Tom's <add number here> plasma build

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21239

- Thank you received: 7250

15 Mar 2017 23:50 #89702

by tommylight

Tom's <add number here> plasma build was created by tommylight

Last 3 days been bussy building the dual Z axis for a new cnc plasma cutter.

The gantry is over 4 meters long taken from a ploter so the max working length is 3.7 meters. Left the rails and cariage as is, the cariage is 32cm wide so more than enough for plasma.

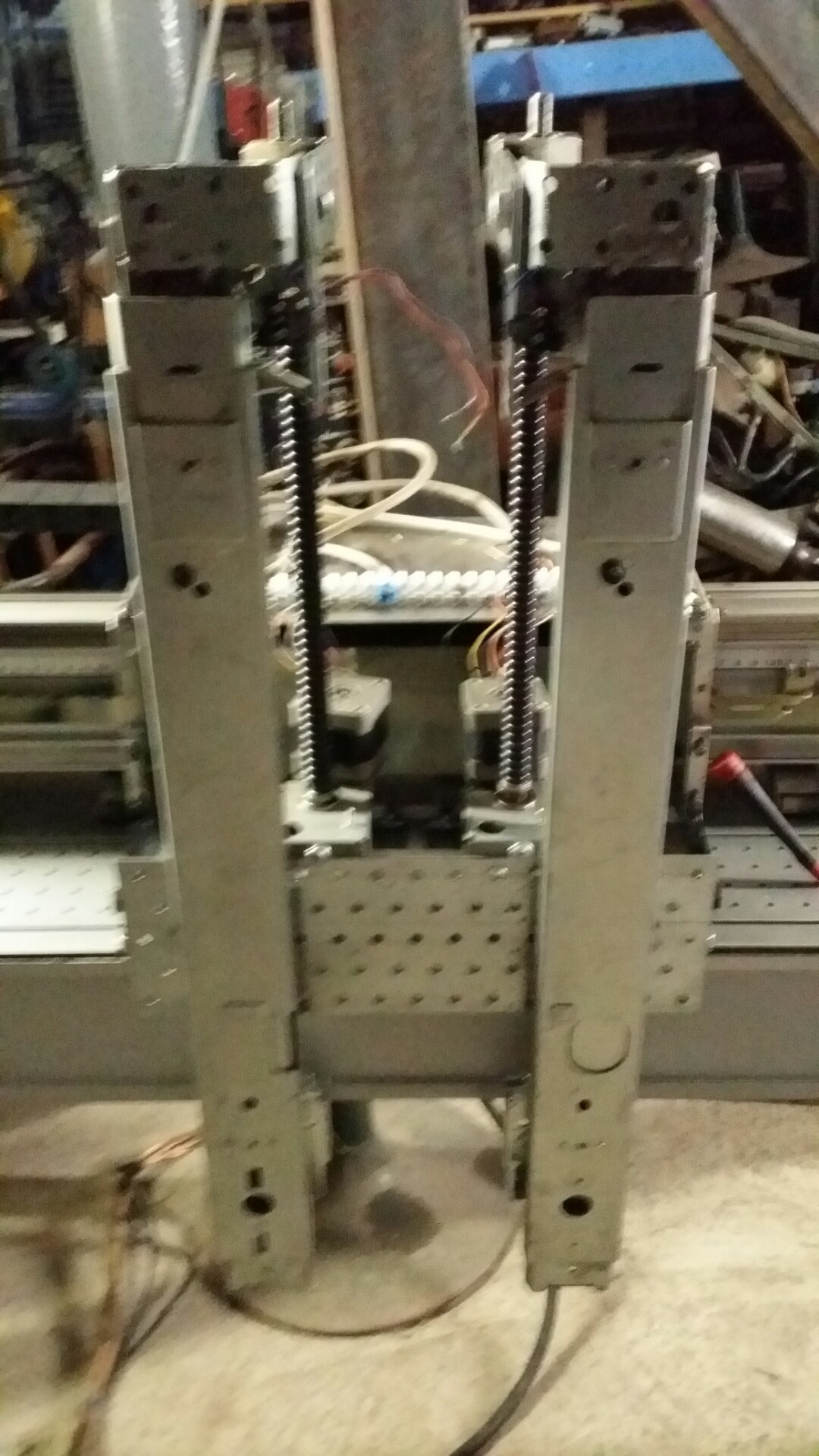

This is how the Z axis looks like now, two double drawer slides from old photocopiers, beefy ones capable of 25 kg each, two 16mm Nook ball screws with 5.08mm pitch (1/5 inch), two nema 17 stepper motors, all bolted to a 45X45 mm Bosch aluminium extrusion and that bolted to the existing cariage.

