Tom's <add number here> plasma build

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11600

- Thank you received: 3900

27 Mar 2017 23:46 #90407

by rodw

Replied by rodw on topic Tom's <add number here> plasma build

Never boring watching your progress. In 2 weeks, you've caught up to where I am after 12 months.... I'm hoping Lee can weld up my table top frame this afternoon. And yes, even my 1200 x 1300 table will weigh close to 400 kg. Please take plenty of photos of your table construction.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21141

- Thank you received: 7221

27 Mar 2017 23:57 #90410

by tommylight

Replied by tommylight on topic Tom's <add number here> plasma build

Will do, of course.

That will be the weight of just the gantry support with gantry and motors. Table will be another 5 to 600 Kg for sure.

I always build separate table for plasma machines, one more step to avoiding interferences.

Where i live, grounding ( earthing ) is uterly unimportant for folks here, that is why we have 4 to 7 deaths from electrocution every year.

I refuse to do any work anywhere without proper grounding.

That will be the weight of just the gantry support with gantry and motors. Table will be another 5 to 600 Kg for sure.

I always build separate table for plasma machines, one more step to avoiding interferences.

Where i live, grounding ( earthing ) is uterly unimportant for folks here, that is why we have 4 to 7 deaths from electrocution every year.

I refuse to do any work anywhere without proper grounding.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21141

