new day new problems

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

12 Apr 2024 21:48 #298136

by acourtjester

new day new problems was created by acourtjester

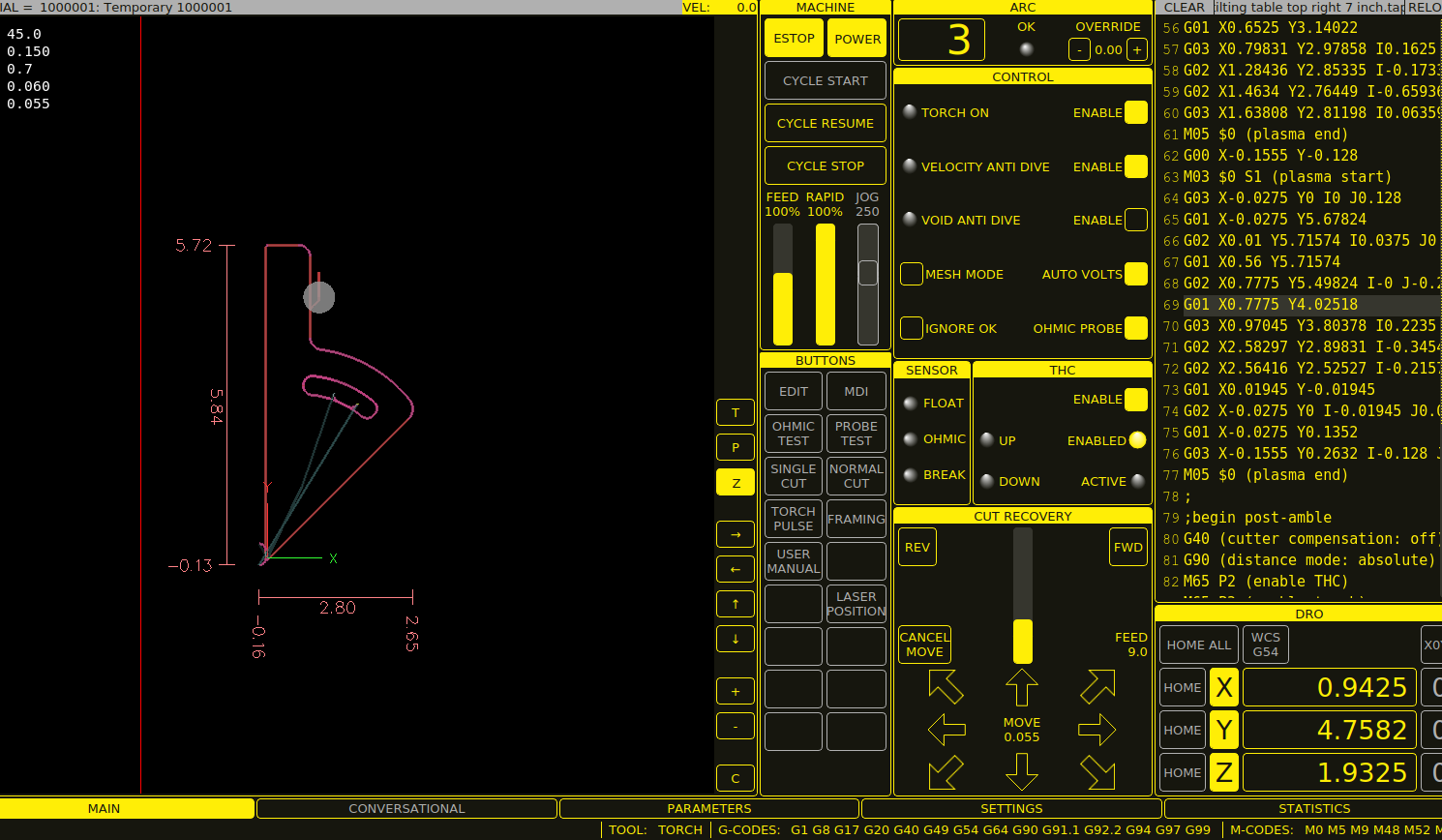

Back again with new problems, some time I get good cuts and other time not at all.