Side view, just in case

And a view from above, already made wiring look a bit nicer but forgot to take a picture.

There are also two micro switches used for probing and 2 springs to pull one rail down if gravity fails to do that.

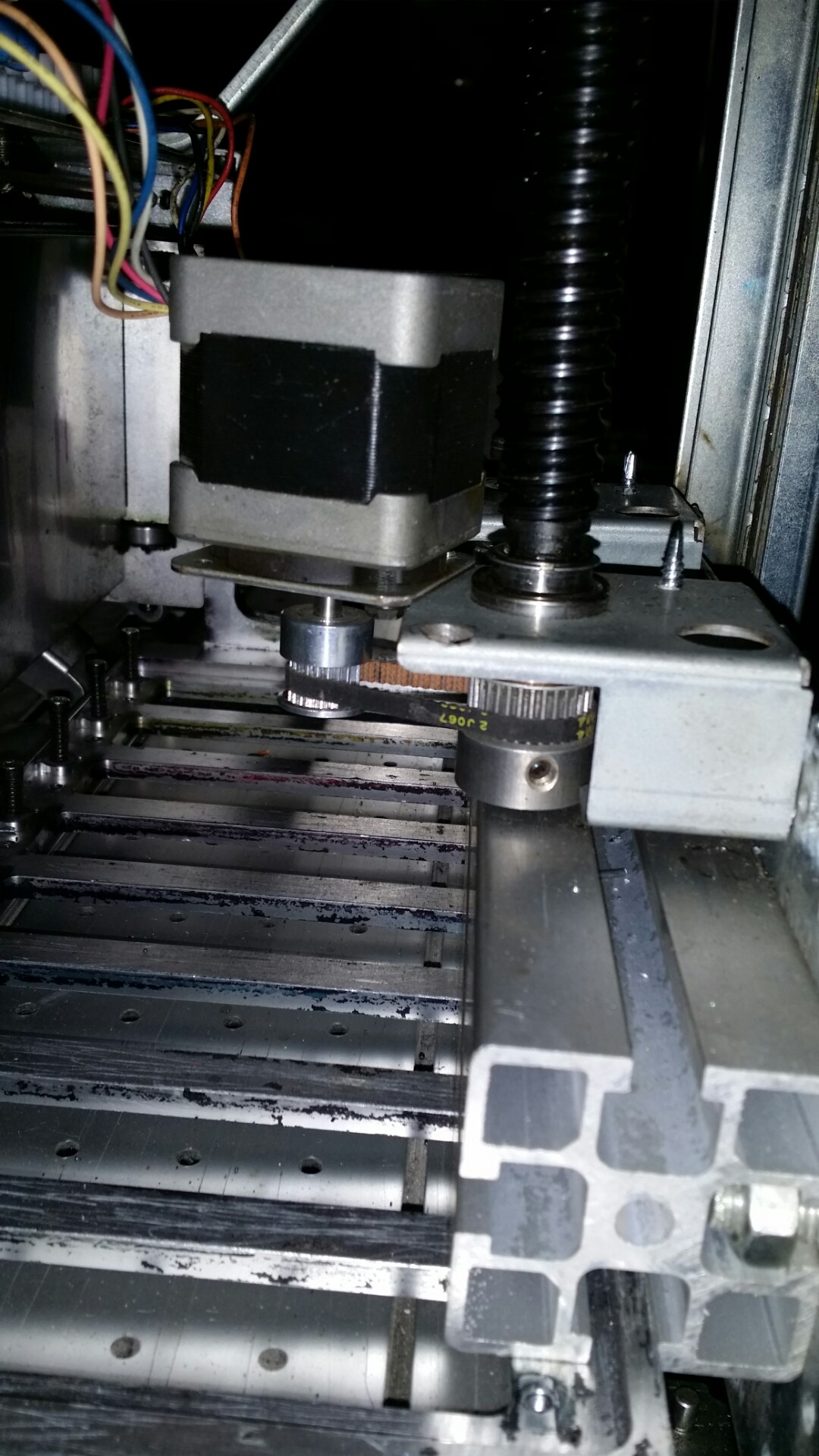

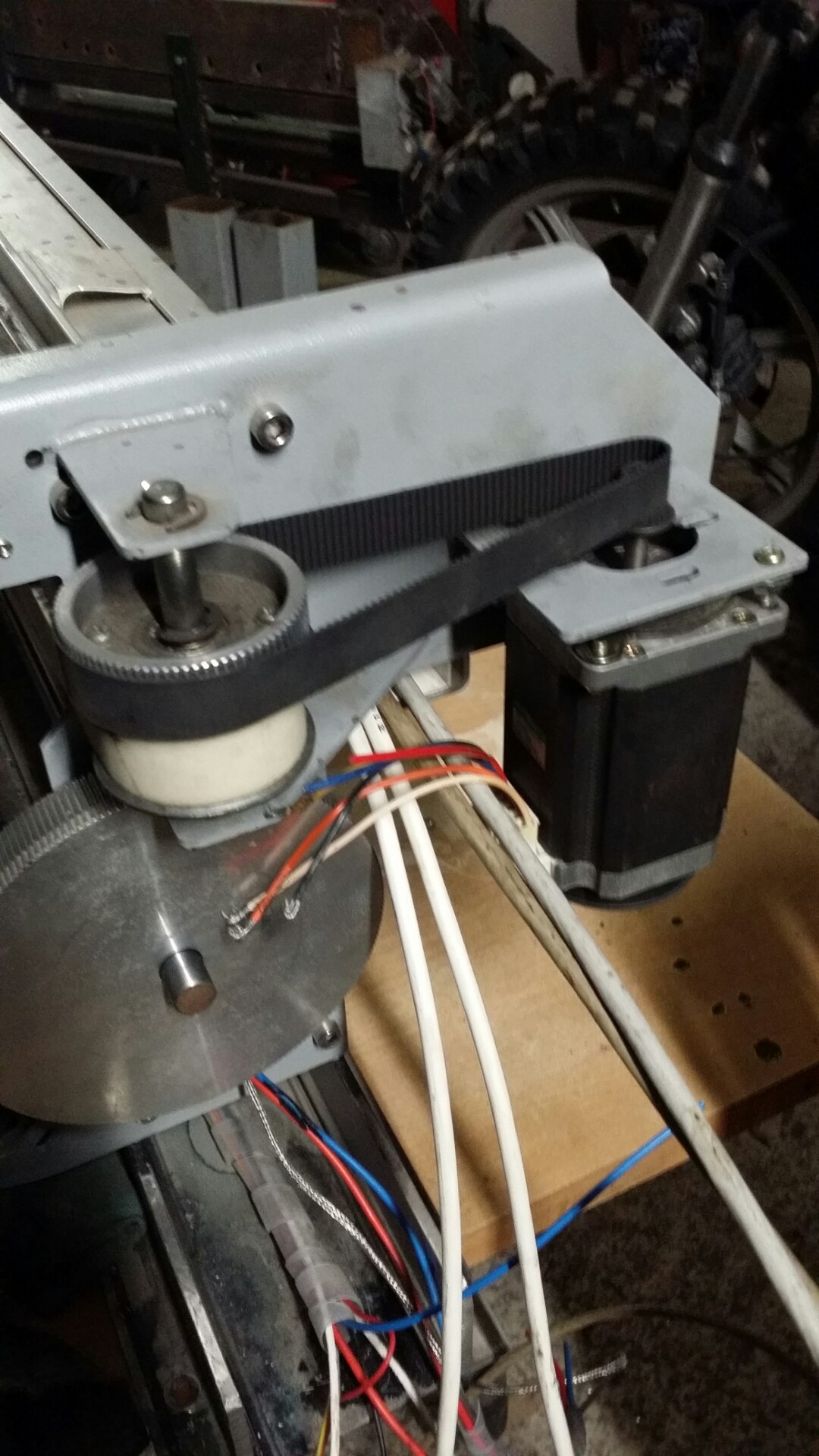

This is the right side of the gantry where the motor for the long move is, i decided to have it move quickly so i put in a nema 24 ( not 23) 5A Sanyo Denki, should be capable of ripping the belt appart easily. Going to use two more of the same for moving the complete gantry on both sides.

This is a side picture of the assembly, taking a frontal picture is not an option as i have 2 of my bikes and 2 bicycles and a lot of mess behind it.

Just in case anyone wonders, one is a 41 year old Yamaha XS500 and the other is Yamaha FZ 750, still bloody quick and i am scared shitless to push it over 100.

More to come so stay tuned....

The gantry is over 4 meters long taken from a ploter so the max working length is 3.7 meters. Left the rails and cariage as is, the cariage is 32cm wide so more than enough for plasma.

