CIgweld Cutskill 60 - adapting to CNC use

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

29 Mar 2021 06:14 #203978

by Joco

Replied by Joco on topic CIgweld Cutskill 60 - adapting to CNC use

Thanks. The schematic on page 5 makes it all clear.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

31 Mar 2021 22:34 #204323

by Joco

Replied by Joco on topic CIgweld Cutskill 60 - adapting to CNC use

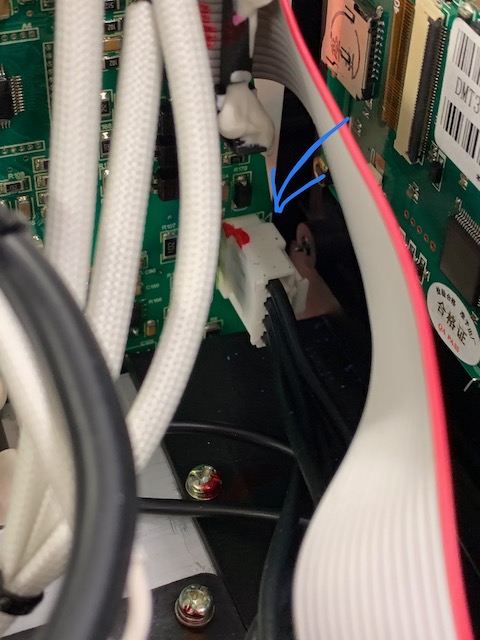

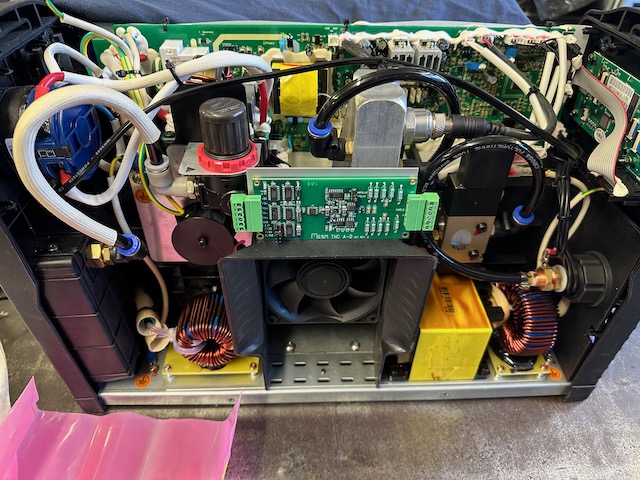

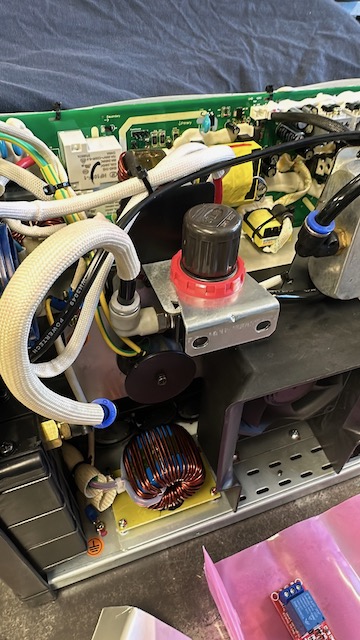

Just a short little post on the insides of the Cutskill 60. The attached image shows the two key control connectors. I'm just working out the best way to splice into the loop that gives control of the torch on/off.

Any ideas welcome.

You can also see the torch connector in the lower center/right of the pic. Looks like it shouldn't be too much of a drama to get a lead off that and (hopefully the work lead which is behind the circuit board out of sight) to be able to create a voltage divider to feed the THCAD that will be mounted (I hope) inside the unit.

Cheers - J.

Any ideas welcome.

You can also see the torch connector in the lower center/right of the pic. Looks like it shouldn't be too much of a drama to get a lead off that and (hopefully the work lead which is behind the circuit board out of sight) to be able to create a voltage divider to feed the THCAD that will be mounted (I hope) inside the unit.

Cheers - J.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

31 Mar 2021 22:58 #204328

by rodw

Replied by rodw on topic CIgweld Cutskill 60 - adapting to CNC use

YOu don't need a voltage divider. Just use the THCAD with an appropriate scaling resistor

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

01 Apr 2021 02:04 #204347

by Joco

Replied by Joco on topic CIgweld Cutskill 60 - adapting to CNC use

Another example of my lack of electrical whatsit.

Isn't the THCAD part of a voltage divider circuit? At least on its input side of things. With the scaling resistors essentially being part of that voltage divider circuit?

Or is there some other form electrical circuit in the mix that is essentially doing the same job?

Isn't the THCAD part of a voltage divider circuit? At least on its input side of things. With the scaling resistors essentially being part of that voltage divider circuit?

