Some 3D printing advice to start this section

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 20963

- Thank you received: 7144

04 Sep 2021 20:40 #219626

by tommylight

Replied by tommylight on topic Some 3D printing advice to start this section

As requested, config attached as is, works with built in parallel port:Hi, any chance of sharing your config?

Please Log in or Create an account to join the conversation.

- scotta

-

- Offline

- Platinum Member

-

Less

More

- Posts: 954

- Thank you received: 486

04 Sep 2021 22:59 #219632

by scotta

I was interested in you MAX_ACCELERATION and STEPGEN_MAXACCEL values. I've always struggled with following error.

I was interested in you MAX_ACCELERATION and STEPGEN_MAXACCEL values. I've always struggled with following error.

BR

Scott

Replied by scotta on topic Some 3D printing advice to start this section

Hi Tom, thanks for sharing. I didn't realise that my config had made it into LinuxCNC.

Hi, any chance of sharing your config?

As requested, config attached as is, works with built in parallel port:

BR

Scott

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 20963

- Thank you received: 7144

04 Sep 2021 23:07 #219633

by tommylight

STEPGEN_MAXACCEL = MAX_ACCELERATION + 25%

That always works.

I do get following errors but only when nearing the base period timing limit.

Replied by tommylight on topic Some 3D printing advice to start this section

Hi Tom, thanks for sharing. I didn't realise that my config had made it into LinuxCNC.

I was interested in you MAX_ACCELERATION and STEPGEN_MAXACCEL values. I've always struggled with following error.

STEPGEN_MAXACCEL = MAX_ACCELERATION + 25%

That always works.

I do get following errors but only when nearing the base period timing limit.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 20963