This is how the Z axis looks like now, two double drawer slides from old photocopiers, beefy ones capable of 25 kg each, two 16mm Nook ball screws with 5.08mm pitch (1/5 inch), two nema 17 stepper motors, all bolted to a 45X45 mm Bosch aluminium extrusion and that bolted to the existing cariage.

Side view, just in case

And a view from above, already made wiring look a bit nicer but forgot to take a picture.

There are also two micro switches used for probing and 2 springs to pull one rail down if gravity fails to do that.

This is the right side of the gantry where the motor for the long move is, i decided to have it move quickly so i put in a nema 24 ( not 23) 5A Sanyo Denki, should be capable of ripping the belt appart easily. Going to use two more of the same for moving the complete gantry on both sides.

This is a side picture of the assembly, taking a frontal picture is not an option as i have 2 of my bikes and 2 bicycles and a lot of mess behind it.

Just in case anyone wonders, one is a 41 year old Yamaha XS500 and the other is Yamaha FZ 750, still bloody quick and i am scared shitless to push it over 100.

More to come so stay tuned....

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11682

- Thank you received: 3937

16 Mar 2017 00:31 #89706

by rodw

Replied by rodw on topic Tom's <add number here> plasma build

Tommy, Looks great. You are certainly faster at this than I am!

I could not work out the stepper dive on the gantry. Is there a worm drive in there somewhere or is it belt driven?

I've got a few parts from Xerox production photocopiers. I found it interesting to see the transition from Pneumatics in the old Docutechs released in 1992 to the stepper driven designs of the newer models.

I could not work out the stepper dive on the gantry. Is there a worm drive in there somewhere or is it belt driven?

I've got a few parts from Xerox production photocopiers. I found it interesting to see the transition from Pneumatics in the old Docutechs released in 1992 to the stepper driven designs of the newer models.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21239

- Thank you received: 7250

16 Mar 2017 00:51 #89708

by tommylight

Replied by tommylight on topic Tom's <add number here> plasma build

Good morning Rod

It is belt driven, the white thick one under the black to motor, 8 meters of it.

This i am doing slowly, i did a smaler one in 4 days once, the chap was in a hury! Was not a nice experience, in 5 days i slept a total of 7 hours, i also had motor mounts ready, but i had to do the whole gantry and Z axis with floating head and electronics and programig.

Forgot to tighten 1 single screw and was mad at myself for such sloppynes, costed me half an hour to figure out why one side of the gantry moves sometimes more and sometimes less than it should at random while the other side is all good.

Well going to grab some Zzzzzz, more work tomorrow, like decide the size of the actual thing. I can do 110 cm in about 3 days have it all set up, or i can do 6 meters in about 3 weeks, granted i have to assembe it on the yard as i can not fit it inside, already cramped there. 4.2X1.7 meters i can still manage to move and work inside, 4.2X7 meters is a no go, yard, rain, sloped concrete, nope no go.

Just thinking out loud!

It is belt driven, the white thick one under the black to motor, 8 meters of it.

This i am doing slowly, i did a smaler one in 4 days once, the chap was in a hury! Was not a nice experience, in 5 days i slept a total of 7 hours, i also had motor mounts ready, but i had to do the whole gantry and Z axis with floating head and electronics and programig.

Forgot to tighten 1 single screw and was mad at myself for such sloppynes, costed me half an hour to figure out why one side of the gantry moves sometimes more and sometimes less than it should at random while the other side is all good.

Well going to grab some Zzzzzz, more work tomorrow, like decide the size of the actual thing. I can do 110 cm in about 3 days have it all set up, or i can do 6 meters in about 3 weeks, granted i have to assembe it on the yard as i can not fit it inside, already cramped there. 4.2X1.7 meters i can still manage to move and work inside, 4.2X7 meters is a no go, yard, rain, sloped concrete, nope no go.

Just thinking out loud!

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

16 Mar 2017 19:05 - 16 Mar 2017 19:06 #89768

by andypugh

Replied by andypugh on topic Tom's <add number here> plasma build

Last edit: 16 Mar 2017 19:06 by andypugh.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11682

- Thank you received: 3937

16 Mar 2017 20:14 #89780

by rodw

And neither did Burntables. I've seen a range of high end tables laid out the same way and I gave serious consideration to making mine like this.

Replied by rodw on topic Tom's <add number here> plasma build

I just invented the vertical plasma table.