Or is there some other form electrical circuit in the mix that is essentially doing the same job?

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

01 Apr 2021 02:17 #204348

by rodw

Replied by rodw on topic CIgweld Cutskill 60 - adapting to CNC use

It sounded like you wanted to build a voltage divider and use the THCAD to When the THCAD scaling resistor is all you need per the formula in the thcad manual.

The following user(s) said Thank You: Joco

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

15 Oct 2021 04:38 - 15 Oct 2021 04:40 #223162

by Joco

Replied by Joco on topic CIgweld Cutskill 60 - adapting to CNC use

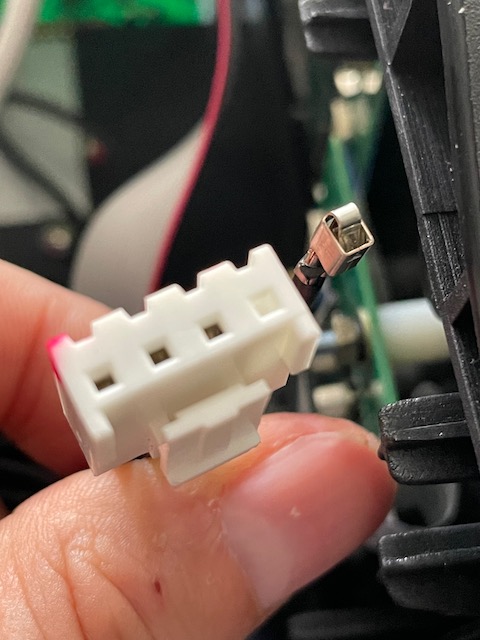

I have managed to have a little win with the Cutskill. I decided to have a crack at splicing into the torch trigger connection located here on the circuit board.

You could do the T splices into the wires but I decided tofix wiring into the plug itself.

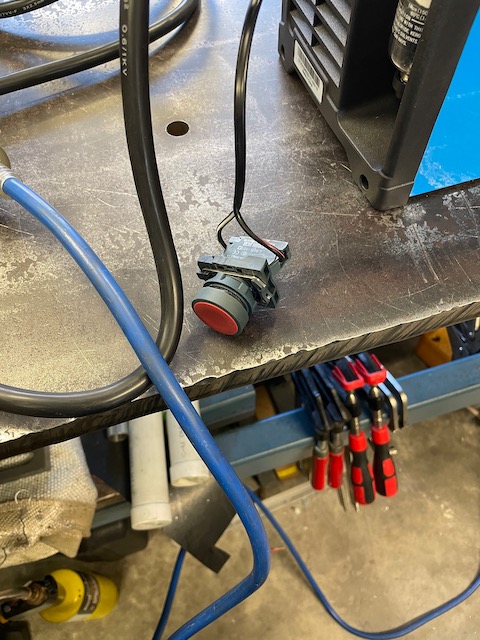

So after some mucking about I ended up with an external button as my "human powered relay".

Then connected the machine torch I had from AliExpress.

Here it is for anyone else interested in what to get for a Cutskill style plasma power source:

www.aliexpress.com/item/1005002211780814...1.0.0.27424c4djYGtBV

So .. after a little bit of trepidation as this was the VERY first time I was trying to fire this torch, I gave it a crack.

40AMP setting, air pressure per the manual. And it WORKED.

You could do the T splices into the wires but I decided tofix wiring into the plug itself.

So after some mucking about I ended up with an external button as my "human powered relay".

Then connected the machine torch I had from AliExpress.

Here it is for anyone else interested in what to get for a Cutskill style plasma power source:

www.aliexpress.com/item/1005002211780814...1.0.0.27424c4djYGtBV

So .. after a little bit of trepidation as this was the VERY first time I was trying to fire this torch, I gave it a crack.

40AMP setting, air pressure per the manual. And it WORKED.

Attachments:

Last edit: 15 Oct 2021 04:40 by Joco. Reason: on going fights with this stupid backward step of an editor.

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

15 Oct 2021 05:10 - 15 Oct 2021 05:12 #223165

by Joco

Replied by Joco on topic CIgweld Cutskill 60 - adapting to CNC use

As a quick followup note, if you decide to purchase the torch I linked you NEED to request two of the pins to be changed. Check their mappins and the mappinsg in your manual and request that change as part of the notes to the seller on placing the order. Also check they are still offering to do these customisations.

In my case my request for the Cutskill 60 was: Please change ARC pins from 1,4 to 5,6

Cheers - James.

In my case my request for the Cutskill 60 was: Please change ARC pins from 1,4 to 5,6

Cheers - James.

Last edit: 15 Oct 2021 05:12 by Joco.

Please Log in or Create an account to join the conversation.

