poor surface quality

- Sternfox

- Offline

- Senior Member

-

Less

More

- Posts: 41

- Thank you received: 7

04 Jul 2025 16:38 #331250

by Sternfox

poor surface quality was created by Sternfox

Hi Peeps,

Im pulling my hair out trying to debug a poor surface problem. I have a LinuxCNC retrofit Haas mini mill. Dimensional accuracy is within 5 microns, perfect. Backlash is around 3 microns.

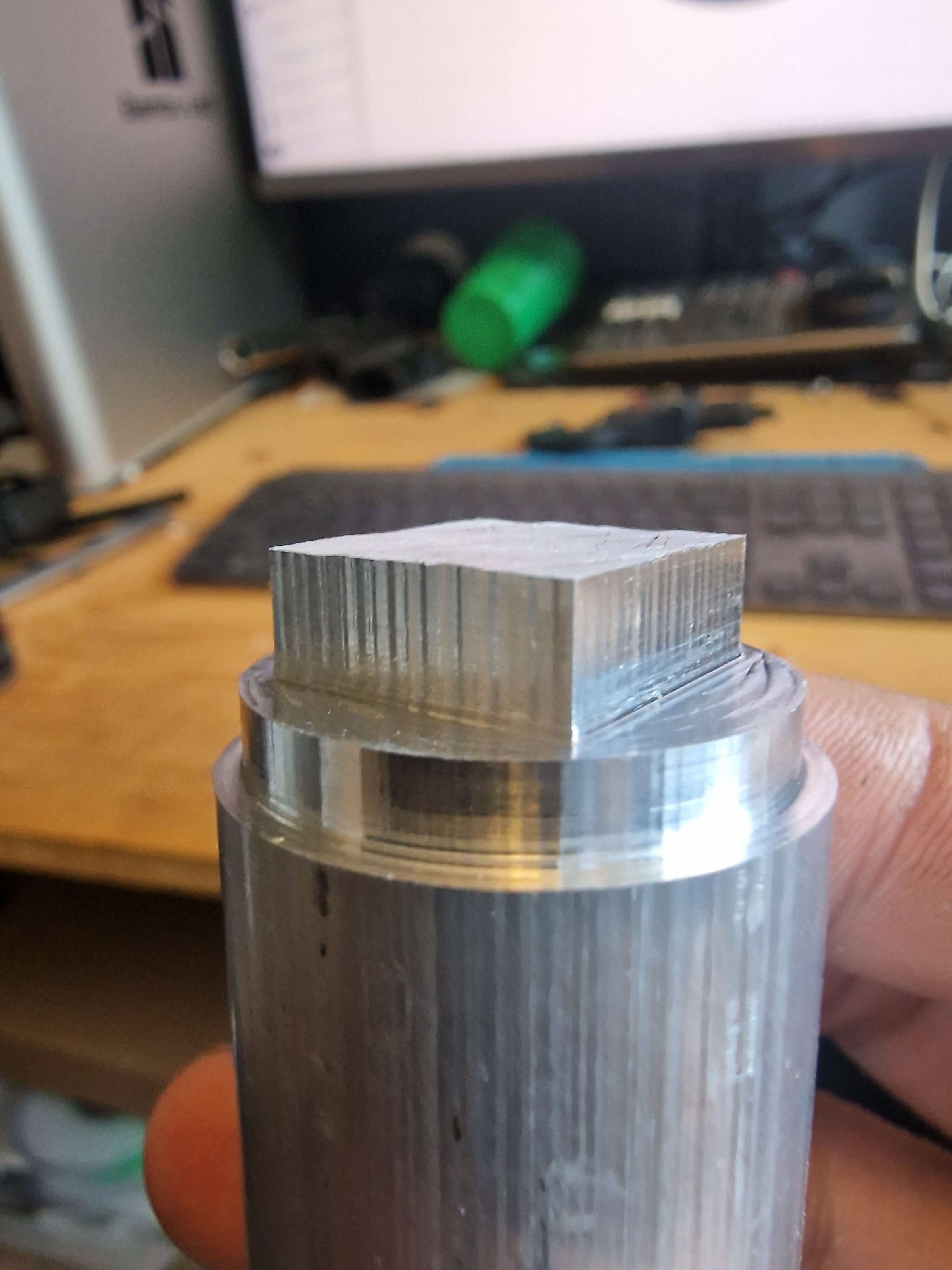

