and export them in a wide array of formats. So if F360 is best for what I'm trying to do then yes I'll try to get it. I just wanted to clarify in case you were thinking I needed CAD as well as CAM.

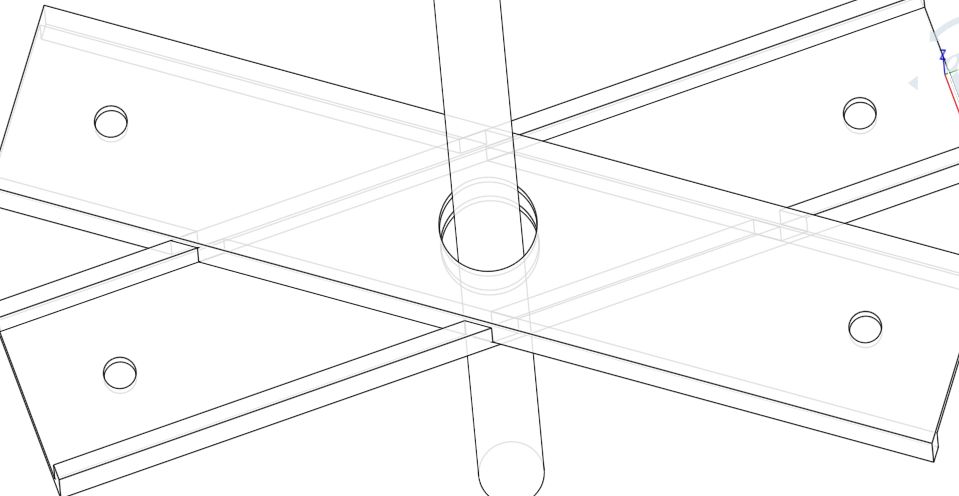

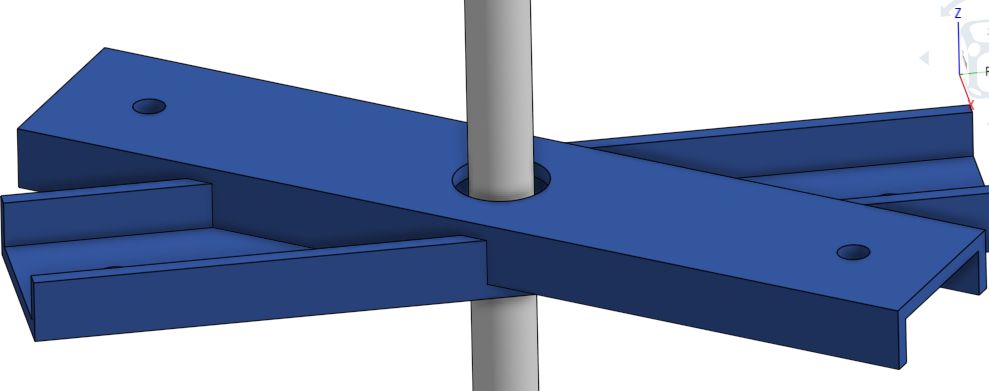

Regarding parts, I will be modifying these parts as I prototype and test things so I hate to do it manually if I'm changing. Again the circles are easy, those are child's play to adjust as needed, even manually. But even from the 2 pics I attached, you can see the slots are different in both of those cases, and they could change quite a number of times before I finish.

So these darn slots are really the part I'm concerned about.

Regarding parts, I will be modifying these parts as I prototype and test things so I hate to do it manually if I'm changing. Again the circles are easy, those are child's play to adjust as needed, even manually. But even from the 2 pics I attached, you can see the slots are different in both of those cases, and they could change quite a number of times before I finish.

So these darn slots are really the part I'm concerned about.

Please Log in or Create an account to join the conversation.

- alan_3301

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 22

12 Nov 2018 19:21 #120506

by alan_3301

Replied by alan_3301 on topic New CAM tutorial with Free Software

It's a really good cam package, that is free for hobby and startup businesses. I really can't stand the cad side of it. I model in another program and import to generate toolpaths. There are many other cam packages, but I doubt there are any free ones that have the same capabilities.

I just did a search and found VisualCAMc which can be run inside of onshape. You may want to check that out. There are many others out there too, here is one example, but I have no experience. simple2dcadcam.sourceforge.net/

I just did a search and found VisualCAMc which can be run inside of onshape. You may want to check that out. There are many others out there too, here is one example, but I have no experience. simple2dcadcam.sourceforge.net/

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19773

- Thank you received: 4601

13 Nov 2018 14:50 #120547

by andypugh

How do you know what angle to put them in in the CAD?

What I sometimes do is make a 2D drawing of the part but dimension it very strangely. Here is an example of how one might dimension an angled slot to make hand-coding G-code easy.

Replied by andypugh on topic New CAM tutorial with Free Software

If it was just holes I would agree. I have done them before with hand-coding and it wasn't bad. But how do I accurately determine the gcode for my slots that have to be at a precise angle? I'm a bit confused by that.

How do you know what angle to put them in in the CAD?

