Plasmac for glue dispenser machine.

- Himarc3D

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 49

20 Jul 2020 23:38 #175279

by Himarc3D

Replied by Himarc3D on topic Plasmac for glue dispenser machine.

Sorry guys for late reply and thank you for the inputs.

vision system could wok with height i consult some companies and its very expensive for my pocket now, i have one used from Keyence i brought to learn just US$150 the package including the camera and lens, control and PLC.

The model CV-X480D cost US$ 18.000 and can handle the height pretty well but i dont have knowledge yet o integrate. The keyence you select the robot maker and is done, support all big players and you can use custom setting too.

Other companies like Yamaha want you buy all their stuff (PLC, Robot, Vision, Software etc) and at the end is very costly and you are lock up with one vendor, every company use their own language to setup the robot...

if i buy from keyence the engineer told they will help to integrate and they asked the Linuxcnc intarface and many questions and i cant answer so i told next time and thanks, if you are looking for vision talk with Keyence staff, im no one but if you have company you can get the vision system for sample even the power supply to test and they send engineer team to you place to help integrate without additional cost.

the other companies i checked isnt that friendly. maybe Cognex if i have companies they are more receptive...but keyence even im no one they talked and told can help me. i checked ROS but too much too learn now so ill go simple.

vision system could wok with height i consult some companies and its very expensive for my pocket now, i have one used from Keyence i brought to learn just US$150 the package including the camera and lens, control and PLC.

The model CV-X480D cost US$ 18.000 and can handle the height pretty well but i dont have knowledge yet o integrate. The keyence you select the robot maker and is done, support all big players and you can use custom setting too.

Other companies like Yamaha want you buy all their stuff (PLC, Robot, Vision, Software etc) and at the end is very costly and you are lock up with one vendor, every company use their own language to setup the robot...

if i buy from keyence the engineer told they will help to integrate and they asked the Linuxcnc intarface and many questions and i cant answer so i told next time and thanks, if you are looking for vision talk with Keyence staff, im no one but if you have company you can get the vision system for sample even the power supply to test and they send engineer team to you place to help integrate without additional cost.

the other companies i checked isnt that friendly. maybe Cognex if i have companies they are more receptive...but keyence even im no one they talked and told can help me. i checked ROS but too much too learn now so ill go simple.

Please Log in or Create an account to join the conversation.

- Himarc3D

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 49

20 Jul 2020 23:40 #175280

by Himarc3D

Replied by Himarc3D on topic Plasmac for glue dispenser machine.

Thanks, ill try

I will open my thread in show your stuff, im finishing search for parts and i pretend start drawing all this week.

thank you very much guys

I will open my thread in show your stuff, im finishing search for parts and i pretend start drawing all this week.

thank you very much guys

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

20 Jul 2020 23:58 #175281

by thefabricator03

Replied by thefabricator03 on topic Plasmac for glue dispenser machine.

I spent six years trying to work out how I could affordably retrofit my Yaskawa Motoman welding robots. It was not until I faced the reality that if I want something done right I need to do it my self was I able to move forward.

Vendor lock in is a very real problem for people like us who want to do something like welding robots or plasma cutters and still be able to fix what you have brought and do it affordably. Most vendors dont want you to be able to use anything but their product. I can understand that but at the same time its very hard and costly to rely on only one vendor if something goes wrong and sometimes it does.

I spent over $10.000 AUD on a CNC plasma controller from CandCNC. The unit never worked correctly since new and when I tried to contact the company they treated me like a idiot. Since using LinuxCNC, I had to learn how to set it up and get it working but the time I spent was far worth it.

It might be hard at first to set up your own vision system, might take a year or so. But the end result will be worth it, not just having the machine working but because you made it yourself and you will be able to do it again relatively cheaply.

Sorry for the long post but your story reminds me of myself and my robots.

