X origin error when machining

- twatchorn

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 0

08 Jun 2020 08:53 #170595

by twatchorn

X origin error when machining was created by twatchorn

Hello,

I have problem with X axis origin seeming to more after touching it off as zero.

I have a 3 axis router and am using Fusion360 (personal edition) for drawing models and creating G code. I have not used it a lot, but recently this problem has started.

Sometimes I will get an error message …. Radius to end arc differs from radius to start…. Message may show when opening the file. If I click Ok and continue the same error may appear again when starting to run machine. If I clear error with crtl & space bar the machining will start about 35 mm to the left of where I wanted it.

If I open the same G code file again I may get no error and machining goes correctly.

But today the first file I opened didn’t show any errors, but still it machined it to the left by maybe more than 35mm.

I will attempt to attach 2 screen shots and the 2 G code files.

I have been using the Fusion web base processor and am not sure now if I have changed between the EMC to EMC2 selection without realizing it.

Which one should I be using??

What is the difference??

I have now downloaded the Fusion EMC2 processor onto my PC. But I still have had the error and wrong machining using that.

Is anyone able to enlighten me as to where my problem maybe?

Thank you

Trevor

I have problem with X axis origin seeming to more after touching it off as zero.

I have a 3 axis router and am using Fusion360 (personal edition) for drawing models and creating G code. I have not used it a lot, but recently this problem has started.

Sometimes I will get an error message …. Radius to end arc differs from radius to start…. Message may show when opening the file. If I click Ok and continue the same error may appear again when starting to run machine. If I clear error with crtl & space bar the machining will start about 35 mm to the left of where I wanted it.

If I open the same G code file again I may get no error and machining goes correctly.

But today the first file I opened didn’t show any errors, but still it machined it to the left by maybe more than 35mm.

I will attempt to attach 2 screen shots and the 2 G code files.

I have been using the Fusion web base processor and am not sure now if I have changed between the EMC to EMC2 selection without realizing it.

Which one should I be using??

What is the difference??

I have now downloaded the Fusion EMC2 processor onto my PC. But I still have had the error and wrong machining using that.

Is anyone able to enlighten me as to where my problem maybe?

Thank you

Trevor

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

08 Jun 2020 09:27 #170600

by bbsr_5a

Replied by bbsr_5a on topic X origin error when machining

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21002

- Thank you received: 7161

08 Jun 2020 09:51 #170605

by tommylight

Replied by tommylight on topic X origin error when machining

Check if you have any offsets active.

Radius error is due to tool being to big for the radius being cut or when starting from an arc.

Radius error is due to tool being to big for the radius being cut or when starting from an arc.

Please Log in or Create an account to join the conversation.

- twatchorn

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 0

08 Jun 2020 09:51 #170607

by twatchorn

Replied by twatchorn on topic X origin error when machining

Thanks for your reply.

I had read questions and answers about the G53 and thought it was all about the Z rising for a tool change. My machine has been doing that with some files.

I will try editing it out.

I have been touching off on the origin center. In the file above, I touched off in the center of the part.

Regards

Trevor

I had read questions and answers about the G53 and thought it was all about the Z rising for a tool change. My machine has been doing that with some files.

I will try editing it out.

I have been touching off on the origin center. In the file above, I touched off in the center of the part.

Regards

Trevor

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21002

- Thank you received: 7161

08 Jun 2020 10:16 #170613

by tommylight

Replied by tommylight on topic X origin error when machining

Personally, never got why some use the centre for cnc machining, it just seems to me plain wrong. I always use the lower left corner for everything.

I have been touching off on the origin center. In the file above, I touched off in the center of the part.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Away

- Administrator

-

Less

More

- Posts: 4602

- Thank you received: 2038

08 Jun 2020 13:26 - 08 Jun 2020 13:30 #170638

by Aciera

Replied by Aciera on topic X origin error when machining

G53 is absolute coordinates and this has never been a problem on my machine. Why would that cause an offset for the start of the gcode that uses G54?

Your parts zero point in CAD/CAM is usually where your G54 zero point is which is usually different from your absolute machine zero (G53). It is certainly somewhat unusual to zero the part at its center. How do you zero off the G54 in regard to your part after homing the machine?

If you do an MDI command G54 G0 X0 Y0 does the machine move to the right position (in your case the center of the part on the machine table)?

