Random Questions on setup

- FlaredFins

- Offline

- Senior Member

-

- Posts: 64

- Thank you received: 8

Couple of issues I encountered and would like to get corrected.

I don't think i have my Z set correctly no issues in cutting or height control, When the machine is homed for the first program run, it runs up to the Z+ Prox / Z home from their it drops down to I'm guessing an offset I put in. it than drops down about 2 inches and zeros the Z drive. not a big deal but when I'm trying to line the torch up it won't go below 0.00 is it better to let the Z axis home off the probe or an upper limit.

On Probe it does this weird little double probe you can watch it come off the probe switch than go back to it than proceeds to cut height. is this normal or am I missing something in the settings?

Randomly had no arc signal from the Hypertherm 65. this was closer to the end of the program about 45 minutes into cutting. I'm guessing it was a Hypertherm issue as I turned it off reseated the CPC port and it came back no issues but eventually did it again. I'm running Mode 1 in QTPlasmac which I believed was the setting when there is a separate ARC ok Signal?

During that no arc ok phase I also noticed that QTPlasmac will attempt three times to fire the torch after the third round of that it powers off with the screen switch and resets the program. Is this normal if it is, is there a way to change the number of rounds it will go through before resetting the whole program.

Appreciate any info on these Items

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17624

- Thank you received: 5156

you may need to add a load resistor to provide the "wetting" current the relay

contacts require. (This current may be as much as 100 mA so requires say a 220 Ohm

5W load resistor)

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21216

- Thank you received: 7246

Wrong ini settings for Z axis, home switch must be up, HOME must be 0, HOME_OFFSET must be something small so it backs of off the switch, 3-5mm is ok, max limit to 0 and min limit to -100 or -150 or whatever the Z axis can do.I don't think i have my Z set correctly no issues in cutting or height control, When the machine is homed for the first program run, it runs up to the Z+ Prox / Z home from their it drops down to I'm guessing an offset I put in. it than drops down about 2 inches and zeros the Z drive.

Yes it is normal and i hate it, this should have never been implemented.On Probe it does this weird little double probe you can watch it come off the probe switch than go back to it than proceeds to cut height. is this normal or am I missing something in the settings?

Try some contact spray.Randomly had no arc signal from the Hypertherm 65. this was closer to the end of the program about 45 minutes into cutting. I'm guessing it was a Hypertherm issue as I turned it off reseated the CPC port and it came back no issues but eventually did it again. I'm running Mode 1 in QTPlasmac which I believed was the setting when there is a separate ARC ok Signal?

