Cincinnati Milacron Arrow 750 Retrofit

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21213

- Thank you received: 7247

20 Apr 2021 20:20 #206563

by tommylight

Replied by tommylight on topic Cincinnati Milacron Arrow 750 Retrofit

Turn the motor shaft by hand just a bit then power on again see if it faults.

Please Log in or Create an account to join the conversation.

- stegrg

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 3

20 Apr 2021 20:46 #206570

by stegrg

Replied by stegrg on topic Cincinnati Milacron Arrow 750 Retrofit

Yes, it faults with the U,V,W wire connected (after turning the shaft a bit) or not connected at all. It seems as though there is a fault within the 8i20 card that can't be cleared by restarting linuxcnc or repowering the 8i20card.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17622

- Thank you received: 5155

20 Apr 2021 21:41 #206575

by PCW

Replied by PCW on topic Cincinnati Milacron Arrow 750 Retrofit

Sounds like maybe a damaged IGBT module

What is the DC supply voltage?

What is the DC supply voltage?

Please Log in or Create an account to join the conversation.

- stegrg

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 3

20 Apr 2021 22:25 - 20 Apr 2021 22:27 #206582

by stegrg

Replied by stegrg on topic Cincinnati Milacron Arrow 750 Retrofit

The DC supply voltage is fixed at 54 volts.

Is there some way I can test the IGBT module to verify it is the culprit?

Is there some way I can test the IGBT module to verify it is the culprit?

Last edit: 20 Apr 2021 22:27 by stegrg.

Please Log in or Create an account to join the conversation.

- stegrg

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 3

22 Apr 2021 11:23 #206780

by stegrg

Replied by stegrg on topic Cincinnati Milacron Arrow 750 Retrofit

Is there anything I can do on my end to figure out the issue with the 8i20 card or should I just ship it to have MESA take a look at it?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17622

- Thank you received: 5155

22 Apr 2021 15:02 #206801

by PCW

Replied by PCW on topic Cincinnati Milacron Arrow 750 Retrofit

Probably has to go back to mesa under RMA.

Please Log in or Create an account to join the conversation.

- stegrg

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 3

23 Apr 2021 14:03 #206869

by stegrg

Replied by stegrg on topic Cincinnati Milacron Arrow 750 Retrofit

I setup another 8i20 card to another servo off the milling machine. When I run the servo in open loop, I hear a small internal clicking/ticking sound that occurs at the same angular location. (The previous servo and 8i20 card did the same thing). I can hear and feel the internal click/tick when I apply 0 amps and turn the shaft by hand.

When I power down Linuxcnc, the shaft spins smooth and free with no indication of an internal tick. Is this the result of misalignment between encoder zero and servo zero? (As a note, I'm currently only running the servo using an SSI interpolated coarse single SIN/COS wave per revolution. The absolute angle value dances around at standstill.)

I'd like to incorporate the fine 2048 SIN/COS waves per revolution but I'm not sure how in bldc.comp. The coarse single SIN/COS wave produces 2048 interpolated readings per revolution while the fine 2048 SIN/COS waves produce 16384 readings per revolution. I was thinking about starting the servo using the coarse single SIN/COS wave and then switching to the fine 2048 SIN/COS waves after it passes an index. The question I have is does BLDC.comp (or Linuxcnc) care if I scale the initial coarse 2048 readings up to 16384 (by a factor of 8) so that the coarse single and fine 2048 SIN/COS waves both have 16384 reading per revolution? (This would mean that the coarse single SIN/COS wave would produce readings that skip values by a factor of 8 until an index is read.)

When I power down Linuxcnc, the shaft spins smooth and free with no indication of an internal tick. Is this the result of misalignment between encoder zero and servo zero? (As a note, I'm currently only running the servo using an SSI interpolated coarse single SIN/COS wave per revolution. The absolute angle value dances around at standstill.)

I'd like to incorporate the fine 2048 SIN/COS waves per revolution but I'm not sure how in bldc.comp. The coarse single SIN/COS wave produces 2048 interpolated readings per revolution while the fine 2048 SIN/COS waves produce 16384 readings per revolution. I was thinking about starting the servo using the coarse single SIN/COS wave and then switching to the fine 2048 SIN/COS waves after it passes an index. The question I have is does BLDC.comp (or Linuxcnc) care if I scale the initial coarse 2048 readings up to 16384 (by a factor of 8) so that the coarse single and fine 2048 SIN/COS waves both have 16384 reading per revolution? (This would mean that the coarse single SIN/COS wave would produce readings that skip values by a factor of 8 until an index is read.)