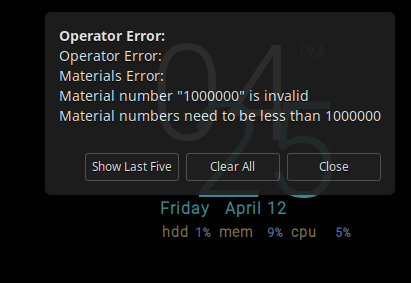

First thing when starting up I get a material error see attached.

I can cut a straight line (7") no problem, Add shapes to a cut and either stops about 1/3 the way through, or may crash the torch into the metal.

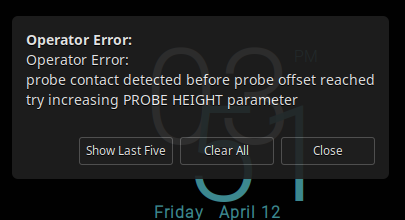

Today after a crash it gave my the restart option, I moved the torch a small amount for restart off the path. The cycle resume button was flashing, when I pushed it the torch moves down touched the metal and retracted. And I get a message about the probe.

I can run without the torch without error with multi-part G-code.

Just did an update/upgrade to V2.10-005.033 do not know if this will help with the problems I am having.

First thing when starting up I get a material error see attached.

I can cut a straight line (7") no problem, Add shapes to a cut and either stops about 1/3 the way through, or may crash the torch into the metal.

Today after a crash it gave my the restart option, I moved the torch a small amount for restart off the path. The cycle resume button was flashing, when I pushed it the torch moves down touched the metal and retracted. And I get a message about the probe.

I can run without the torch without error with multi-part G-code.

Just did an update/upgrade to V2.10-005.033 do not know if this will help with the problems I am having.

Attachments:

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

12 Apr 2024 22:05 #298137

by acourtjester

Replied by acourtjester on topic new day new problems

Ok this may have been the problem I have with the material list. I looked in SheetCam and I had many other then plasma tools that showed very high tool number. I will rerun the tool conversion in the morning with only Plasma tools.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21362

- Thank you received: 7286

12 Apr 2024 23:37 #298144

by tommylight

Replied by tommylight on topic new day new problems

I would disable "auto volts" and in the settings tab set the VAD to 60 or 65%.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

13 Apr 2024 00:02 #298147

by phillc54

Replied by phillc54 on topic new day new problems

You cannot have material numbers of 1000000 or greater in the material file.

The last error shows that you are using offset probing. You must have the probe height set to higher than the thickest material that you will cut. Probe height is measured from the Z axis lower limit, it is not the material thickness.

linuxcnc.org/docs/devel/html/plasma/qtpl...plasma:initial-setup

The last error shows that you are using offset probing. You must have the probe height set to higher than the thickest material that you will cut. Probe height is measured from the Z axis lower limit, it is not the material thickness.

linuxcnc.org/docs/devel/html/plasma/qtpl...plasma:initial-setup

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

13 Apr 2024 01:48 - 13 Apr 2024 01:49 #298152

by acourtjester

Replied by acourtjester on topic new day new problems

Thanks as usual for the info, you guys are great. I assume with the "auto Volts" off it gets the THC volts from the material list or G-code setting.

Question under the THC there is a box named Auto Activate, should it be on or off??

Question under the THC there is a box named Auto Activate, should it be on or off??

Last edit: 13 Apr 2024 01:49 by acourtjester. Reason: spelling

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21362

- Thank you received: 7286

13 Apr 2024 02:05 #298153

by tommylight

Replied by tommylight on topic new day new problems

On.