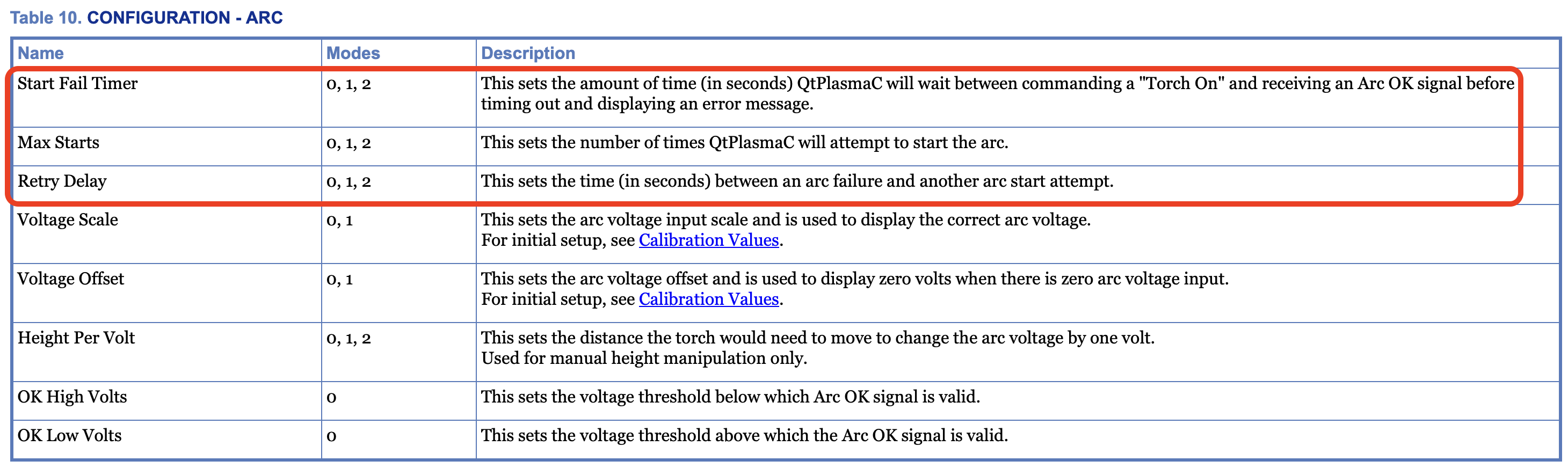

Yes it is and can be set in the config tab, so can time between retries. Do not forget to save after changing.During that no arc ok phase I also noticed that QTPlasmac will attempt three times to fire the torch after the third round of that it powers off with the screen switch and resets the program. Is this normal if it is, is there a way to change the number of rounds it will go through before resetting the whole program.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Some info on the Z axis:I don't think i have my Z set correctly no issues in cutting or height control, When the machine is homed for the first program run, it runs up to the Z+ Prox / Z home from their it drops down to I'm guessing an offset I put in. it than drops down about 2 inches and zeros the Z drive. not a big deal but when I'm trying to line the torch up it won't go below 0.00 is it better to let the Z axis home off the probe or an upper limit.

linuxcnc.org/docs/devel/html/plasma/qtpl...plasma:initial-setup

The two most common reasons for this are:On Probe it does this weird little double probe you can watch it come off the probe switch than go back to it than proceeds to cut height. is this normal or am I missing something in the settings?

- The Probe Height is set too high compared to Safe Height.

- Probe Height is set below the material height and the first probe trip is done at Setup Speed then the second trip is done at Probe Speed.

Not sure what you mean by resetting, the program should go into pause mode after the failed attempts.During that no arc ok phase I also noticed that QTPlasmac will attempt three times to fire the torch after the third round of that it powers off with the screen switch and resets the program. Is this normal if it is, is there a way to change the number of rounds it will go through before resetting the whole program.

linuxcnc.org/docs/devel/html/plasma/qtpl...lasma:parameters-tab

Attachments:

Please Log in or Create an account to join the conversation.

- FlaredFins

- Offline

- Senior Member

-

- Posts: 64

- Thank you received: 8

By resetting I mean instead of a pause it takes you back to line 1 of the G-code. I'm going to look into what Tommy wrote in his post.

On the Probe item. I have some confusion and it will probably be cleared up when I get my Z axis set correctly. But what happens when there are conflicts in your post vs what is set in parameters. Which supersedes the other. qtplasmac or the Gcode in the file?

Please Log in or Create an account to join the conversation.

- FlaredFins

- Offline

- Senior Member

-

- Posts: 64

- Thank you received: 8

Please Log in or Create an account to join the conversation.