As is so often the case with things I invent, I didn't invent it first

And neither did Burntables. I've seen a range of high end tables laid out the same way and I gave serious consideration to making mine like this.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21239

- Thank you received: 7250

17 Mar 2017 00:19 #89785

by tommylight

Replied by tommylight on topic Tom's <add number here> plasma build

Already had a stone engraver like that, realy nice and useful until someone crashed a 200kg stone on the gantry.

I would love to do that vertical, but it needs a vent, a big one, ducting etc. Also there is the problem of faling parts and magnets are useless on a plasma, covered in fine dust hard to clean.

Back to build,

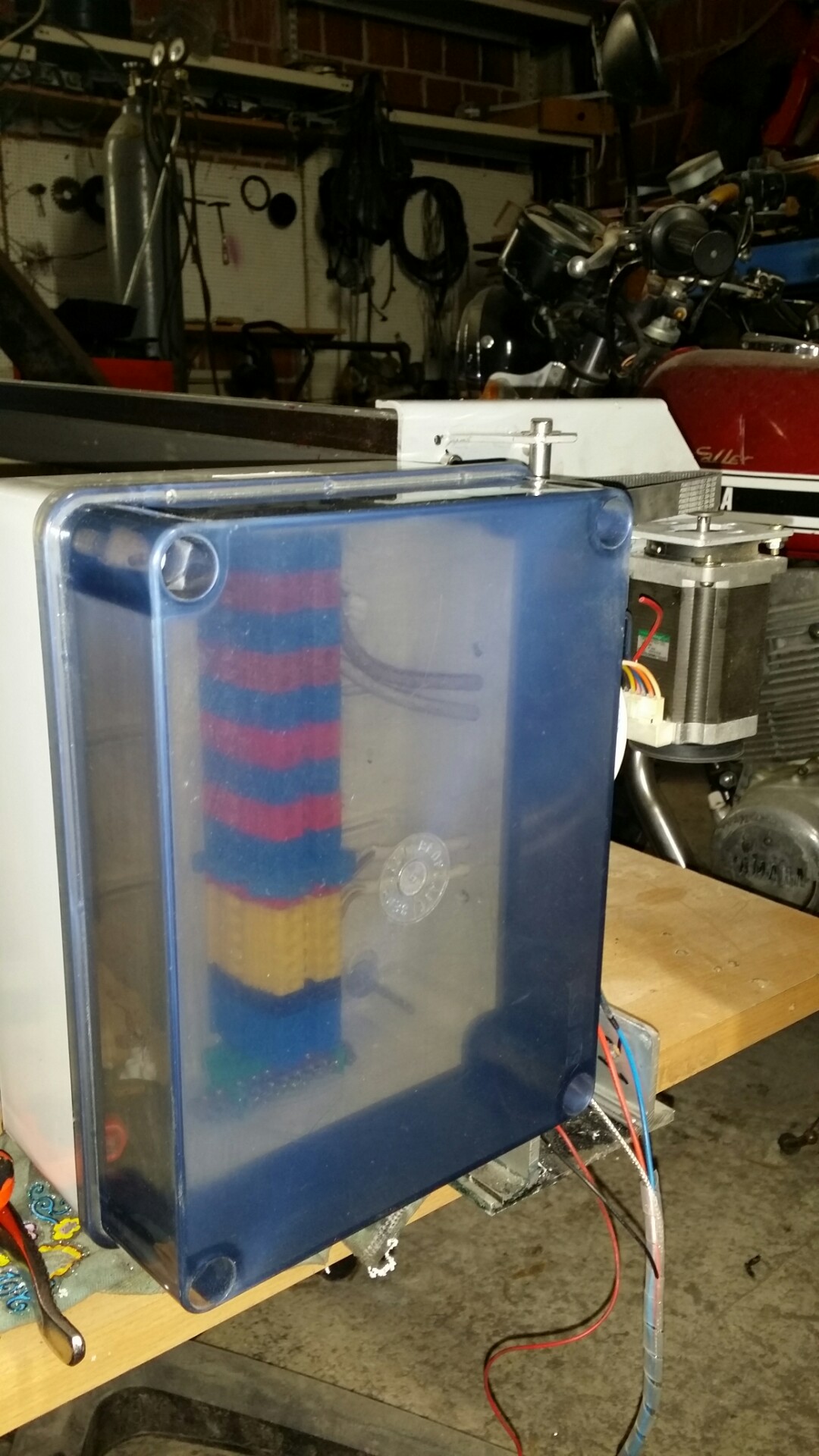

Had to change 4 micro switches, they where normaly open, i like to use normaly closed so if they disconnect, it will alert. Also added a box for wiring so it looks more pleasing. I plan on installing white LED lights under the gantry the whole length, and add red green and blue LED on the Z cariage, so when i make the thin plastic enclosure, it will have status colored lights as per RodW instructions. It will be a nice WOW effect for sure.