Vendor lock in is a very real problem for people like us who want to do something like welding robots or plasma cutters and still be able to fix what you have brought and do it affordably. Most vendors dont want you to be able to use anything but their product. I can understand that but at the same time its very hard and costly to rely on only one vendor if something goes wrong and sometimes it does.

I spent over $10.000 AUD on a CNC plasma controller from CandCNC. The unit never worked correctly since new and when I tried to contact the company they treated me like a idiot. Since using LinuxCNC, I had to learn how to set it up and get it working but the time I spent was far worth it.

It might be hard at first to set up your own vision system, might take a year or so. But the end result will be worth it, not just having the machine working but because you made it yourself and you will be able to do it again relatively cheaply.

Sorry for the long post but your story reminds me of myself and my robots.

Please Log in or Create an account to join the conversation.

- Himarc3D

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 49

21 Jul 2020 00:11 #175285

by Himarc3D

Replied by Himarc3D on topic Plasmac for glue dispenser machine.

isnt long at all and ill try the Linuxcnc way too in the future i hope i can use vision from opensource too, i cant help with code now...you watched this video

The following user(s) said Thank You: Mike_Eitel, phillc54, tommylight, Clive S

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21276

- Thank you received: 7265

21 Jul 2020 07:47 #175307

by tommylight

Replied by tommylight on topic Plasmac for glue dispenser machine.

That is very interesting, thank you.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

30 Nov 2020 05:52 #190651

by thefabricator03

Replied by thefabricator03 on topic Plasmac for glue dispenser machine.

Any updates on this project Himarc3D? I am very interested in seeing if you got it working.

Please Log in or Create an account to join the conversation.

- Himarc3D

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 49

01 Dec 2020 13:44 - 01 Dec 2020 13:50 #190759

by Himarc3D

Replied by Himarc3D on topic Plasmac for glue dispenser machine.