What I sometimes do is make a 2D drawing of the part but dimension it very strangely. Here is an example of how one might dimension an angled slot to make hand-coding G-code easy.

Please Log in or Create an account to join the conversation.

- hatch789

-

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 0

13 Nov 2018 15:53 #120565

by hatch789

Replied by hatch789 on topic New CAM tutorial with Free Software

Hi Andy it's funny I was thinking about this just last night and considering hand coding again but with that exact question (issue) you were trying to explain: How does one use a coordinate system to pinpoint where exactly I need to cut through that sidewall and at the specific angle I need. If I can figure those things out I could do MDI.

To answer your question the angles come from the number of blade-pairs in my turbine assembly. If I have 3 blade pairs they need to be 60 degrees apart. If I have 4 they need to be 45 degrees apart. I have 5 blade pairs so they need to be 36 degrees apart. Basically 180 / # of blade pairs.

But even if I can come up with how to do the angle in a coordinate system. I still need to hit the spot exactly on the sidewall so that when these 2 parts are nested together their center holes line up exactly in the Z-Axis.

It was for this reason that I felt a proper CAM solution directly from the CAD part would be best. Because one little change to my angle and poof my whole MDI needs to be thrown out the window due to how these slots would change.

The pics below are of 2 nested U-Channel pieces 36 degrees apart. But you can imagine these slots would change drastically if my angle changes to say 45 degrees apart or 30 degrees apart (implying 4 blade pairs or 6 blade pairs).

For a better overall understanding of my invention you view my youtube playlist of my Harmony VAWT project.

To answer your question the angles come from the number of blade-pairs in my turbine assembly. If I have 3 blade pairs they need to be 60 degrees apart. If I have 4 they need to be 45 degrees apart. I have 5 blade pairs so they need to be 36 degrees apart. Basically 180 / # of blade pairs.

But even if I can come up with how to do the angle in a coordinate system. I still need to hit the spot exactly on the sidewall so that when these 2 parts are nested together their center holes line up exactly in the Z-Axis.

It was for this reason that I felt a proper CAM solution directly from the CAD part would be best. Because one little change to my angle and poof my whole MDI needs to be thrown out the window due to how these slots would change.

The pics below are of 2 nested U-Channel pieces 36 degrees apart. But you can imagine these slots would change drastically if my angle changes to say 45 degrees apart or 30 degrees apart (implying 4 blade pairs or 6 blade pairs).

For a better overall understanding of my invention you view my youtube playlist of my Harmony VAWT project.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11629

- Thank you received: 3916

13 Nov 2018 19:14 #120596

by rodw

Replied by rodw on topic New CAM tutorial with Free Software

A friend of mine uses Onshape and exports the files to something F360 can open to use its CAM function. Give it a go.

Please Log in or Create an account to join the conversation.

- hatch789

-

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 0

13 Nov 2018 19:18 #120597

by hatch789

Replied by hatch789 on topic New CAM tutorial with Free Software

That's exactly what I did. STEP file export. But now I'm trying to learn some F360 basics to flip and twist my model so that it's oriented properly in F360. It's standing on end in there now. LOL

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11629

- Thank you received: 3916

13 Nov 2018 19:39 #120600

by rodw

Replied by rodw on topic New CAM tutorial with Free Software

See what settings are available in the export. It might be that you have not oriented the part in Onshape correctly. It would be better to fix it at the source before the export. I don't have any Onshape experience.

Please Log in or Create an account to join the conversation.

- alan_3301

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 22

13 Nov 2018 19:42 #120601

by alan_3301

Replied by alan_3301 on topic New CAM tutorial with Free Software

On the top left the is a button that defaults to "modeling" or something like that. Click it and choose "CAM" or similar.

The click setup, new setup, and in the box you can define the coordinate system however you want. I prefer selecting X and Y axis by clicking the appropriate box, then a feature on the model. You may have to check the flip x or flip y checkboxes, and then on the origin selection you can pick model box point, stock box point, or a few other options.

Im sure there is a video tutorial somewhere. I would start here: www.google.com/search?q=fusion+360+cam+s...ygB&biw=1920&bih=922

The click setup, new setup, and in the box you can define the coordinate system however you want. I prefer selecting X and Y axis by clicking the appropriate box, then a feature on the model. You may have to check the flip x or flip y checkboxes, and then on the origin selection you can pick model box point, stock box point, or a few other options.

Im sure there is a video tutorial somewhere. I would start here: www.google.com/search?q=fusion+360+cam+s...ygB&biw=1920&bih=922

Please Log in or Create an account to join the conversation.

- hatch789

-

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 0

13 Nov 2018 20:01 #120604

by hatch789

Replied by hatch789 on topic New CAM tutorial with Free Software

Yeah thank you Alan, I am still at work so I have to wait to get home to try this. I should have mentioned that before. I probably would have figured it out already if I was home today. But unfortunately I don't get to do this stuff all day long.

Thank you for the URL link.

Thank you for the URL link.

Please Log in or Create an account to join the conversation.

Time to create page: 0.202 seconds