- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Hypertherm MAX PRO 200 CNC Connections - Quick Question

Hypertherm MAX PRO 200 CNC Connections - Quick Question

- RDA

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 43

29 Sep 2023 20:45 #281881

by RDA

Replied by RDA on topic Hypertherm MAX PRO 200 CNC Connections - Quick Question

Hello,

Sorry I have been on the road and did not read the messages.

I did delete my posts per request to not get anyone killed or get their equipment blown up.

I don't know how to explain this better but example on a maxpro, the pilot arc is not 10kV, the OCV according to the specs is 360VDC, this is the max the plasma can push out. The HF is there only to ignite the pilot, after the very short ignition phase the pilot arc has ignited and that is max 360VDC.

Overly simplified you can think the ignition to be like a piezo ignited lighter and the flame being the pilot. The very high voltage you make by pushing the lighter ignition "button" is there only for a fraction of a second to ignite the flame.

When the current starts to flow also from the work lead (pilot arc touches the plate), the current is ramped up and the cutting arc is formed.

Someone please correct me if I am wrong.

Sorry I have been on the road and did not read the messages.

I did delete my posts per request to not get anyone killed or get their equipment blown up.

I don't know how to explain this better but example on a maxpro, the pilot arc is not 10kV, the OCV according to the specs is 360VDC, this is the max the plasma can push out. The HF is there only to ignite the pilot, after the very short ignition phase the pilot arc has ignited and that is max 360VDC.

Overly simplified you can think the ignition to be like a piezo ignited lighter and the flame being the pilot. The very high voltage you make by pushing the lighter ignition "button" is there only for a fraction of a second to ignite the flame.

When the current starts to flow also from the work lead (pilot arc touches the plate), the current is ramped up and the cutting arc is formed.

Someone please correct me if I am wrong.

Please Log in or Create an account to join the conversation.

- RDA

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 43

29 Sep 2023 20:57 #281882

by RDA

Replied by RDA on topic Hypertherm MAX PRO 200 CNC Connections - Quick Question

Actually it is not that difficult, I have seen these in the wild. I am now talking about reputable plasmas like MaxPro, HPR, XPR, Qseries, HiFocus...You pretty much just need to handle the MHz range pulse. In all cases I have seen these actually working and withstanding the HF, they just have pulse withstanding resistors. Maybe some smoothing components but they are after the divider network.With care, you can make a voltage divider that will work with

10KV HF, but you do _NOT_ want to pipe the HF signal anywhere

near the control electronics.

Much better to tap the sense point from before

the "Tesla coil". Any DC voltage drop in this coil is minimal

and easily compensated for if needed.

Please Log in or Create an account to join the conversation.

- RDA

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 43

30 Sep 2023 12:11 #281927

by RDA

Replied by RDA on topic Hypertherm MAX PRO 200 CNC Connections - Quick Question

Hello all and sorry for the quick message yesterday. I wasn't sure if I had time this morning to write so I just made a quick post to let you know I have not abandoned this.

I agree that Jim Colt has some pretty good stuff written around the internet and he knows his stuff about plasma and especially hypertherm plasma's.

I know people don't have to believe that I know anything about what I am saying, but I do know a thing or two about plasma's.

I am all about learning and wish to learn new stuff about plasma. There is a ton of knowledge around the globe to learn, so if I am wrong I would highly appreciate if someone corrects me and tells me how these things work.

So if someone could correct me in the following statements, I would highly appreciate it:

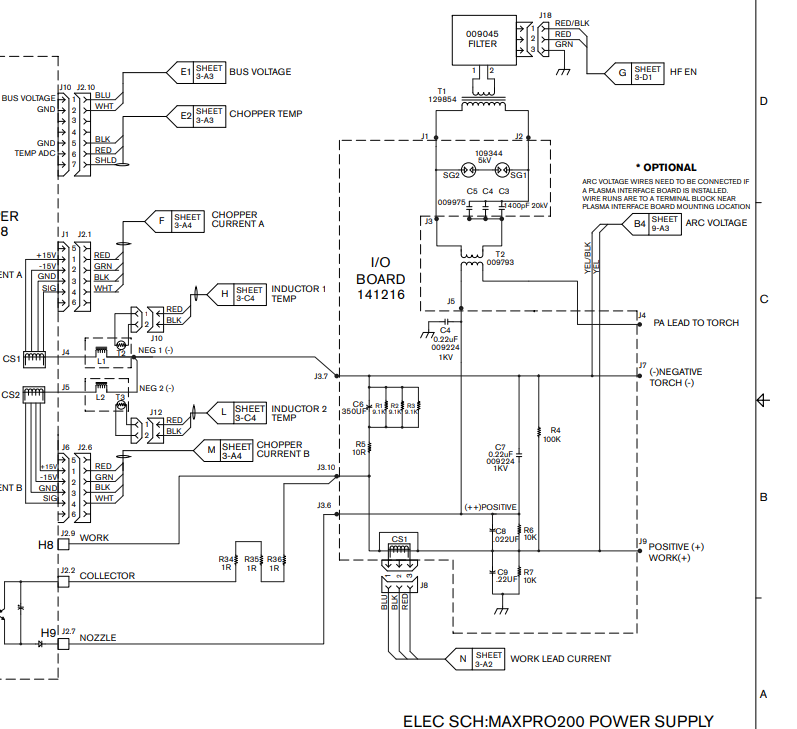

1. HF that is used to ignite the pilot arc is generated between the electrode and the tip. As a reference to my claim I refer to the maxpro200 manual page 201. You can see the HF transformer in the pilot lead, connector J4. At the same page you can find a note to take the arc voltage between negative and positive from the torch side of the transformer.

2. Pilot arc cannot exceed the OCV of the plasma.

Here is a link to the maxpro200 manual MaxPro 200 manual

Instead of just telling I am wrong, please let me know how I am wrong and how this stuff actually works.

I agree that Jim Colt has some pretty good stuff written around the internet and he knows his stuff about plasma and especially hypertherm plasma's.

I know people don't have to believe that I know anything about what I am saying, but I do know a thing or two about plasma's.

I am all about learning and wish to learn new stuff about plasma. There is a ton of knowledge around the globe to learn, so if I am wrong I would highly appreciate if someone corrects me and tells me how these things work.

So if someone could correct me in the following statements, I would highly appreciate it:

1. HF that is used to ignite the pilot arc is generated between the electrode and the tip. As a reference to my claim I refer to the maxpro200 manual page 201. You can see the HF transformer in the pilot lead, connector J4. At the same page you can find a note to take the arc voltage between negative and positive from the torch side of the transformer.

2. Pilot arc cannot exceed the OCV of the plasma.

Here is a link to the maxpro200 manual MaxPro 200 manual

Instead of just telling I am wrong, please let me know how I am wrong and how this stuff actually works.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11600

- Thank you received: 3900

30 Sep 2023 13:26 #281933

by rodw

Replied by rodw on topic Hypertherm MAX PRO 200 CNC Connections - Quick Question

Tommy knows more than me on this subject so I have included a copy of the drawing but I would have thought J3.6 an J3.7 would be better places to pick up the voltage for a THCAD. That seems to be where PCW suggested.

It does not really matter how long the HV pulse is, it can still damage stuff. I can understand your reluctance to deviate from the manual

It does not really matter how long the HV pulse is, it can still damage stuff. I can understand your reluctance to deviate from the manual

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17556

- Thank you received: 5130

30 Sep 2023 14:20 #281935

by PCW

Replied by PCW on topic Hypertherm MAX PRO 200 CNC Connections - Quick Question

Actually there is no real issue with this type of machine (HF pilot start) since the

arc voltage is always taken across the output capacitor so contains no HV/HF.

That is, only the pilot connection has the high voltage high frequency signal.

The issue is with non-pilot HF start units where the HF start circuit is in series between

the main plasma supply and the torch.

On these machines the arc voltage must be taken ahead of the HF transformer.

(unless you want to make your EMI issues much worse)

arc voltage is always taken across the output capacitor so contains no HV/HF.

That is, only the pilot connection has the high voltage high frequency signal.

The issue is with non-pilot HF start units where the HF start circuit is in series between

the main plasma supply and the torch.

On these machines the arc voltage must be taken ahead of the HF transformer.

(unless you want to make your EMI issues much worse)

The following user(s) said Thank You: tommylight, RDA

Please Log in or Create an account to join the conversation.

- RDA

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 43

30 Sep 2023 16:01 #281941

by RDA

The only thing you need to be worried is, like Tommy said, HF noise, but that's EMI, quite strong EMI. For this reason (similar to ohmic sensing) you would want the resistor network to be pulse withstanding.

The way the pilot arc is ignited with HF, as explained in the maxpro manual, is how all the major branded industrial plasma's are done. The HF is done between nozzle and electrode.

Replied by RDA on topic Hypertherm MAX PRO 200 CNC Connections - Quick Question

Exactly and if Rod looks at the schematic the you want to measure arc voltage between work and electrode, those in the "same" position are in the manual J3.7 and J3.10, you do not want to measure the tip voltage, that would be the 3.7. And if you follow the J3.7 and J3.10 it leads directly to the backwall work and electrode terminals.Actually there is no real issue with this type of machine (HF pilot start) since the

arc voltage is always taken across the output capacitor so contains no HV/HF.