- aussietom

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 0

14 Oct 2023 13:40 #282990

by aussietom

Replied by aussietom on topic CIgweld Cutskill 60 - adapting to CNC use

Hiya James,

Just checking if you progressed on this any further and thought the cutskill 60 + the torch was a good fit for plasma cnc table or not?

Thanks,

-Tom

Just checking if you progressed on this any further and thought the cutskill 60 + the torch was a good fit for plasma cnc table or not?

Thanks,

-Tom

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

18 Oct 2023 08:37 #283219

by Joco

Replied by Joco on topic CIgweld Cutskill 60 - adapting to CNC use

Check out my plasma table build thread. From this point one we get more into final adjustments to the cutskill.

forum.linuxcnc.org/show-your-stuff/42118...rea?start=150#281696

If you are prepared to do the adjustments (minor at that) then its a pretty reasonable option given it will deliver 60A. Machine torch is a key addition. I got a PTM-80 but there are PTM-60's out there. For some reason more expensive. And when you get it you need to make sure the pins on the adpator are correctly mapping to the the pins on the cutskill. The default for these torches is not always what you want. When I got my PTM-80 torch having it custom wired for the Cutskill was an option. I just needed to spell out what pins I wanted for connected to trigger and consumable installed ok.

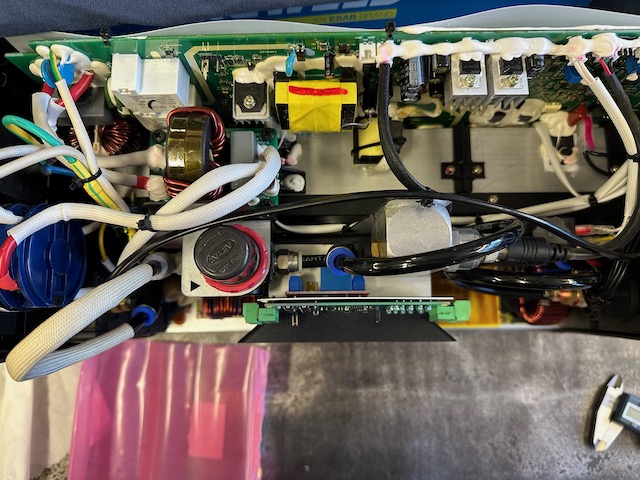

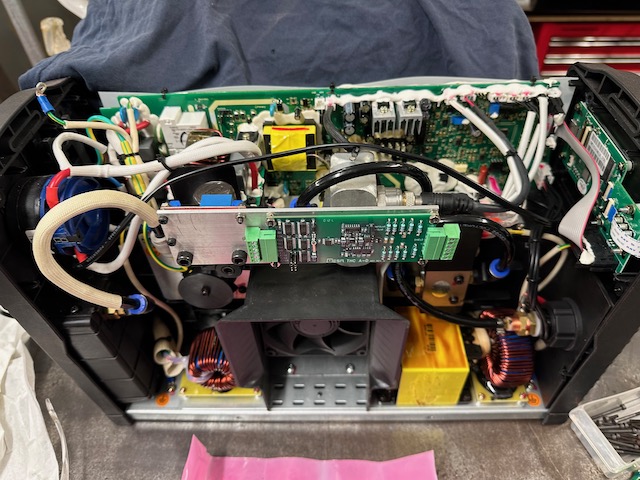

Splicing into the Trigger circuit wasn't hard and installing the thcad and a relay into the unit and wiring it up to my own custom CNC port took a little itme to be careful but ultimately wasn't difficult.

Now it looks like it came from factory with a cnc port and the conneciton is all operating with an internal THCAD-10 for reading the voltage.

Cheers - J.

forum.linuxcnc.org/show-your-stuff/42118...rea?start=150#281696

If you are prepared to do the adjustments (minor at that) then its a pretty reasonable option given it will deliver 60A. Machine torch is a key addition. I got a PTM-80 but there are PTM-60's out there. For some reason more expensive. And when you get it you need to make sure the pins on the adpator are correctly mapping to the the pins on the cutskill. The default for these torches is not always what you want. When I got my PTM-80 torch having it custom wired for the Cutskill was an option. I just needed to spell out what pins I wanted for connected to trigger and consumable installed ok.

Splicing into the Trigger circuit wasn't hard and installing the thcad and a relay into the unit and wiring it up to my own custom CNC port took a little itme to be careful but ultimately wasn't difficult.

Now it looks like it came from factory with a cnc port and the conneciton is all operating with an internal THCAD-10 for reading the voltage.

Cheers - J.

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

18 Oct 2023 08:43 #283220

by Joco

Replied by Joco on topic CIgweld Cutskill 60 - adapting to CNC use

Attachments:

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.770 seconds