hobbing helical gear

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4622

- Thank you received: 2045

04 Sep 2020 19:38 #180743

by Aciera

Replied by Aciera on topic hobbing helical gear

I have no idea what kind of gears these are. Information is a bit scant, really.

I just follow my own curiosity here.

Hm, crossed helical gears, there is always something more to look up

I just follow my own curiosity here.

Hm, crossed helical gears, there is always something more to look up

Please Log in or Create an account to join the conversation.

- jefsaro

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 104

- Thank you received: 4

05 Sep 2020 05:41 #180779

by jefsaro

Replied by jefsaro on topic hobbing helical gear

yes it's crossed helical gears 90 degres.

there is a way to catch the head badly with the calculations and the settings of the machine

there is a way to catch the head badly with the calculations and the settings of the machine

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

06 Sep 2020 17:25 #181042

by CORBETT

Replied by CORBETT on topic hobbing helical gear

@jefsaro

I am assuming you have figured out what to do after henk replied that there is a second gear train for the differential. So basically you need to put a stepper or servo on the second gear train and setup in LCNC.

Andy (andypugh) will be the guy to talk with about setting it up in LCNC. That guy is brilliant, and has been working on this for a really long time.

@Aciera

Yeah at first I thought they were referring to herringbone gears when they said crossed helical, but crossed helical is setup like a worm gear. There would have to be some good mathematics involved to get everything meshed up correctly, especially when one gear is smaller than the other like a worm setup.

I wonder if you get more play in this setup compared to a worm setup? This has peaked my interest.

Robert

I am assuming you have figured out what to do after henk replied that there is a second gear train for the differential. So basically you need to put a stepper or servo on the second gear train and setup in LCNC.

Andy (andypugh) will be the guy to talk with about setting it up in LCNC. That guy is brilliant, and has been working on this for a really long time.

@Aciera

Yeah at first I thought they were referring to herringbone gears when they said crossed helical, but crossed helical is setup like a worm gear. There would have to be some good mathematics involved to get everything meshed up correctly, especially when one gear is smaller than the other like a worm setup.

I wonder if you get more play in this setup compared to a worm setup? This has peaked my interest.

Robert

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4622

- Thank you received: 2045

06 Sep 2020 17:57 #181053

by Aciera

Replied by Aciera on topic hobbing helical gear

@CORBETT

I don't really know a lot about gears. I thought maybe I could glean some information by following this project. Alas I have the distinct feeling this is not going to be the busiest of threads. Feels more like milking stones.

Maybe just a language thing though. And he probably gets more stuff done than me.

Anyway, you seem to have one of those gear hobbers sitting around, maybe you could convert that with all the bells and whistles now?

After all there is no time like the present, is there?

I don't really know a lot about gears. I thought maybe I could glean some information by following this project. Alas I have the distinct feeling this is not going to be the busiest of threads. Feels more like milking stones.

Maybe just a language thing though. And he probably gets more stuff done than me.

Anyway, you seem to have one of those gear hobbers sitting around, maybe you could convert that with all the bells and whistles now?

After all there is no time like the present, is there?

The following user(s) said Thank You: CORBETT

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

07 Sep 2020 02:11 #181082

by CORBETT

Replied by CORBETT on topic hobbing helical gear

@Aciera

LOL, I have milked stones...

"After all there is no time like the present, is there?"

Yes I need a good push to get going with it... been trying to reduce some other projects so I can get this one started. Like everyone, way too many irons in the fire, LOL.

LOL, I have milked stones...

"After all there is no time like the present, is there?"

Yes I need a good push to get going with it... been trying to reduce some other projects so I can get this one started. Like everyone, way too many irons in the fire, LOL.

Please Log in or Create an account to join the conversation.

- Ravi0000

- Offline

- New Member

-

Less

More

- Posts: 1

- Thank you received: 0

24 Feb 2021 18:31 #200010

by Ravi0000

Replied by Ravi0000 on topic hobbing helical gear

Hello everyone I m Ravi form India patna BIHAR

Making a cnc gear hobbing machine for helical gear cutting

Making a cnc gear hobbing machine for helical gear cutting

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4622

- Thank you received: 2045

25 Feb 2021 07:43 #200066

by Aciera

Replied by Aciera on topic hobbing helical gear

Ah, another one.

So are you also refitting an older manual machine?

So are you also refitting an older manual machine?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 19762

- Thank you received: 4589

28 Feb 2021 22:35 #200473

by andypugh

Unfortunately I was not really reading the forum when this was discussed.

I keep meaning to make a helical gear, but have not done so yet.

There are two things to do:

1) Angle the hob to the gear by the normal amount (hob lead angle) and by the helix angle

2) Add in an extra movement of the hob relative to the blank proportional to the distance travelled along the gear shaft axis.