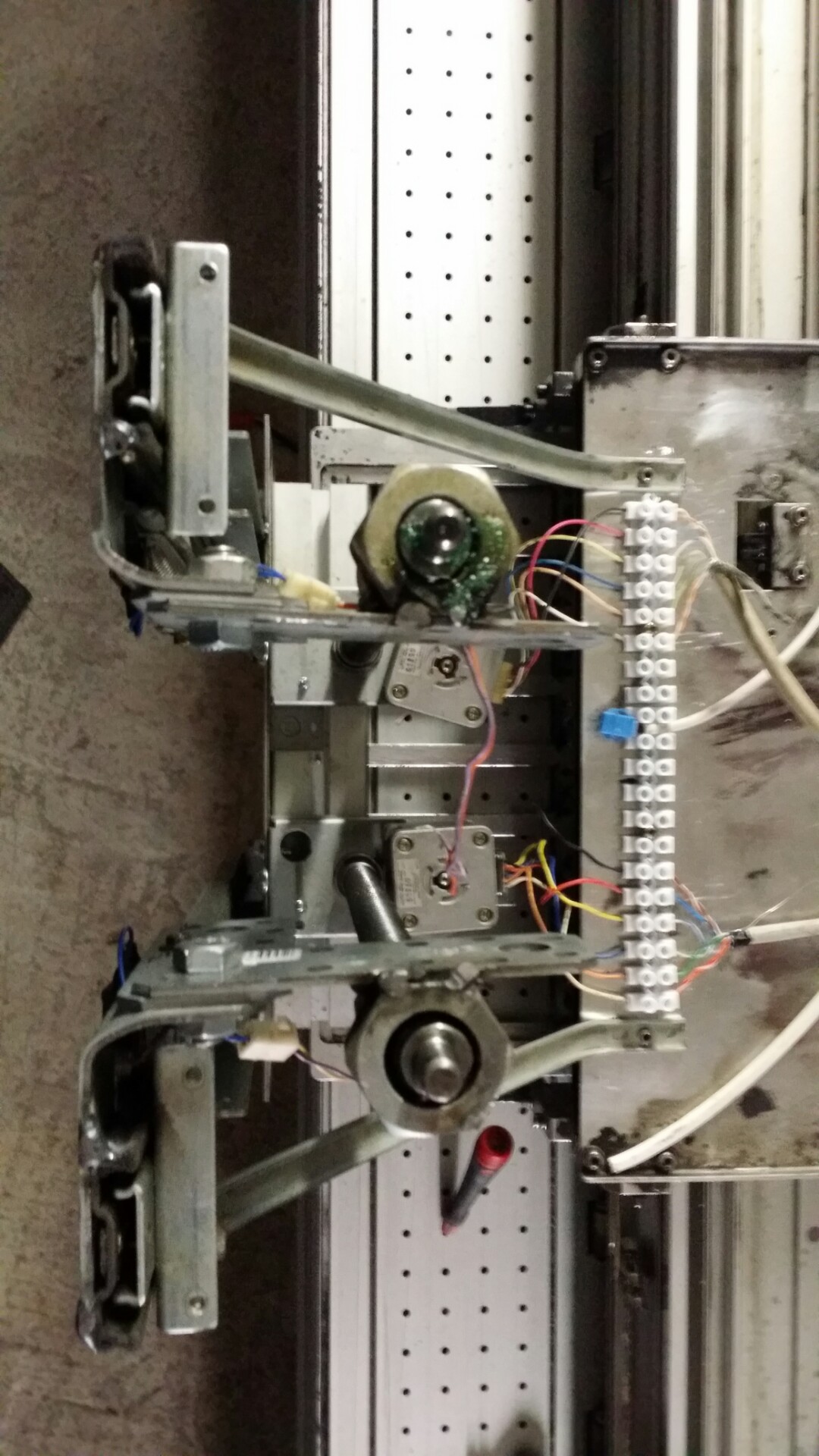

This is the interconnect box

Also added some tubing for probe and limit switch wiring on the Z axis to prevent them from tangling on moving parts.

Regards,

Tom

I would love to do that vertical, but it needs a vent, a big one, ducting etc. Also there is the problem of faling parts and magnets are useless on a plasma, covered in fine dust hard to clean.

