Some 3D printing advice to start this section

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21332

- Thank you received: 7280

25 Jul 2021 23:01 - 27 Jul 2021 11:52 #215911

by tommylight

Some 3D printing advice to start this section was created by tommylight

When using 3D printers, no matter what is happening, remember this:

Do Not Panic !!!

As with everything, the internet is full of information about 3D printing, from very good to plain wrong so much so that leveling a small table has become the most beaten subject.

-Leveling the bed is as simple using the "paper" method or the 0.2mm tool that comes with new printers,

-Leveling should be done once, only if removing something stuck or moving the printer to another spot should leveling be done again,

-On machines with dual Z motors/screws, level the gantry, not the table, using just one provided tool is no good, it is much better having two of whatever that can fit under the gantry and is of the same exact height,

-After the initial leveling, start to print something and use the menu to find "baby stepping the Z", this has several names but they all do the same thing - allow moving Z while printing in very small steps, so while the machine is still heating raise whatever value is there at least 0.2 to 0.4mm, wait for printing to start and check how high is the nozzle then lower it slowly till you get a bit squished line, not totally squished,

-After the above printing is done, check how good the part was stuck to the bed after it cools a bit, to stick and hard to remove=raise the nozzle by 0.03 to 0.05mm, if it did not stick well enough=lower the nozzle by 0.03 to 0.05mm,

-Never level or move anything regarding the bed, till you physically move the printer or have to remove something with large surface from the bed and think the bed might have moved,

-Do not ever try to fix something after changing the filament and the prints do not work as before, even PLA from the same company with different colors will have different properties, by now went over 4 types of Creality PLA not including the ones included with printers, Gembird makes good quality PLA, PETG and PLA+, PLA+ from Gembird with gold color is not the same as Blue one = gold needs higher nozzle temp, layers are easier to detach, warps less than blue.

-Bed temperatures for PLA and PLA+ never over 50C, forget internet 60C malaki, that always ends up with "elephant foot" as that is the temperature that PLA start softening. CURA slicer has "initial layer bed temp" and the rest of the print temp so if you get bad sticking, set the initial layer to 60C and the normal temp to 50C, if stuff sticks to good set it to 40 for everything.

-Clean the bed with soapy water, not IPA (alcohol), use a USED towel (new ones shed a lot)

-

To late, need sleep, will be adding more for sure.

Do Not Panic !!!

As with everything, the internet is full of information about 3D printing, from very good to plain wrong so much so that leveling a small table has become the most beaten subject.

-Leveling the bed is as simple using the "paper" method or the 0.2mm tool that comes with new printers,

-Leveling should be done once, only if removing something stuck or moving the printer to another spot should leveling be done again,

-On machines with dual Z motors/screws, level the gantry, not the table, using just one provided tool is no good, it is much better having two of whatever that can fit under the gantry and is of the same exact height,

-After the initial leveling, start to print something and use the menu to find "baby stepping the Z", this has several names but they all do the same thing - allow moving Z while printing in very small steps, so while the machine is still heating raise whatever value is there at least 0.2 to 0.4mm, wait for printing to start and check how high is the nozzle then lower it slowly till you get a bit squished line, not totally squished,

-After the above printing is done, check how good the part was stuck to the bed after it cools a bit, to stick and hard to remove=raise the nozzle by 0.03 to 0.05mm, if it did not stick well enough=lower the nozzle by 0.03 to 0.05mm,

-Never level or move anything regarding the bed, till you physically move the printer or have to remove something with large surface from the bed and think the bed might have moved,

-Do not ever try to fix something after changing the filament and the prints do not work as before, even PLA from the same company with different colors will have different properties, by now went over 4 types of Creality PLA not including the ones included with printers, Gembird makes good quality PLA, PETG and PLA+, PLA+ from Gembird with gold color is not the same as Blue one = gold needs higher nozzle temp, layers are easier to detach, warps less than blue.

-Bed temperatures for PLA and PLA+ never over 50C, forget internet 60C malaki, that always ends up with "elephant foot" as that is the temperature that PLA start softening. CURA slicer has "initial layer bed temp" and the rest of the print temp so if you get bad sticking, set the initial layer to 60C and the normal temp to 50C, if stuff sticks to good set it to 40 for everything.