Exactly how the maths works out will depend on the machine. On my mill the X feed direction swings with the table (which sets the hob angle), whereas on a conventional hobber I don't think that it does.

This second part could be done in two ways:

a) By rotating the blank by an extra amount. The problem here is that the extra amount depends on the radius of the cut

b) By shifting the hob along the hob axis. This should work at any radius (but I haven't analysed it, this is just visualising it). It has the advantage of evening the wear on the hob. It has the disadvantage that the hob might not actually be long enough.

b) Would be easy on my my milling-machine hobber, but might not even be an option on a real hobbing machine.

Both are equally easy in HAL. Just another scale and sum. You don't need to worry about the absolute position of the linear axis even, as the starting point will be in the numbers from the start.

If I was to make helical gears there would be a lot of nylon or wax practice parts made first, whilst I checked the maths.

Replied by andypugh on topic hobbing helical gear

I think I'll let Andy figure that out overnight and wait for him to present his solution (including a GUI).

Unfortunately I was not really reading the forum when this was discussed.

I keep meaning to make a helical gear, but have not done so yet.

There are two things to do:

1) Angle the hob to the gear by the normal amount (hob lead angle) and by the helix angle

2) Add in an extra movement of the hob relative to the blank proportional to the distance travelled along the gear shaft axis.

Exactly how the maths works out will depend on the machine. On my mill the X feed direction swings with the table (which sets the hob angle), whereas on a conventional hobber I don't think that it does.

This second part could be done in two ways:

a) By rotating the blank by an extra amount. The problem here is that the extra amount depends on the radius of the cut

b) By shifting the hob along the hob axis. This should work at any radius (but I haven't analysed it, this is just visualising it). It has the advantage of evening the wear on the hob. It has the disadvantage that the hob might not actually be long enough.

b) Would be easy on my my milling-machine hobber, but might not even be an option on a real hobbing machine.

Both are equally easy in HAL. Just another scale and sum. You don't need to worry about the absolute position of the linear axis even, as the starting point will be in the numbers from the start.

If I was to make helical gears there would be a lot of nylon or wax practice parts made first, whilst I checked the maths.

Please Log in or Create an account to join the conversation.