Back to build,

Had to change 4 micro switches, they where normaly open, i like to use normaly closed so if they disconnect, it will alert. Also added a box for wiring so it looks more pleasing. I plan on installing white LED lights under the gantry the whole length, and add red green and blue LED on the Z cariage, so when i make the thin plastic enclosure, it will have status colored lights as per RodW instructions. It will be a nice WOW effect for sure.

This is the interconnect box

Also added some tubing for probe and limit switch wiring on the Z axis to prevent them from tangling on moving parts.

Regards,

Tom

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

17 Mar 2017 09:00 #89804

by andypugh

Put the magnet in a nitrile glove (or similar) before use and turn the glove inside out around the dust.

Works well when there are not plasma sparks, might be less effective with sparks.

Replied by andypugh on topic Tom's <add number here> plasma build

magnets are useless on a plasma, covered in fine dust hard to clean.

Put the magnet in a nitrile glove (or similar) before use and turn the glove inside out around the dust.

Works well when there are not plasma sparks, might be less effective with sparks.

The following user(s) said Thank You: tommylight, snugglylovemuffin

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11682

- Thank you received: 3937

17 Mar 2017 09:25 #89806

by rodw

The one I saw used tabs to hold the workpieces in place and the cutting area was fully enclosed with sliding access doors for fume control and the material slid in from one end. I see that Sheetcam does tabbing...

Replied by rodw on topic Tom's <add number here> plasma build

Put the magnet in a nitrile glove (or similar) before use and turn the glove inside out around the dust.

Works well when there are not plasma sparks, might be less effective with sparks.

The one I saw used tabs to hold the workpieces in place and the cutting area was fully enclosed with sliding access doors for fume control and the material slid in from one end. I see that Sheetcam does tabbing...

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21239

- Thank you received: 7250

17 Mar 2017 10:57 #89814

by tommylight

Replied by tommylight on topic Tom's <add number here> plasma build

I meant magnets on the table, to hold the pieces while cutting, otherwise someone must be standing there and removing pieces as they are cut. Magnets do not like heat at all.

I am seriously considering doing that but not vertical, slanted at 50 to 60 degrees, would be much harder to dislodge parts when the torch pases over them while the air is still on. We cut mostly 3mm sheets with lots of smal cuts, so the air pressure from the torch is enough to flip and move parts.

Thank you for the never ending source of ideas and solutions.

Tom

I am seriously considering doing that but not vertical, slanted at 50 to 60 degrees, would be much harder to dislodge parts when the torch pases over them while the air is still on. We cut mostly 3mm sheets with lots of smal cuts, so the air pressure from the torch is enough to flip and move parts.

Thank you for the never ending source of ideas and solutions.