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17622

- Thank you received: 5155

23 Apr 2021 14:45 #206874

by PCW

Replied by PCW on topic Cincinnati Milacron Arrow 750 Retrofit

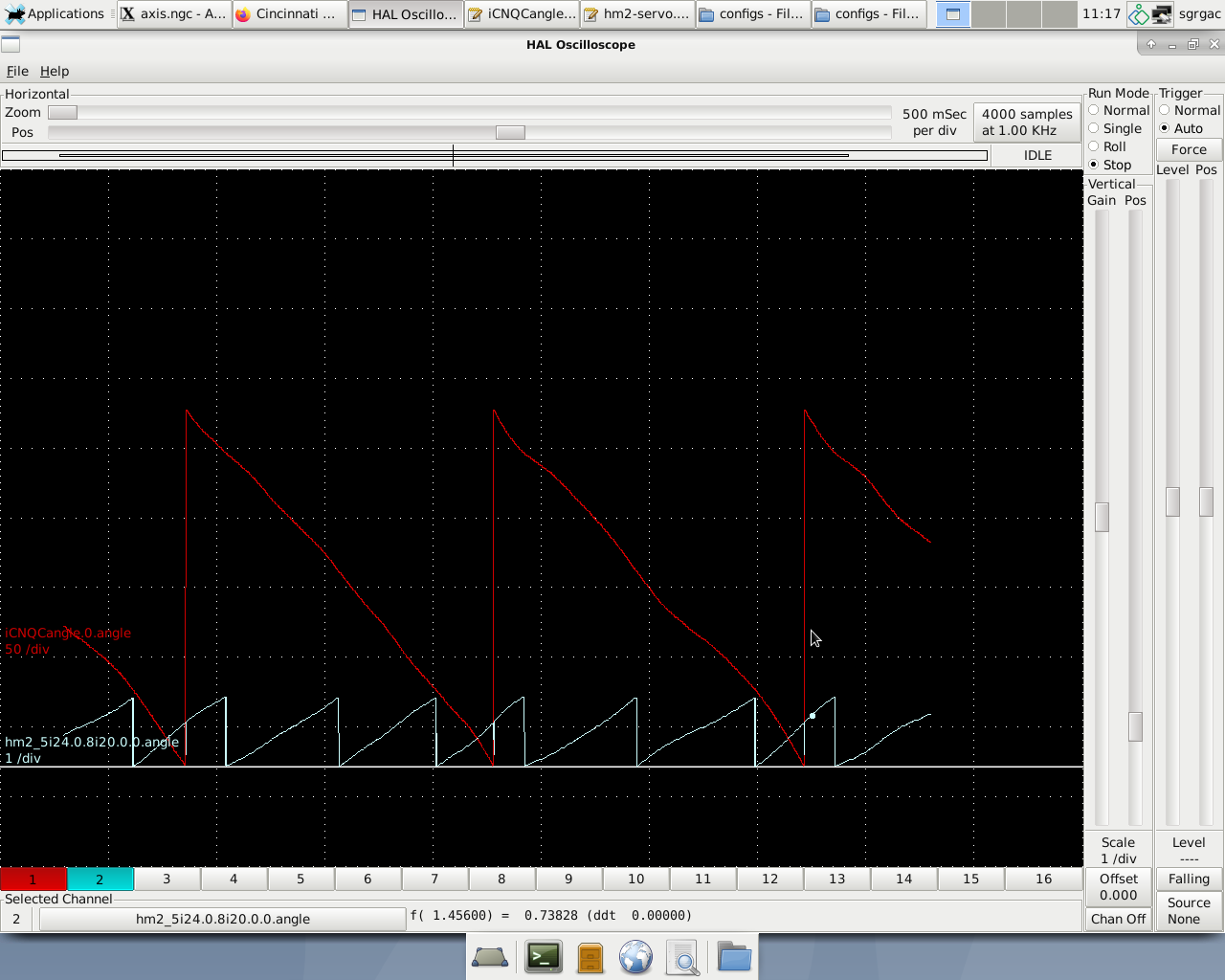

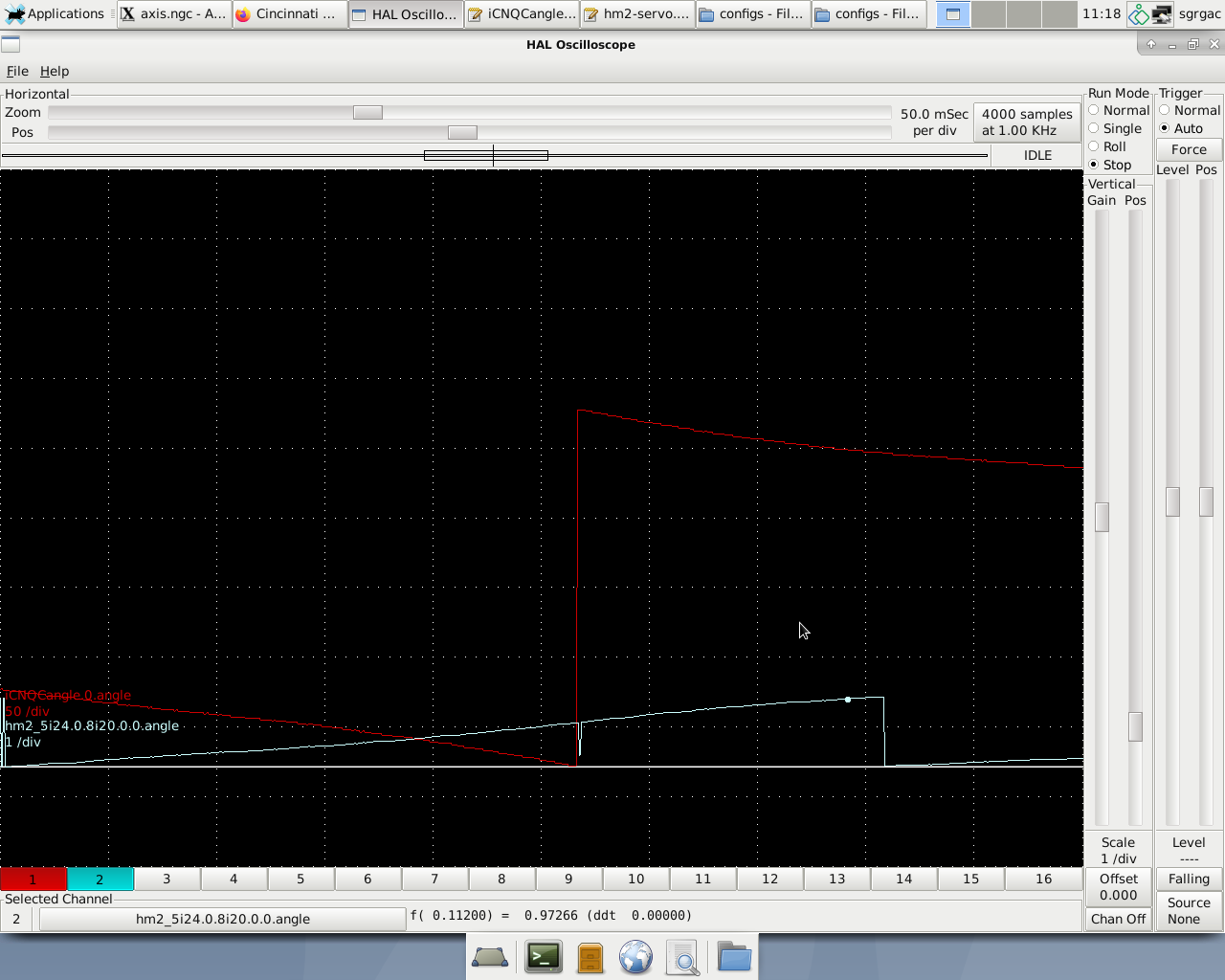

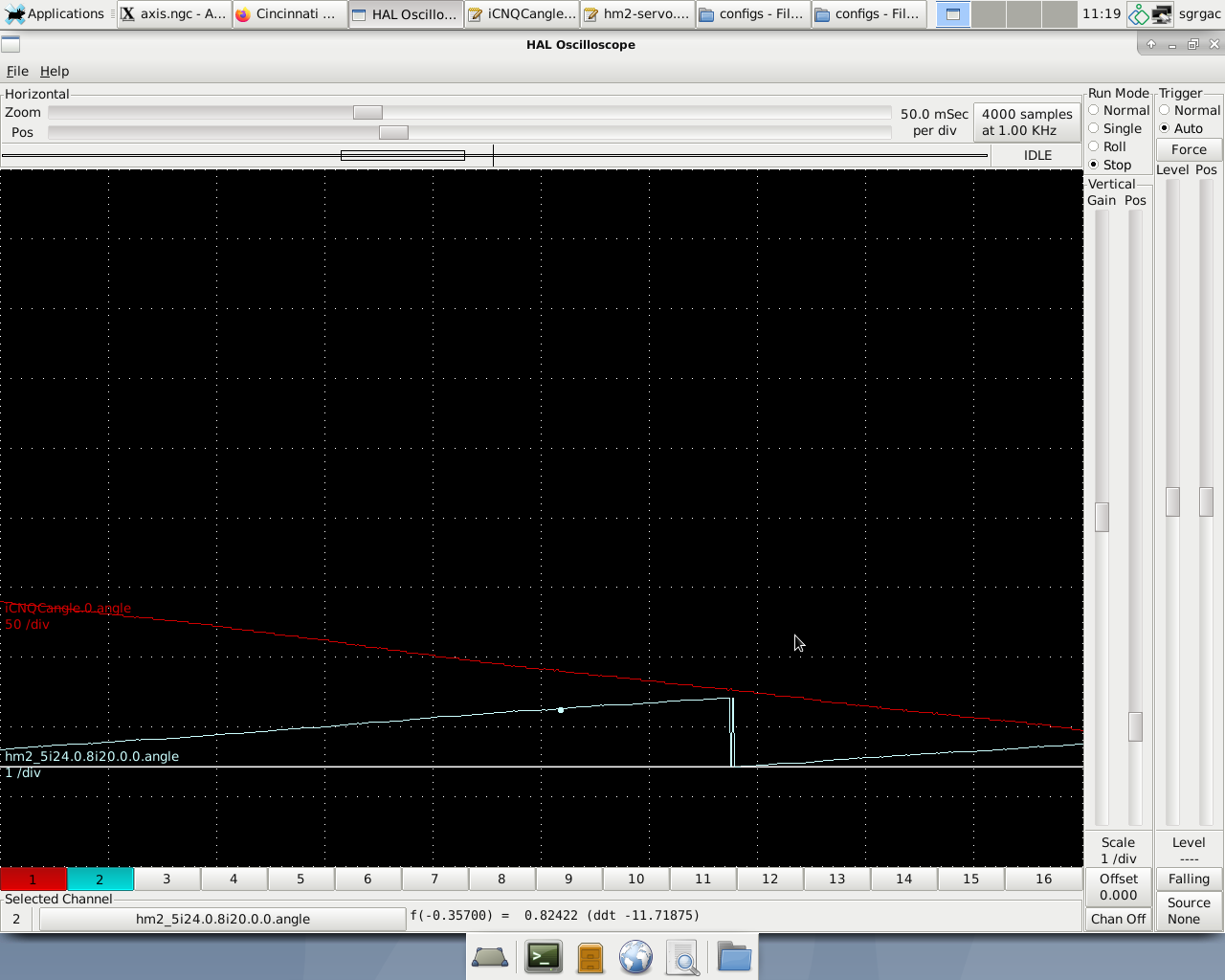

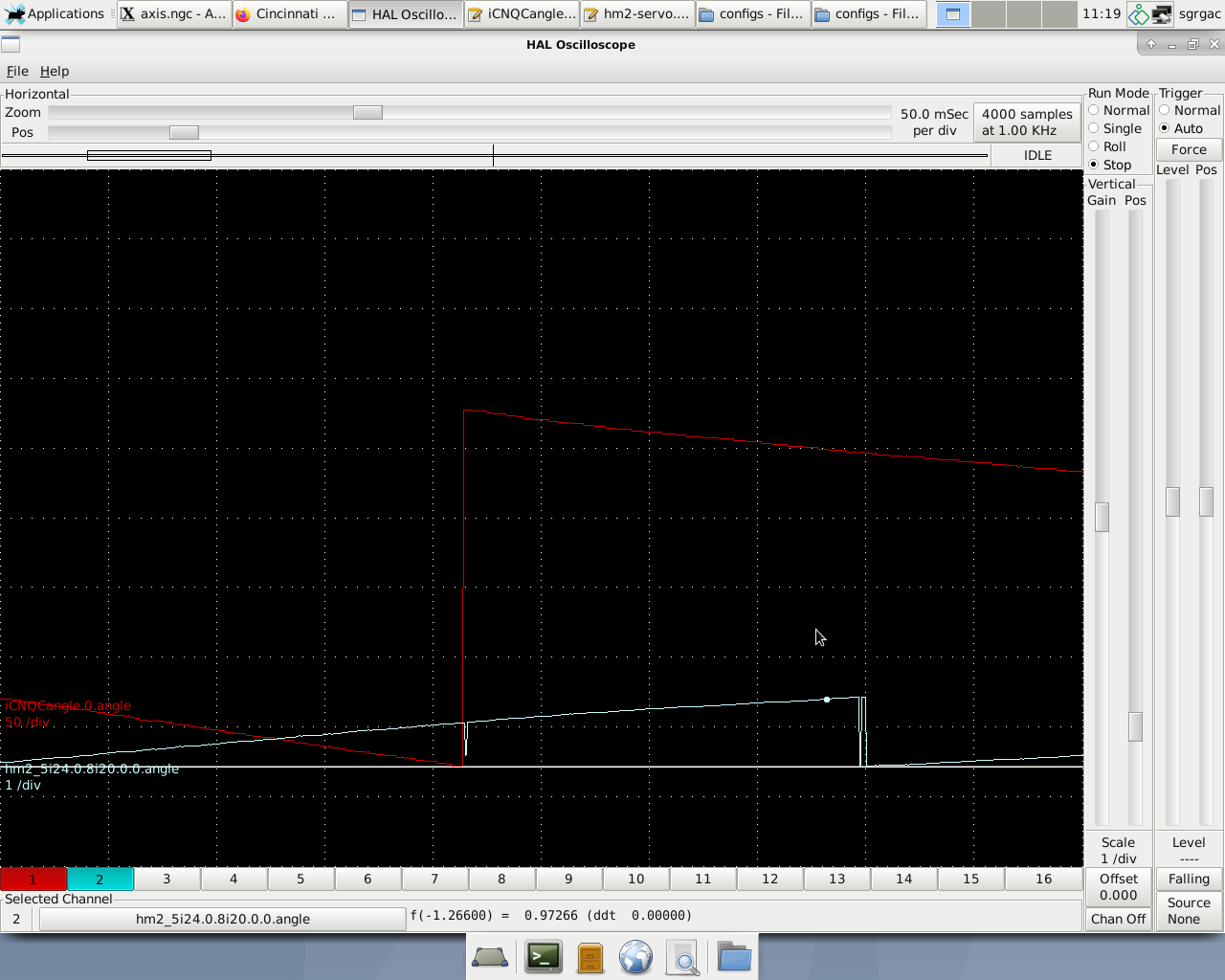

I would not think its an alignment error but rather a discontinuity in the angle

sent to the 8I20. You might plot the angle with halscope when moving at a low speed

to see what's going on

sent to the 8I20. You might plot the angle with halscope when moving at a low speed

to see what's going on

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