- timo

- Offline

- Elite Member

-

Less

More

- Posts: 170

- Thank you received: 49

24 Apr 2021 09:59 - 24 Apr 2021 10:05 #206941

by timo

Replied by timo on topic hobbing helical gear

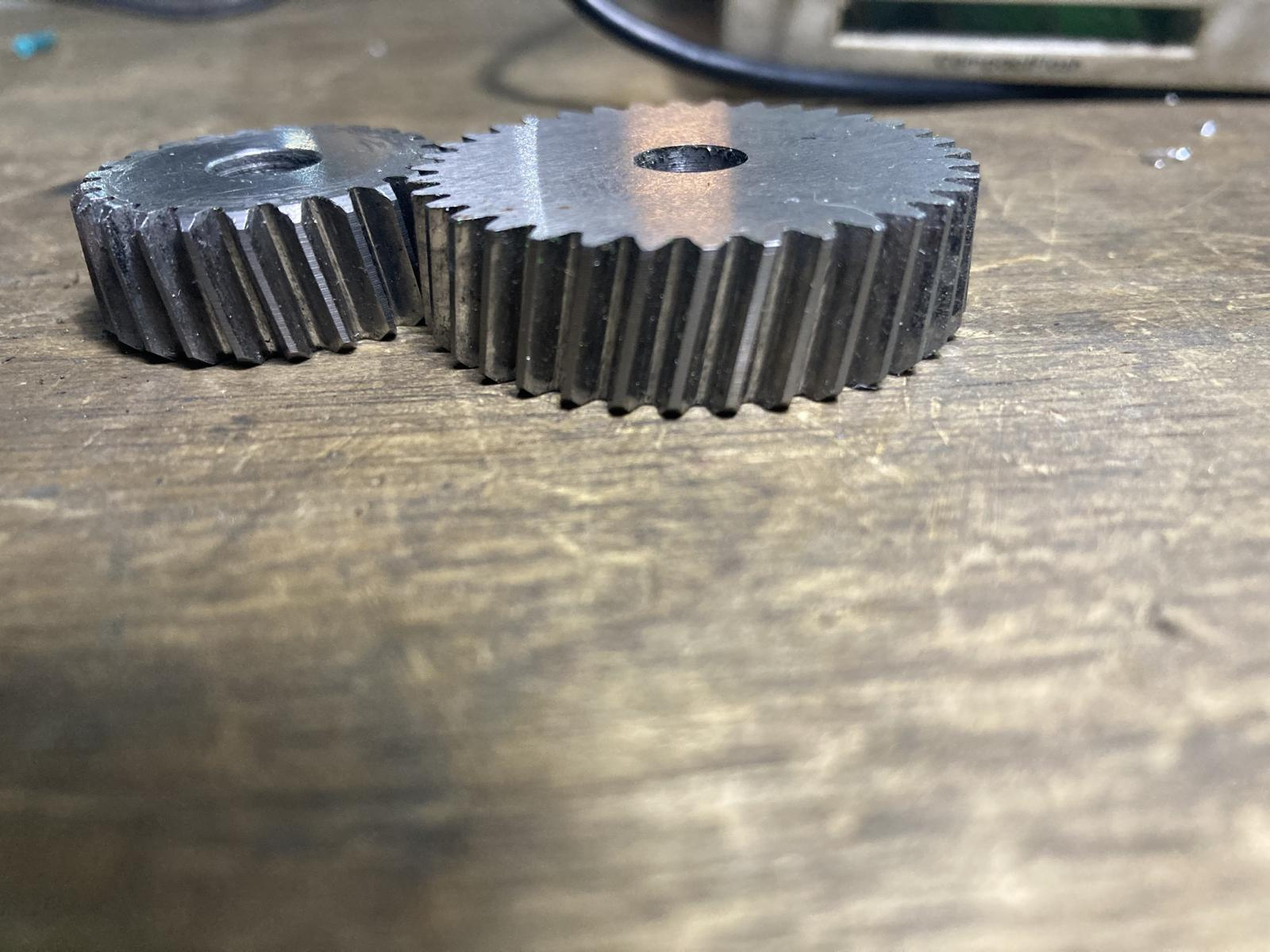

Hello all,

quite some time ago I tried this based on andies Youtube advise and forum information.

For not too steep helix angles with the hob it can be simply done ( on my machine to move the column down while traversing the hob ) As far as I recall it is not dependent on blank diameter, but as the hob is tilted the hob does not move along its axle, but slightly off.

Did not notice that yet.

I have experimented with rotation of the blank for that Andie suggested another scale and hooking it up to the x-position.

I am a little stuck with figuring out what numbers to put into the hal file.

Did someone get it running yet?

Greetings Timo

p.s. the gear were made shifting the hob. Problems why I am not happy with hob shifting.

The width of the gears will be limited to 10 or so mm, rotating the gear blank would allow thicker gears, or cutting more than one at a time.

machine looks like this.

quite some time ago I tried this based on andies Youtube advise and forum information.

For not too steep helix angles with the hob it can be simply done ( on my machine to move the column down while traversing the hob ) As far as I recall it is not dependent on blank diameter, but as the hob is tilted the hob does not move along its axle, but slightly off.

Did not notice that yet.

I have experimented with rotation of the blank for that Andie suggested another scale and hooking it up to the x-position.

I am a little stuck with figuring out what numbers to put into the hal file.

Did someone get it running yet?

Greetings Timo

p.s. the gear were made shifting the hob. Problems why I am not happy with hob shifting.

The width of the gears will be limited to 10 or so mm, rotating the gear blank would allow thicker gears, or cutting more than one at a time.

machine looks like this.

Last edit: 24 Apr 2021 10:05 by timo. Reason: adding picture

The following user(s) said Thank You: tommylight, johnmc1

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 404

- Thank you received: 92

24 Apr 2021 17:20 #206960

by Henk

Replied by Henk on topic hobbing helical gear

On our Pfauter PE500 (running Linuxcnc) at work, the z axis is parallel to the work piece axis, which is on the C axis. The Y axis is parallel to the hob/spindle, so when you apply a hob shift or hob axial movement, the C axis must rotate by a corresponding amount, determined by the gear reference diameter and the angle of the B axis ( hob tilt axis).

When hobbing a helical gear, the Y axis generally stays in the same position, although it is possible to use axial feed as well to spread the wear across the hob. The Y axis or hob shift is not used to generate the helix angle though.

The Helix angle is generated by additional C axis movement linked to the Z axis (X in your case), this ratio is determined by the Lead of the gear being cut.

The last link that determines the C axis position, is the hob or spindle. this relationship is determined by the number of teeth on the job, and the number of hob starts.

These three relationships are summed, and the result drives the C axis position.

When hobbing a helical gear, the Y axis generally stays in the same position, although it is possible to use axial feed as well to spread the wear across the hob. The Y axis or hob shift is not used to generate the helix angle though.

The Helix angle is generated by additional C axis movement linked to the Z axis (X in your case), this ratio is determined by the Lead of the gear being cut.

The last link that determines the C axis position, is the hob or spindle. this relationship is determined by the number of teeth on the job, and the number of hob starts.

These three relationships are summed, and the result drives the C axis position.

The following user(s) said Thank You: johnmc1

Please Log in or Create an account to join the conversation.

Time to create page: 0.140 seconds