OpenPnP with LinuxCNC via linuxcncrsh?

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

26 Apr 2023 11:55 #269971

by blazini36

Replied by blazini36 on topic OpenPnP with LinuxCNC via linuxcncrsh?

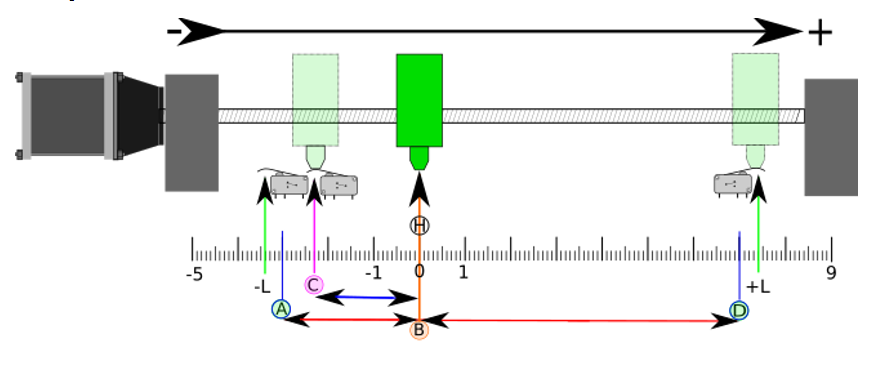

That's not quite what I meant. If you did that then you would have no limit switch unless you add 2 more. I was winging it when I machined my head base, I added 2 threaded holes for inductive proximity switches positioned as limits. I planned on doing what I said first, now I plan on adding the potI think I like your previous idea of having a switch permanently made when the axes is not at home and someway down. That way, you could use two switches (one for each side) and have the centre point where neither switch is made and hence home. So homing would be simply:

- See which switch is made

- Move that side so that it goes up

- Stop when the switch in no longer made

And as long as the switches are at the same height, finding the true centre point wouldn't be too hard, just halve the distance from when the switch on one side releases to when the switch on the other side makes.

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

26 Apr 2023 12:36 #269972

by blazini36

Replied by blazini36 on topic OpenPnP with LinuxCNC via linuxcncrsh?

Ya wanna explain that process to me? I know how homing and LinuxCNC works but I'd like you to explain the process to me with "1 switch + home offset" so I can explain where it fails and maybe you'll understand.1 switch + home_offset will home it anywhere, including in the middle.

As for precission, it uses a stepper with a pulley directly driving heads, so even a cheap microswitch will be more precise than the drive parts.

Using an optical switch and a 0.9 degree motor seems better for accuracy, as there is no need for a lot of torque, and this is for very small parts.

Please Log in or Create an account to join the conversation.

- plhsystems

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 0

26 Apr 2023 12:52 - 26 Apr 2023 12:54 #269974

by plhsystems

Replied by plhsystems on topic OpenPnP with LinuxCNC via linuxcncrsh?

I wan't too concerned about limit switches, as long as you can find home and know the what maximum travel is then you should be good, but if you machined the head already then pots are probably the best way to go.

Last edit: 26 Apr 2023 12:54 by plhsystems.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21148

- Thank you received: 7221

26 Apr 2023 13:09 #269976

by tommylight

Replied by tommylight on topic OpenPnP with LinuxCNC via linuxcncrsh?

Two rigid coupled heads, say left side top is home with the switch, then offset to reach the middle.

Cr@p, as i was writing this it occured to me why you insist it is not ok, when homing one of the heads moves down to the botton!

So this is what i was missing.

Ok, then having the home switch stay active for half of the travel and not active for the other half, and setting hal to completely ignore homing switch after homing is complete?

Might need some hal stuff but should be doable, home in one direction if switch is tripper, in the other direction if the switch is opened ?

Cr@p, as i was writing this it occured to me why you insist it is not ok, when homing one of the heads moves down to the botton!

So this is what i was missing.

Ok, then having the home switch stay active for half of the travel and not active for the other half, and setting hal to completely ignore homing switch after homing is complete?

Might need some hal stuff but should be doable, home in one direction if switch is tripper, in the other direction if the switch is opened ?

Please Log in or Create an account to join the conversation.