- Thank you received: 7221

29 Mar 2017 00:37 - 29 Mar 2017 00:40 #90473

by tommylight

Replied by tommylight on topic Tom's <add number here> plasma build

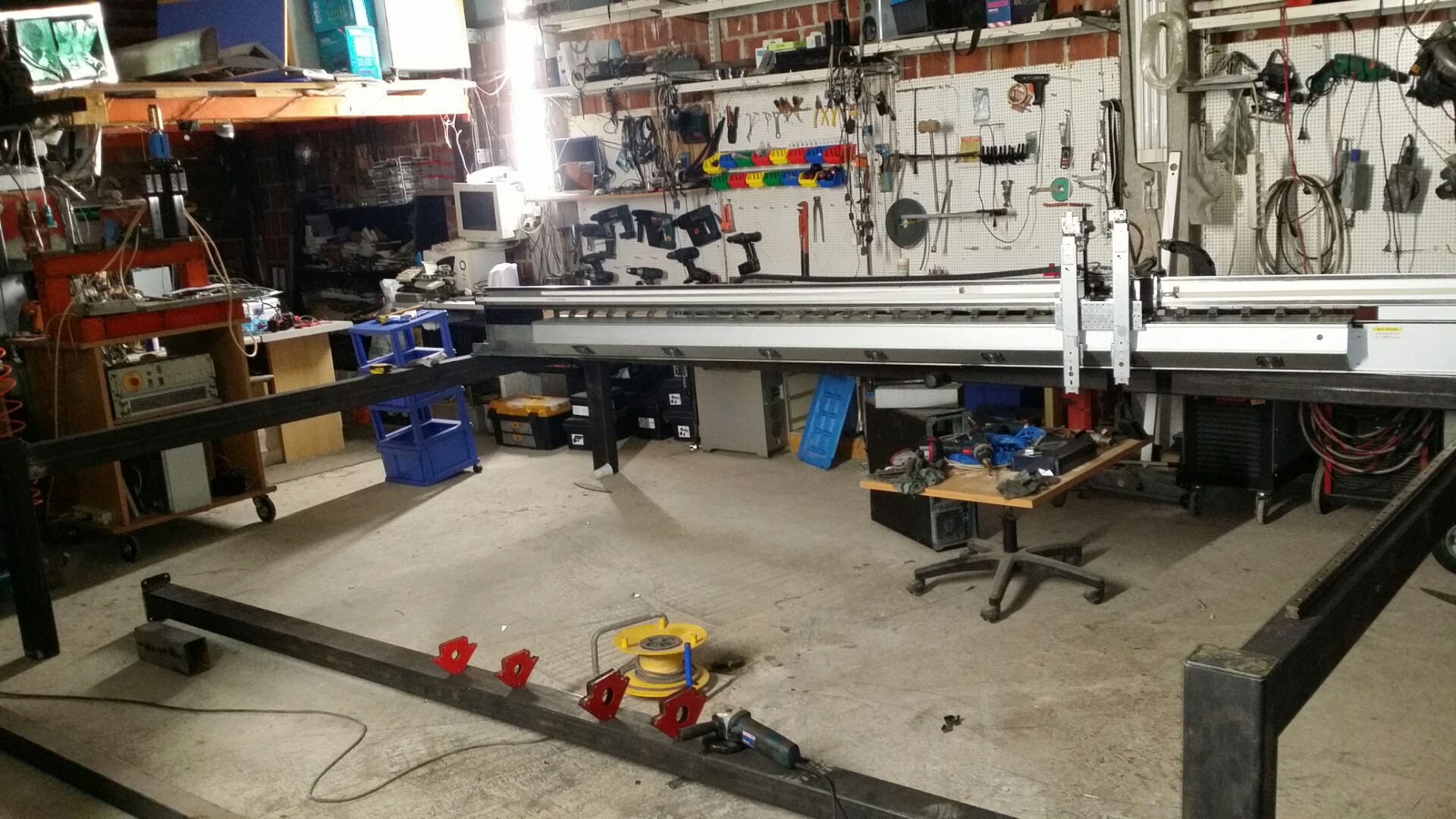

Got some more done today, had to call a friend to help as everything is to heavy for one person. Got to drill and tap ( by hand mind you ) 24 M10 holes, took over 3 hours, drill 4mm, drill 7mm, drill 9.1mm left twist of all things, tap M10. Holes on the plates where done yesterday at 8mm so had to do them again at 10mm. Tomorrow more joy of drillin a spot with 7mm drill, change to 4mm drill through, change to 5mm drill again, tap M6 by hand <== repeat this 41 times at 6cm distances, i already did one tonight to spare some work. The other side will have 2 card engine belt tensioners as bearings and no rail, but will have a rack, or if i can find, long car engine toothed belts. Already got the water pump pulleys. I try to use common stuff as much as possible as i can easily find them localy, was told a 2.6 meter long belt would cost 35 Euro, way cheaper than rack and pinion, and plenty strong for forces it will encounter, minus the vibrations and the setup time neede for proper rack mounting. Oh and i can buy new in a box with warranty water pumps for 10 euro a piece, just add another big pulley, and we got a reduction. Well the water pumps have sealings and that needs some force to move, so the seals must come off, or use other bearings.

Below are some pictures from today, had to move a lot of stuff in the workshop to make it fit and be able to move around, got the motorcycles and bikes out last night and covered them with a tarp, forgot to mention i own another Kawasaki GPZ600 besides 2 Yamahas, stripped to the bones literarly just the frame and wheels with brakes, will do a bettery setup when i get old......oh wait, i am already old so got to hurry. The engine from the Kawasaki is mounted on a compressor tank with an 3KW motor, waiting for 4 valves to be run as an air compressor. The good things : it has water cooling so can run all day if required, has lubrication with alarm sensors if it goes low, and can be spun at 11.500 RPM, so filling a 300 liter tank should take about 2 minutes.

Ok ok on to pictures....

Below are some pictures from today, had to move a lot of stuff in the workshop to make it fit and be able to move around, got the motorcycles and bikes out last night and covered them with a tarp, forgot to mention i own another Kawasaki GPZ600 besides 2 Yamahas, stripped to the bones literarly just the frame and wheels with brakes, will do a bettery setup when i get old......oh wait, i am already old so got to hurry. The engine from the Kawasaki is mounted on a compressor tank with an 3KW motor, waiting for 4 valves to be run as an air compressor. The good things : it has water cooling so can run all day if required, has lubrication with alarm sensors if it goes low, and can be spun at 11.500 RPM, so filling a 300 liter tank should take about 2 minutes.

Ok ok on to pictures....

Last edit: 29 Mar 2017 00:40 by tommylight. Reason: to many pictures

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11600

- Thank you received: 3900

29 Mar 2017 03:21 #90479

by rodw

Replied by rodw on topic Tom's <add number here> plasma build

Tommy,

Looking good. I just love the feed rollers on your gantry

Looking good. I just love the feed rollers on your gantry

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21141

- Thank you received: 7221

29 Mar 2017 10:34 #90491

by tommylight

Replied by tommylight on topic Tom's <add number here> plasma build

They do no harm so i left them there, would have saved about 1kg if removed, not much.

Thanks.

Thanks.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11600

- Thank you received: 3900

29 Mar 2017 10:49 #90492

by rodw

Tommy, it was just on account of my background that I noticed them. I used to run a digital printing plant until somebody decided that nobody was allowed to do what I did in our government so they threw me on the scrap heap a few years ago along with $1.0m of new equipment. We printed 42 million pages per year with 99.7% on time delivery in a 48 hour timeframe. I do have a video on youtube showing our plant but thought I better keep to topic....

Replied by rodw on topic Tom's <add number here> plasma build

They do no harm so i left them there, would have saved about 1kg if removed, not much.

Thanks.

Tommy, it was just on account of my background that I noticed them. I used to run a digital printing plant until somebody decided that nobody was allowed to do what I did in our government so they threw me on the scrap heap a few years ago along with $1.0m of new equipment. We printed 42 million pages per year with 99.7% on time delivery in a 48 hour timeframe. I do have a video on youtube showing our plant but thought I better keep to topic....

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21141

- Thank you received: 7221

29 Mar 2017 10:58 #90493

by tommylight

Replied by tommylight on topic Tom's <add number here> plasma build

That must have sucked bad. I wonder......nevermind.