24 Apr 2021 01:09 #206914

by andypugh

It's probably not worth the trouble for _commutation_. BLDC motors work just fine with 6 steps, Fanuc went to a 16 step scheme. DC servos never had a 2048-segment commutator. 2048 is _more_ than enough resolution for commutation. The question is whether it is good data.

Replied by andypugh on topic Cincinnati Milacron Arrow 750 Retrofit

I'd like to incorporate the fine 2048 SIN/COS waves per revolution but I'm not sure how in bldc.comp.

It's probably not worth the trouble for _commutation_. BLDC motors work just fine with 6 steps, Fanuc went to a 16 step scheme. DC servos never had a 2048-segment commutator. 2048 is _more_ than enough resolution for commutation. The question is whether it is good data.

Please Log in or Create an account to join the conversation.

- stegrg

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 3

24 Apr 2021 15:38 #206955

by stegrg

Replied by stegrg on topic Cincinnati Milacron Arrow 750 Retrofit

I reduced the coarse angle resolution to 256 (from 2048) which has eliminated the absolute angle dancing around values at standstill. If there isn't anything significant to be gained from higher signal resolutions (for commutation purposes), I might leave it at this value or reduce it further in the future.

I manually spun the servo shaft and plotted the coarse absolute angle and the 8i20 angle in Hal Oscilloscope. There is definitely something going on. It seems like the 8i20 angle is momentarily being driven to zero just after the absolute angle resets back to 255.

Attached are screenshots as well as some zoomed in areas. Anybody have any ideas what may be causing this?

I manually spun the servo shaft and plotted the coarse absolute angle and the 8i20 angle in Hal Oscilloscope. There is definitely something going on. It seems like the 8i20 angle is momentarily being driven to zero just after the absolute angle resets back to 255.

Attached are screenshots as well as some zoomed in areas. Anybody have any ideas what may be causing this?

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 0.250 seconds