- Thank you received: 7144

17 Jul 2022 12:32 #247560

by tommylight

Replied by tommylight on topic Some 3D printing advice to start this section

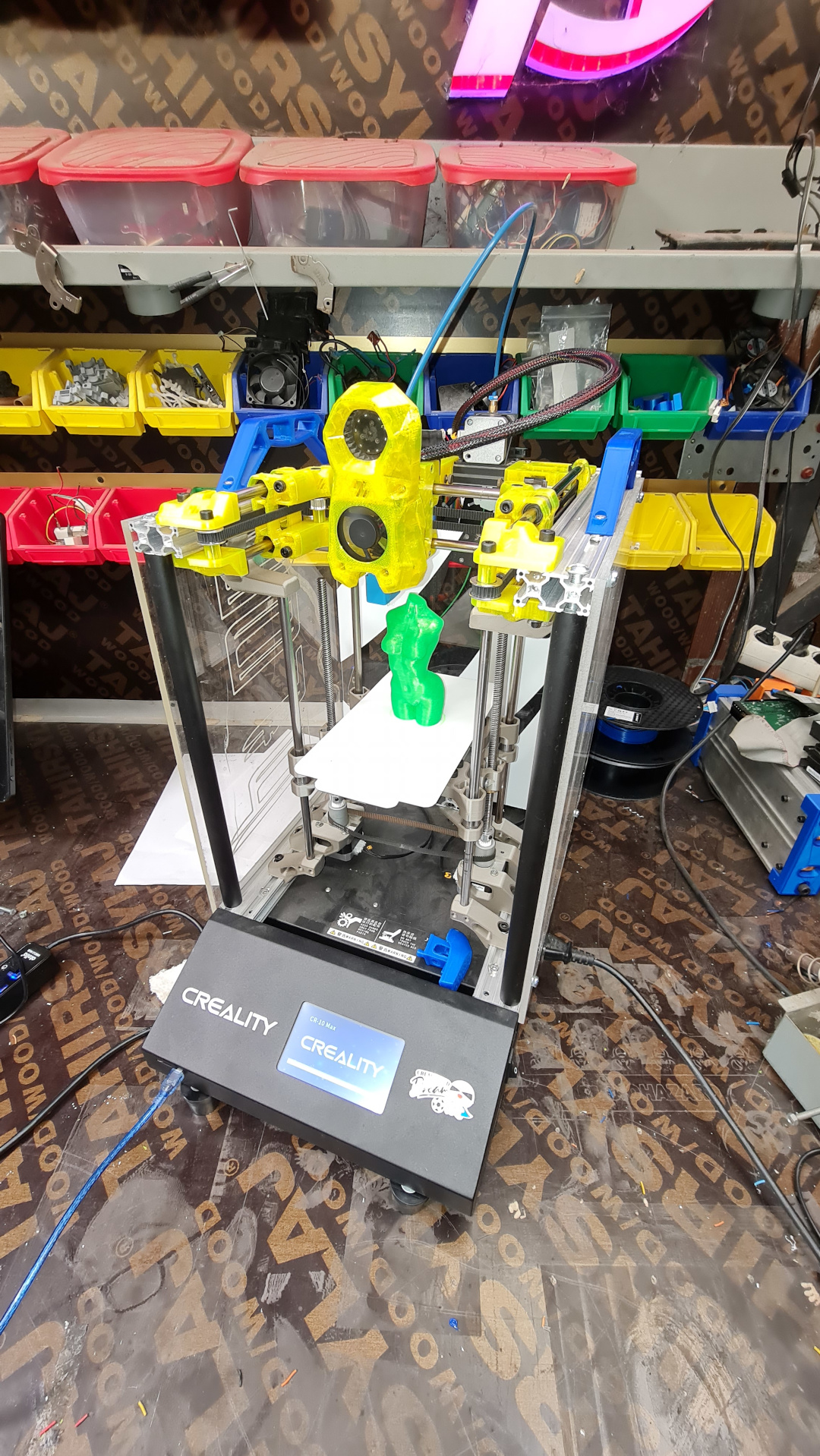

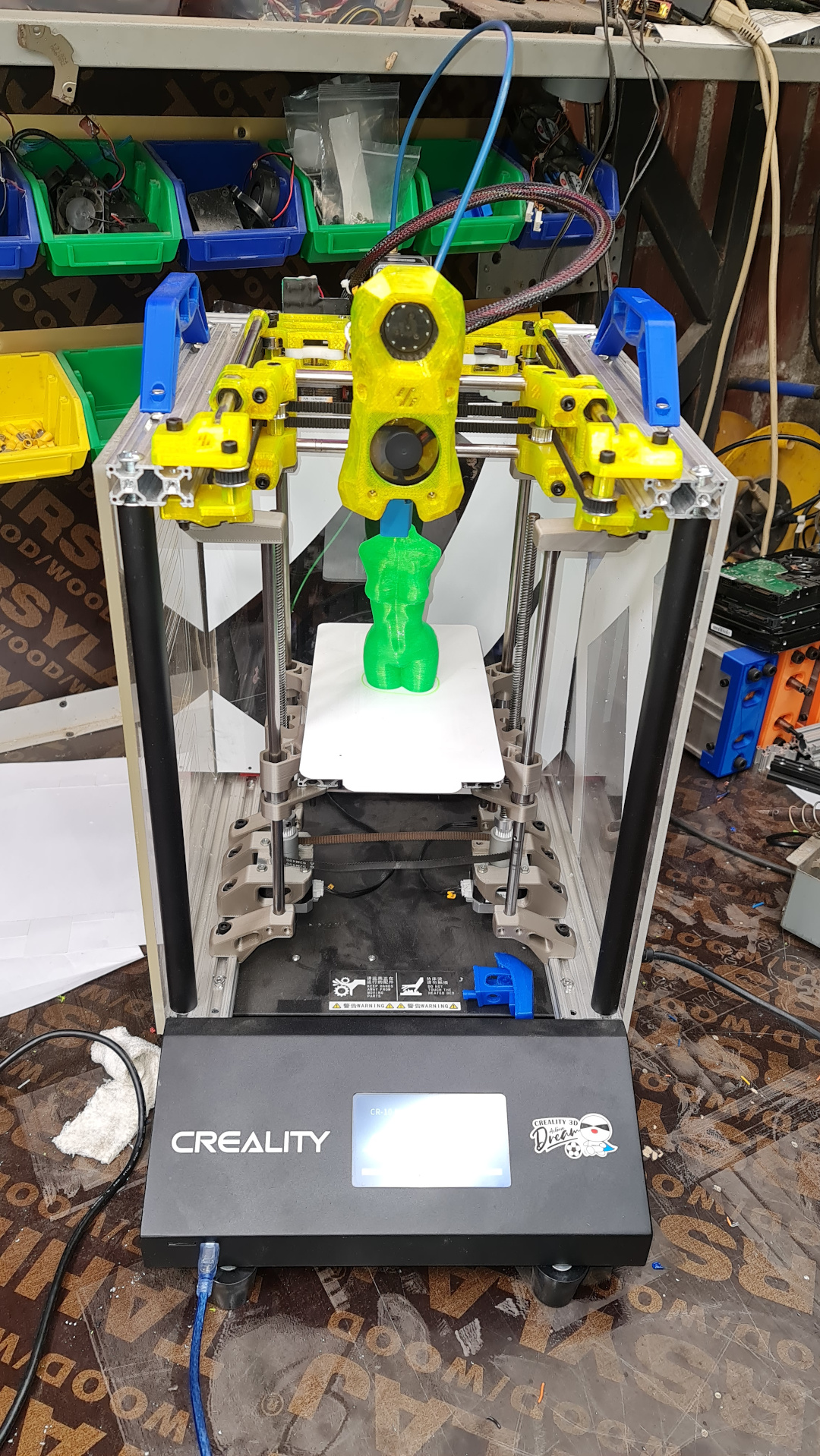

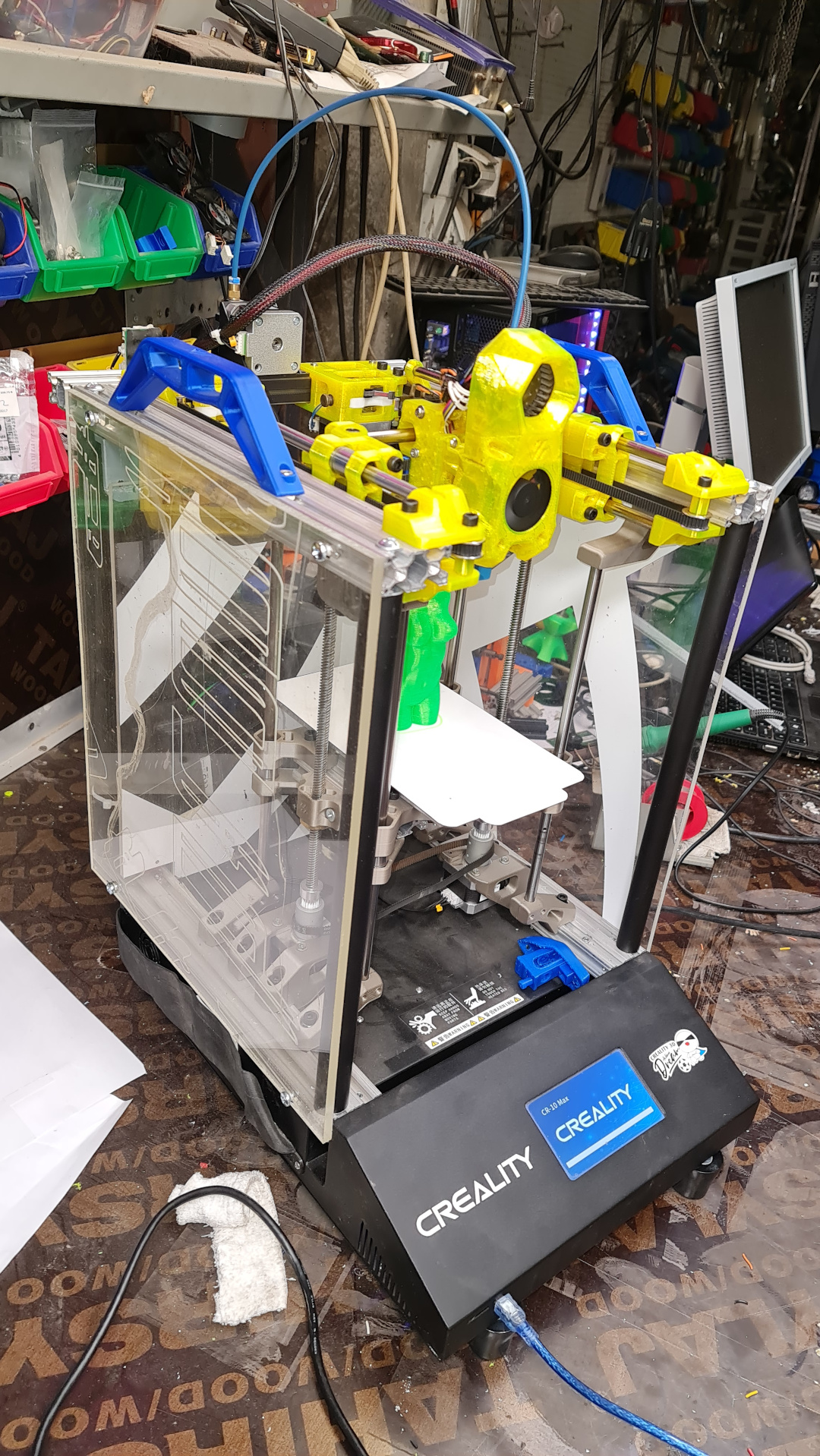

Here is another of my monstrosities, a Voron Legacy mounted on the Creality CR-10 MAX control box.

Original Creality board with silent drives, BL-Touch, AfterBurner with a Volcano hot end, double Z, etc.

Also attaching the config for it, someone on youtube requested it, remove the .txt after download.

Original Creality board with silent drives, BL-Touch, AfterBurner with a Volcano hot end, double Z, etc.

Also attaching the config for it, someone on youtube requested it, remove the .txt after download.

The following user(s) said Thank You: my1987toyota, Guardiola

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

13 Dec 2022 16:32 #259329

by machinedude

Replied by machinedude on topic Some 3D printing advice to start this section

i just bought my first one for a Christmas present for myself yesterday  nothing fancy just something cheap to play with. just noticed that the operating system is Linux so not sure what that means at this point