Then again, where is that scrap heap located???

Thanks for sharing bro, i am taking it easy today as my right hand hurts badly from all the hand drilling and taping yesterday, although i have to push on later today, as Mr. Smith from Matrix said : It is inevitable!

Regards,

Tom

Then again, where is that scrap heap located???

Thanks for sharing bro, i am taking it easy today as my right hand hurts badly from all the hand drilling and taping yesterday, although i have to push on later today, as Mr. Smith from Matrix said : It is inevitable!

Regards,

Tom

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11600

- Thank you received: 3900

29 Mar 2017 11:43 #90496

by rodw

I know the feeling. I did cheat a bit using a laser cutter to drill the holes. That saved me a lot of time but tapping them all for rails and racks took me 2 days. I did about 50 M10 last weekend the old fashioned way just like you did.and it took a while... I worked off a drawing and stuffed up 1 measurement so will have to fill one hole with weld and redo. I've only got 18 M12 to go...

It was good to see how you joined your table together. Thanks for the clear photos. Filed away in my grey matter for the next one.

Replied by rodw on topic Tom's <add number here> plasma build

i am taking it easy today as my right hand hurts badly from all the hand drilling and taping yesterday, although i have to push on later today, as Mr. Smith from Matrix said : It is inevitable!

Regards,

Tom

I know the feeling. I did cheat a bit using a laser cutter to drill the holes. That saved me a lot of time but tapping them all for rails and racks took me 2 days. I did about 50 M10 last weekend the old fashioned way just like you did.and it took a while... I worked off a drawing and stuffed up 1 measurement so will have to fill one hole with weld and redo. I've only got 18 M12 to go...

It was good to see how you joined your table together. Thanks for the clear photos. Filed away in my grey matter for the next one.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21141

- Thank you received: 7221

30 Mar 2017 23:07 #90614

by tommylight

Replied by tommylight on topic Tom's <add number here> plasma build

Did not do much yesterday and today, was out and about looking at some used parts, found a bunch of Allen Bradley VFD Powerflex 700 at 5.5 KW, some ABB VFD at 15 and 45 KW that i have no use for yet and a nice 2.6KW servo motor. Did not buy anything at all, was asked 250 euro for the 700, 1500 for ABB and 200 for the servo. Price was no big deal, the pittiful state they were in was. Will have to wait a few days and make an offer for 700 and motor and some other stuff i currently do not need at all.

Back on topic,

Got the gantry in place although i did not drill and tap all the holes for the HGR25 rail, just in case i do not bend or brake something while putting the thing in place. Made a holder for the 2 belt tensioner rollers for the side with no rail from 2 pieces of 45X45 aluminium extrusion ( Bosch ), added a piece of metal 32X25Cm above the carriages and under the gantry as i had it already drilled for HGH25 cariages, so now the gantry slides nicely.

Will have to do something for reduction, but i am waiting to get a bigger lathe that should arive in a few days, the small one i have squeels like a piggy when i do HRC45 steel shafts. Also should get the long belts so i can test how it does moving the heavy gantry so i will have to make some holding and adjusting brackets for them.

More fun ( i can say that now since i have not much tapping left to do )

Regards,

Tom

Back on topic,

Got the gantry in place although i did not drill and tap all the holes for the HGR25 rail, just in case i do not bend or brake something while putting the thing in place. Made a holder for the 2 belt tensioner rollers for the side with no rail from 2 pieces of 45X45 aluminium extrusion ( Bosch ), added a piece of metal 32X25Cm above the carriages and under the gantry as i had it already drilled for HGH25 cariages, so now the gantry slides nicely.

Will have to do something for reduction, but i am waiting to get a bigger lathe that should arive in a few days, the small one i have squeels like a piggy when i do HRC45 steel shafts. Also should get the long belts so i can test how it does moving the heavy gantry so i will have to make some holding and adjusting brackets for them.

More fun ( i can say that now since i have not much tapping left to do )

Regards,

Tom

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21141

- Thank you received: 7221

01 Apr 2017 15:38 #90711

by tommylight

Replied by tommylight on topic Tom's <add number here> plasma build

Had a smal accident yesterday morning, of the 3 people involved in 2 cars i was the only one injured, call it bad luck. Just a smal neck and face injury, so now walking in right turns as the left side is stiff.

Still managed to mount a holder and 2 wheels to the outside of gantry support so it can not move sideways. Did a check on the force requred to move the gantry and it needs 1.5Kg to start and 1Kg afterwards to keep it moving, or what i like to call smooooooth.

More to come after a bit of rehab.

Still managed to mount a holder and 2 wheels to the outside of gantry support so it can not move sideways. Did a check on the force requred to move the gantry and it needs 1.5Kg to start and 1Kg afterwards to keep it moving, or what i like to call smooooooth.

More to come after a bit of rehab.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.337 seconds