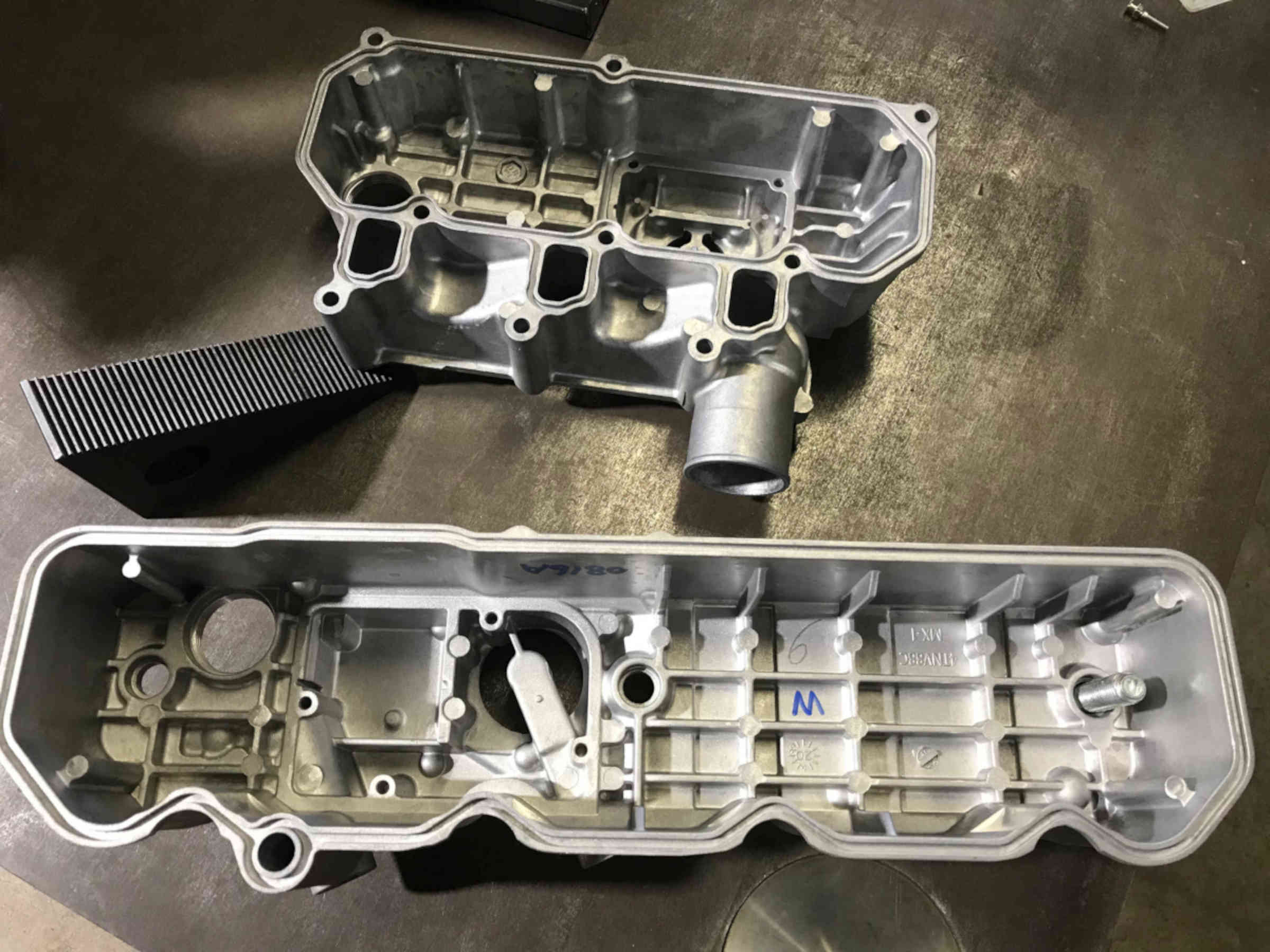

Yes but im still working and learning how to do the thing. mechanical part is ok.

I wrote a lot here but i pushed wrong button and erased all...anyway 12/14 ill take the machine to the customer and get feedback after 2 weeks and adjust all and make prober GUI. now im using AXIS but i have touch panel...and i need more simple screen like BP Touch style

the machine have temperature and weight control, im learning gcode the real GCode because my background was 3D printer...

When i finish ill open one thread at show your stuff.

the total covers is 40 models...i get some cover models to make test and adjust.

I wrote a lot here but i pushed wrong button and erased all...anyway 12/14 ill take the machine to the customer and get feedback after 2 weeks and adjust all and make prober GUI. now im using AXIS but i have touch panel...and i need more simple screen like BP Touch style

the machine have temperature and weight control, im learning gcode the real GCode because my background was 3D printer...

When i finish ill open one thread at show your stuff.

the total covers is 40 models...i get some cover models to make test and adjust.

Last edit: 01 Dec 2020 13:50 by Himarc3D.

The following user(s) said Thank You: tommylight, thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

02 Dec 2020 01:34 #190821

by thefabricator03

Replied by thefabricator03 on topic Plasmac for glue dispenser machine.

Thanks for the update. I find your application very interesting.

Please Log in or Create an account to join the conversation.

- Himarc3D

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 49

03 Dec 2020 06:09 - 03 Dec 2020 06:35 #190935

by Himarc3D

Replied by Himarc3D on topic Plasmac for glue dispenser machine.

I tried teaching using pendant and logging the coordinates using teaching.py...very time consuming, before i start using Linuxcnc I imagined can teach like weld robot (weld robot is time consuming too but little more fast and smooth arc) I remembered i have scanner so now just take few minutes and send to Design X > NX > Sheetcam > Linuxcnc

Last edit: 03 Dec 2020 06:35 by Himarc3D.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

03 Dec 2020 06:37 #190936

by thefabricator03

Replied by thefabricator03 on topic Plasmac for glue dispenser machine.

Could you tell us more about your scanner please. Is it a 3d hand held unit? What kind of retail price does it cost?

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.635 seconds