-Clean the bed with soapy water, not IPA (alcohol), use a USED towel (new ones shed a lot)

-

To late, need sleep, will be adding more for sure.

Last edit: 27 Jul 2021 11:52 by tommylight. Reason: more info

The following user(s) said Thank You: Bari, anfänger, shpatb, my1987toyota

Please Log in or Create an account to join the conversation.

- shpatb

-

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 62

28 Jul 2021 00:21 #216085

by shpatb

Replied by shpatb on topic Some 3D printing advice to start this section

my filament would leave rough edges .Raised the temp of bed from 50 to 60 and printing filament from 200 to 210 degrees, works marvelous now.

My printing settings : (PLA )

printing temp :210deg

speed :50 to 55 mm/s

bed :60deg

bed initial :60.deg

other settings depends on the part Im making .

My printing settings : (PLA )

printing temp :210deg

speed :50 to 55 mm/s

bed :60deg

bed initial :60.deg

other settings depends on the part Im making .

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21332

- Thank you received: 7280

28 Jul 2021 00:43 #216088

by tommylight

Replied by tommylight on topic Some 3D printing advice to start this section

Some pictures would help, but since i know you have Creality CR-10S PRO V2, it comes with an aluminium bed so i would not use anything above 40C for the bed with big stuff and 45 for small stuff, big stuff is very hard to get off of it, it sticks to damn good to it!

As for hotend temps, i use 210 to 215 for standard speeds and 220-235 for 0.8mm nozzle and fast prints with thick lines when a lot of filament has to get melted.

As a side note, today i had my first nozzle plug on the Ender 5 Plus, took 2 hours to figure out and tear the hotend apart, get the PTFE tube out after removing all the fans and being careful not to mess up the BL Touch, heating and cooling several times, etc etc. Damn that PTFE tube is slippery!

As for hotend temps, i use 210 to 215 for standard speeds and 220-235 for 0.8mm nozzle and fast prints with thick lines when a lot of filament has to get melted.

As a side note, today i had my first nozzle plug on the Ender 5 Plus, took 2 hours to figure out and tear the hotend apart, get the PTFE tube out after removing all the fans and being careful not to mess up the BL Touch, heating and cooling several times, etc etc. Damn that PTFE tube is slippery!

The following user(s) said Thank You: shpatb

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

28 Jul 2021 18:32 - 28 Jul 2021 18:39 #216138

by robertspark

Replied by robertspark on topic Some 3D printing advice to start this section

I stumbled across this that may offer a neat linuxcnc 3d printer option via the pi

using the small 3d printer stepper drives. (no I'm not advertising and have no affiliation to the product)

www.tindie.com/products/niujl123/64bit-3...04&mc_eid=cec848815a

pinout here

github.com/markniu/PandaPi/wiki/Pins-Map

I was looking at it as a Bob for the pi to run linuxcnc not Marin and precompiled images etc that seem to have poor comments on.

using the small 3d printer stepper drives. (no I'm not advertising and have no affiliation to the product)

www.tindie.com/products/niujl123/64bit-3...04&mc_eid=cec848815a

pinout here

github.com/markniu/PandaPi/wiki/Pins-Map

I was looking at it as a Bob for the pi to run linuxcnc not Marin and precompiled images etc that seem to have poor comments on.

Last edit: 28 Jul 2021 18:39 by robertspark.

Please Log in or Create an account to join the conversation.

- shpatb

-

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 62

28 Jul 2021 18:38 #216139

by shpatb

Replied by shpatb on topic Some 3D printing advice to start this section

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Doogie

- Offline

- Premium Member

-

Less

More

- Posts: 108

- Thank you received: 18

30 Jul 2021 19:25 #216380

by Doogie

Replied by Doogie on topic Some 3D printing advice to start this section

I've found it takes some tuning of hotend temps for each filament color and especially differing vendors. Material densities effect heat transfer and viscosity.