[edit]

Where IS absolute zero (G53) on your machine? Is it in the lower left corner?

Your parts zero point in CAD/CAM is usually where your G54 zero point is which is usually different from your absolute machine zero (G53). It is certainly somewhat unusual to zero the part at its center. How do you zero off the G54 in regard to your part after homing the machine?

If you do an MDI command G54 G0 X0 Y0 does the machine move to the right position (in your case the center of the part on the machine table)?

[edit]

Where IS absolute zero (G53) on your machine? Is it in the lower left corner?

Last edit: 08 Jun 2020 13:30 by Aciera.

Please Log in or Create an account to join the conversation.

- twatchorn

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 0

09 Jun 2020 07:49 #170781

by twatchorn

Replied by twatchorn on topic X origin error when machining

Hi,

I have done some experimenting today and have noted the following

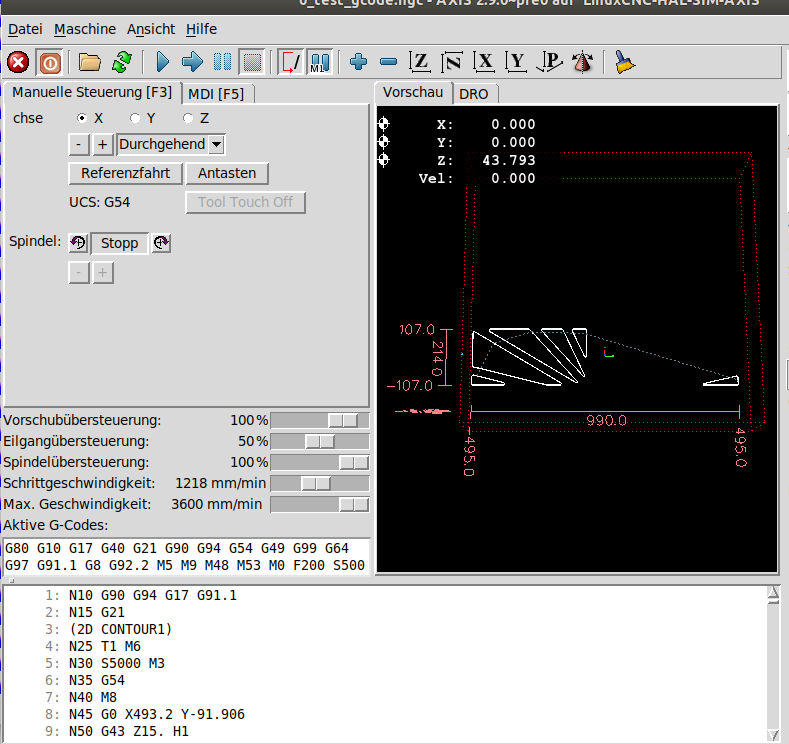

After starting the Router program, the first time the file is opened you can see an approach tool path starting from the right of the correct start point. (see curser on screenshot1).

If I open the file again it only shows the correct start point (see curser on screenshot2). This is the same if I open the file again.

I only get what you see in screenshot1 if this file is the first file I open after starting the router program.

Screenshot3 shows what happens I start machining process of screenshot1. The tool travels toward the correct start point then the display quickly moves to wrong start point at the right, but the machine does NOT travel for the portion shown in yellow (at curser). This is where the 35mm X axis off set is coming in as the machine travels back to what is meant to be the correct start point (in this case milling an unwanted groove as it goes!)

Screenshot4 shows the same error showing on a different file. Again if I open the file a second time it opens with only the correct start point.

The files that have shown the radius error respond like the above. If the file is opened the second time the error does not show.

Aciera question

“If you do an MDI command G54 G0 X0 Y0 does the machine move to the right position (in your case the center of the part on the machine table)?”

It is the center of the part when before I start machining.

Once I start machining and I see it is not in the right place and stop the program, if I do G54 G0 X0 Y0 it goes to the center of part on Y and 35mm to the left of center on X.

Aciera question

“Where IS absolute zero (G53) on your machine? Is it in the lower left corner?”

G53 g0 x0 y0 takes head to right hand top corner. But I home to the left hand bottom corner with X home position = -1550 and Y home = -850

Tommylight advice

“Check if you have any offsets active.