- plhsystems

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 0

26 Apr 2023 14:11 - 26 Apr 2023 15:46 #269982

by plhsystems

Replied by plhsystems on topic OpenPnP with LinuxCNC via linuxcncrsh?

That should work. I was thinking 2 switches but you do only need 1, if the switch is made, move one direction until it releases and if not, move the other way until it activates.

Last edit: 26 Apr 2023 15:46 by plhsystems.

Please Log in or Create an account to join the conversation.

- plhsystems

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 0

26 Apr 2023 19:02 - 26 Apr 2023 19:05 #269992

by plhsystems

Replied by plhsystems on topic OpenPnP with LinuxCNC via linuxcncrsh?

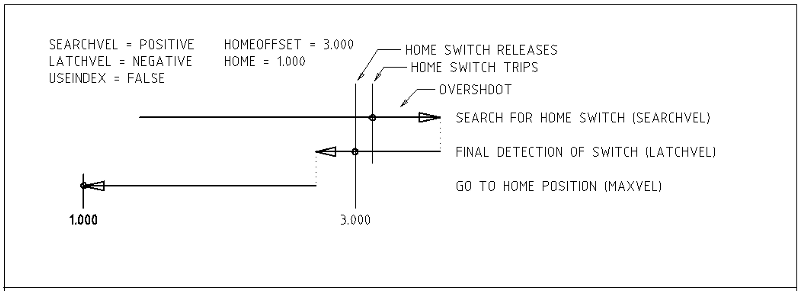

Having read the homing section of the manual, it looks like what we are trying to achieve is standard, i.e. the axis travels in one direction until the switch is made and reverses until the switch releases, exactly what we need

And by what I can gather from this pic

The home switch is ignored after homing anyway, please correct me if I am wrong

And by what I can gather from this pic

The home switch is ignored after homing anyway, please correct me if I am wrong

Attachments:

Last edit: 26 Apr 2023 19:05 by plhsystems.

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

26 Apr 2023 20:17 #269998

by blazini36

Replied by blazini36 on topic OpenPnP with LinuxCNC via linuxcncrsh?

Home switch is only valid during the actual homing procedure.