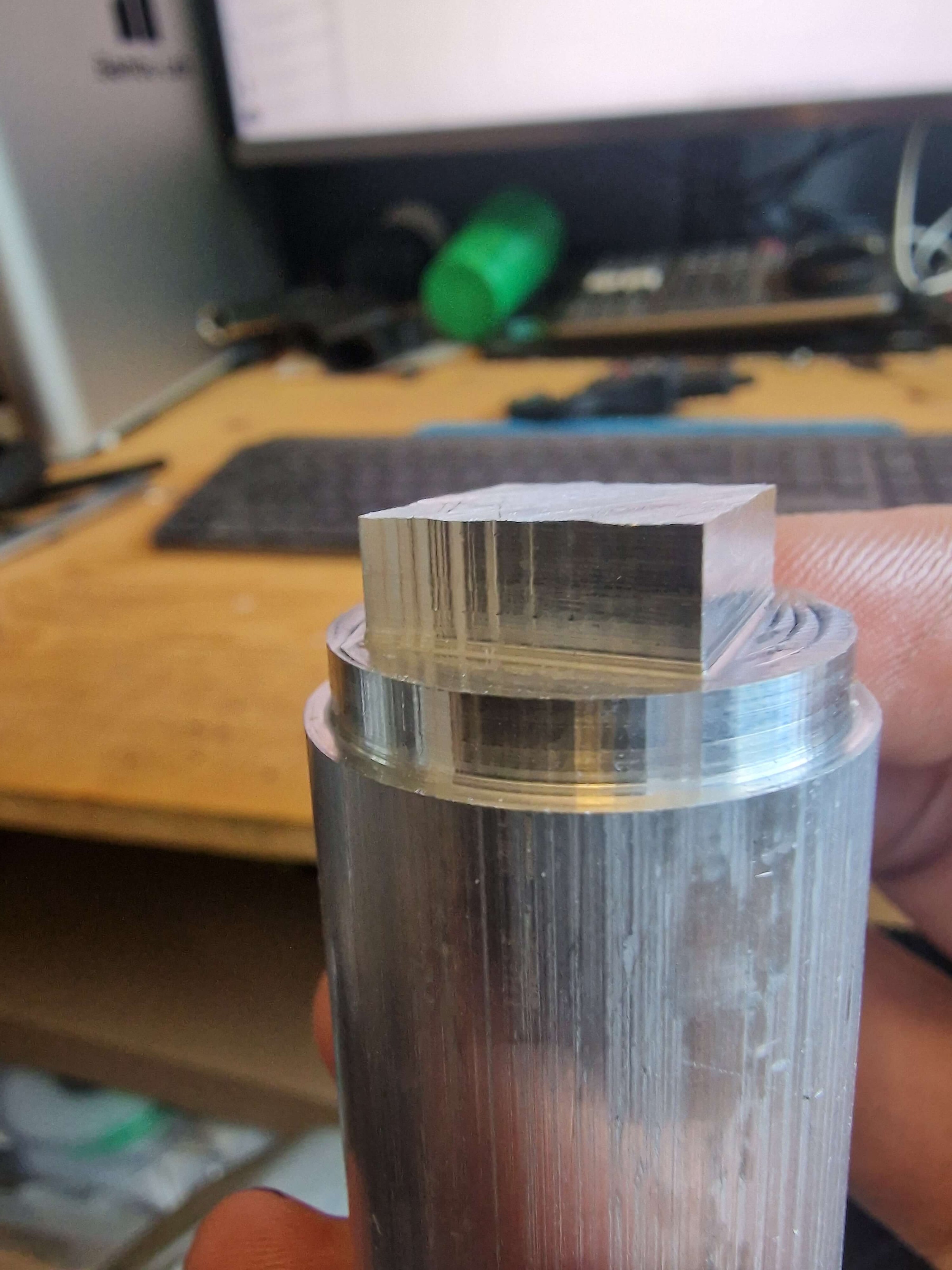

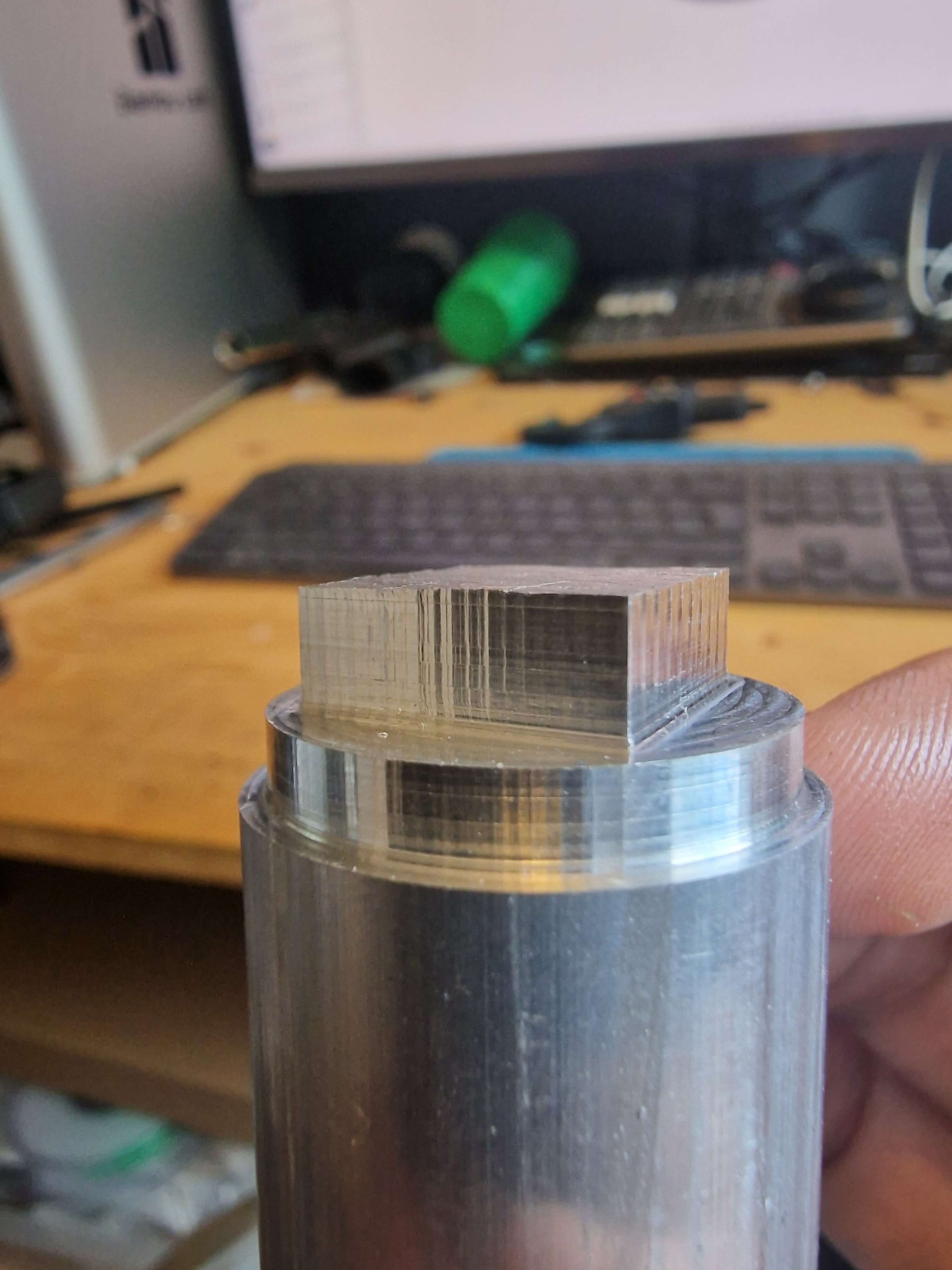

The problem is the even faceting im getting, this is only on round or any move that needs the x and y axis working together. Straight lines in x and y are a nice and smooth surface finish. I have attached a few pics for reference.

the cutting strategy was adapive clearing with 0.5mm stock to leave cleaned up with a profile toolpath

The square was oriented with the points facing north, south, east and west, forcing them to be cut using both servo motors.

I'm using AC servo motors with 10.000 steps per rev. So 1 micron per pulse.

I'm running a 2 ms servo thread, probe basic on linuxcnc 2.9

for this cut I used 0.001 tolerance and tried smoothing on and off with no difference. I also used G64 p0.01 makes no difference

if you look at the images you can see the faceting lines, they all measure around 1.5mm between each line.

any thoughts?