That is, only the pilot connection has the high voltage high frequency signal.

The issue is with non-pilot HF start units where the HF start circuit is in series between

the main plasma supply and the torch.

On these machines the arc voltage must be taken ahead of the HF transformer.

(unless you want to make your EMI issues much worse)

The only thing you need to be worried is, like Tommy said, HF noise, but that's EMI, quite strong EMI. For this reason (similar to ohmic sensing) you would want the resistor network to be pulse withstanding.

The way the pilot arc is ignited with HF, as explained in the maxpro manual, is how all the major branded industrial plasma's are done. The HF is done between nozzle and electrode.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21131

- Thank you received: 7219

30 Sep 2023 16:37 #281942

by tommylight

Replied by tommylight on topic Hypertherm MAX PRO 200 CNC Connections - Quick Question

See "optional", it literally says the wiring is taken from a terminal block near plasma interface board, not where the drawing shows them.

It also shows:

- 2 of spark gapes rated at 5KV in series (read about it, or you will think this is the max, it is not)

- several 20KV capacitors in parallel to high voltage transformer

-- means the voltage is over 10KV but under 20KV.

And a lot of over 1KV parts on the outputs.

The HF/HV transformer has one side wired to positive, so that would make it's way to THC if taken as shown, but in this case would still be OK as PCW mentioned.

The fact remains, those are the same wires so does not influence readings, but where you wire the THC does matter a lot. As far as possible from HF/HV stuff, and sure as hell not at the torch terminals, not even for blow back start that produces the least amount of interference.

Yet, there are THC wired to terminals and working, but the risk is way to high to tell people it is OK.

Even if the THC survives and works, any personnel working on the machine might have hands touching the THC wires in the control box when the torch fires thinking it is 5V or 10V stuff, most probably will survive blow back and be dizzy for a day or two, most probably will not survive HV or HF/HV, if wired at the torch terminals.

-Examples

As a side note, search youtube for "welding robot crash", it is MIG welding, has no HF/HV of any kind, max voltage in open circuit is 50V, working voltage 22-28V, yet it ruined the robot on first arc! It does not read the voltage, the only wires to MIG is torch on through a relay, yet the induced EMI is more than enough to send it flying. No proper shielding/grounding in place.

Also on youtube, Jeremy Fielding ruined his robot on first arc, again no THC, no voltage reading, just torch on. But no proper shielding/grounding.

-Home work

take a car ignition coil, wire it to a battery while holding the wires = nothing happens when touching the battery but it does when disconnecting them, a lot. Any transformer will do instead of ignition coil, try primary and secondary, preferably with 12V battery, bigger jolt!

DO NOT try this if you have known heart issues, people with chronic arrhythmia will probably not survive this, despite being "only 12V"!!!

It also shows:

- 2 of spark gapes rated at 5KV in series (read about it, or you will think this is the max, it is not)

- several 20KV capacitors in parallel to high voltage transformer

-- means the voltage is over 10KV but under 20KV.

And a lot of over 1KV parts on the outputs.

The HF/HV transformer has one side wired to positive, so that would make it's way to THC if taken as shown, but in this case would still be OK as PCW mentioned.

The fact remains, those are the same wires so does not influence readings, but where you wire the THC does matter a lot. As far as possible from HF/HV stuff, and sure as hell not at the torch terminals, not even for blow back start that produces the least amount of interference.

Yet, there are THC wired to terminals and working, but the risk is way to high to tell people it is OK.

Even if the THC survives and works, any personnel working on the machine might have hands touching the THC wires in the control box when the torch fires thinking it is 5V or 10V stuff, most probably will survive blow back and be dizzy for a day or two, most probably will not survive HV or HF/HV, if wired at the torch terminals.

-Examples

As a side note, search youtube for "welding robot crash", it is MIG welding, has no HF/HV of any kind, max voltage in open circuit is 50V, working voltage 22-28V, yet it ruined the robot on first arc! It does not read the voltage, the only wires to MIG is torch on through a relay, yet the induced EMI is more than enough to send it flying. No proper shielding/grounding in place.

Also on youtube, Jeremy Fielding ruined his robot on first arc, again no THC, no voltage reading, just torch on. But no proper shielding/grounding.

-Home work

take a car ignition coil, wire it to a battery while holding the wires = nothing happens when touching the battery but it does when disconnecting them, a lot. Any transformer will do instead of ignition coil, try primary and secondary, preferably with 12V battery, bigger jolt!