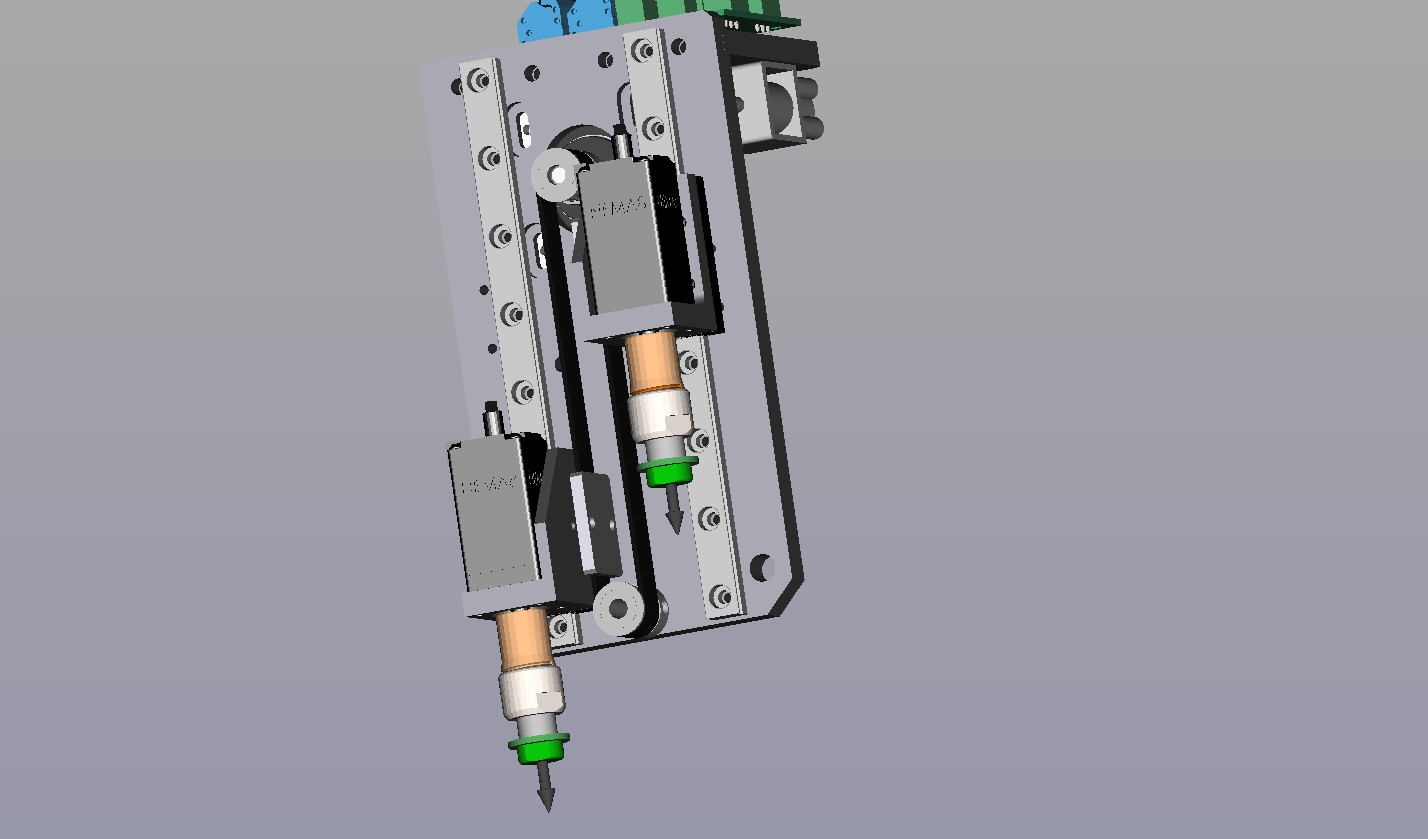

For a setup like the one I pictured several posts back, that's actually pretty easy to do. You just mount an inductive proximity switch on top of the base behind one of the gear racks. The switch will be active about 40% of the range which is probably fine. That is a standard homing procedure, you set it up to travel towards the side that activates the switch, after it makes it backs off. If it's made when homing is started it only travels in the back-off direction.

That only works if you're setup mechanically allows it. Personally I'll be doing something like a 5-turn potentiometer and using the HOME_ABSOLUTE_ENCODER = 2. The nice thing about this is it actually is an "absolute encoder" So it adds closed loop feedback for little coin.

For a setup like the one I pictured several posts back, that's actually pretty easy to do. You just mount an inductive proximity switch on top of the base behind one of the gear racks. The switch will be active about 40% of the range which is probably fine. That is a standard homing procedure, you set it up to travel towards the side that activates the switch, after it makes it backs off. If it's made when homing is started it only travels in the back-off direction.

That only works if you're setup mechanically allows it. Personally I'll be doing something like a 5-turn potentiometer and using the HOME_ABSOLUTE_ENCODER = 2. The nice thing about this is it actually is an "absolute encoder" So it adds closed loop feedback for little coin.

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

26 Apr 2023 21:08 #270010

by blazini36

Replied by blazini36 on topic OpenPnP with LinuxCNC via linuxcncrsh?

Actually what I think I'll do is use one of these "high-torque" pots as the lower pulley shaft threaded in from the back.

www.digikey.com/en/products/detail/tt-el.../8146R5KL-25/4780742

Not much modification needed.

Not much modification needed.

Attachments:

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- plhsystems

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 0

27 Apr 2023 07:52 #270043

by plhsystems

Replied by plhsystems on topic OpenPnP with LinuxCNC via linuxcncrsh?

They're quite expensive, I think I'll stick with the switch

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

27 Apr 2023 20:13 #270081

by blazini36

Replied by blazini36 on topic OpenPnP with LinuxCNC via linuxcncrsh?

A $35 pot is not expensive considering the cost of everything else. I'm only using the "expensive" pot because it's serving as an axle for the lower pulley. The same type of pot in a lower duty version mounted freely to the stepper or lower pulley is alot less expensive.

But to each their own, this is what I'm doing.

But to each their own, this is what I'm doing.

Please Log in or Create an account to join the conversation.

Time to create page: 0.141 seconds