As for LinuxCNC doing 3D printing, my Creality Ender 3 is running LinuxCNC/Remora(remora-docs.readthedocs.io/en/latest/) with an SKR v1.4 turbo board and TMC2208( TMC2209 is better ) drivers. Works very well.

As for LinuxCNC doing 3D printing, my Creality Ender 3 is running LinuxCNC/Remora(remora-docs.readthedocs.io/en/latest/) with an SKR v1.4 turbo board and TMC2208( TMC2209 is better ) drivers. Works very well.

The following user(s) said Thank You: tommylight, my1987toyota

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21332

- Thank you received: 7280

03 Sep 2021 12:43 #219513

by tommylight

Replied by tommylight on topic Some 3D printing advice to start this section

VORON Legacy @300mm/s , ACC @15000mm/s/s !!!

www.instagram.com/p/CTW_cgjDm8m/?utm_medium=share_sheet

Not yet finished, waiting ....

www.instagram.com/p/CTW_cgjDm8m/?utm_medium=share_sheet

Not yet finished, waiting ....

The following user(s) said Thank You: shpatb, my1987toyota

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21332

- Thank you received: 7280

03 Sep 2021 12:45 #219514

by tommylight

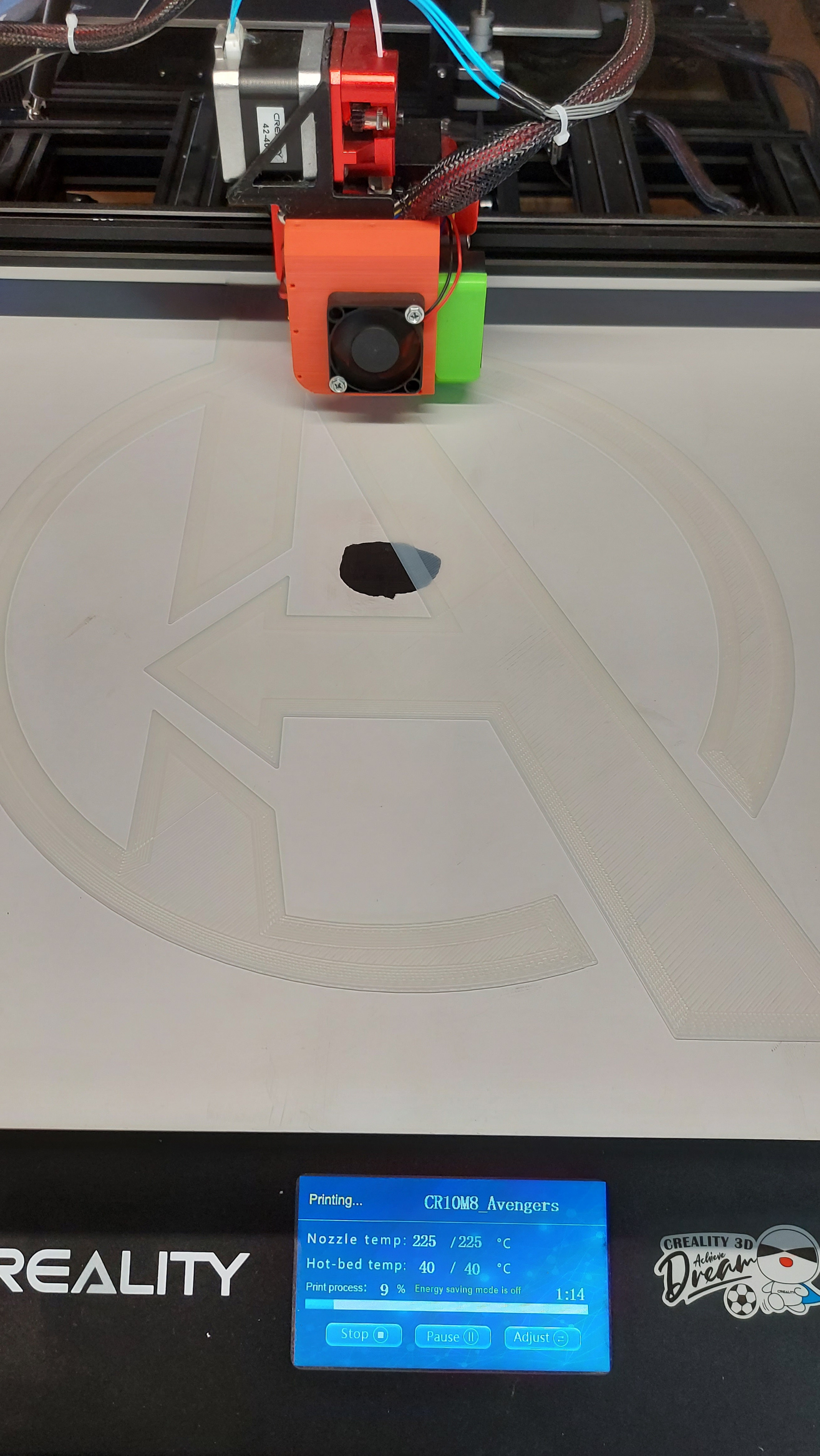

That is on Creality CR-10 MAX latest version modified to direct extruder with 0.8mm nozzle and 1mm width, 0.32mm layer height.

Never mind the bed it got ruined by printing everything at the centre, it is cheap magnetic stuff at 10 Euro/meter and 60m width, enough for the Max and when changing it only the top needs to be replaced making it 5 Euro! PLA and PLA+ stick to it even without heating except very small parts.

Replied by tommylight on topic Some 3D printing advice to start this section

That is on Creality CR-10 MAX latest version modified to direct extruder with 0.8mm nozzle and 1mm width, 0.32mm layer height.

Never mind the bed it got ruined by printing everything at the centre, it is cheap magnetic stuff at 10 Euro/meter and 60m width, enough for the Max and when changing it only the top needs to be replaced making it 5 Euro! PLA and PLA+ stick to it even without heating except very small parts.

Attachments:

The following user(s) said Thank You: shpatb, my1987toyota

Please Log in or Create an account to join the conversation.

- scotta

-

- Offline

- Platinum Member

-

Less

More

- Posts: 956

- Thank you received: 486