DO NOT try this if you have known heart issues, people with chronic arrhythmia will probably not survive this, despite being "only 12V"!!!

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21131

- Thank you received: 7219

30 Sep 2023 16:48 #281944

by tommylight

-

Homework for you, get a DVM and measure the voltage between nozzle and work piece when the torch fires, it is OK as you say as it is between ..... It is not OK, it will blow your DVM

---

This has become an exercise in futility.

Replied by tommylight on topic Hypertherm MAX PRO 200 CNC Connections - Quick Question

You really have to stop insisting on this, you keep forgetting the arc is used to make a path for the high current, so it is connecting torch electrode to work piece, sending the full brunt to THC, if connected at the torch terminals.The HF is done between nozzle and electrode.

-

Homework for you, get a DVM and measure the voltage between nozzle and work piece when the torch fires, it is OK as you say as it is between ..... It is not OK, it will blow your DVM

---

This has become an exercise in futility.

Please Log in or Create an account to join the conversation.

- RDA

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 43

30 Sep 2023 17:45 #281949

by RDA

- PCW just stated above that its totally fine using the torch connections.

- You can see from the schematic I linked, that the HF transformer is between the nozzle and electrode

You stated that the internet is full of misinformation, I am trying here to correct that. You also stated that people should read up on Jim Colts comments, quote from here HF by Jim Colt

" All of Hypertherms high end industrial plasma cutters (HSD130, MaxPro200, all HPRXD systems) use a high voltage, high frequency discharge between the electrode and the nozzle (inside the torch) to ionize the gas"

I believe you assume that the pilot arc and HF are the same thing, they are not. HF is used only to ignite the pilot, it has nothing to do with transfering the arc to the work piece, that's what the pilot arc is for and that arc is ignited by the HF.

Replied by RDA on topic Hypertherm MAX PRO 200 CNC Connections - Quick Question

I really don't know what your problem is and I can assure I am not the one needing to homework.

The HF is done between nozzle and electrode.

You really have to stop insisting on this, you keep forgetting the arc is used to make a path for the high current, so it is connecting torch electrode to work piece, sending the full brunt to THC, if connected at the torch terminals.

-

Homework for you, get a DVM and measure the voltage between nozzle and work piece when the torch fires, it is OK as you say as it is between ..... It is not OK, it will blow your DVM

---

This has become an exercise in futility.

- PCW just stated above that its totally fine using the torch connections.

- You can see from the schematic I linked, that the HF transformer is between the nozzle and electrode

You stated that the internet is full of misinformation, I am trying here to correct that. You also stated that people should read up on Jim Colts comments, quote from here HF by Jim Colt

" All of Hypertherms high end industrial plasma cutters (HSD130, MaxPro200, all HPRXD systems) use a high voltage, high frequency discharge between the electrode and the nozzle (inside the torch) to ionize the gas"

I believe you assume that the pilot arc and HF are the same thing, they are not. HF is used only to ignite the pilot, it has nothing to do with transfering the arc to the work piece, that's what the pilot arc is for and that arc is ignited by the HF.

Please Log in or Create an account to join the conversation.

- RDA

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 43

30 Sep 2023 17:53 - 30 Sep 2023 20:55 #281950

by RDA

Replied by RDA on topic Hypertherm MAX PRO 200 CNC Connections - Quick Question

I tried to edit as I have done before but it messes up the quotes and links. There is a typo in the above post that can be misleading. Torch connections --> is should be actually torch connection as its just a single cable going to the torch, work being the table reference so only one wire.

Edit: If anyone still thinks I am wrong, despite on my drawing (that I deleted on request), my efforts in trying to explain through schematics and even referencing to an old Jim Colt post, please check the youtube video below published by hypertherm:

Understanding plasma arc ignition

After looking at the video and still believing that the HF is not done between the electrode and nozzle, I give up. As stated by me earlier, this is how the arc ignition is done byt all the major industrial plasma brands. If a xyz chinese manufacturer does it differently, then they do. But the topic was about a Hypertherm Maxpro.

Edit: If anyone still thinks I am wrong, despite on my drawing (that I deleted on request), my efforts in trying to explain through schematics and even referencing to an old Jim Colt post, please check the youtube video below published by hypertherm:

Understanding plasma arc ignition

After looking at the video and still believing that the HF is not done between the electrode and nozzle, I give up. As stated by me earlier, this is how the arc ignition is done byt all the major industrial plasma brands. If a xyz chinese manufacturer does it differently, then they do. But the topic was about a Hypertherm Maxpro.

Last edit: 30 Sep 2023 20:55 by RDA.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Hypertherm MAX PRO 200 CNC Connections - Quick Question

Time to create page: 0.172 seconds