Encoders vs. Tachometers ???

- jCandlish

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 77

- Thank you received: 4

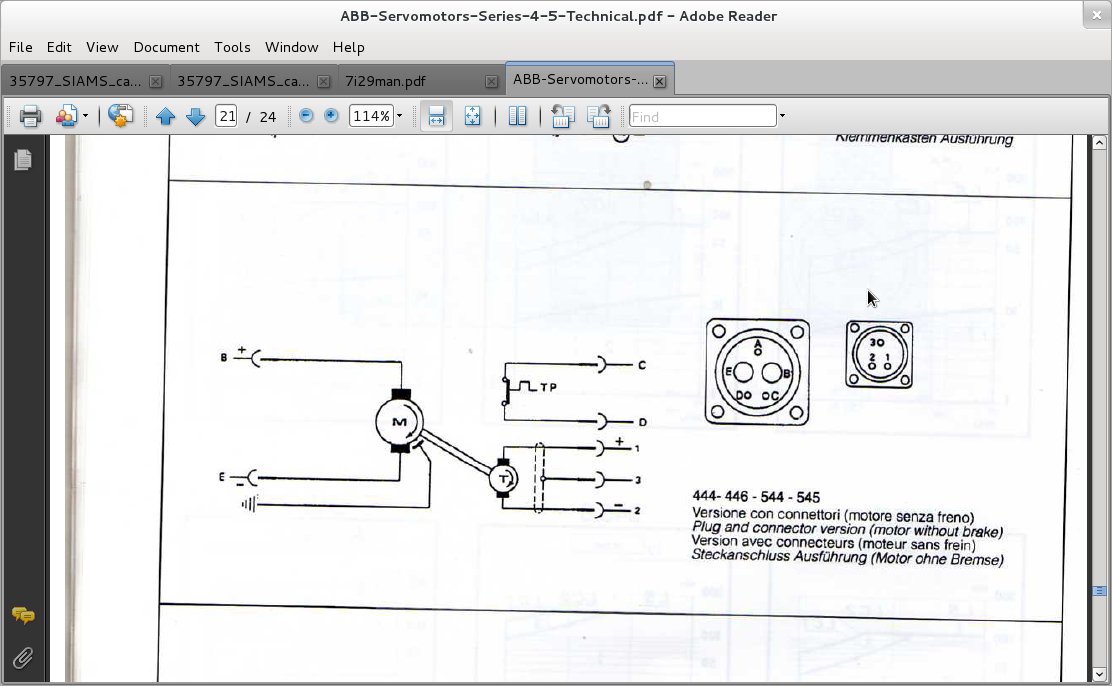

But for getting the breadboard going I was ass-u-ming that my 544 ABB/Isoflux servos where encoder equiped, especially as the diagram of the existing Seidel/Bobray amp is showing a feedback loop labeled 'tach'.

I found the documentation for the servos:

Oh Woe!

It turns out tach. and _tach. are 0.02V/rpm, although the servos are equiped 'with encoder resolver 2and shaft'.

So, what is the easy way out here? Electroncially convert the DC tacho to a pulse train (mechanically jimmy the commutator in the tach) or add a pupose made encoder?

What would be "best practise", given that the ultimate reference are the glass scales?

Thanks

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17338

- Thank you received: 5049

you are using the original velocity mode drives. They do not and cannot provide position

information. Position information must come from encoders/resolver/scales.

Please Log in or Create an account to join the conversation.

- jCandlish

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 77

- Thank you received: 4

The tachs are for _velocity_ feedback for the motor drives, and need to remain if

you are using the original velocity mode drives. They do not and cannot provide position

information. Position information must come from encoders/resolver/scales.

That is clear. My error was in assuming that the 7i29 would provide a trivial interface.

The problem remains, how to interface the analog velocity signal.

I have on order with mesanet 7i29 + 7i47s + 7i37ta, so no analog in.

Regards

_jC

.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

- Posts: 3990

- Thank you received: 992

Analog in to what?

John

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17338

- Thank you received: 5049

Please Log in or Create an account to join the conversation.

- jCandlish

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 77

- Thank you received: 4

Typically with a 7I29 , a shaft encoder is used for position and velocity feedback

And so my question is, and remains, what is the easy way to convert the analog signal to a pulse train. See original post.

I suppose the tacho generator has a commutator, maybe the simplest approach is to break that.

A negative logic pulse-train would be nice for safety reasons, and an out of the box (PLL?) circuit would be neat.

Cheers

_jC

.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17338

- Thank you received: 5049

Please Log in or Create an account to join the conversation.

- jCandlish

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 77

- Thank you received: 4

No need, just use an encoder, better in every way

Great! Who has a donkey that deficates encoders?

Edit: and it isn't better in every way unless its negative logic. Otherwise a failure of the device leads to a runaway.

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

- Posts: 7230

- Thank you received: 2106

First your machine should have a feedback device already somewhere (unless the drive is a step and direction servo).

The easiest would be to use it.

If the linear scale is the feedback device you can have tuning issues since the scale is not directly connected

to the motor.

next easiest would be to add a rotary encoder. which should work better then the linear scale.

The hardest would be trying to make a tach (a velocity sensor) act as an encoder (a position sensor)

And it is possible to have the PID control shutdown the motor if the encoder breaks

Peter has talked of this before. I believe it does it by counting how long the PID is saturated at maximum output

and if too long ( the servo is not keeping track ) it sets the output to zero.

You give very little detail of your situation to recommend much more.

Hope that helps

PS if rereading your post - I think you are stuck on trying to get the analog tach signal into linuxcnc via the 7i29.

What everyone is saying is you don't want the analog signal!

Please Log in or Create an account to join the conversation.

- jCandlish

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 77

- Thank you received: 4

hmm no need to beat us up for our advice.

The advice was taken in the nature it was given. 'Better in every way' is a remarkably bold assertion.

And it is possible to have the PID control shutdown the motor if the encoder breaks

Peter has talked of this before. I believe it does it by counting how long the PID is saturated at maximum output

and if too long ( the servo is not keeping track ) it sets the output to zero.

This is my next area of inquiry. How can I find out more about Servo-Loop fault conditions in EMC2?

Who is Peter?

You give very little detail of your situation to recommend much more.

Hope that helps

The information on PID control shutdown is new and helpful to me. I hope someone can follow up with more information about this.

What additional information can I provide. I have ABB/IsoFlux 544 series Servomotors with integrated 0.02V/rpm tachometers. My goal is to drive these motors with 7i29 H-Bridges using EMC2 for control. My machine is also equiped with Heidenhain glass scales and EXE-602E resolvers, that I had thought to use in a secondary feedback loop.

PS if rereading your post - I think you are stuck on trying to get the analog tach signal into linuxcnc via the 7i29.

Not quite. I am stuck on using the existing analog tach signal with EMC2. Period.

What everyone is saying is you don't want the analog signal!

Agreed. But its what I have now to start with.

That both tachometer and encoder feedback are positive logic an therefore subject to runaway in a wire fault condition is troublesome to me. This is also a concern of mine in using the Heidenhain scales in a feedback loop, because they are not robust. I need to learn how EMC2 bounds feedback following errors.

Anyway does it really matter to EMC2 if the primary servo feedback is encoder derived (Radians) or tacho derived (dRadians/dT)?

Thanks for letting me think out loud.

_jC

.

Please Log in or Create an account to join the conversation.