Im pulling my hair out trying to debug a poor surface problem. I have a LinuxCNC retrofit Haas mini mill. Dimensional accuracy is within 5 microns, perfect. Backlash is around 3 microns.

The problem is the even faceting im getting, this is only on round or any move that needs the x and y axis working together. Straight lines in x and y are a nice and smooth surface finish. I have attached a few pics for reference.

the cutting strategy was adapive clearing with 0.5mm stock to leave cleaned up with a profile toolpath

The square was oriented with the points facing north, south, east and west, forcing them to be cut using both servo motors.

I'm using AC servo motors with 10.000 steps per rev. So 1 micron per pulse.

I'm running a 2 ms servo thread, probe basic on linuxcnc 2.9

for this cut I used 0.001 tolerance and tried smoothing on and off with no difference. I also used G64 p0.01 makes no difference

if you look at the images you can see the faceting lines, they all measure around 1.5mm between each line.

any thoughts?

Attachments:

Please Log in or Create an account to join the conversation.

- djdelorie

- Away

- Senior Member

-

Less

More

- Posts: 45

- Thank you received: 10

04 Jul 2025 22:13 #331274

by djdelorie

Replied by djdelorie on topic poor surface quality

I had similar problems with my servo system, and solved most of it by tuning the servos better. A loose servo control loop will look precise and accurate, until you put it under load. Can you rotate the servos by hand, at all, when they should be "holding"? If so, retune them.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21362

- Thank you received: 7287

04 Jul 2025 22:43 #331276

by tommylight

Replied by tommylight on topic poor surface quality

Also, are both servo drives powered from the same power supply?

Please Log in or Create an account to join the conversation.

- Sternfox

- Offline

- Senior Member

-

Less

More

- Posts: 41

- Thank you received: 7

04 Jul 2025 22:47 #331278

by Sternfox

Replied by Sternfox on topic poor surface quality

I will take the covers off and give this a try. Thanks man.

Please Log in or Create an account to join the conversation.

- Sternfox

- Offline

- Senior Member

-

Less

More

- Posts: 41

- Thank you received: 7

04 Jul 2025 22:49 #331280

by Sternfox

Replied by Sternfox on topic poor surface quality

Hi tommy. They are ac servos all connected to the same 240v supply. Would the tuning be done via lunuxcnc or on the servo amp? They are step and direction drives. Thanks

Please Log in or Create an account to join the conversation.

- tivoi

-

- Offline

- Senior Member

-

Less

More

- Posts: 67

- Thank you received: 20

05 Jul 2025 07:12 #331300

by tivoi

Replied by tivoi on topic poor surface quality

Which type of servo drive do you use?

Please Log in or Create an account to join the conversation.

- Sternfox

- Offline

- Senior Member

-

Less

More

- Posts: 41

- Thank you received: 7

05 Jul 2025 22:46 #331350

by Sternfox

Replied by Sternfox on topic poor surface quality

They are lichauan a5 drives

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21362

- Thank you received: 7287

05 Jul 2025 23:17 #331354

by tommylight

Replied by tommylight on topic poor surface quality

1. measure the voltage powering the drives at standstill, when 1 axis is moving and when both axis are moving.

2. while motors are enabled and not turning, use pliers and try to move the motor, how much does it roughly move?

2. while motors are enabled and not turning, use pliers and try to move the motor, how much does it roughly move?

Please Log in or Create an account to join the conversation.