Tom

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21239

- Thank you received: 7250

19 Mar 2017 01:44 #89874

by tommylight

Replied by tommylight on topic Tom's <add number here> plasma build

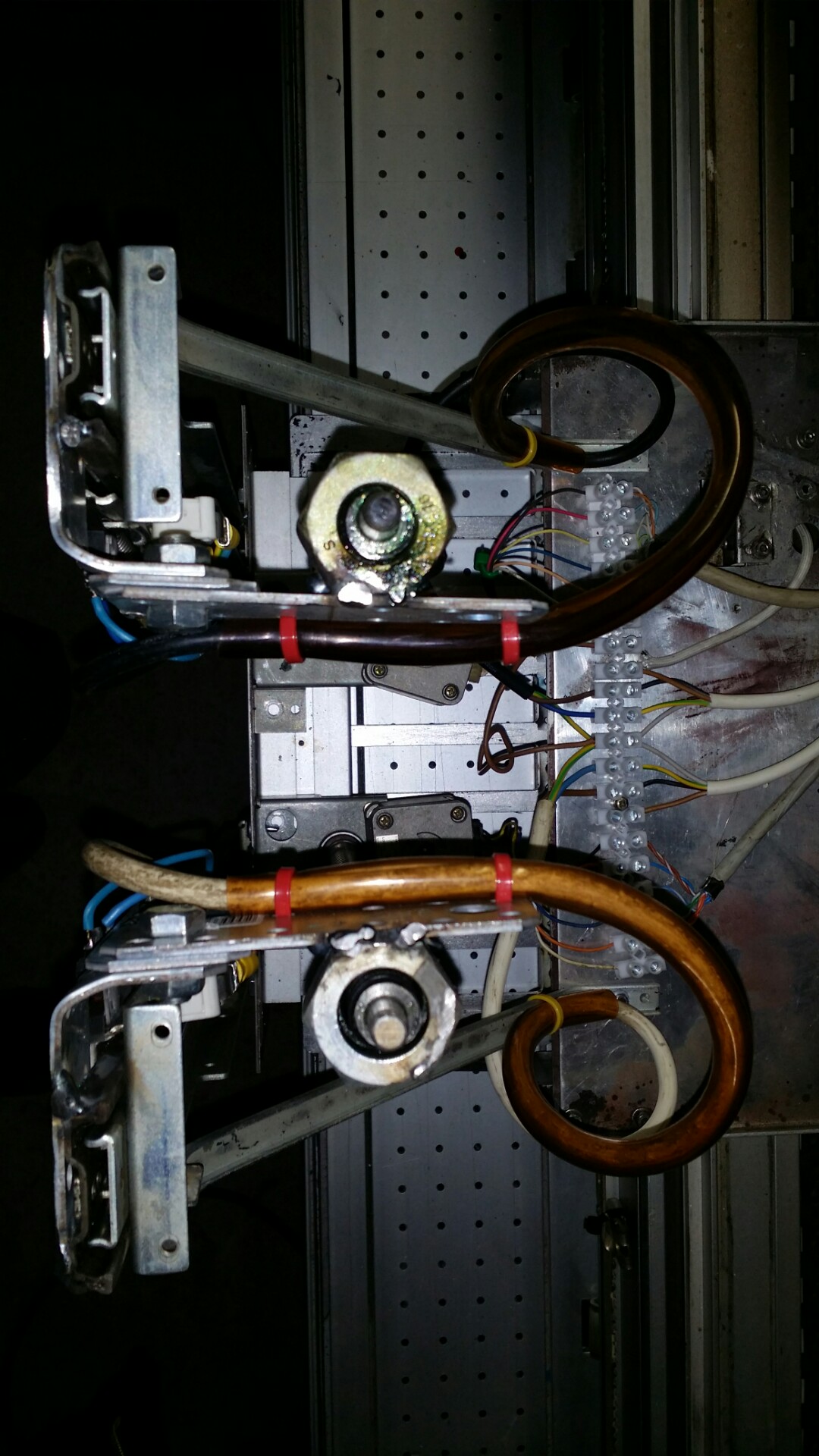

Last night i recieved the vantai drives, 4X422 and 3X806 and 2X BOB. Unpack and mount on a piece of plate, added plenty of stuff, so tonight i was doing the wiring and testing. Had some serious troubleshooting with BOB's since the output signal is realy bad, like horror show bad, on the Tektronix scope it looks like saw blade, not a nice one at that.

On the other hand, drives work perfectly, current control is all good, checked with DC current clamps, current reduction at idle works as advertised, agan clamps, microsteping works perfectly smooth, again clamps while running the motors realy slow to se the current change, no heat after half hour of testing at 5A RMS, motor Sanyo Denki 5A got mildly warm during the test.

All in all, very pleased with the drives, especialy after using Lam Technologies drives, they are without a doubt the best stepper drives money can buy. I have yet to see drives that can do 200kHz pulses without a hitch, and can not be destroyed on purpose ( i did try, even reversing the polarity of the power supply will not kill them, misswiring the motor between different outputs, nothing.)

The only problem, price, 2 vantai for 1 Lam Tech.

Will have to order some more vantai for sure

Here is a picture of them while i was thinkin on how to mount them for reduced wiring, ended up diferently so will add another picture tomorrow.

Regards,

Tom

On the other hand, drives work perfectly, current control is all good, checked with DC current clamps, current reduction at idle works as advertised, agan clamps, microsteping works perfectly smooth, again clamps while running the motors realy slow to se the current change, no heat after half hour of testing at 5A RMS, motor Sanyo Denki 5A got mildly warm during the test.

All in all, very pleased with the drives, especialy after using Lam Technologies drives, they are without a doubt the best stepper drives money can buy. I have yet to see drives that can do 200kHz pulses without a hitch, and can not be destroyed on purpose ( i did try, even reversing the polarity of the power supply will not kill them, misswiring the motor between different outputs, nothing.)

The only problem, price, 2 vantai for 1 Lam Tech.

Will have to order some more vantai for sure

Here is a picture of them while i was thinkin on how to mount them for reduced wiring, ended up diferently so will add another picture tomorrow.

Regards,

Tom

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.264 seconds