It can if they are set there, but if not, it will use the voltage set under cut volts, and can be adjusted while cutting by using the Override buttons near the voltage readout on the main screen.I assume with the "auto Volts" off it gets the THC volts from the material list or G-code setting.

The following user(s) said Thank You: acourtjester

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

14 Apr 2024 21:18 #298257

by acourtjester

Replied by acourtjester on topic new day new problems

Redoing the tool list in SheetCam (plasma only tools) and then the material conversion in LinuxCNC corrected the problem on the message at the start about the material over 1000000.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

15 Apr 2024 21:09 - 15 Apr 2024 21:11 #298313

by acourtjester

Replied by acourtjester on topic new day new problems

Well the pest is back, different problem.

I have updated to version 033, and now my plasma table has a new problem.

When I fire the torch I get an error showing from one to all limit switches tripped.

Now I am running Proximity sensors which work fine under the home all at the start up. And when I try to test the Ohmic sensor I can see it functioning in Hal Show but when clicking on the Ohmic test button the display lightens up and the ohmic led does not light. I have attached a video showing these actions.

drive.google.com/file/d/1Fj7Qm9ozVSof0kO.../view?usp=drive_link

The only changes to the controller is the update to version 033.

I have updated to version 033, and now my plasma table has a new problem.

When I fire the torch I get an error showing from one to all limit switches tripped.

Now I am running Proximity sensors which work fine under the home all at the start up. And when I try to test the Ohmic sensor I can see it functioning in Hal Show but when clicking on the Ohmic test button the display lightens up and the ohmic led does not light. I have attached a video showing these actions.

drive.google.com/file/d/1Fj7Qm9ozVSof0kO.../view?usp=drive_link

The only changes to the controller is the update to version 033.

Last edit: 15 Apr 2024 21:11 by acourtjester.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21362

- Thank you received: 7286

16 Apr 2024 00:41 #298320

by tommylight

Replied by tommylight on topic new day new problems

Always a wiring/grounding/shielding issue, my advice, fix this before doing any more tests, start with making sure the machine has proper grounding from the mains outlet or separate grounding just fro the machine.When I fire the torch I get an error showing from one to all limit switches tripped.

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

16 Apr 2024 00:59 - 16 Apr 2024 01:16 #298322

by acourtjester

Replied by acourtjester on topic new day new problems

I am not saying you are wrong but I have fought noise problems before on other tables I built. Troubleshooting includes the "What was the last thing you did before the problem" . With this it was the update/upgrade.

I have used Cat 6 cables for signal with feed through panel plugs and shielded other cables. The shields are terminated in the controller only. The Plasma cable is completely isolated from all other cables I use a boom for that cable. The attached video is from last month with an older version of QTPlasmaC without a single hick up. This all came from the latest update.

This is the 10th table I have built and I have used other control electronics and software, so I understand the noise problems that can happen. the other problem with the ohmic sensor came also with the new version, that is not noise related. As my other video shows the ohmic signal is input to QTPlasmaC Hal show but not through to where it need to be in the software.

drive.google.com/file/d/1mTytmUI8LUFoJ-7.../view?usp=drive_link

I have used Cat 6 cables for signal with feed through panel plugs and shielded other cables. The shields are terminated in the controller only. The Plasma cable is completely isolated from all other cables I use a boom for that cable. The attached video is from last month with an older version of QTPlasmaC without a single hick up. This all came from the latest update.

This is the 10th table I have built and I have used other control electronics and software, so I understand the noise problems that can happen. the other problem with the ohmic sensor came also with the new version, that is not noise related. As my other video shows the ohmic signal is input to QTPlasmaC Hal show but not through to where it need to be in the software.

drive.google.com/file/d/1mTytmUI8LUFoJ-7.../view?usp=drive_link

Last edit: 16 Apr 2024 01:16 by acourtjester. Reason: added info

Please Log in or Create an account to join the conversation.

Time to create page: 0.183 seconds