nothing fancy just something cheap to play with. just noticed that the operating system is Linux so not sure what that means at this point

my thoughts came back to things related to plasma in the sense of light and fast being a plus so i avoided the bed slinger set up and kept it simple and avoided the delta type configuration too

my thoughts were telling me the style with the bed feeding up and down might have a better chance of doing faster prints since the X and Y axis are light and doing most of the work? of course i am just taking a guess and could be completely wrong

my thoughts came back to things related to plasma in the sense of light and fast being a plus so i avoided the bed slinger set up and kept it simple and avoided the delta type configuration too

my thoughts were telling me the style with the bed feeding up and down might have a better chance of doing faster prints since the X and Y axis are light and doing most of the work? of course i am just taking a guess and could be completely wrong

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

14 Dec 2022 07:14 #259423

by machinedude

Replied by machinedude on topic Some 3D printing advice to start this section

did some looking and it looks like the printer i ordered is a clone of the Ender-5 S1. ender has this printer on sale for $503 at the moment and i Picked up the Sovol SV05 for $286, Sovol is weird in the sense they use Creality parts on their machines but have their name on the machine?

any ways there are some sort cuts on the Sovol machine but still looks like a good starter machine. print speeds are nowhere near the Ender 5 S1 and the hot end is rated lower plus the interface is not fancy but it is almost half the cost.

what would be a respectable print speed on average for PLA ?

any ways there are some sort cuts on the Sovol machine but still looks like a good starter machine. print speeds are nowhere near the Ender 5 S1 and the hot end is rated lower plus the interface is not fancy but it is almost half the cost.

what would be a respectable print speed on average for PLA ?

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 20963

- Thank you received: 7144

14 Dec 2022 17:13 #259478

by tommylight

Replied by tommylight on topic Some 3D printing advice to start this section

Sovol makes decent ptinters and a good base to improve on, later, after you get a feel for what it can do.