Radius error is due to tool being to big for the radius being cut or when starting from an arc.”

The only off sets I can see are to do with height clearance etc

I did try removing the G53 lines on the door file and it made no difference.

Regards

Trevor

I have done some experimenting today and have noted the following

After starting the Router program, the first time the file is opened you can see an approach tool path starting from the right of the correct start point. (see curser on screenshot1).

If I open the file again it only shows the correct start point (see curser on screenshot2). This is the same if I open the file again.

I only get what you see in screenshot1 if this file is the first file I open after starting the router program.

Screenshot3 shows what happens I start machining process of screenshot1. The tool travels toward the correct start point then the display quickly moves to wrong start point at the right, but the machine does NOT travel for the portion shown in yellow (at curser). This is where the 35mm X axis off set is coming in as the machine travels back to what is meant to be the correct start point (in this case milling an unwanted groove as it goes!)

Screenshot4 shows the same error showing on a different file. Again if I open the file a second time it opens with only the correct start point.

The files that have shown the radius error respond like the above. If the file is opened the second time the error does not show.

Aciera question

“If you do an MDI command G54 G0 X0 Y0 does the machine move to the right position (in your case the center of the part on the machine table)?”

It is the center of the part when before I start machining.

Once I start machining and I see it is not in the right place and stop the program, if I do G54 G0 X0 Y0 it goes to the center of part on Y and 35mm to the left of center on X.

Aciera question

“Where IS absolute zero (G53) on your machine? Is it in the lower left corner?”

G53 g0 x0 y0 takes head to right hand top corner. But I home to the left hand bottom corner with X home position = -1550 and Y home = -850

Tommylight advice

“Check if you have any offsets active.

Radius error is due to tool being to big for the radius being cut or when starting from an arc.”

The only off sets I can see are to do with height clearance etc

I did try removing the G53 lines on the door file and it made no difference.

Regards

Trevor

Please Log in or Create an account to join the conversation.

- Aciera

-

- Away

- Administrator

-

Less

More

- Posts: 4602

- Thank you received: 2038

09 Jun 2020 08:04 - 09 Jun 2020 08:30 #170783

by Aciera

Replied by Aciera on topic X origin error when machining

Ok so you get an offset of 35mm in X when you do a G54 G0 X0 Y0. This looks very much like an active offset: linuxcnc.org/docs/html/gcode/g-code.html#gcode:g92

When you get the 35mm offset in X after G54 G0 X0 Y0 does the DRO show X 0 or X 35?

Try this: MDI command G54 G0 X0 Y0. If it does not move to the center (ie you get your 35mm offset) do MDI command G92.1 (this removes all G92 Offsets) and try G54 G0 X0 Y0 again.

Note what is happening in the DRO for the X axis does it read 0 or not.

[edit]

Maybe also have a look in the linuxcnc.var of your config and check that parameters 5211-5219 are zero.

When you get the 35mm offset in X after G54 G0 X0 Y0 does the DRO show X 0 or X 35?

Try this: MDI command G54 G0 X0 Y0. If it does not move to the center (ie you get your 35mm offset) do MDI command G92.1 (this removes all G92 Offsets) and try G54 G0 X0 Y0 again.

Note what is happening in the DRO for the X axis does it read 0 or not.

[edit]

Maybe also have a look in the linuxcnc.var of your config and check that parameters 5211-5219 are zero.

Last edit: 09 Jun 2020 08:30 by Aciera.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Away

- Administrator

-

Less

More

- Posts: 4602

- Thank you received: 2038

09 Jun 2020 09:29 #170790

by Aciera

Replied by Aciera on topic X origin error when machining

Just noticed that your gcode files start with '%'.

Is there a reason for that? No idea if it makes a difference but maybe try without it.

Is there a reason for that? No idea if it makes a difference but maybe try without it.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21002

- Thank you received: 7161

09 Jun 2020 10:42 #170805

by tommylight

Replied by tommylight on topic X origin error when machining

All of my gcode files begin and end with % sign, that is required if there are no M codes to mark the end of gcode file.Just noticed that your gcode files start with '%'.

Is there a reason for that? No idea if it makes a difference but maybe try without it.

Please Log in or Create an account to join the conversation.

Time to create page: 0.126 seconds