- FlaredFins

- Offline

- Senior Member

-

- Posts: 64

- Thank you received: 8

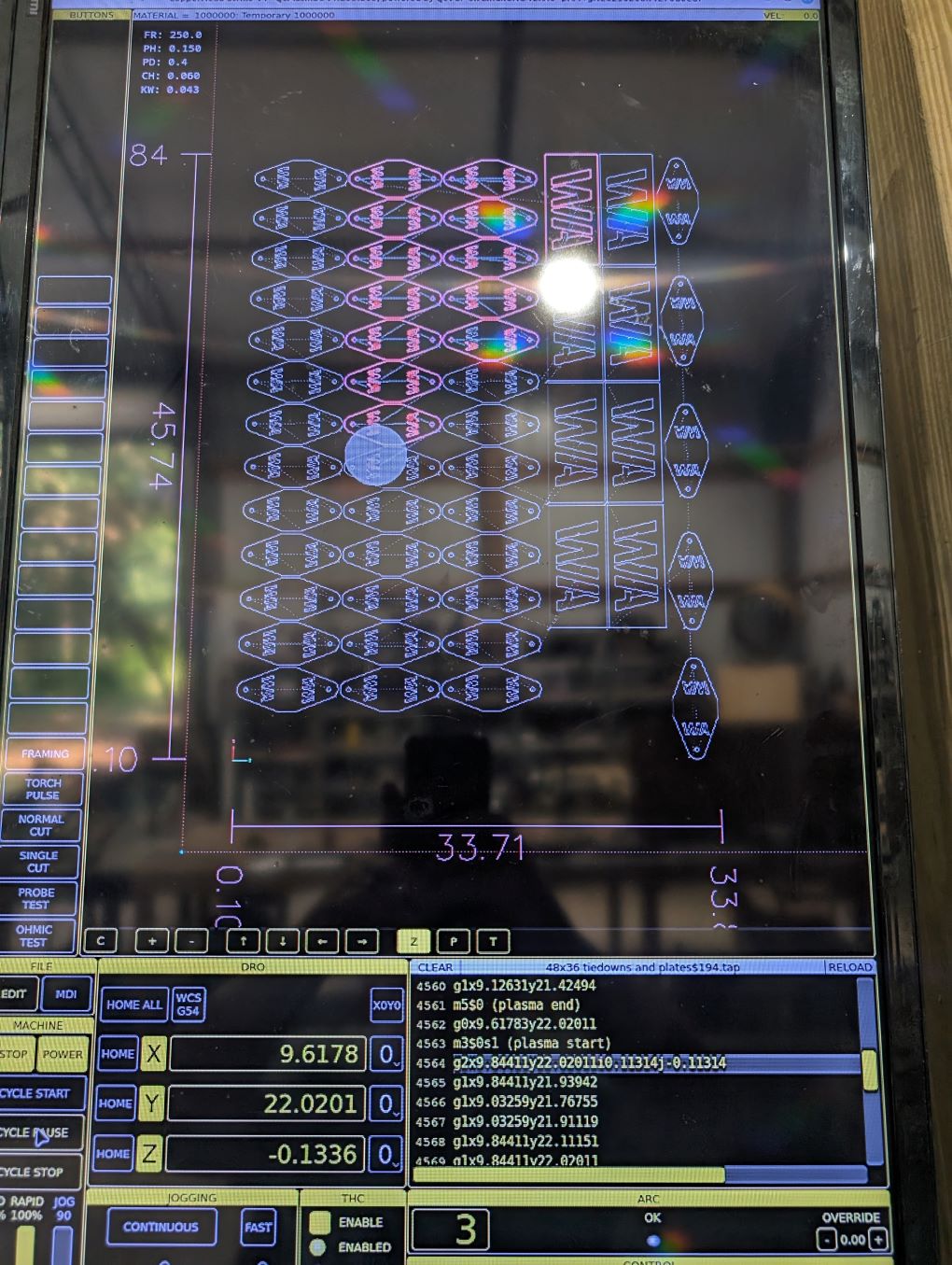

Another question I left out yesterday not an issue but more of curiosity. while cutting I noticed one of the plates showing in red that it had been cut already and then it went back to white like it hadn't been cut yet. this is more than likely in the manual but thought I'd ask. Is this also part of cut recovery so as long as it is still red that's how far back you can go for cut recovery?

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21216

- Thank you received: 7246

Hard to spot as multiple paths/layers can not be seen in 2D.

Please Log in or Create an account to join the conversation.

- FlaredFins

- Offline

- Senior Member

-

- Posts: 64

- Thank you received: 8

Please Log in or Create an account to join the conversation.

- FlaredFins

- Offline

- Senior Member

-

- Posts: 64

- Thank you received: 8

POS = 7.00

NEG = 0.00

Final Pos = .125

Home switch location = .125

Search Direction = POS

Home Latch = Opposite

This appears to work except when it homes it does its magic dance it sets the position to .317. OK.... go to do a probe test and it drops to around -.63 and says no no no your going below the limit.

why isnt it setting the position to 6.875

Please Log in or Create an account to join the conversation.