03 Sep 2021 22:21 #219557

by scotta

Replied by scotta on topic Some 3D printing advice to start this section

Hi, any chance of sharing your config? I'm tempted to start playing with some speed tests. Especially when I get the STM32 version of Remora working.VORON Legacy @300mm/s , ACC @15000mm/s/s !!!

www.instagram.com/p/CTW_cgjDm8m/?utm_medium=share_sheet

Not yet finished, waiting ....

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21332

- Thank you received: 7280

03 Sep 2021 22:47 #219558

by tommylight

Replied by tommylight on topic Some 3D printing advice to start this section

Not at all, if i remember to do it tomorrow, i gladly will.

The config comes with LinuxCNC, the same one you are using after rechecking who is asking....

It did require a lot of editing to make it work as for some reason the .inc file was not read at all on a PC with RTAI kernel, using parallel port for now so i had to lower micro stepping to 4, the poor thing started undressing after several runs at that speed so i also have to chase screws on the table!

While we are at it, do you happen to have the motor mounts and idlers for 12mm rod? I did print some i found on the net for Bosch Rexroth 45x45 alu profile, came out nice, use 12mm rod, bot the motor is not where it should be for the Hypercube.

Already have the hotend/X printed and mounted.

BTW, i can not buy 20x20 alu extrusions here nor order them due to some ... issues!

The config comes with LinuxCNC, the same one you are using after rechecking who is asking....

It did require a lot of editing to make it work as for some reason the .inc file was not read at all on a PC with RTAI kernel, using parallel port for now so i had to lower micro stepping to 4, the poor thing started undressing after several runs at that speed so i also have to chase screws on the table!

While we are at it, do you happen to have the motor mounts and idlers for 12mm rod? I did print some i found on the net for Bosch Rexroth 45x45 alu profile, came out nice, use 12mm rod, bot the motor is not where it should be for the Hypercube.

Already have the hotend/X printed and mounted.

BTW, i can not buy 20x20 alu extrusions here nor order them due to some ... issues!

Please Log in or Create an account to join the conversation.

Time to create page: 0.125 seconds