Start with 30 to 50mm/s for PLA.

Slicers do a good job of having usable configurations for almost all 3D printers. Almost, as for Vorons it has to slow everything!

And, do not get distracted by printing speeds, the imaginary 250 to 1000mm/s are far from reality.

They can be achieved, of course, but that implies using specialised hotends, starting from Volcano or CHT and up to Goliath by VEZ 3D, corexy with very lite gantry and extruders, runny/flowy materials, etc, etc.

Anyway you look at it, 150 to 200mm is reachable, anything above is to much fuss and money for low returns and plenty of failed prints.

And, just in case you get convinced by the youtube videos to run Klipper, you do NOT need a RPI of any kind, any old PC will work with it and be much cheaper, and more useable.

Start with 30 to 50mm/s for PLA.

Slicers do a good job of having usable configurations for almost all 3D printers. Almost, as for Vorons it has to slow everything!

And, do not get distracted by printing speeds, the imaginary 250 to 1000mm/s are far from reality.

They can be achieved, of course, but that implies using specialised hotends, starting from Volcano or CHT and up to Goliath by VEZ 3D, corexy with very lite gantry and extruders, runny/flowy materials, etc, etc.

Anyway you look at it, 150 to 200mm is reachable, anything above is to much fuss and money for low returns and plenty of failed prints.

And, just in case you get convinced by the youtube videos to run Klipper, you do NOT need a RPI of any kind, any old PC will work with it and be much cheaper, and more useable.

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

14 Dec 2022 20:43 #259499

by machinedude

Replied by machinedude on topic Some 3D printing advice to start this section

on the Sovol website they suggest 80mm/s for this printer but i would imagine it's different for the different materials you choose to print in too.

i was planning on using fusion 360 for my solid files and Cura for my slicer program at this point Cura seems to be pretty popular. looks pretty straight forward from what i have seen so far.

i was planning on using fusion 360 for my solid files and Cura for my slicer program at this point Cura seems to be pretty popular. looks pretty straight forward from what i have seen so far.

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

17 Dec 2022 16:21 #259736

by machinedude

Replied by machinedude on topic Some 3D printing advice to start this section

It's pretty bad when you don't even have the new 3D printer and you start adding to the list of things you want to upgrade to and just have a better set up for printing in a wider range of materials and avoid preventable issues before they happen.

So I invested in filament dryer since sales seem to be going on now. while i was at it i picked up the bi-metal heat break and a nozzle package with different sizes and materials for some more range in filament choices. cheap upgrade to be able to get more into the higher temp materials. i seen a video were all that was needed to changed was settings in the firmware. so for a few bucks in upgrade parts seemed like a good move and for an added bonus the tip set has some cleaning tools for tips.

So I invested in filament dryer since sales seem to be going on now. while i was at it i picked up the bi-metal heat break and a nozzle package with different sizes and materials for some more range in filament choices. cheap upgrade to be able to get more into the higher temp materials. i seen a video were all that was needed to changed was settings in the firmware. so for a few bucks in upgrade parts seemed like a good move and for an added bonus the tip set has some cleaning tools for tips.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 20963

- Thank you received: 7144

17 Dec 2022 17:33 #259745

by tommylight

Replied by tommylight on topic Some 3D printing advice to start this section

Filament dryer is waste of money, you have a heated bed, set it to 50 or 70 for PETG, put a lid on it.

Heatbreak is a must, PETG likes higher temps than what the internet says, so for slow printing 250, fast 265.

And do not bother with ABS and ASA, everything besides some specialised ones are cr@p.

Use HIPS, much better in every respect and can happily print at 245, with much, much better layer adhesion.

Heatbreak is a must, PETG likes higher temps than what the internet says, so for slow printing 250, fast 265.

And do not bother with ABS and ASA, everything besides some specialised ones are cr@p.

Use HIPS, much better in every respect and can happily print at 245, with much, much better layer adhesion.

The following user(s) said Thank You: machinedude, my1987toyota

Please Log in or Create an account to join the conversation.

Time to create page: 0.185 seconds