- Sternfox

- Offline

- Senior Member

-

Less

More

- Posts: 41

- Thank you received: 7

09 Jul 2025 20:46 #331596

by Sternfox

Replied by Sternfox on topic poor surface quality

Hi tommy,

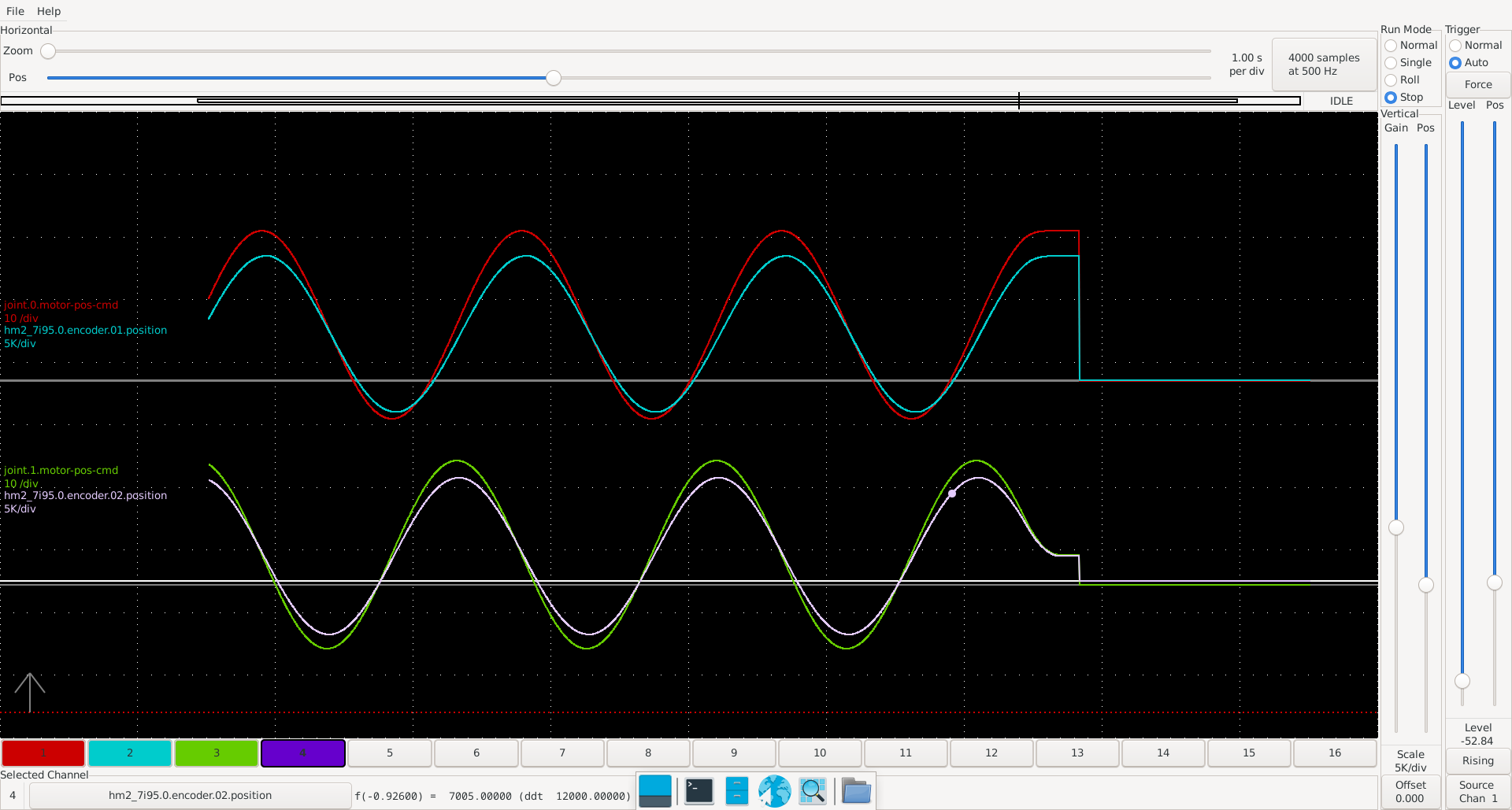

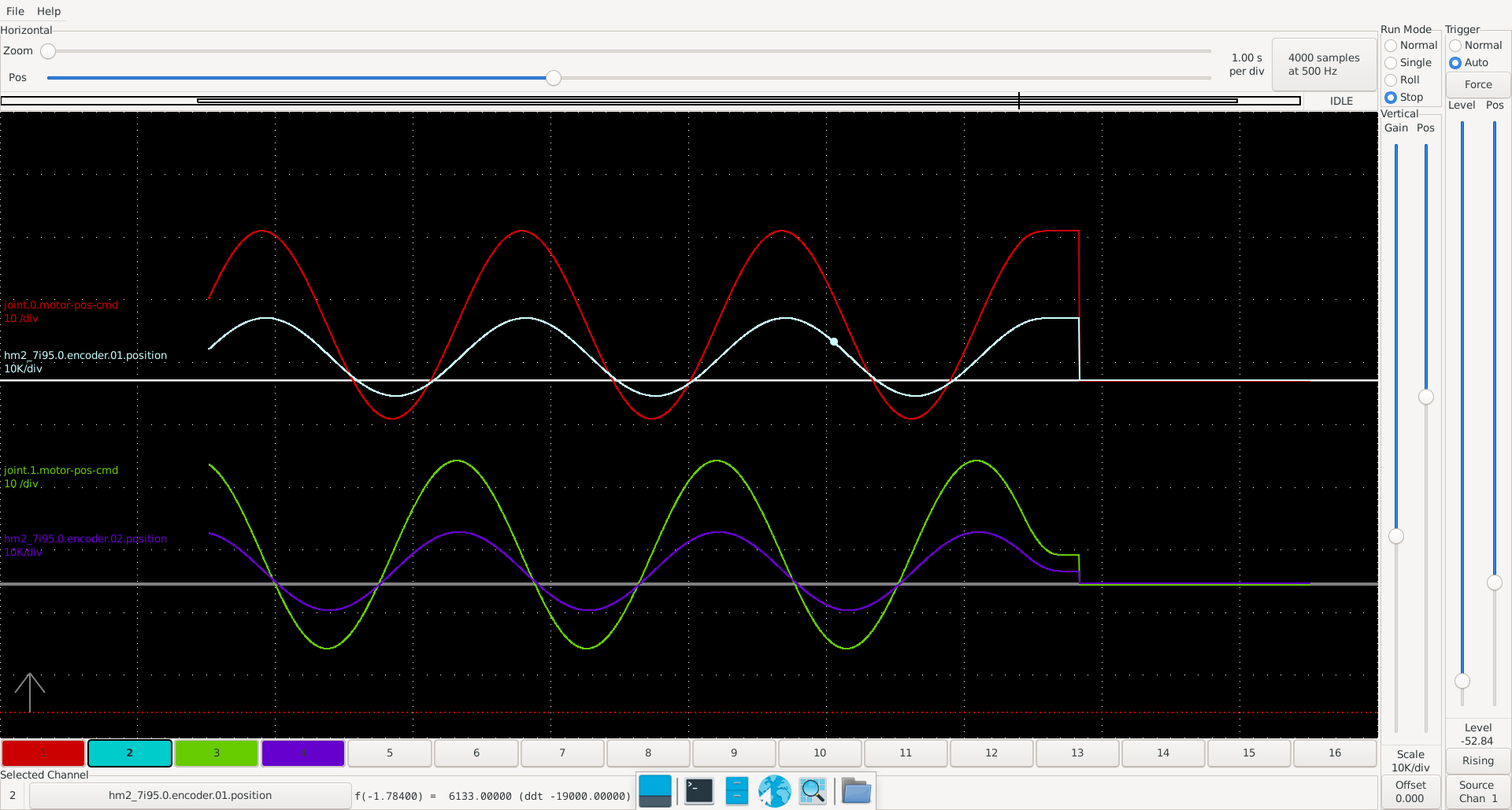

The voltage was the same at both drivers. I have dug a bit deeper and used Halscope and probed

Joint.0.motor-pos-cmd against hm2_7i95.0.encoder.01.position

For both X and Y, I cut a few circles using arcs, and this is my result. Looks like the motor isn't keeping up with the encoder?

I wasnt sure what /k to use, so I have attached two screenshots, one all even /k and some scaled to fita better curve. This is all new to me so apologies in advance.

I'm using Step/Dir Servos, I have just temporarily fed the endcoder back to LinuxCNC for testing.

Im using 1kw ac servos by Litchaun 4NM the machine is a Haas mini mill. any thoughts?

The voltage was the same at both drivers. I have dug a bit deeper and used Halscope and probed

Joint.0.motor-pos-cmd against hm2_7i95.0.encoder.01.position

For both X and Y, I cut a few circles using arcs, and this is my result. Looks like the motor isn't keeping up with the encoder?

I wasnt sure what /k to use, so I have attached two screenshots, one all even /k and some scaled to fita better curve. This is all new to me so apologies in advance.

I'm using Step/Dir Servos, I have just temporarily fed the endcoder back to LinuxCNC for testing.

Im using 1kw ac servos by Litchaun 4NM the machine is a Haas mini mill. any thoughts?

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17729

- Thank you received: 5186

09 Jul 2025 22:00 #331598

by PCW

Replied by PCW on topic poor surface quality

As had been suggested before, it looks like the drives themselves need tuning.

Please Log in or Create an account to join the conversation.

Time to create page: 0.530 seconds